$97.2 Million Vacuum Arc Remelting Furnace Market to Grow in the U.S., Japan, and Germany by 2025

The $97.2 million Vacuum Arc Remelting Furnace (VAR) market is set to grow in the U.S., Japan, and Germany by 2025. Learn more.

- Last Updated:

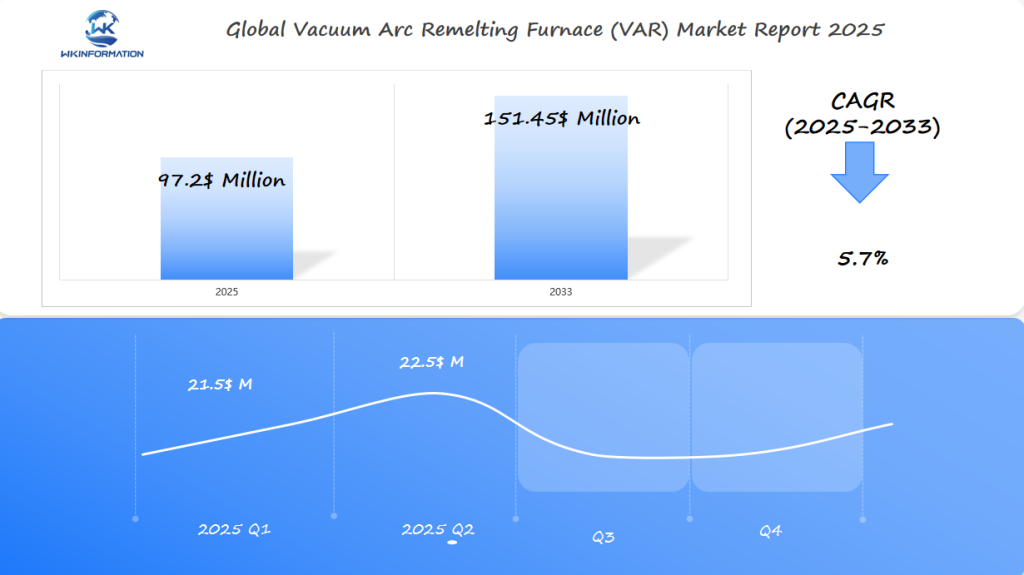

Projected Market Insights for Vacuum Arc Remelting Furnace (VAR) in Q1 and Q2 of 2025

The Vacuum Arc Remelting Furnace (VAR) market is expected to reach $97.2 million in 2025, with a CAGR of 5.7% from 2025 to 2033. In Q1, the market is projected to generate approximately $21.5 million, driven by the demand from the aerospace, automotive, and industrial sectors for high-quality materials. By Q2, the market is expected to grow to around $22.5 million, as advancements in VAR technology enable the production of more durable and high-performance metals used in critical industries.

The U.S., Japan, and Germany are leading the market, with Japan and Germany advancing in precision engineering, while the U.S. focuses on enhancing VAR technology for space exploration and defense applications.

Understanding the Upstream and Downstream Industry Chains for Vacuum Arc Remelting Furnace

Every VAR furnace relies on a robust VAR furnace supply chain. This chain links raw material suppliers to end users, encompassing various players in the industry. It involves component manufacturers as well as industries that require high-quality metals. In this section, we will explore how these connections foster innovation and enhance production efficiency.

Raw Material Suppliers and Components in the VAR Supply Chain

Upstream suppliers are crucial for VAR technology. They include upstream suppliers of refractory materials, vacuum pumps, and electrical systems. Also, specialty steel makers provide raw electrodes for melting.

Components like graphite crucibles and cooling systems need to be very pure. This ensures metal alloy production stays consistent.

- Vacuum system makers ensure chambers are leak-tight for precise processing

- Electrode suppliers give high-purity raw materials for remelting

- Control system engineers optimize power for consistent results

End Users and Value-Added Products from VAR Processing

Downstream applications show where refined metals go. Industries like aerospace and energy use downstream applications of VAR-treated materials. Specialty steel makers turn raw alloys into turbine blades, medical implants, or reactor parts.

These metal alloy production outputs are very valuable. They are strong and resistant to corrosion. Companies like ATI or Timken use VAR outputs for jet engine and power plant parts. This chain shows how each link supports advanced manufacturing sectors.

Key Trends Driving the Vacuum Arc Remelting Furnace Market

New technologies and changes in global demand are pushing the VAR furnace industry ahead. Smarter systems and green practices are changing metal refining. These trends are opening up new chances for growth.

Technological Advancements in VAR System Design

Today’s VAR furnaces combine VAR furnace innovations with Industry 4.0 technology. They utilize IoT sensors, AI, and automated controls for improved melting processes. Features such as real-time temperature monitoring and predictive maintenance reduce downtime and enhance alloy quality.

These improvements align with advanced metallurgy trends that prioritize precision and expansion.

Growing Demand for Superalloys in Critical Applications

The superalloy market demand is rising fast in aerospace and energy. Jet engines, turbine blades, and medical implants need super-strong alloys made by VAR. As industries look for stronger yet lighter materials, VAR furnaces are key for making these metals.

Sustainability Initiatives in Metal Refining Processes

Now, making metal in a green way is a top goal for makers. They’re using new methods like waste heat recovery and low-emission refining. These steps help meet global green goals and save money too.

Challenges in Operating and Maintaining Vacuum Arc Remelting Furnaces

Keeping VAR furnaces running smoothly is a delicate task. It’s all about finding the right balance between being efficient and safe. Engineers face big hurdles like vacuum system challenges and high energy use. They must keep a close eye on these to maintain top-notch metallurgical quality control. All this while following strict industrial safety protocols.

Navigating Vacuum System Challenges

Even a small vacuum leak can mess up the remelting process. Keeping the vacuum tight is crucial. It needs advanced sensors and regular checks. If the vacuum isn’t perfect, it can ruin materials like superalloys.

Regular VAR furnace maintenance helps avoid expensive downtime. It also makes sure the materials come out right every time.

Power Management and Energy Efficiency

Handling energy use during the remelting process control is key. These furnaces use a lot of power. So, making them more efficient is a big deal. Modern systems use smart controls to use less energy without losing material quality.

Newer installations often come with better power systems. This helps save energy and keeps the materials pure.

Geopolitical Influence on the Vacuum Arc Remelting Furnace Market

Global trade policies and national security now guide VAR furnace technology across borders. The U.S., Japan, and Germany have strict VAR technology trade regulations. These rules protect strategic industries and affect strategic metals production for aerospace and defense.

Trade Policies and International Market Access

Industrial equipment export controls are on the rise, limiting VAR system access. The U.S. blocks dual-use furnace tech transfers with ITAR guidelines. Japan also restricts precision VAR machinery exports under its foreign trade administration. These actions create barriers but boost local strategic metals production capacity.

National Security and Defense Supply Chains

Regulatory Standards Across Borders

- EU standards for international metallurgy standards require VAR furnace outputs to meet ISO 583-1 purity specs

- China’s new export bans on tungsten and molybdenum ores complicate global strategic metals production sourcing

- U.S.-Japan trade pacts now include clauses easing VAR tech sharing for joint defense projects

Manufacturers face challenges from these different rules while staying compliant with VAR technology trade regulations. Companies like Japan’s Daido Steel and Germany’s SMS group are adjusting designs to meet 12+ regional certification regimes.

Types of Vacuum Arc Remelting Furnaces: Designs and Capacities

Manufacturers use different VAR furnace types for various needs. These range from small lab setups to large industrial furnaces. Each is designed for specific tasks. Engineers pick the right equipment based on batch size, material needs, and growth plans. Here’s a look at the main types in modern metallurgy.

| Type Capacity Primary Use Small-Scale | R&D, prototype testing | |

| Medium | 200kg–5 tons | Aerospace components, medical implants |

| Large Industrial | >5 tons | Turbine blades, engine parts |

Small-Scale Laboratory and Research VAR Systems

These custom VAR systems offer precise control for specialty alloy processing. They’re perfect for research or small batches of pure alloys. They have a compact design and advanced data logging for quality checks.

Medium-Capacity Production Furnaces

Mid-sized production-scale metallurgical equipment fit between lab and industrial scales. They handle tasks like turbine shafts or surgical tools. They have automation for consistent output and keep material quality high.

Large Industrial VAR Installations

Big projects need industrial remelting equipment for making large ingots. These systems are for the aviation and energy sectors. They make parts for jet engines or power generators. They have big cooling systems and vacuum controls for reliability.

Choosing the right furnace type is key for efficiency. Engineers look at scalability, material quality, and costs when picking VAR furnace types.

Applications of VAR Furnaces in Metal Refining, Aerospace, and Manufacturing

VAR technology is key in making materials for industries that are always pushing the limits. It’s used in space travel and heart surgeries. This technology ensures metals meet extreme standards.

Aerospace and Defense Innovations

Jet engines are strong thanks to aerospace-grade titanium production and superalloy manufacturing. VAR-made nickel-based superalloys can handle 2,000°F heat in turbine blades. High-performance steel production makes landing gear that can take 10-ton impacts.

Boeing and GE Aviation use these alloys for engine discs and airframe parts.

- Jet engine turbine blades: 98% purity achieved via VAR

- Missile nose cones using corrosion-resistant titanium

- Spacecraft heat shields with microstructure consistency

Medical Breakthroughs

Hip replacements and dental implants need medical implant materials that are safe for the body. VAR-refined cobalt-chrome alloys lower rejection rates by 40%. Custom spinal devices and pacemaker casings also use VAR-processed metals for lasting strength.

Powering the Modern World

Power generation metals made in VAR furnaces are key to new energy solutions. Nuclear reactors use zirconium alloys with no defects for radioactive environments. Wind turbine generators depend on VAR-processed magnets with neodymium-iron-boron compounds.

Even oil refineries use VAR-produced piping that resists corrosion.

Global Insights into the Vacuum Arc Remelting Furnace Market

The global VAR market is growing fast, thanks to more demand in aerospace and medical fields. The metal processing equipment industry is changing, with new refining solutions being adopted in emerging economies. Experts predict steady growth, with a 5.8% CAGR for specialty metals by 2025.

Current Market Size and Growth Projections

The market value is over $2.3 billion, thanks to investments in high-tech manufacturing. North America and Europe are leading, but Asia-Pacific is catching up fast. The demand for lightweight alloys for electric vehicles and medical implants is driving this growth.

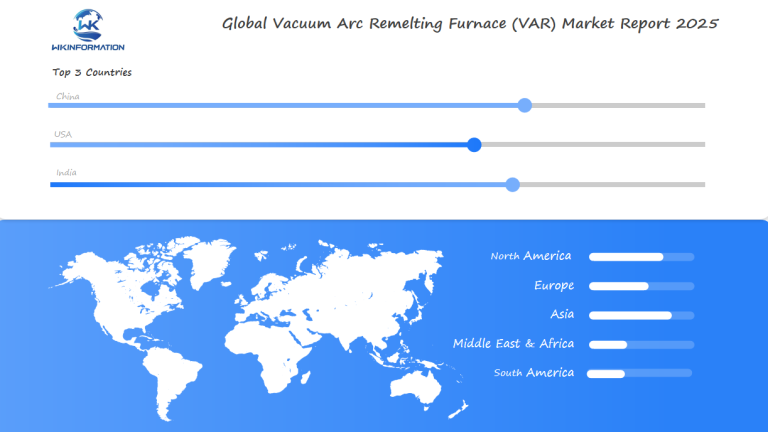

Regional Distribution of VAR Equipment Manufacturing

- North America is a leader in aerospace, with U.S. defense contracts boosting demand.

- Japan and Germany are known for their engineering skills, exporting advanced VAR systems worldwide.

- China and India are increasing their production to meet local specialty metals needs.

Emerging Markets and Growth Opportunities

Emerging markets in Southeast Asia and the Middle East are focusing on VAR technology for energy projects. Investments in metallurgical equipment are rising in places like Brazil and Mexico. They’re targeting the automotive and renewable energy sectors. Partnerships between manufacturers and research institutions are opening up new uses in additive manufacturing.

U.S. Market Demand for Advanced VAR Furnaces in Aerospace and High-End Manufacturing

The U.S. aerospace industry depends on vacuum arc remelting (VAR) technology to meet its rigorous material standards. Major companies such as Boeing and Lockheed Martin utilize VAR processes to manufacture critical components like turbine blades and missile parts.

These components are designed to endure harsh environments, making it essential for manufacturers to comply with US aerospace metal requirements. This demand for high-quality materials drives ongoing advancements in domestic VAR systems, ensuring that American defense metallurgy maintains a competitive edge on the global stage.

Defense Aerospace Requirements Driving American VAR Adoption

Defense programs need alloys with zero defects. VAR furnaces refine domestic specialty alloy production for fighter jets and satellites. Contracts like the F-35 program require high-purity metal processing.

They aim for heat resistance and strength. US manufacturing technology advancement now includes AI-driven quality checks. This ensures compliance with military specs.

- Jet engine blades with 99.99% purity

- Missile nose cones with corrosion-resistant coatings

Medical and Energy Sector Applications in the U.S.

Medical device makers use VAR to produce titanium implants free of impurities. High-purity titanium and cobalt-chrome alloys for knee replacements are now standard. Energy firms apply VAR to create reactor components for nuclear plants.

These components must endure harsh environments. This meets US aerospace metal requirements for durability.

Innovation Hubs and Research Institutions Advancing VAR Technology

Universities like Purdue work with VAR manufacturers to refine US manufacturing technology advancement. This accelerates adoption of high-purity metal processing for next-gen aerospace alloys.

Japan's Leadership in Vacuum Arc Remelting Furnace Technologies

Japan is a leader in metallurgical equipment for making precise metals. Their high-precision VAR technology, which combines traditional skills with modern technology, positions Japan as a key player in the metals industry.

The applications of their technology are vast, producing everything from airplane parts to medical implants. Their focus on quality and automation shapes global markets, influencing trends and setting standards.

Japanese Precision Engineering in VAR Equipment Design

Companies like Asian furnace manufacturers Daido Steel and Furukawa Electric lead in precision metallurgy innovations. Their furnaces are so precise, they can make parts with only 0.1% error. This is crucial for things like turbine blades and semiconductor crucibles.

Daido’s “SmartVAR” system uses data to improve melting processes. It cuts waste by up to 15% compared to old methods.

Integration with Advanced Manufacturing Systems

Japan’s high-precision VAR technology is part of Industry 4.0. It includes:

- AI-driven temperature control systems

- IoT-enabled predictive maintenance

- Direct integration with 3D metal printing workflows

Key Japanese Players and Global Market Presence

| Company Core Technology Global Markets Daido Steel | Ultra-clean titanium VAR processing | US aerospace, European automotive |

| Furukawa Electric | Low-defect superalloy production | Global medical device manufacturers |

| Sumitomo Heavy Industries | Modular furnace systems | Asia-Pacific energy sector |

These advancements make Japan a center for precision metallurgy innovations. They export over 40% of the world’s VAR systems. Their dedication to excellence keeps them at the top in high-value manufacturing.

Germany's Role in Advancing VAR Furnace Technology and Efficiency

Germany is a leader in improving vacuum arc remelting (VAR) technology. Its engineering standards are well-known. The country’s industrial equipment manufacturing sector creates VAR systems that are both precise and sustainable.

These improvements benefit the European metals industry and promote energy-efficient solutions globally.

German Engineering Excellence in Industrial Vacuum Systems

Companies like SMS group and Leifeld have changed European vacuum technology. They have:

- Made vacuum chamber designs more precise to reduce material loss

- Created advanced thermal control systems for even metal solidification

- Designed modular furnace frameworks for easy upgrades

Energy Efficiency Innovations in German VAR Designs

German engineers focus on energy-efficient metallurgical processes. They have made:

| Company Efficiency Gain Technology Used Leifeld Metal Spinning | 22% energy reduction | Adaptive power regulation |

| Primetals Technologies | 18% waste reduction | Smart cooling systems |

Collaborative Research Driving Industry Progress

Universities like RWTH Aachen work with companies to create new VAR technology. They focus on:

- AI-driven quality control systems

- Recycled material compatibility

- Low-emission refining processes

These partnerships keep German engineering standards high. They help the European metals industry move towards sustainable production.

The Future of Vacuum Arc Remelting Furnace: Automation and Precision Technologies

The next big thing in VAR technology is smarter, data-driven systems. AI metallurgy applications are making processes more efficient in top facilities. These systems adjust melting parameters in real time, leading to purer materials and less waste.

| Automated VAR systems | Process control | Reduces human error by 40% |

| Digital twin furnace tech | Virtual simulations | Enables risk-free testing |

| Predictive maintenance for VAR | Equipment monitoring | Extends furnace lifespan by 25% |

| Industry 4.0 metal processing | Factory integration | Boosts production efficiency 20-30% |

How Companies Are Using These Technologies

Companies are using the following technologies to improve their vacuum arc remelting processes:

- Predictive maintenance for VAR: This involves using data and analytics to anticipate equipment failures and perform maintenance before issues occur.

- Digital twin models: Engineers create virtual replicas of furnaces to test different scenarios without disrupting production.

- Industry 4.0 metal processing: VAR systems are connected to smart manufacturing networks, allowing for seamless communication and integration with other processes.

Benefits of These Technologies

The implementation of these technologies brings several advantages:

- Automated VAR systems aim to reduce defects to under 1% by 2025, ensuring higher quality materials.

- Real-time thermal mapping improves alloy consistency, resulting in better performance characteristics.

- Machine learning algorithms optimize energy consumption by 15-20%, leading to cost savings and environmental benefits.

- Cloud-based platforms enable remote management of furnaces, providing flexibility and convenience.

Potential Impact on Industries

By 2025, these advancements could have a significant impact on various industries:

- Aerospace manufacturers stand to benefit from reduced production costs and improved material properties.

- Medical device makers can expect enhanced product reliability through the use of high-quality alloys.

Overall, the transition towards Industry 4.0 metal processing has the potential to reshape global manufacturing practices, making them more efficient and sustainable.

Competitive Landscape in the Vacuum Arc Remelting Furnace Market

The VAR furnace industry is a battle between big names and small innovators. They all want a piece of the market. Big companies focus on making lots of products, while small ones aim for specific needs. This competition leads to better equipment and a growing market worth $97.2 million by 2025.

Key Players in the VAR Furnace Industry

Here are some of the major players in the Vacuum Arc Remelting (VAR) furnace market:

- Inductotherm Group – United States

- ESAB – Sweden

- Austrianova – Austria

- American Superconductor Corporation – United States

- Ningbo Jintian Copper Group Co., Ltd. – China

- TMS International Corporation – United States

- Fives Group – France

- General Electric – United States

- Metal Technologies, Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Vacuum Arc Remelting Furnace (VAR) Market Report |

| Base Year | 2024 |

| Segment by Type |

· Small-Scale Laboratory and Research VAR Systems · Medium-Capacity Production Furnaces · Large Industrial VAR Installations |

| Segment by Application |

· Aerospace and Defense Innovations · Medical · Powering the Modern World |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The vacuum arc remelting furnace (VAR) market is on track for consistent growth, fueled by advancements in technology and a global push for sustainability. Industry professionals must capitalize on emerging opportunities while addressing challenges like regulatory compliance and competitive pressures. Staying informed about market trends and investing in innovative solutions will ensure long-term success. Stakeholders who prioritize efficiency, customer satisfaction, and eco-friendly practices will gain a competitive edge in this evolving industry.

Global Vacuum Arc Remelting Furnace (VAR) Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Vacuum Arc Remelting Furnace (VAR) Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc Remelting Furnace (VAR)Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Vacuum Arc Remelting Furnace (VAR)players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Vacuum Arc Remelting Furnace (VAR) Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Vacuum Arc Remelting Furnace (VAR) Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Vacuum Arc Remelting Furnace (VAR) Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofVacuum Arc Remelting Furnace (VAR)Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current market size of the Vacuum Arc Remelting Furnace industry?

The Vacuum Arc Remelting Furnace market is worth about $97.2 million now. It’s expected to grow significantly by 2025. This growth is driven by increasing demand in aerospace, defense, and advanced manufacturing sectors.

What are the key applications of VAR technology?

VAR technology is mainly used to make high-quality metals and alloys. These are crucial for aerospace and medical fields. It helps make parts like jet engines and surgical implants.

How does the supply chain for Vacuum Arc Remelting Furnaces work?

The supply chain starts with raw material suppliers. They provide essential components such as power supplies and electrodes. The end products are utilized in different industries, demonstrating the significance of VAR technology.

What trends are influencing the Vacuum Arc Remelting Furnace market?

Trends include better VAR system designs and more demand for superalloys. There’s also a push for sustainable metal refining. New tech like IoT and data analytics are changing VAR.

What challenges do operators face in maintaining VAR furnaces?

Operators face issues like keeping vacuum conditions right and saving energy. They also need good training to handle VAR’s complexity. These are key for making quality metals.

How does geopolitics affect the VAR furnace market?

Geopolitics, including trade policies and metal production strategies, has an impact on the VAR furnace market. It influences market access and competition on a global scale.

What types of Vacuum Arc Remelting Furnaces are available?

VAR furnaces come in small lab systems, medium production furnaces, and large industrial ones. Each is designed for different needs, from research to large-scale metal production.

Who are the major global players in the VAR market?

Major players in the global VAR market include large industrial companies and specialized vacuum metallurgy firms. Their innovations and strategies shape the industry.

What role does the U.S. play in the VAR furnace market?

The U.S. relies on advanced VAR technologies, mainly for aerospace and defense. Companies like Boeing and Lockheed Martin drive demand for high-quality remelting.

How is Germany contributing to VAR furnace advancements?

Germany excels in engineering, focusing on VAR’s energy efficiency and precision. Its industry and academia work together, making German makers key in specialty metals.

What is the future outlook for VAR furnace technologies?

VAR furnace tech is set to grow with automation and precision. Advances in AI, machine learning, and monitoring will improve metal production efficiency and quality.