$3.16 Billion Tungsten Penetrator Market Set for Growth in the U.S., Russia, and China by 2025

Explore the Tungsten Penetrator market trends, growth drivers, and regional insights. Discover how defense and industrial sectors fuel its global expansion.

- Last Updated:

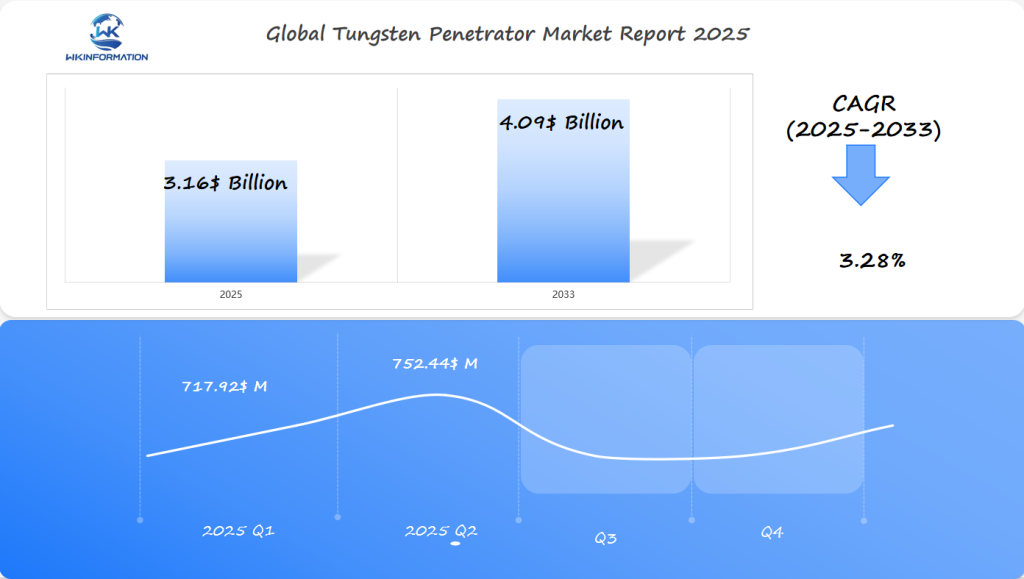

Projected Market Insights for Tungsten Penetrator in Q1 and Q2 of 2025

The Tungsten Penetrator market is expected to reach $3.16 billion in 2025, with a CAGR of 3.28% from 2025 to 2033. In Q1, the market is anticipated to generate around $717.92 million, driven by the increasing use of tungsten-based materials in defense and military applications due to their superior density and penetration capabilities. By Q2, the market is expected to rise to approximately $752.44 million, as defense contracts and military modernization projects expand.

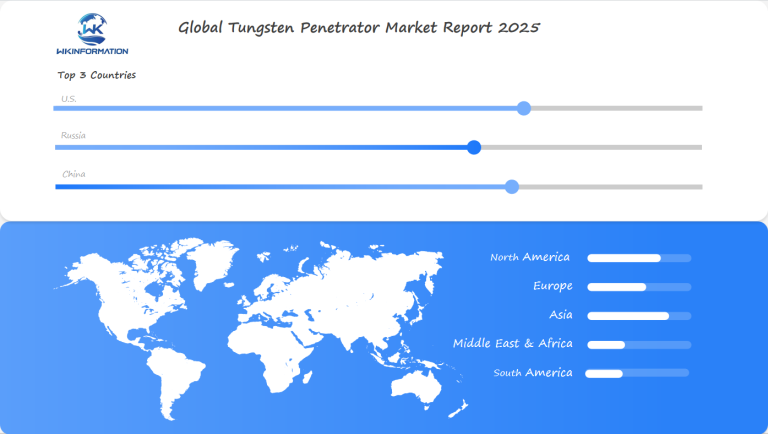

The U.S., Russia, and China are leading players in this market. The U.S. remains at the forefront with its extensive defense spending and military technology advancements, while Russia and China continue to invest heavily in military development. As defense and aerospace applications continue to demand high-performance materials, the tungsten penetrator market is expected to experience steady growth in these regions.

Understanding the Upstream and Downstream Industry Chains for Tungsten Penetrators

Understanding the industry chains of tungsten penetrators provides crucial insights into market dynamics.

Upstream Processes: Mining and Refining

The upstream processes start with mining and refining. Tungsten is mainly obtained from ores such as scheelite and wolframite, which require large-scale mining activities. These ores go through a process called beneficiation to increase the concentration of tungsten, and then refining methods are used to obtain high-purity tungsten powder or ingots. This serves as the primary material for production.

Downstream Applications: Defense and Industrial Sectors

Tungsten penetrators play a crucial role in the defense industry, where they are used in kinetic energy weapons and armor-piercing ammunition. This is one of the key applications of tungsten in the downstream sector.

In addition to defense, the industrial sector also utilizes tungsten’s unique properties for various purposes. For instance, drilling tools benefit from tungsten’s density and strength, making them more efficient in penetrating tough surfaces. Furthermore, radiation shielding materials employ tungsten’s high atomic number to effectively block harmful radiation.

These applications highlight how tungsten’s characteristics make it valuable in both defense and industrial sectors. However, it’s important to consider the environmental impact of these downstream applications, such as upstream and downstream emissions, which can have significant implications for sustainability.

Importance of Analyzing Industry Chains

Analyzing these industry chains provides a complete understanding of the factors that drive market growth and those that limit it. By gaining insights into the complex processes involved in mining and refining (the supply side) as well as the various industries that use these materials (the downstream sectors), stakeholders can effectively navigate the changing market.

This broader viewpoint improves strategic planning, making sure that it aligns with industry needs and technological progress.

Key Trends in the Tungsten Penetrator Market: Defense and Industrial Applications

The tungsten penetrator market is experiencing a surge in demand, particularly within defense applications. The primary driver here is the increased use of kinetic energy weapons, which leverage tungsten’s high density and hardness to enhance their effectiveness. These weapons are crucial for modern military strategies, necessitating materials that offer superior penetration capabilities.

In the realm of industrial applications, tungsten penetrators are finding new utilities. Drilling tools benefit from tungsten’s durability, making it an ideal choice for demanding environments like mining and construction. Additionally, its efficacy as a radiation shielding material is gaining attention, especially in medical and nuclear industries where safety standards are stringent.

Technological advancements continue to shape market dynamics. Innovations in material sciences are refining tungsten penetrator designs, making them more efficient and adaptable to various conditions. This progress not only enhances product performance but also expands potential application areas, contributing significantly to market growth.

These trends underscore the increasing relevance of tungsten penetrators across diverse sectors, driven by both defense needs and industrial innovations. As technology evolves, so too does the potential for these materials to address emerging challenges across industries.

Challenges in Tungsten Penetrator Production and Material Innovation

Producing tungsten penetrators at scale is fraught with challenges that can hinder market growth. High production costs stem from the complex processes involved in extracting and refining tungsten. The sourcing of raw materials also presents difficulties, particularly due to tungsten’s limited geographical availability and the geopolitical factors that affect its supply chain.

The Need for Innovative Approaches

Navigating these production challenges requires innovative approaches in material science. Recent advancements are making significant strides in improving the design and performance characteristics of tungsten penetrators. Innovations focus on enhancing tensile strength and density, essential properties that determine a penetrator’s effectiveness.

Tangible Improvements for End-Users

These material innovations are not just theoretical; they translate into tangible improvements for end-users. For instance, modified alloys and composites are being developed to achieve superior penetration capabilities in defense applications, while also offering better wear resistance for industrial uses like drilling.

Industry Response

Industry players are keenly aware of these hurdles and innovations, driving research and development investments to overcome production challenges and capitalize on new material technologies. As this sector continues to evolve, understanding both the obstacles and breakthroughs remains crucial for stakeholders looking to maintain a competitive edge in the dynamic tungsten penetrator market landscape.

Geopolitical Factors Affecting the Tungsten Penetrator Market

Geopolitical factors significantly impact the supply chains and trade relations for tungsten penetrators, especially among major global players such as the U.S., Russia, and China. These countries not only produce and consume tungsten but also affect market dynamics through their political and economic policies.

China’s Influence

China dominates the tungsten market, holding approximately 62% of the global share. Its control over tungsten resources gives it significant power over pricing and availability, affecting international trade relations. China’s rules on export limits and taxes can greatly impact global supply chains, causing market instability.

The U.S. as a Key Consumer

The U.S. may not be the leading producer, but it plays a crucial role as a consumer. Ongoing geopolitical tensions between the U.S. and China could result in strategic stockpiling or sourcing from other suppliers, which in turn may impact market stability.

Russia’s Geopolitical Strategies

Russia has its own geopolitical strategies that can change trade dynamics. Its relationships or conflicts with other countries can affect supply routes and global pricing structures for tungsten penetrators.

These geopolitical factors have significant effects on the market, potentially resulting in greater competition for resources, changes in trade policies, and evolving alliances that could redefine market access and pricing strategies for tungsten penetrators globally.

Market Segmentation: Types and Applications of Tungsten Penetrators

Understanding the market segmentation of tungsten penetrators provides valuable insight into its diverse applications across various industries. This market can be broadly categorized into two main types:

1. Cemented Carbide Products

Cemented carbide products are known for their exceptional hardness and resistance to wear. They are essential in various applications such as cutting tools, mining machinery, and heavy-duty equipment. Their long-lasting nature makes them irreplaceable in industries that demand strong performance in harsh environments.

2. Mill Products

Mill products are known for their high density and tensile strength, making them ideal for defense applications. These products can withstand intense kinetic forces, making them suitable for use in armor-piercing ammunition and missile components.

The significance of this segmentation is crucial for industries that heavily rely on the unique properties of tungsten. For example:

- The aerospace and defense sectors benefit greatly from tungsten’s high melting point and density, which are essential for both kinetic energy penetrators and protective armaments.

- In the industrial sector, tungsten’s application extends to drilling tools, where its resistance against wear improves operational efficiency.

Each type serves specific industrial needs, emphasizing the importance of targeted production strategies to meet sector-specific demands. By understanding these segments, stakeholders can make informed decisions about resource allocation and technological investment in the tungsten penetrator market.

Tungsten Penetrators in Military, Mining, and Energy Industries

Tungsten penetrators are extremely hard, dense, and resistant to extreme conditions. These properties make them valuable in various industries such as military, mining, and energy.

Military Applications

In the military field, tungsten is commonly used in armor-piercing ammunition. It offers superior penetration capabilities against heavily armored targets. Additionally, its high melting point and non-toxic characteristics make it a preferred alternative to depleted uranium in kinetic energy projectiles, anti-tank rounds, and guided missile warheads.

Mining Sector

The mining industry relies on tungsten-based drilling and cutting tools for extracting hard rock and mineral resources. Tungsten carbide-tipped drill bits and blasting tools enhance efficiency and durability in deep-earth drilling and tunneling operations. This significantly reduces equipment wear and maintenance costs.

Energy Industry

The energy sector also benefits from tungsten penetrators, especially in oil and gas exploration. Here, tungsten-based components enhance the performance of drilling equipment in extreme high-pressure and high-temperature environments.

As technology continues to advance and push the boundaries of material performance, tungsten penetrators remain essential in industries that require precision, strength, and dependability.

Global Insights into the Tungsten Penetrator Market

Global Market Trends:

The tungsten penetrator market is experiencing significant global trends that are influencing its growth. One of the main factors driving this growth is the increased demand from defense sectors around the world, which is fueled by the ongoing need for advanced military equipment. Tungsten’s unique characteristics, such as its high density and tensile strength, make it the preferred choice for kinetic energy penetrators and armor-piercing ammunition. Furthermore, advancements in material science and additive manufacturing are broadening the applications of tungsten penetrators across various industries. This trend aligns with the findings in a report about CRMs for strategic technologies and sectors in the EU, which highlights the importance of materials like tungsten in certain strategic sectors.

U.S. Market Demand for Tungsten Penetrators in Defense Applications

The U.S. defense sector has a strong demand for tungsten penetrators due to their superior density, hardness, and armor-piercing capabilities. Tungsten, a high-density metal, is widely used in kinetic energy penetrators for armor-piercing munitions, offering a non-toxic alternative to depleted uranium rounds.

Key Factors Driving Demand

- Modernization of Military Capabilities: The increasing focus on modernizing military capabilities and enhancing the lethality of munitions has driven continued investment in tungsten-based projectiles for anti-armor, artillery, and aerial defense applications.

- Domestic Supply Development: The U.S. defense industry relies on a secure and stable supply of tungsten, prompting efforts to develop domestic sources and reduce dependency on foreign suppliers.

- Geopolitical Tensions: As global geopolitical tensions rise, the demand for advanced tungsten-based ammunition is expected to grow, reinforcing its critical role in U.S. military strategy.

These factors collectively contribute to the strong demand for tungsten penetrators in the U.S. defense sector.

Russia’s Military Use of Tungsten Penetrators and Production Capacity

Russia has long integrated tungsten penetrators into its military arsenal, leveraging the material’s high density and impact resistance to enhance the effectiveness of its anti-armor weaponry. The country’s defense industry utilizes tungsten-based projectiles in tank ammunition, artillery shells, and guided missile systems designed to counter advanced armor technologies.

Domestic Production Capacity

Russia has a strong ability to produce tungsten domestically, which gives them the independence to develop tungsten munitions without relying on other countries. This self-sufficiency in tungsten production is a strategic advantage, especially in light of the recent shifts in military raw material supply chain strategies, which highlight the importance of securing domestic sources for critical materials.

Technological Advancements

Additionally, advancements in Russian military technology continue to refine tungsten penetrator designs, improving penetration efficiency and battlefield effectiveness. These developments are detailed in a report which explores the technological enhancements in military weaponry.

Ongoing Military Engagements

Russia’s ongoing military operations and efforts to upgrade its armed forces make tungsten an essential part of its military-industrial strategy, particularly in defense applications.

China’s Role in Tungsten Penetrator Technology and Production

China is a major player in the global tungsten market, holding a large share of the world’s tungsten reserves and production. This strategic advantage enables China to be a key supplier of tungsten penetrators for both its own defense needs and international markets.

Chinese Military Investments

The Chinese military has invested heavily in tungsten-based armor-piercing ammunition, integrating the technology into its expanding arsenal of tanks, artillery systems, and air-to-ground munitions.

Advancements in Tungsten Processing

China has also been improving its tungsten processing abilities, creating high-performance alloys that increase the strength and effectiveness of kinetic energy projectiles.

Future Outlook

China’s ongoing military modernization efforts and increasing geopolitical influence are expected to play a crucial role in shaping the future of advanced munitions and defense capabilities. This includes its involvement in tungsten penetrator technology and production

The Future of Tungsten Penetrators: Advancements and Market Trends

The tungsten penetrator market is expected to undergo significant changes in product design by 2025 due to various technological advancements.

Key Technologies Shaping the Future

- Additive manufacturing: This technology is expected to play a crucial role in improving the precision and efficiency of tungsten component production. It has the potential to significantly lower production costs and time, giving manufacturers a competitive advantage.

- Nanotechnology: Another area with great promise is nanotechnology. By refining the microstructure of tungsten at a nanoscale level, it may be possible to greatly enhance its strength and durability—two critical qualities for penetrator applications. These breakthroughs can drive demand in various industries such as aerospace and defense.

Challenges for Manufacturers

Manufacturers face challenges in adapting to these changing industry needs:

- Sourcing raw materials: Geopolitical factors affecting supply chains make it difficult to acquire the necessary raw materials for production.

- Maintaining cost-effectiveness while integrating cutting-edge technologies: Balancing the costs associated with implementing advanced technologies while still being competitive in pricing is an ongoing challenge.

The Role of Research and Development

Despite these obstacles, the commitment to research and development (R&D) is likely to foster innovative solutions that will push the market forward. Companies that invest in technology-driven strategies are expected to take the lead, setting new standards for performance and sustainability in tungsten penetrators.

The combination of these advancements will create a dynamic future landscape for this growing market segment.

Competitive Dynamics in the Tungsten Penetrator Industry

The tungsten penetrator market is shaped by several major players who are crucial in influencing industry dynamics:

- A.L.M.T. Corp. — Japan

- ATI – Allegheny Technologies Incorporated — USA

- Buffalo Tungsten Inc. — USA

- Umicore N.V. — Belgium

- WOLFRAM Company JSC — Russia

- China Molybdenum Co. Ltd. — China

- H.C. Starck GmbH — Germany

- Kennametal Inc. — USA

- Plansee Group — Austria

- Xiamen Tungsten Co. Ltd. — China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Tungsten Penetrator Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Tungsten Penetrator Market is expected to grow significantly, reaching $3.16 billion by 2025. This growth is primarily due to tungsten’s unique properties and its wide range of uses in industries like defense, aerospace, and manufacturing. However, challenges such as high production costs and geopolitical factors still play a role in shaping the market.

For stakeholders looking to take advantage of this potential, it’s important to understand these dynamics. Exploring additional resources, such as Wkinformation Research reports, can provide valuable insights into this evolving industry.

To succeed in this competitive market and seize new opportunities, businesses must prioritize innovation and form strategic partnerships.

Global Tungsten Penetrator Market Report (Can Read by Free sample) – Table of Contents Chapter 1: Tungsten Penetrator Market Analysis Overview Competitive Forces Analysis (Porter’s Five Forces) Strategic Growth Assessment (Ansoff Matrix) Industry Value Chain Insights Regional Trends and Key Market Drivers Tungsten Penetrator Market Segmentation Overview Chapter 2: Competitive Landscape Global Tungsten Penetrator players and Regional Insights oKey Players and Market Share Analysis Sales Trends of Leading Companies oYear-on-Year Performance Insights Competitive Strategies and Market Positioning oKey Differentiators and Strategic Moves Chapter 3: Tungsten Penetrator Market Segmentation Analysis Key Data and Visual Insights oTrends, Growth Rates, and Drivers Segment Dynamics and Insights oDetailed Market Analysis by Segment Chapter 4: Regional Market Performance Consumer Trends by Region oHistorical Data and Growth Forecasts Regional Growth Factors oEconomic, Demographic, and Technological Impacts Challenges and Opportunities in Key Regions Regional Trends and Market Shifts Key Cities and High-Demand Areas Chapter 5: Tungsten Penetrator Emerging and Untapped Markets Growth Potential in Secondary Regions oTrends, Challenges, and Opportunities Chapter 6: Product and Application Segmentation Product Types and Innovation Trends Application-Based Market Insights Chapter 7: Tungsten Penetrator Consumer Insights Demographics and Buying Behaviors oTarget Audience Profiles Chapter 8: Key Findings and Recommendations Summary of Tungsten Penetrator Market Insights Actionable Recommendations for Stakeholders

Chapter 1: Tungsten Penetrator Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Tungsten Penetrator MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Tungsten Penetratorplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Tungsten Penetrator Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Tungsten Penetrator Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Tungsten Penetrator Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofTungsten Penetrator Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth value of the tungsten penetrator market by 2025?

The tungsten penetrator market is projected to reach a value of $3.16 billion by 2025, driven by the unique properties of tungsten that enhance its demand.

What are the key applications of tungsten penetrators in various industries?

Tungsten penetrators have several important uses across different industries:

- Defense Applications: Tungsten penetrators are primarily used in defense applications, particularly in kinetic energy weapons such as armor-piercing projectiles.

- Drilling Tools: In the oil and gas industry, tungsten penetrators are utilized in drilling tools for their exceptional hardness and ability to withstand high temperatures and pressures.

- Radiation Shielding: Tungsten’s dense nature makes it an effective material for radiation shielding, and tungsten penetrators find applications in radiation shielding materials used in medical and industrial settings.

What challenges do manufacturers face in producing tungsten penetrators?

Manufacturers encounter several challenges, including high production costs and difficulties in sourcing raw materials, which can impact the scalability of tungsten penetrator production.

How do geopolitical factors influence the tungsten penetrator market?

Global politics have a significant impact on tungsten supply chains and trade relations among major players such as the U.S., Russia, and China. This, in turn, shapes the overall landscape of the tungsten penetrator market.

What are the emerging trends impacting the tungsten penetrator market?

Current trends include increased demand for tungsten penetrators in defense sectors and emerging industrial applications, supported by ongoing technological advancements that enhance product design and performance.

Who are the key players in the tungsten penetrator industry?

Major companies operating in the tungsten penetrator market include Xiamen Tungsten and Global Tungsten & Powders. These companies use competitive strategies to establish a strong presence in this growing sector.