$1.96 Billion Waveguide Straight Component Market Surge by 2025: Key Insights from the U.S., Germany, and Japan

Analyze the Waveguide Straight Component Market trends, growth drivers, and projections from 2025-2033, with insights into industry applications and regional dynamics.

- Last Updated:

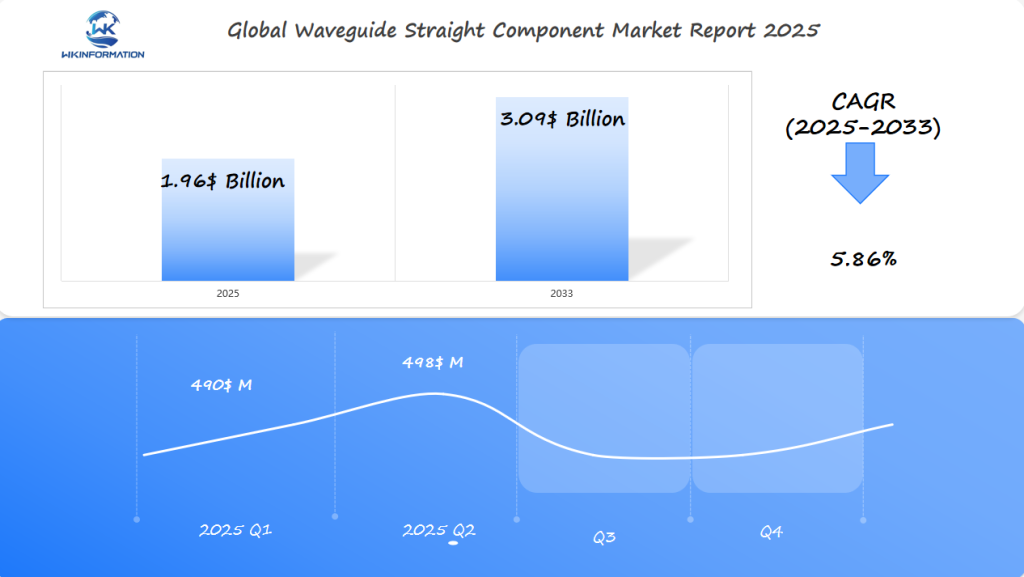

Waveguide Straight Component Market Q1 and Q2 2025 Forecast

The Waveguide Straight Component market is estimated to reach $1.96 billion in 2025, growing at a CAGR of 5.86% from 2025 to 2033. In Q1 2025, the market is projected to generate around $490 million, driven by its essential role in optical communication systems, radar, and satellite applications. These components are crucial in guiding electromagnetic waves in systems that require high precision and minimal signal loss.

The demand is particularly strong in the U.S., Germany, and Japan, where advancements in 5G infrastructure, space technologies, and military applications are expanding rapidly.

By Q2 2025, the market is expected to reach $498 million, supported by the growing demand for next-generation communication technologies, including 5G, satellite internet, and radar systems. Increased government spending on defense and aerospace projects is further driving growth, alongside rising investments in telecommunications infrastructure.

As the telecom industry continues to evolve, waveguide components are gaining traction as a key enabler for high-speed and reliable data transmission.

Exploring the Upstream and Downstream Industry Chains for Waveguide Straight Component

Upstream Industry Chain:

-

Raw Materials Supply

-

Metals and Alloys: Aluminum, copper, brass, and stainless steel are commonly used due to their conductivity and machinability.

-

Dielectrics and Insulating Materials: Used in hybrid or dielectric-loaded waveguides.

-

Precision Machining Tools: CNC machines, metal forming tools, and welding equipment.

-

-

Component Fabrication

-

Machining & Milling: For shaping waveguide tubes to precise dimensions.

-

Surface Treatment: Including anodizing, plating (e.g., gold, silver), and polishing to improve conductivity and reduce signal loss.

-

Quality Testing: Dimensional inspection, VSWR (Voltage Standing Wave Ratio) testing, and insertion loss measurement.

-

Downstream Industry Chain:

-

Assembly & Integration

-

Integration into RF and microwave systems for communications, radar, and satellite technology.

-

Connection with flanges, bends, twists, and other waveguide components.

-

-

Application Sectors

-

Aerospace & Defense: Used in radar, navigation systems, and satellite communications.

-

Telecommunications: In high-frequency transmission systems, including 5G backhaul.

-

Medical Devices: For MRI and therapeutic equipment requiring precise EM wave control.

-

Scientific Research: High-energy physics labs and microwave research setups.

-

-

Distribution & Service

-

OEMs & System Integrators: Incorporate components into broader RF systems.

-

Aftermarket Services: Maintenance, replacement, and performance upgrades.

-

Key Trends Driving the Waveguide Straight Component Market: Growth in Aerospace and Telecommunications

Component manufacturing is moving forward fast. The aerospace and telecommunications sectors are leading this growth. They need high-performance systems to work well.

Aerospace Innovations

In aerospace, Boeing and Lockheed Martin focus on making waveguide components light yet strong. These parts improve radar and communication systems for planes and satellites. New component manufacturing methods make these parts thinner and more precise, without adding weight.

Telecommunications Advancements

Telecommunications companies like Ericsson and Nokia are using waveguide straight components for 5G. These parts handle high frequencies, making data transmission fast in cities. The main drivers of growth are:

- Rising R&D investments in microwave technology

- Adoption of automation in component manufacturing lines

- Growing defense budgets pushing radar system upgrades

Breakthroughs in materials, like copper-alloy composites, make components more durable in extreme temperatures. As we need more global connections, advancements in component manufacturing will keep up.

Challenges in Waveguide Straight Component Production and Material Sourcing

Creating waveguide straight components needs a lot of precision. But, producers face many challenges at every step. Material shortages and higher costs make supply chains unstable, especially for aerospace needs.

Metal Selection Issues

Engineers have a hard time choosing metals like aluminum or copper. These metals are key for systems that work at high frequencies. They must balance how durable the metal is with its cost.

Impact of Supply Chain Issues

- Supply shortages cause delays in production, especially for rare alloys used in radar and satellite systems.

- Material costs can change a lot, making it hard for manufacturers to keep profits up.

- For aerospace, strict technical specs mean more parts get rejected during quality checks.

Possible Solutions

Using automated tools and working with global partners can help. Companies like Arco Components and Rogers Corporation are teaming up with local suppliers. This helps them avoid the ups and downs of the market.

Investing in research and development for new materials could also help. It could make it easier to find alternatives to traditional supplies.

Geopolitical Influence on the Waveguide Straight Component Market

Global trade policies and regional conflicts are reshaping the procurement and usage of waveguide straight components. Trade rules and tariffs are increasing production costs, while changes in regulations in major markets such as the U.S. and Europe are altering supply dynamics.

For instance, telecommunications infrastructure projects now frequently require the use of local parts to comply with national security regulations.

- U.S. export controls restrict component exports to specific countries, affecting radar and defense projects.

- EU 5G guidelines favor domestic suppliers, increasing demand for region-specific waveguide designs.

- Sanctioned nations encounter limited access to advanced materials, disrupting global production networks.

In response to these challenges, companies like L-3Harris and Cobham are establishing local factories to mitigate border issues. These strategic moves underscore the significant impact of politics on technology and market access. As trade agreements evolve, maintaining robust telecommunications infrastructure is essential for both military and commercial requirements.

Types of Waveguide Straight Components: Rectangular, Circular, and Flexible Designs

Waveguide straight components come in three main types. Each is made for different uses.

- Rectangular waveguides are the most common. They are great for sending microwave signals in straight lines. Their solid shape helps keep the signal strong. This is key for radar systems, where keeping the signal clear is crucial.

- Circular waveguides have a round shape. This makes them perfect for curved systems, like aircraft radomes. They keep the signal steady, even when moving.

- Flexible waveguides are bendy. They’re great for places that move a lot, like satellite dishes. They can bend without losing their signal quality.

Engineers pick the right design based on what they need. For example, flexible waveguides are good for ships because they handle shakes well. Rectangular ones are best for labs because they’re steady.

Each type is made to last and work well. They help in defense, telecom, and research.

Applications of Waveguide Straight Components in Telecommunications, Radar Systems, and Aerospace

Waveguide straight components are key for today’s tech. In telecommunications, they make 5G signals stronger, helping data move smoothly. For radar systems, they improve detection in military and aviation gear. In aerospace, they keep satellites and jets working well at high altitudes and speeds.

Telecommunications

Used in base stations to cut down on interference, crucial for secure military networks funded through defense procurement budgets.

Radar Systems

Essential in airborne systems like those from Raytheon and Northrop Grumman, boosting aircraft navigation and threat detection.

Aerospace

NASA and Boeing use these components in spacecraft and commercial planes to handle extreme temperatures and vibrations.

Defense procurement agencies focus on these components for radar upgrades. Contracts from the U.S. Department of Defense often require high-performance waveguides for modern warfare needs. For instance, the F-35 fighter jets use these parts to keep their radar stealth. As 5G grows, telecom and defense firms work together, sharing tech to help both sectors.

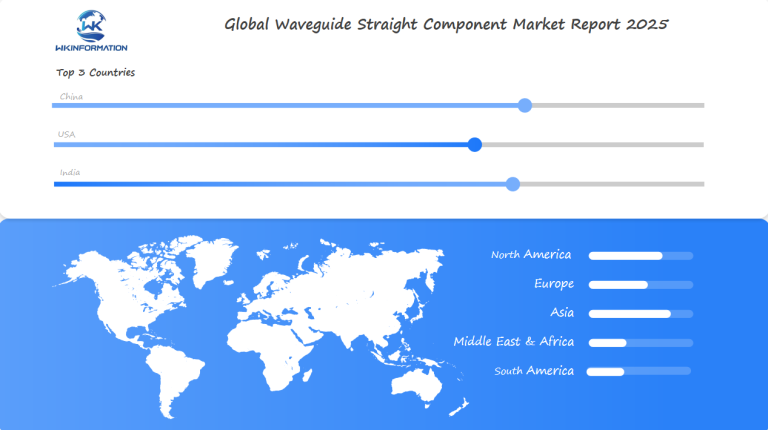

Global Insights into the Waveguide Straight Component Market

Global demand for waveguide straight components is growing fast. This is thanks to new markets and tech advancements. Analysts say sectors like aerospace and telecom are leading the way, pushing for better materials and making.

Strategic partnerships and government support in defense projects are also helping. This makes these components more popular.

waveguide market growth trends

- Asia-Pacific regions show rapid adoption for 5G infrastructure and radar systems.

- North America and Europe lead in high-frequency component production, backed by established industry players.

- Africa and the Middle East are emerging markets for defense and telecom upgrades.

Companies are investing in R&D to meet the growing demand. They’re also forming new partnerships to reach more areas. With 5G and space projects on the rise, making components durable and efficient is key.

Investors are looking for low-loss transmission solutions. This shows there are big opportunities in high-frequency uses, such as those offered by these advanced waveguide straight components.

U.S. Market Demand for Waveguide Straight Components in Military and Communication Sectors

Waveguide straight components are crucial for innovation in U.S. military and telecom systems. With the expansion of 5G networks and the modernization of defense, the demand for these components is increasing. Companies such as L-3 Harris Technologies and Keysight Technologies are prioritizing supply chain integration to ensure that domestic production can meet urgent requirements.

Key Factors Driving Demand

Here are the main reasons behind the growing demand for waveguide straight components:

- Rising 5G infrastructure projects: These projects require high-frequency waveguide parts for fast data transmission.

- Military contracts: Radar systems and satellite communications rely on dependable domestic suppliers.

- Supply chain integration: By reducing delays, this approach ensures that critical projects receive their components on time.

Impact on Supply Chain

The table below illustrates how supply chain integration is benefiting both the military and telecom sectors:

| Military | Radar upgrades, satellite communications | Local suppliers shorten delivery times and enhance security |

| Telecom | 5G rollouts, urban networks | Domestic manufacturing cuts costs and improves reliability |

Companies that invest in supply chain integration have the opportunity to receive federal grants and defense contracts. For instance, Raytheon collaborates with metal fabricators in the Midwest to meet strict military specifications. Similarly, telecom firms like Verizon are utilizing U.S.-based suppliers to avoid delays caused by global shipping.

Germany’s Role in Waveguide Straight Component Production for European Defense and Telecom

Germany is a leader in making waveguide straight components. They provide top-notch solutions for Europe’s defense and telecom networks. Their material quality control ensures components meet strict standards. This makes them key for high-frequency systems across the continent.

How Germany Ensures Quality in Waveguide Production

Germany’s expertise in waveguide production is backed by several key factors:

- Advanced material quality control systems reduce defects in aluminum and copper alloys used in waveguides.

- Partnerships with EU nations ensure seamless integration into radar systems and 5G infrastructure.

- Innovative coating technologies extend component lifespan in harsh environmental conditions.

German Companies Leading the Way

German companies like Friedrich Kugel GmbH and HUBER+SUHNER use automated tools during production. This reduces human mistakes. Their work meets ISO 9001 standards, ensuring components work well under extreme conditions. Military and telecom clients rely on German parts for critical tasks, from submarine communications to satellite uplinks.

Focus on Quality Control and Research

Germany focuses on material quality control and research and development. This keeps them as Europe’s main supplier. Their skills meet and go beyond NATO and ETSI standards, boosting the region’s tech power. As 5G networks grow, German innovation leads the way globally.

Japan’s Leadership in Waveguide Straight Component for Advanced Radar and Satellite Systems

Japan is leading in waveguide straight component innovation. Companies like Mitsubishi Electric and NEC have mastered innovative design. They create high-performance systems for radar and satellites.

Their focus on precision ensures components meet strict standards. This is crucial for aerospace and telecommunications.

| Mitsubishi Electric | Multi-beam radar systems using compact waveguides |

| NEC | Lightweight satellite components with low signal loss |

| Advantest | Automated testing tools for waveguide quality control |

Japan innovative design waveguide components

Japanese firms work with global partners like Lockheed Martin. They integrate innovative design into next-gen defense systems. This speeds up 5G network and space communication advancements.

Recent projects include compact radar antennas for drones and satellites. Japan is committed to leading-edge research.

Japan keeps investing in R&D. They focus on material science and miniaturization. This makes their components faster and more reliable.

Japan’s leadership ensures they play a big role in setting future industry standards.

The Future of Waveguide Straight Component: Innovations in High-Frequency and Low-Loss Transmission

Tomorrow’s waveguide straight components will use new technologies to meet the need for speed and reliability. Engineers are working with materials like carbon-reinforced polymers and ultra-pure metals to cut down on signal loss. These changes will make high-frequency transmission better in systems like radar and satellites.

1. Material Science Breakthroughs

Companies like Keysight Technologies are testing graphene coatings to handle higher power without overheating.

2. Design Evolution

3D printing enables complex geometries, optimizing signal paths for high-frequency transmission in compact devices.

3. Smart Manufacturing

AI-driven quality checks ensure components meet exacting standards for aerospace and 5G infrastructure.

These upgrades will help industries:

- Transfer data faster for telecom networks

- Get sharper radar images for defense

- Make lighter components for space missions

Big names like Boeing and Lockheed Martin are testing these new waveguides. By 2026, the market for high-frequency transmission is expected to grow by 7% each year. As 5G grows and space exploration increases, these new technologies will offer smarter, more durable solutions for our global tech needs.

Competitive Landscape in the Waveguide Straight Component Market

Top players in the waveguide straight component market are working hard to lead the way. Companies like Amphenol, Pasternack, and TE Connectivity are focusing on low-loss performance. They aim to meet the growing needs in aerospace and telecom.

Here are some of the key companies operating in the waveguide straight component market:

- Aerowave – United States

- Pasternack – United States

- Apollo Microwaves – Canada

- Centric RF – United States

- DEEWAVE Electronics – China

- Quantum Microwave – United States

- RFHIC – South Korea

- WENTEQ Microwave – United States

- Precision Millimeter Wave – United States

- Fairview Microwave – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Waveguide Straight Component Market Report |

| Base Year | 2024 |

| Segment by Type |

· Rectangular · Circular · Flexible Designs |

| Segment by Application |

· Telecommunications · Radar Systems · Aerospace |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Waveguide straight components play a vital role across telecommunications, radar systems, and aerospace industries. In telecommunications, they enable efficient signal transmission for 5G networks and beyond. For radar systems, they provide crucial support in military and civilian applications, ensuring accurate detection and tracking capabilities.

In aerospace, these components are essential for satellite communications and aircraft navigation systems. As technology continues to advance, the demand for high-quality waveguide straight components will only increase, making them indispensable elements in modern communications and defense infrastructure. Their reliability, precision, and versatility continue to drive innovation and progress across these critical sectors, ensuring better connectivity and enhanced performance in our increasingly connected world.

Global Waveguide Straight Component Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Waveguide Straight Component Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Waveguide Straight Component Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Waveguide Straight Componentplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Waveguide Straight Component Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Waveguide Straight Component Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Waveguide Straight Component Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Waveguide Straight Component Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current trend in the Waveguide Straight Component Market?

The Waveguide Straight Component Market is growing fast. This growth is mainly because of new advancements in aerospace and telecommunications. By 2025, the market is expected to hit $1.96 billion, thanks to the need for better high-frequency and low-loss technologies.

What are the main challenges faced in the production of Waveguide Straight Components?

Making Waveguide Straight Components is tough. Issues like efficiency problems, hard-to-find materials, and supply shortages are big challenges. Also, changing costs and technical issues, especially in aerospace, make it hard to keep quality high.

How do geopolitical factors influence the Waveguide Straight Component Market?

Politics can have a significant impact on the Waveguide Straight Component Market. Factors such as tariffs and trade regulations can influence the manufacturing and distribution processes. For instance, rules implemented in regions like the U.S. and Europe may create challenges in production and sales, resulting in potential cost and stability concerns.

What types of Waveguide Straight Components are available?

There are many types of Waveguide Straight Components. You can find rectangular, circular, and flexible ones. Each type helps improve efficiency in areas like radar and telecommunications.

In what industries are Waveguide Straight Components commonly used?

Waveguide Straight Components are essential in various industries. They find extensive applications in:

- Telecommunications

- Radar systems

- Aerospace

These components play a crucial role in enhancing signal clarity, improving detection capabilities, and ensuring dependable performance in challenging environments.

What is the U.S. market demand for Waveguide Straight Components?

The U.S. is seeing more demand for Waveguide Straight Components. This is especially true in the military and communication fields. The need for better defense and communication systems is driving this demand, leading to new projects and investments.

How does Germany contribute to the Waveguide Straight Component market?

Germany is a major player in the Waveguide Straight Component market. They focus on high-quality materials and innovative manufacturing processes. This ensures that their components are dependable and establishes a benchmark for the worldwide market.

What advancements is Japan making in Waveguide Straight Component technology?

Japan is leading the way in Waveguide Straight Component technology. They’re developing advanced radar and satellite systems. Their emphasis on precision engineering and strategic investments is influencing global standards and promoting collaboration.

What future innovations can we expect in the Waveguide Straight Component market?

We can expect to see better high-frequency and low-loss transmission in the future. Research and development in new materials and methods will improve efficiency and performance. This will help the technology meet future challenges.

Who are the major players in the Waveguide Straight Component Market?

The Waveguide Straight Component Market has several big players. They’re all about innovation and keeping costs down. Companies stand out by showing how they perform better than others, using case studies and reports to show their market strategies.