$2.42 Billion Slewing Drives Market Rises in 2025: U.S., India, and Brazil Push Renewable Energy and Industrial Automation

Explore the $2.42 billion slewing drives market’s growth in 2025, driven by renewable energy expansion in the U.S., India, and Brazil.

- Last Updated:

Slewing Drives Market Q1 and Q2 2025 Forecast

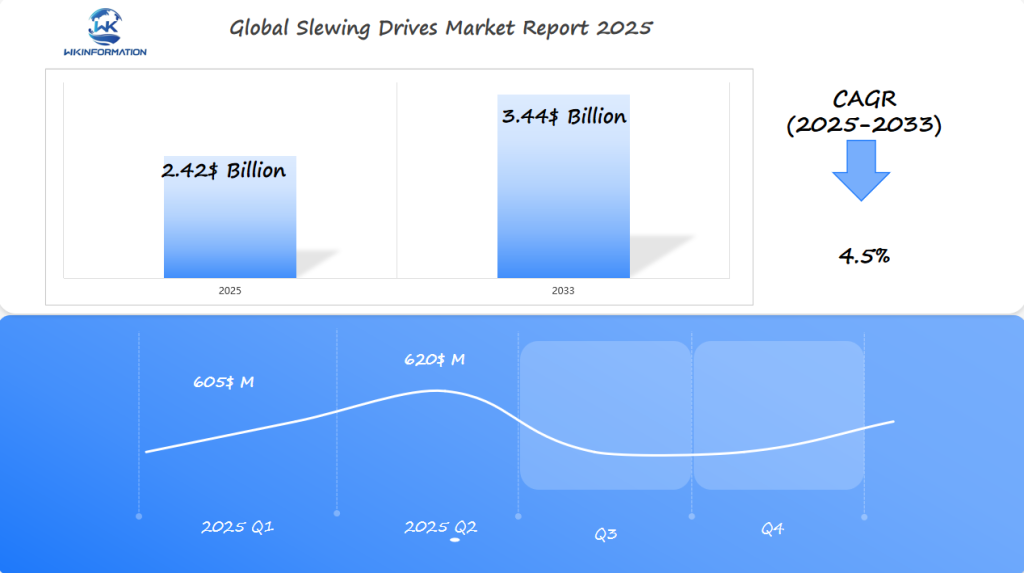

The Slewing Drives market is estimated to reach $2.42 billion in 2025, with a CAGR of 4.5% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $605 million, driven by strong demand in the U.S., India, and Brazil, particularly in renewable energy, construction, and automotive industries. Slewing drives are crucial components in solar trackers, wind turbines, and material handling systems, and their adoption is growing rapidly due to the shift towards renewable energy.

By Q2 2025, the market is forecast to reach $620 million, with India and Brazil investing heavily in infrastructure development and renewable energy projects. The U.S. continues to see steady demand for slewing drives in automated machinery and construction equipment, especially as automation and robotics play an increasingly critical role in various sectors.

Exploring the Upstream and Downstream Industry Chains for Slewing Drives

The journey of slewing drives components begins with the upstream supply chain. Suppliers give us steel, lubricants, and bearings. These are then turned into gears and housings through precise machining. This step is key to heavy machinery efficiency as it ensures parts meet high standards.

The Upstream Supply Chain

Here are the key processes involved in the upstream supply chain for slewing drives:

- Raw material sourcing: Getting top-quality metals and lubricants

- Manufacturing: Creating durable gear assemblies through precision engineering

- Quality control: Testing at every production stage to ensure quality

The downstream chains handle delivery and application. Slewing drives are used in wind turbines, construction equipment, and robotics. Improving logistics here helps cost optimization by cutting down delays and waste. Distributors work with manufacturers to meet global demand.

The Downstream Supply Chain

The following processes are crucial in the downstream supply chain for slewing drives:

- Transportation: Efficiently moving finished products from factories to end-users

- Distribution: Collaborating with distributors to reach various markets worldwide

- Application: Implementing slewing drives in industries such as renewable energy, construction, and automation

Connecting these chains makes a smooth path from raw materials to finished products. Good coordination between suppliers, factories, and buyers ensures consistent quality and lower costs. This helps in innovation and growth in renewable energy and industrial sectors globally.

Key Trends Driving the Slewing Drives Market: Growth in Solar Tracking and Heavy Machinery

Advances in solar tracking systems are changing how slewing drives are used. Modern solar farms need precise motion control to get the most energy. This makes slewing drives key for renewable energy projects. With the U.S. investing in solar, the need for reliable slewing drives is growing.

Heavy machinery also drives innovation. Construction and mining equipment use worm gear performance to handle heavy loads. New gear designs last longer and need less maintenance, helping meet industrial efficiency goals.

- Solar tracking systems boost adoption in renewable energy projects

- Heavy machinery upgrades prioritize worm gear performance for heavy-duty tasks

- Global supply chain shifts affect geopolitical risks in manufacturing

Geopolitical risks are still a worry, with trade policies and raw material availability impacting costs. To avoid disruptions, manufacturers are finding new suppliers. At the same time, worm gear technology is improving, balancing cost and reliability.

These trends show how downstream applications and tech improvements are driving market growth. As industries face global challenges, slewing drives are crucial for modern projects around the world.

Challenges in Slewing Drives Manufacturing and Cost Optimization

Creating high-performance slewing drives requires great precision. Spur gear reliability is a big challenge because small flaws can stop machines. Engineers work hard to make durable parts without spending too much.

These systems work well under different loads, cutting down on downtime. For example, Siemens Gamesa uses them in turbines to get 15% more wind energy in coastal areas.

| Spur gear wear | Hardened steel coatings | Extends lifespan by 30% |

| High production costs | 3D-printed prototypes | Cuts R&D time by 25% |

| Wind energy integration limits | Dual-axis alignment tech | Increases turbine efficiency |

Lowering costs isn’t just about cheaper materials. Using lightweight alloys and simple designs also helps. NSK’s new hybrid gears, with both spur and helical teeth, reduce energy loss by 10%. This shows how new ideas meet the need for better wind energy integration.

Geopolitical Influence on the Slewing Drives Market

Trade policies and global partnerships greatly influence the slewing drives market. Countries investing in industrial equipment upgrades or robotics advancements see a rise in demand. For example, U.S. trade agreements can make exporting components cheaper. But, tariffs can mess up supply chains.

Key Geopolitical Factors and Their Market Impact

| North America | U.S. energy policies | Rises demand for wind energy systems |

| Asia-Pacific | India’s Make in India initiative | Boosts local industrial equipment upgrades |

| Latin America | Brazil’s solar expansion | Drives robotics advancements in renewable tech |

Political stability in places like China and Germany affects global prices. Countries focusing on infrastructure development see more use of advanced slewing drives. As trade changes, companies must adjust to stay competitive in this sector.

How Geopolitical Factors Affect the Slewing Drives Market

Here are some ways geopolitical factors can impact the slewing drives market:

- Regional conflicts can slow down infrastructure development projects, affecting slewing drive adoption.

- Sharing technology between nations can speed up innovation in heavy machinery sectors.

- Sanctions on materials like rare earth metals can increase production costs.

Slewing Drives Market by Type: Worm Gear, Spur Gear, and Dual-Axis Systems

The slewing drives market is divided into three main types: worm gear, spur gear, and dual-axis systems. New technologies in automation in manufacturing, precision engineering, and material advancements have changed their design and performance. These changes have also made them more affordable.

- Worm Gear Drives: These drives use precision engineering and are great for high-torque needs like cranes and wind turbines. They are small but powerful.

- Spur Gear Drives: Perfect for solar tracking systems, they are durable thanks to material advancements. They use corrosion-resistant alloys for outdoor use.

- Dual-Axis Systems: Thanks to automation in manufacturing, they are cost-effective and versatile. They are used in robotics and construction equipment.

Each type of system meets industry needs by constantly improving. Precision engineering ensures they are accurate. Material advancements make them last longer. Automation in manufacturing makes them more available in sectors like renewable energy and construction.

Applications of Slewing Drives in Renewable Energy, Construction, and Robotics

Slewing drives power important machinery in many fields. In renewable energy, they help solar panels follow the sun. This boosts energy capture and supports solar energy opportunities.

Slewing drives applications in renewable energy

- Renewable Energy: Solar tracking systems and wind turbine yaw mechanisms reduce energy waste.

- Construction: Cranes and excavators use slewing drives for precise material handling and heavy lifting.

- Robotics: Automated manufacturing arms and drones leverage these drives for agile, high-precision movements.

The U.S. market dynamics support these uses, with government help for solar and building projects. Companies like SunPower and GE Renewable Energy use slewing drives in their work. This shows the growing need for these drives.

| Industry | Application | Impact |

| Renewable Energy | Solar trackers | 20-30% efficiency gains in energy output |

| Construction | Heavy equipment rotation | Enhanced safety and workload capacity |

| Robotics | Automated assembly lines | Boosts production speed by 40% in automotive sectors |

These examples show the importance of innovation in the U.S. market dynamics. Slewing drives are key in making sustainable and smart infrastructure. They are used in Texas wind farms and California solar parks.

Global Insights into the Slewing Drives Market

Global market trends show a growing need for slewing drives. This is especially true in India and Brazil, where innovation is on the rise. In Indian market expansion, big projects and green energy are key drivers. Solar and wind farms need precise machines, which boosts demand for these parts.

The Brazilian solar sector is also booming. Solar farms use slewing drives for tracking panels. This makes Brazil a key market for makers. Suppliers are making designs fit these needs while keeping costs down.

- India’s construction boom fuels demand for construction machinery with integrated slewing drives.

- Brazil’s solar energy growth ties directly to advancements in dual-axis drive systems.

- Global manufacturers focus on lightweight materials to meet international standards.

From Asia to South America, these markets show how global market trends are shaped by local needs. Companies are now making flexible products to meet different needs. This ensures they stay ahead in this changing field.

The U.S.’s Growing Demand for Slewing Drives in Wind Energy and Industrial Equipment

In the U.S., companies are using slewing drives for wind turbines and industrial machines. This move is driven by a growing need for renewable energy and modernizing factories. The competitive market landscape is led by big names like Siemens Gamesa and General Electric, pushing innovation in wind energy.

Challenges Manufacturers Face

Manufacturers face market cost challenges due to higher steel prices and supply chain issues. To stay ahead, they use advanced manufacturing methods. These include automation and precision engineering, which lower costs and improve quality.

How Additive Manufacturing Helps

Additive manufacturing, for example, reduces waste in gear production. This makes slewing drives more affordable.

Where Slewing Drives Are Needed

Wind farms in Texas and California need these drives for turbine rotation, increasing demand. Factories in the Midwest use them for heavy machinery, helping with construction and logistics. Industry experts say:

As the market grows, companies must balance costs with innovation. Partnerships between tech startups and established manufacturers are crucial. The goal is to combine advanced manufacturing with sustainability to drive growth without losing quality.

Brazil’s Emerging Solar Energy Sector and Demand for Slewing Drives

Brazil’s solar energy sector is growing fast, thanks to new energy trends and government support. As the country builds more renewable projects, companies are looking at slewing drives for solar tracking systems. These systems move panels to catch more sunlight, increasing energy production.

Brazil’s sunny weather makes these systems very important for utilities and farms.

Cost-effective solutions are crucial here. Slewing drives help save on maintenance while making systems more efficient. Manufacturers are making products that fit Brazil’s different market segmentation, from small rural projects to big utility plants. This flexibility meets the needs of all parts of the country.

- Southern states focus on industrial-scale solar farms.

- Northeast regions prioritize community-based solar initiatives.

Investments in solar are opening up chances for slewing drive suppliers. As Brazil goes for cleaner energy, the need for these parts will grow. Companies that offer flexible designs and work with local partners can grab this growing market.

India’s Expanding Infrastructure and Heavy Machinery Market for Slewing Drives

India’s infrastructure growth and focus on renewable energy open up new chances for slewing drives in heavy-duty applications. Fast urban growth and government plans like the National Solar Mission boost demand for construction, mining, and green energy tools. Projects like the Sagarmala port network and solar parks need advanced slewing systems.

Heavy-duty Applications in India

Indian makers focus on efficiency in production to meet the demand. Companies like Larsen & Toubro and Tata Advanced Systems use automation to save costs and increase output. These steps meet global standards while meeting local needs for strong, efficient machinery.

Key areas seeing the use of slewing drives include:

- Wind turbine setups in Tamil Nadu and Gujarat

- Smart city and industrial corridor construction

- Heavy mining equipment in Odisha and Chhattisgarh

Collaborations with global players like Siemens Gamesa and Vestas are speeding up the adoption of green energy solutions. This makes India a key spot for innovation in renewable energy and heavy industry. U.S. companies looking to expand globally can benefit from India’s growing needs.

The Future of Slewing Drives: Automation, Precision Engineering, and Material Advancements

Manufacturing is changing how slewing drives are made. Companies like Siemens and Bosch Rexroth are leading in precision engineering. They aim to make drives last longer and use less energy. This could save money and meet the growing need for better parts.

Renewable Energy Success: The Role of New Materials

New materials are key to renewable energy success. Slewing drives are now made with lightweight alloys and coatings that resist corrosion. This makes them perfect for offshore wind farms. Engineers test carbon fiber composites to withstand extreme weather, increasing lifespan by up to 30%.

Automation: The Game Changer in Manufacturing

- Industrial automation cuts production time by 40% through robotic assembly lines.

- AI-driven quality checks reduce defects in gear manufacturing.

- Cloud-based monitoring tracks wear patterns in real time.

Automation is not just about speed; it’s about precision. Factories in the U.S. are using IoT sensors to improve production. This move supports global goals for reliable renewable energy infrastructure.

The Future: Slewing Drives Powering a Sustainable World

As materials and automation improve, the next decade could see slewing drives powering everything from smart factories to green energy grids.

Competitive Landscape in the Slewing Drives Market

As the slewing drives market grows, top names like Nord Drive Systems and Bosch Rexroth focus on premium quality engineering. They invest in technological advancements such as precise gear design and smart sensors. This helps them stay competitive and meet the demand for renewable energy projects.

Key Players in the Slewing Drives Market

Here are some of the key players operating in the slewing drives market:

- Bonfiglioli S.P.A – Italy

- Cone Drive Operations Inc. – United States

- IMO Group – Germany

- Kavitsu Bearings – India

- Kinematics Manufacturing LLC – United States

- Liebherr Group – Switzerland / Germany

- TGB Group Technologies – Spain

- Rothe Erde Germany GmbH – Germany

- Zeus Hydratech – United Kingdom

- Luoyang LDB – China

Overall

| Report Metric | Details |

|---|---|

| Report Name |

Global Slewing Drives Market Report |

| Base Year | 2024 |

| Segment by Type |

· Worm Gear · Spur Gear · Dual-Axis Systems |

| Segment by Application |

· Renewable Energy · Construction · Robotics |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage |

Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Slewing drives continue to be essential components across renewable energy, construction, and robotics sectors. Their versatility and reliability make them indispensable in solar tracking systems, wind turbines, construction equipment, and automated manufacturing processes.

As technology advances and global demand for sustainable solutions grows, slewing drives will play an increasingly vital role in powering the machinery of tomorrow. With ongoing improvements in materials, manufacturing processes, and design capabilities, these crucial components will remain at the forefront of industrial innovation, enabling more efficient, precise, and sustainable operations across multiple industries.

Global Slewing Drives Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Slewing Drives Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Slewing DrivesMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Slewing Drivesplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Slewing Drives Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Slewing Drives Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Slewing Drives Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofSlewing DrivesMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are slewing drives?

Slewing drives are small, versatile gear systems that transfer rotational motion. They are commonly used in various industries such as renewable energy, construction, and robotics.

How do slewing drives support renewable energy initiatives?

Slewing drives help solar panels track the sun. This maximizes energy collection and efficiency.

What types of slewing drives are available in the market?

The market offers worm gear, spur gear, and dual-axis systems. Each has its own benefits for different uses.

What are the key trends influencing the slewing drives market as of 2025?

Trends include better solar tracking technology, more automation in heavy machinery, and increased investment in green energy.

What challenges do manufacturers face in producing slewing drives?

Manufacturers struggle with:

- Keeping spur gear reliable

- Cutting costs

- Meeting demand for quality products

How do geopolitical factors impact the slewing drives market?

Politics can change trade policies and market stability. This can boost or slow down the growth of industrial equipment.

In which industries are slewing drives most commonly used?

Slewing drives are key in renewable energy, construction, and robotics. They’re needed for precise positioning.

What is the future outlook for the slewing drives market?

The future looks bright. It’s driven by automation, precision engineering, and new materials technology.

Why is the U.S. market significant for slewing drives?

The U.S. is important because of its growing need for slewing drives in wind energy and industrial equipment. Plus, there’s a lot of innovation in manufacturing.

How is India progressing in the slewing drives industry?

India’s infrastructure growth is increasing demand for slewing drives. The country is focusing on sustainable energy in heavy machinery.

What is Brazil’s role in the slewing drives market?

Brazil is becoming a big player in solar energy. This is driving demand for slewing drives with its focus on affordable, innovative energy solutions.