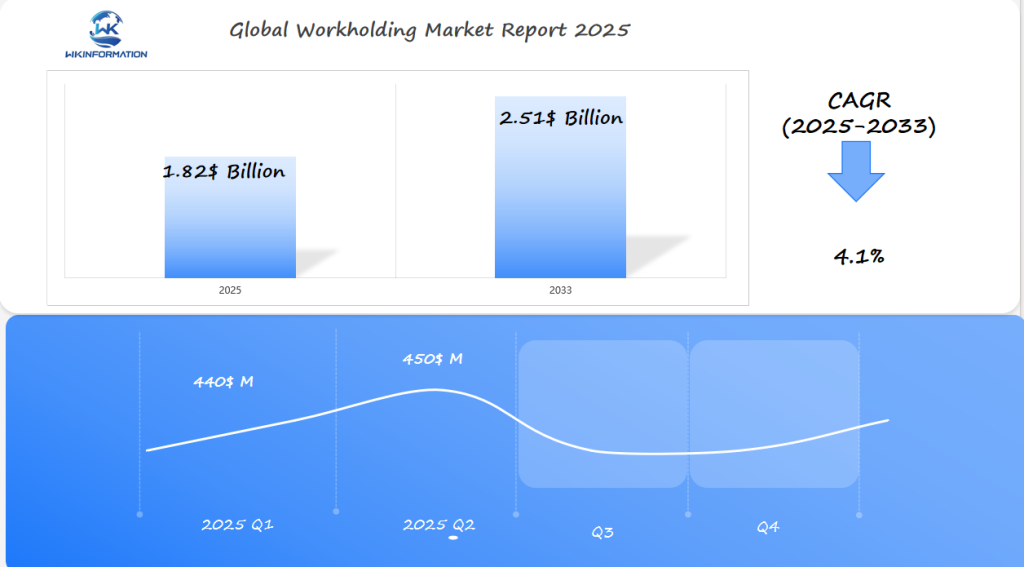

Workholding Market Expected to Exceed $1.82 Billion by 2025, Accelerated by Manufacturing Growth in Germany, China, and the U.S.

Discover the latest trends in the Workholding Market, expected to reach $1.82 billion by 2025 as manufacturing growth accelerates.

- Last Updated:

Workholding Market Q1 and Q2 of 2025

The Workholding market is projected to reach $1.82 billion in 2025, with a CAGR of 4.1% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $440 million, with Q2 witnessing a slight increase to $450 million, driven by the growing demand for precision machining across industries such as aerospace, automotive, and metalworking. Workholding solutions are essential for ensuring stability and accuracy in manufacturing processes, particularly in high-precision industries.

Germany, China, and the U.S. will play a crucial role in the growth of this market, as these countries are home to some of the world’s leading manufacturers in automotive, aerospace, and machinery. Germany’s robust industrial base, China’s expanding manufacturing sector, and the U.S.’s strong focus on advanced manufacturing technologies ensure that these nations will continue to dominate the Workholding market in 2025.

Upstream and Downstream Industry Chain Analysis in the Workholding Market

The Workholding Market’s supply chain is a complex network involving various stakeholders, including raw material suppliers and end-users. For manufacturers to make informed decisions and stay competitive, it’s crucial to understand this supply chain.

Understanding the supply chain dynamics

The supply chain dynamics in the Workholding Market are influenced by several factors, including raw material availability, manufacturing capabilities, and market demand. Efficient supply chain management enables workholding manufacturers to respond promptly to changes in market conditions and customer needs.

The role of the upstream industry chain

The upstream industry chain, which includes raw material suppliers and component manufacturers, plays a vital role in determining the quality and cost of workholding solutions. Any disruptions in the upstream supply chain can have a ripple effect, impacting the overall production and delivery of workholding products.

The significance of raw material costs

The cost of raw materials is a significant factor in the production of workholding solutions. Fluctuations in raw material costs can directly impact the pricing and profitability of workholding products. Manufacturers must closely monitor raw material costs and adjust their strategies accordingly to maintain profitability.

For instance, an increase in steel prices can lead to higher production costs for workholding devices made from steel. To mitigate such effects, manufacturers may explore alternative materials or optimize their production processes to reduce waste and improve efficiency.

By understanding the dynamics of the supply chain and the impact of raw material costs, workholding manufacturers can develop effective strategies to navigate the complexities of the Workholding Market.

Key trends and innovations in precision workholding devices

Innovations in precision workholding devices are driving growth in the Workholding Market. The manufacturing industry is undergoing a significant transformation with the introduction of advanced workholding technologies.

The increasing demand for precision and efficiency in manufacturing processes has resulted in the creation of innovative workholding solutions. These advancements are not only enhancing the accuracy of manufacturing but also boosting overall productivity.

Advancements in Workholding Technology

The workholding technology has seen significant advancements in recent years, with a focus on improving precision and reducing production time. Some of the key advancements include the development of modular workholding systems and the use of advanced materials.

Emerging Trends in Precision Engineering

Emerging trends in precision engineering are playing a crucial role in shaping the Workholding Market. Trends such as the use of advanced materials, miniaturization, and the integration of smart technologies are driving innovation.

Some of the emerging trends include:

- Use of advanced materials like ceramics and composites

- Miniaturization of workholding devices

- Integration of smart technologies like IoT and AI

Here’s a comparison of traditional and modern workholding devices:

| Feature | Traditional Workholding Devices | Modern Workholding Devices |

| Precision | Lower precision | Higher precision |

| Material | Conventional materials | Advanced materials like ceramics and composites |

| Flexibility | Limited flexibility | Highly modular and flexible |

Barriers and challenges in automation and precision manufacturing

Technical challenges and cost complexities are major hurdles in the adoption of advanced workholding solutions.

The Workholding Market faces challenges from advancing technology and the growing need for precision. Technical issues in automation and precision manufacturing are significant obstacles that must be overcome for ongoing growth and innovation.

Overcoming technical challenges

One of the primary technical challenges is achieving high precision and accuracy in workholding systems. This requires advanced materials and manufacturing techniques that can maintain tight tolerances and withstand the rigors of high-speed machining.

Innovative solutions such as advanced clamping systems and precision-ground components are being developed to address these challenges. For instance, the use of modular fixturing systems allows for greater flexibility and precision in machining operations.

Addressing cost and complexity issues

The cost and complexity of advanced workholding solutions can be a significant deterrent for many manufacturers. Cost reduction strategies and simplification of complex systems are essential to making these solutions more accessible.

A detailed comparison of different workholding solutions and their associated costs is provided in the table below:

| Workholding Solution | Cost | Complexity Level |

| Modular Fixturing Systems | High | Medium |

| Precision-Ground Components | Very High | High |

| Advanced Clamping Systems | Medium | Low |

The table highlights the varying costs and complexity levels associated with different workholding solutions, helping manufacturers make informed decisions.

By understanding and addressing these challenges, the Workholding Market can continue to evolve and meet the demands of an increasingly complex manufacturing landscape.

Geopolitical influences on global manufacturing practices

Geopolitical influences on global manufacturing practices can significantly impact how industries operate, the cost of production, and the movement of goods across borders.

1. Trade Wars and Tariffs

-

Trade tensions: Trade disputes, such as those between the U.S. and China, can result in the imposition of tariffs and other trade barriers. These measures increase the cost of raw materials, components, and finished products, disrupting supply chains.

-

Shifting manufacturing hubs: To avoid high tariffs or trade restrictions, companies might move production to countries with favorable trade agreements or lower tariffs, leading to the redistribution of manufacturing activities worldwide.

2. Supply Chain Vulnerabilities

-

Dependency on specific regions: Geopolitical tensions can expose the vulnerabilities in global supply chains, especially when manufacturing relies on specific countries for key components. For example, reliance on China for electronics or Taiwan for semiconductors could be disrupted due to geopolitical conflicts.

-

Reshoring and nearshoring: In response to disruptions such as the COVID-19 pandemic, and rising geopolitical risks, companies are increasingly moving manufacturing closer to home markets (nearshoring) or back to their home countries (reshoring) to reduce risk.

3. Political Instability

-

Impact on local manufacturing: Countries experiencing political instability or conflicts (e.g., civil wars, coups, or violent protests) can face disruptions in their manufacturing sectors. This includes delays, damage to factories, or loss of access to critical infrastructure.

-

Risk of sanctions: Political instability can lead to the imposition of economic sanctions by other countries, further hindering access to international markets and causing disruptions to supply chains.

4. Labor Costs and Regulations

-

Labor rights and wages: Geopolitical factors often shape labor laws, including wages, benefits, and working conditions. Regions with favorable labor laws (e.g., low wages in certain developing countries) can attract manufacturers looking to reduce costs. However, as labor laws evolve, manufacturers may need to adjust their operations.

-

Environmental and safety regulations: Different countries have varying standards for environmental protection, worker safety, and ethical manufacturing. Geopolitical changes can prompt manufacturers to adjust their production processes to comply with new laws or to take advantage of looser regulations in other regions.

Segmentation by workholding type and material solutions

The Workholding Market can be segmented based on the type of workholding solution and the materials used in these solutions. This segmentation is crucial for understanding the diverse needs of the manufacturing industry, and how different workholding solutions cater to these needs.

Types of Workholding Solutions

Workholding solutions come in various forms, including clamping systems, vises, and chucks. Each of these solutions is designed to serve specific purposes in the manufacturing process, such as holding parts in place during machining or assembly.

Clamping Systems

Clamping systems are widely used for their versatility and ability to securely hold a variety of workpiece shapes and sizes.

Vises

Vises offer precision and are often used in applications requiring high accuracy.

Chucks

Chucks, on the other hand, are typically used in turning operations and are valued for their ability to grip round or irregularly shaped parts.

Importance of Material Selection in Workholding Applications

The choice of material for workholding applications is critical and depends on factors such as durability, precision, and cost-effectiveness. Common materials used include steel, aluminum, and advanced composites, each offering unique benefits.

For instance:

- Steel is often used for its high strength and durability, making it suitable for heavy-duty applications.

- Aluminum, being lightweight and corrosion-resistant, is preferred in applications where weight reduction is crucial.

- Advanced composites offer a combination of high strength, low weight, and resistance to wear and corrosion, making them ideal for demanding workholding applications.

The selection of the appropriate material solution is vital for ensuring the efficiency and effectiveness of workholding systems in various manufacturing processes.

Increasing Demand for Workholding Solutions in CNC and Automation Industries

Workholding solutions have become essential in CNC machining and automation, leading to increased demand across various manufacturing industries. These solutions provide the precision and efficiency required in today’s manufacturing processes.

Workholding in CNC Machining

In CNC machining, workholding solutions play a vital role in ensuring the precision and accuracy of the machining process. Advanced workholding devices such as jigs, fixtures, and clamps are designed to securely hold workpieces in place, minimizing errors and improving productquality.

The complexity of modern CNC machining operations demands workholding solutions that can accommodate intricate workpiece geometries and provide consistent holding forces. Innovative workholding technologies, including modular fixturing systems and zero-point clamping, are being adopted to enhance flexibility and reduce setup times.

The increasing adoption of automation in manufacturing has created a growing demand for workholding solutions that can seamlessly integrate with automated systems. Automated workholding systems are designed to work in conjunction with CNC machines, robots, and other automated equipment to streamline production workflows.

Key features of automation-friendly workholding solutions include:

- Quick-change capabilities to minimize downtime

- Compatibility with robotic loading and unloading systems

- Integration with Industry 4.0 technologies for smart manufacturing

As manufacturers continue to embrace automation, the demand for workholding solutions that can support these advanced manufacturing systems is expected to grow. Leading manufacturers are investing in the development of innovative workholding technologies that can meet the evolving needs of automated production environments.

Global market insights for Workholding solutions

The global Workholding Market is set to grow significantly, driven by increasing demand for precision manufacturing.

The market size for Workholding solutions is expected to expand due to advancements in technology and the growing need for precision workholding devices.

Market size and growth projections

The Workholding Market is expected to grow significantly due to industrial growth and technological advancements.

Some key factors influencing market growth include:

- Increasing demand for precision manufacturing

- Advancements in workholding technology

- Growing adoption of automation in industries

Global Workholding Market trends

Regional market trends play a crucial role in shaping the global Workholding Market.

The growth of manufacturing in Asia is a significant trend influencing the market.

Some of the key regional trends include:

- Growth of manufacturing in Asia

- Increasing adoption of automation in European industries

- Rising demand for precision workholding devices in North America

These trends are expected to drive the global Workholding Market forward, providing opportunities for manufacturers and suppliers.

Germany’s Advanced Manufacturing Sector Driving Workholding Technology

Germany’s advanced manufacturing sector, known for its precision, quality, and innovation, is significantly influencing the evolution of workholding technology. As a leader in manufacturing, Germany’s industry plays a crucial role in driving advancements in workholding technology.

Manufacturing Industry Overview

Germany’s manufacturing sector is known for its strong focus on quality, precision, and innovation. The industry is supported by a highly skilled workforce and a robust infrastructure that enables the development and use of advanced manufacturing technologies.

Key Features of Germany’s Manufacturing Industry:

- High precision and quality standards

- Innovative manufacturing technologies

- Skilled workforce

- Strong infrastructure

Workholding Technology Advancements in Germany

Germany is leading the way in workholding technology advancements, with many innovations coming from the region. German manufacturers are at the forefront of creating complex workholding solutions that meet the requirements of various industries such as automotive, aerospace, and machinery.

Some of the key advancements in workholding technology include:

- Improved precision and accuracy

- Increased flexibility and adaptability

- Enhanced automation capabilities

China’s rapid industrial expansion fueling workholding system demand

As China’s manufacturing industry continues to grow, the need for sophisticated workholding systems is becoming increasingly evident. The country’s industrial expansion has been driven by government initiatives and significant investments in manufacturing infrastructure.

Overview of China’s Industrial Expansion

China’s industrial sector has experienced rapid growth over the past decade, driven by large-scale investments in technology and infrastructure. This growth has led to an increased demand for advanced manufacturing solutions, including workholding systems.

The Chinese government has implemented various policies to support the growth of the manufacturing sector, including subsidies for technology adoption and investments in industrial infrastructure. These initiatives have created a favorable environment for manufacturers to adopt advanced workholding technologies.

Demand for Workholding Systems in China

The demand for workholding systems in China is driven by the need for precision and efficiency in manufacturing. As Chinese manufacturers increasingly adopt CNC machining and automation technologies, the demand for high-quality workholding solutions is rising.

Workholding systems are critical in ensuring the precision and consistency of manufactured parts. The growing demand for these systems is driven by the expanding aerospace, automotive, and electronics industries in China.

The U.S.'s focus on automation and precision engineering applications

With a strong emphasis on innovation, the U.S. is advancing in automation and precision engineering applications, driving growth in the manufacturing sector.

The U.S. manufacturing industry is a significant contributor to the country’s economy, with a strong presence of industries such as aerospace and automotive, which heavily rely on advanced manufacturing technologies.

U.S. Manufacturing Industry Overview

The U.S. manufacturing industry is known for using advanced technologies like automation and precision engineering to improve productivity and stay competitive.

Key Sectors Driving Growth

The following sectors are playing a significant role in this growth:

- Aerospace: Requires high precision and complex manufacturing processes.

- Automotive: Adopting automation to improve production efficiency and product quality.

- Medical Devices: Needing precision engineering for intricate components.

Importance of Precision Engineering

Precision engineering is crucial in various U.S. industries as it allows for the production of complex components with high accuracy. Here are some key applications:

- Aerospace Component Manufacturing: Precision engineering is used to produce complex aerospace parts.

- Medical Device Production: Intricate medical devices are manufactured using precision engineering techniques.

- Automotive Parts: High-precision parts are produced for the automotive industry, enhancing vehicle performance and safety.

The combination of automation and precision engineering is reshaping the U.S. manufacturing scene, helping industries achieve better efficiency and product quality.

Future growth and developments in the Workholding Market

The Workholding Market is poised for significant growth driven by emerging trends and technological advancements. As the manufacturing sector continues to evolve, the demand for innovative workholding solutions is expected to rise.

Emerging Trends and Technologies

The future of workholding is closely tied to advancements in precision engineering and automation. Technologies such as Industry 4.0, Internet of Things (IoT), and Artificial Intelligence (AI) are transforming the manufacturing landscape, creating new opportunities for workholding solutions.

- Increased adoption of automated workholding systems

- Growing demand for precision workholding devices

- Integration of smart technologies into workholding solutions

Future Market Projections

As these trends continue to shape the industry, the Workholding Market is expected to experience substantial growth. Projections indicate that the market will continue to expand as manufacturing processes become more sophisticated and the need for efficient, precise workholding solutions increases.

Competitive analysis of leading workholding manufacturers

The competitive landscape of the Workholding Market is dominated by several key players who are constantly innovating and expanding their product offerings to gain a competitive edge.

These leading manufacturers are focused on developing advanced workholding solutions that cater to the evolving needs of the manufacturing industry.

Key Players in the Workholding Market

- DESTACO – United States

- ENERPAC – United States

- Gerardi SPA – Italy

- Jergens Inc. – United States

- TE-CO – United States

- Alpha Workholding Solutions – United States

- Emuge Corporation – United States

- EROWA LTD – Switzerland

- LANG Technik GmbH – Germany

- Pierson Workholding – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Workholding Market Report |

| Base Year | 2024 |

| Segment by Type |

· Clamping Systems · Vises · Chucks |

| Segment by Application |

· Automotive · Aerospace · General Manufacturing · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Workholding Market is set to grow significantly, driven by advancements in manufacturing technology and increasing demand for precision workholding devices. As discussed, the market is influenced by various factors, including the expansion of CNC and automation industries.

Key Takeaways

The key findings of this article highlight the trends, challenges, and future developments in the Workholding Market. The market is expected to exceed $1.82 billion by 2025, driven by growth in manufacturing sectors, particularly in Germany, China, and the U.S.

Implications for Industry Stakeholders

The implications of these findings are significant for manufacturers and stakeholders in the Workholding Market. As the market continues to evolve, companies must adapt to emerging trends and technologies to remain competitive. Understanding the key findings and implications will enable stakeholders to make informed decisions and capitalize on growth opportunities.

Global Workholding Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Workholding Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- WorkholdingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Workholdingplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Workholding Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Workholding Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Workholding Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWorkholdingMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Workholding Market?

The growth of the Workholding Market is driven by:

- The expansion of the manufacturing sector

- Increasing demand for precision workholding devices in various industries, including CNC and automation

How do raw material costs impact the Workholding Market?

Fluctuations in raw material costs can impact the profitability of workholding manufacturers, as the cost of raw materials plays a significant role in determining the pricing of workholding solutions.

What are the emerging trends in precision engineering?

Emerging trends in precision engineering include the use of advanced materials and designs, driving the growth of the Workholding Market.

What are the technical challenges in automation and precision manufacturing?

Technical challenges, such as achieving high precision and accuracy, are significant hurdles in automation and precision manufacturing.

How is the Workholding Market segmented?

The Workholding Market can be segmented based on the type of workholding solution and material used, with different types of workholding solutions catering to various manufacturing needs.

What is driving the demand for workholding in CNC and automation industries?

The demand for workholding solutions is driven by their application in CNC and automation industries, where workholding solutions play a critical role in ensuring precision and accuracy.

What are the regional market trends in the Workholding Market?

Regional market trends, such as the growth of manufacturing in Asia, are influencing the Workholding Market, with countries like China and Germany driving the demand for workholding solutions.

What is the outlook for the global Workholding Market?

The global Workholding Market is expected to experience significant growth, driven by the increasing demand for precision workholding devices and advancements in manufacturing technology.

Who are the leading manufacturers in the Workholding Market?

The Workholding Market is highly competitive, with several leading manufacturers competing for market share, including those from Germany, the U.S., and China.

What are the future growth prospects for the Workholding Market?

The Workholding Market is expected to experience significant growth in the future, driven by emerging trends and technologies, including advances in precision engineering and automation.