2025 Global Silicon Micro Melt Pressure Sensor Market Insights Exploring $1,455 Million Opportunities in the US, China,

Explore the dominant players shaping the Silicon Micro Melt Pressure Sensor Market, including the US, China, and Germany, amid Trump’s manufacturing policies.

- Last Updated:

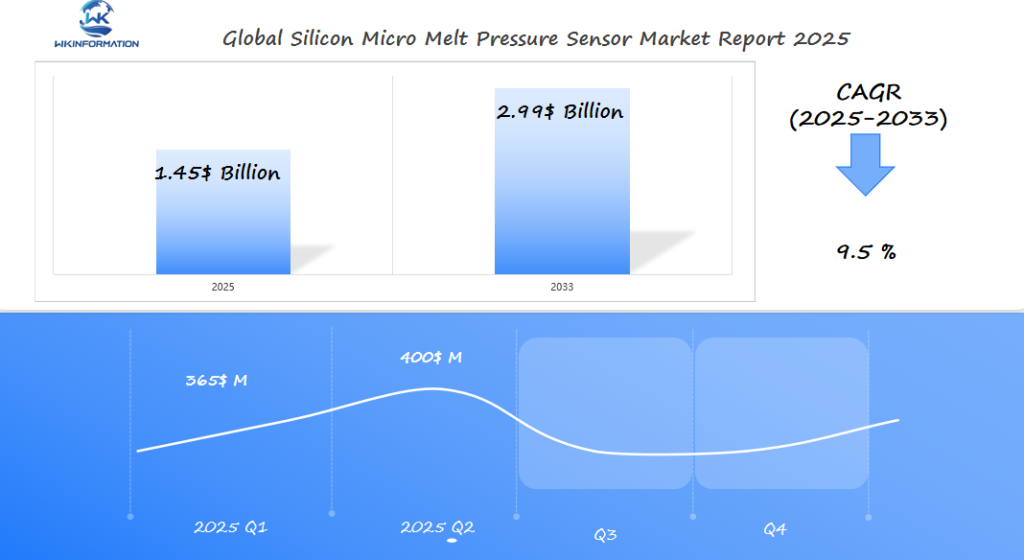

Silicon Micro Melt Pressure Sensor Market Forecast for Q1 and Q2 of 2025

The Silicon Micro Melt Pressure Sensor market is forecasted to grow from USD 1,455 million in 2025, with a consistent CAGR of 9.5% from 2025 to 2033. By the end of Q1 2025, the market size is projected to reach around USD 365 million, driven by increased demand in industries such as automotive, medical devices, and industrial automation. By Q2 2025, this market is expected to grow to approximately USD 400 million, as pressure sensors become more integral in precision monitoring applications.

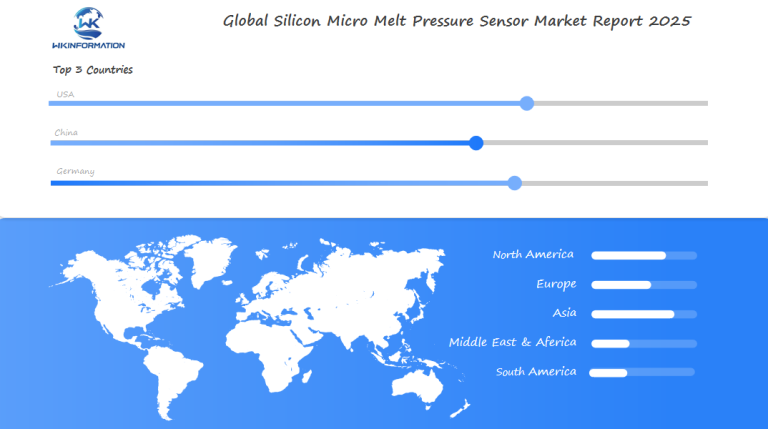

The US, China, and Germany are the leading countries in this market, as these nations continue to innovate and integrate advanced sensor technologies in various sectors. In the US, demand is driven by applications in medical devices and industrial processes, while China’s expansion in the automotive sector and electronics manufacturing contributes significantly to market growth. Germany’s leadership in precision engineering and automation technologies will also play a key role in shaping the market over the next few quarters.

Key Takeaways

- The $1,455 million market opportunity shows how fast silicon micro melt pressure sensors are being used.

- Things like better manufacturing and using IoT are making the market grow.

- The US and China are leading in making and improving these sensors.

- Using these sensors in cars and planes is making the market forecast 2025 look even better.

- Improvements in technology are helping solve cost and rule problems, keeping the market growing.

Understanding the Upstream and Downstream Chain in the Silicon Micro Melt Pressure Sensor Market

Thepressure sensor supply chainis key to making silicon micro melt pressure sensors. It starts with getting raw materials and ends with delivering the final product. Each step affects the cost, quality, and how available the product is. Let’s explore how this system works and where new chances can be found.

Mapping the Silicon Micro Melt Pressure Sensor Supply Chain

Thesilicon sensor manufacturing processstarts withupstream supplierslike quartz refiners and semiconductor foundries. They give high-purity silicon wafers and precise parts needed for making sensors. Now, companies are trying to control more of the process to avoid problems with thepressure sensor supply chain.

Key Raw Materials and Component Suppliers

Important materials include polysilicon, precise resistors, and MEMS parts. Big names like STMicroelectronics and TE Connectivity make sure these parts are available. But, whenupstream suppliersrun out, it can cause delays, as seen in 2023.

Distribution Channels and End-User Industries

Products get to the market through special distributors like Avnet and Digi-Key. They servedownstream applicationsin cars, planes, and medical devices. For instance, car makers use these sensors in engines, and medical devices use them for diagnostics.

This whole system needs to be flexible to meet cost, innovation, and global demand needs.

Trends Transforming the Silicon Micro Melt Pressure Sensor Market

Pressure sensor technology is changing fast. It’s now used in factories and medical devices. Three big changes are making a big impact:

Miniaturization and Performance Enhancements

Today, sensors are smaller and smarter. Sensor miniaturization lets them fit into tiny devices like health monitors and machines. TE Connectivity and Bosch Sensortec have made sensors that are 40% smaller but more accurate.

This change makes devices more efficient and easy to carry around.

Industry 4.0 and IoT Integration

IoT pressure sensors are key to smart factories. Siemens and Emerson use their Industry 4.0 sensors with platforms like . These systems help predict when machines need maintenance and improve workflows.

They’ve cut downtime by up to 30% in tests.

Sustainability and Energy Efficiency

Green manufacturing is leading to sustainable manufacturing sensors. Honeywell has made sensors that use 25% less energy. They can measure pressure while being kind to the environment.

This approach is not only good for the planet but also sets companies apart in the market.

The Key Challenges Facing the Silicon Micro Melt Pressure Sensor Market

The silicon micro melt pressure sensor market is growing. But, it faces many challenges. These include technical, financial, and regulatory hurdles. Innovators must find ways to overcome these obstacles and use them to drive innovation.

Technical Limitations and Development Hurdles

Manufacturers struggle with silicon sensor limitations in harsh conditions. For example:

- High-temperature sensor challenges affect metal casting, where silicon can’t handle the heat well.

- Corrosive environments require better materials, but this slows down chemical processing.

- Miniaturization and durability are hard to balance, especially in aerospace and medical fields.

- “Meeting temperature thresholds remains a bottleneck for high-temperature sensor challenges,” a 2024 report says. It points to R&D in ceramic substrates and adaptive calibration systems.

Cost Pressures and Price Sensitivity

Profit margins are tight because buyers want lower sensor cost reduction without losing quality. To address this, companies are:

- Automating production to save on labor costs.

- Using AI for quality control to reduce waste.

- Working with raw material suppliers for bulk discounts.

Regulatory Compliance and Standards

Meeting sensor regulatory compliance worldwide is complex. For instance:

- EU RoHS directives require non-toxic materials, increasing R&D costs.

- US FDA approvals for medical sensors add 12–18 months to product launches.

- Asian markets focus on certifications like IEC 61508 for safety-critical systems.

To overcome these challenges, companies need agile supply chains, reinvestment in R&D, and partnerships for global certifications. This will help achieve long-term profitability.

Geopolitical Impacts on the Silicon Micro Melt Pressure Sensor Market

Global trade tensions are changing how companies make silicon micro melt pressure sensors. Semiconductor trade policies and silicon sensor trade barriers between big countries are making firms rethink their supply chains. Now, they focus on being resilient rather than just saving money.

Trade Policies and Tariff Implications

US-China trade fights have added geopolitical supply chain risks for sensor makers. Trade policies, like export controls on advanced chips, slow down production. Companies like Bosch and Honeywell are now planning to use two sources to avoid high tariffs.

Silicon sensor trade barriers have made parts cost up to 15% more in key markets, reports say.

- US Section 301 tariffs added 25% duties on Chinese sensor components

- EU’s Foreign Subsidies Regulation complicates cross-border tech transfers

- Japan’s Strategic Goods Control Law restricts semiconductor exports to non-allies

Regional Manufacturing Shifts

Companies are moving sensor manufacturing reshoring to avoid disruptions. Texas and Indiana are getting new production sites for pressure sensors, thanks to federal grants. This move is part of a bigger trend: 42% of US manufacturers moved production since 2022, the Reshoring Initiative says.

Producing locally reduces reliance on unstable international markets.

National Security and Tech Sovereignty Concerns

“Tech sovereignty isn’t optional—it’s essential for maintaining industrial competitiveness.” – Pentagon Supply Chain Task Force Report (2024)

Pressure sensors in aerospace and defense are now seen as strategic tech under new US export rules. Governments are investing in tech sovereignty, with $1.2B for domestic sensor tech since 2022. Military contractors like Raytheon are requiring suppliers to meet strict “friend-shoring” criteria for defense contracts.

Decoding the Silicon Micro Melt Pressure Sensor Market Segmentation: Types and Technologies

There are many types of pressure sensors to fit different needs. Knowing these types helps businesses pick the right one. The main differences are in how they sense pressure, what they can measure, and how they connect.

Strain Gauge vs. Piezoresistive Sensing Technologies

Strain gauge technology works by changing shape to sense pressure. It’s good for simple uses because it’s affordable. On the other hand, piezoresistive melt sensors use semiconductors for precise readings. They’re best for high-precision fields like aerospace or medicine.

| Technology | Accuracy | Cost |

|---|---|---|

| Strain gauge technology | Moderate | Lower |

| Piezoresistive | High | Higher |

Single-Point vs. Multi-Point Pressure Measurement Solutions

Single-point sensors measure pressure at one spot, perfect for simple setups. Multi-point pressure measurement systems, however, track pressure across several areas. This is key for complex machines like those in injection molding.

- Single-point: Lower cost, basic monitoring

- Multi-point: Enhanced diagnostics, higher upfront expense

Wired vs. Wireless Configuration Options

Wired pressure sensors provide steady readings but are less mobile. Wireless pressure sensors offer more freedom but need strong security to avoid data loss.

| Configuration | Advantages | Challenges |

|---|---|---|

| Wired | Reliable signals | Less mobility |

| Wireless | Easy installation | Security risks |

“The right sensor type balances technical needs with operational practicality.” — Industry Analyst, 2024

The Growing Applications of Silicon Micro Melt Pressure Sensors in Diverse Sectors

Silicon micro melt pressure sensors are changing the game in many industries. They offer precise control and reliability. This makes them key for improving operations, safety, and meeting high standards across various sectors.

Plastic Extrusion and Injection Molding Applications

These sensors help keep material flow steady in plastic processing. They watch over the process in real-time, helping to cut down on waste in car and packaging making.

Food Processing and Pharmaceutical Manufacturing

In the food industry pressure monitoring, they keep packaging and processing areas clean. For drug making, they ensure exact pressure control, meeting FDA and ISO rules.

Automotive and Aerospace Implementation

In cars, they’re used in fuel systems and to check tire pressure, boosting performance. For planes, they watch over hydraulic and engine pressures, keeping everyone safe in tough flight conditions.

| Industry | Key Applications | Key Requirements |

|---|---|---|

| Plastic Processing | Extrusion, Injection Molding | High-temperature resistance |

| Food & Pharma | Sterilization, Packaging | Hygienic design, FDA compliance |

| Automotive | Fuel systems, Braking | Wide pressure range, durability |

| Aerospace | Engine monitoring, Hydraulics | Extreme temperature tolerance |

These sensors are key in making products better and safer. They’re essential for quality and making things work better. Their ability to adapt makes them a vital part of innovation in quality and efficiency.

Global Market Trends for Silicon Micro Melt Pressure Sensors: Regional Performance

Regional performance shapes the global pressure sensor market size and defines where opportunities lie. From Asia-Pacific’s manufacturing hubs to North America’s tech-driven sectors, this section breaks down how regions differ in adoption and growth.

Regional pressure sensor growth forecast varies widely. Key international market comparison highlights:

- Asia-Pacific: Driven by automotive and industrial sectors, this region holds 42% of the global pressure sensor market size.

- North America: High adoption rates in aerospace and oil/gas sectors fuel steady demand.

- Europe: Sustainability mandates boost IoT-enabled sensors in manufacturing.

Market Size and Growth Rate Comparisons

North America and Europe show stable regional sensor adoption rates. Asia-Pacific leads in annual growth (8.2% CAGR). Latin America and the Middle East are catching up as emerging sensor markets due to infrastructure projects.

Regional Adoption Drivers and Barriers

Adoption barriers like high R&D costs slow progress in some regions. Government incentives in India and Southeast Asia are accelerating adoption. A 2024 industry report notes:

“Emerging markets prioritize cost-effective solutions, while mature markets demand precision and connectivity.”

Emerging Markets with High Growth Potential

Sub-Saharan Africa and Eastern Europe present untapped potential. Countries like Vietnam and Brazil are adopting sensors for smart manufacturing. For example, Brazil’s automotive sector now uses 15% more silicon micro melt sensors than in 2023.

Manufacturers adapting to regional needs—like ruggedized designs for harsh climates—will dominate. The global pressure sensor market size could hit $2 billion by 2030 if these trends continue.

US Market Trends in Silicon Micro Melt Pressure Sensors

Changes in the are growing. They’re building more to meet US sensor demand trends. This push for local innovation is helping industries grow.

US Manufacturing Renaissance and Reshoring Impact

Reshoring is boosting growth. Big names like Emerson Electric and Siemens are focusing on US industrial automation sensors. They want a strong supply chain.

Factories are now using parts made in the US. This move cuts down on imports. It also brings Silicon Valley and the Midwest closer together.

Key Industry Verticals Driving US Demand

- Aerospace: Sensors improve testing and making of aircraft parts

- Defense: Military uses sensors for missile systems

- Healthcare: Medical devices get better with sensor technology

Competitive Landscape and Local Innovation

There’s a lot of teamwork between American sensor manufacturers and schools. The University of Michigan and Tekmetrics Inc. are working together. They’re making sensors better for tough places.

Startups like SensoTech Solutions are bringing new ideas. They’re using AI to improve sensors. This keeps the US at the top in US pressure sensor market tech.

China's Influence on the Growth of Silicon Micro Melt Pressure Sensors

China has become a major player in making silicon micro melt pressure sensors. It has changed how things are made and innovated around the world. Now, over 60% of Asia’s pressure sensors come from China. This part talks about how China’s plans are changing the market.

Manufacturing Capabilities and Capacity Expansion

China’s factories are working harder to keep up with demand. They’ve invested a lot in Asia pressure sensor production. Companies like those in the China semiconductor industry are making sensors better.

New places in Guangdong and Sichuan are making things cheaper. This makes China more competitive worldwide.

Domestic Innovation and International Competition

Chinese companies are moving from just putting things together to Chinese sensor innovation. Startups like Sensory Technology and government-backed labs are making precise sensors. This is making old rivals in Germany and Japan work harder to keep up.

They need to offer better quality and prices. Programs like Made in China 2025 help fund research. This leads to new discoveries.

Belt and Road Initiative Impacts on Market Reach

The Belt and Road Initiative is helping China’s Belt and Road sensor market grow. It’s reaching out to over 60 countries. Projects in Southeast Asia and Eastern Europe are using Chinese sensors for their projects.

- South Asia: Industrial automation partnerships

- Middle East: Oil and gas monitoring systems

- Eastern Europe: Smart city sensor deployments

This move is part of China’s plan to be 40% of the world’s sensor exports by 2025.

What's Driving the Silicon Micro Melt Pressure Sensor Market in Germany?

Germany is known worldwide for its precision engineering. This drives the growth of the German pressure sensor market. Smart factories and high quality standards make it a place of innovation. Local industries are leading the way in global trends.

“Collaboration between German firms and research institutes ensures precision engineering sensors set new benchmarks in reliability and accuracy.”

Industry 4.0 and Smart Manufacturing Adoption

Factories adopting Industry 4.0 sensor implementation use German manufacturing sensors. These devices help with real-time data analysis. This reduces downtime and boosts efficiency in car and machine production.

Precision Engineering and Quality Standards

German car makers need precision engineering sensors to meet ISO and DIN standards. These sensors ensure perfect performance in engine assembly or hydraulic system tests. Even a 0.1% error is not allowed in this market.

Automotive and Machine Tool Industry Demand

Car giants use automotive pressure monitoring systems for car body welding or tire pressure tests. Machine tool makers put sensors in CNC machines for better metal cutting. This reduces waste and costs.

Germany’s mix of tradition and technology keeps its sensor market leading. Companies like SICK and Endress+Hauser work on R&D partnerships. They offer solutions that are affordable yet cutting-edge.

Future Outlook: Innovations and Developments in the Silicon Micro Melt Pressure Sensor Market

As industries look for smarter solutions, the silicon micro melt pressure sensor market is set for big changes. New future pressure sensor technology is changing how these devices work and connect with important systems.

Advanced Materials and Fabrication Techniques

Scientists are working on advanced sensor materials like graphene composites and ceramic alloys. These materials can handle very high temperatures and corrosion, making sensors last longer in tough places. New ways to make sensors, like 3D printing, let them be made just right for different needs.

AI and Machine Learning Integration

AI-enabled sensors will quickly analyze data, giving insights ahead of time. For example, they can spot problems in oil pipelines before they happen. Machine learning helps sensors work better, adjusting to changing conditions without needing to be reset.

Predictive Maintenance and Self-Calibrating Sensors

New self-calibrating pressure sensors and predictive maintenance sensors cut down on downtime. They can adjust on their own to changes or new conditions. Imagine sensors telling engineers when maintenance is needed weeks ahead—this is what’s happening in smart factories now.

Quantum sensing is still far off, but it could bring super-accurate measurements soon. The next ten years will see these advancements lead to better efficiency, cost savings, and new uses in making things and energy.

Competitive Analysis in the Silicon Micro Melt Pressure Sensor Market

-

Honeywell – United States

-

STMicroelectronics – Switzerland

-

NXP Semiconductors – Netherlands

-

Infineon Technologies AG – Germany

-

Sensata Technologies – United States

-

Ams AG – Austria

-

TE Connectivity – Switzerland

-

Emerson Electric Co. – United States

-

Kistler Group – Switzerland

-

Endress+Hauser AG – Switzerland

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Silicon Micro Melt Pressure Sensor Market Report |

| Base Year | 2024 |

| Segment by Type |

· Piezoresistive Sensors · Capacitive Sensors · Resonant Sensors |

| Segment by Application |

· Automotive Industry · Medical Equipment · Industrial Automation · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Key Takeaways for Market Stakeholders

For those in the business, it’s key to do a market opportunity assessment. Look for areas like the US and China where growth is high. Users in cars and healthcare get better results with these advanced sensors.

It’s important to balance making money now with investing in research and development for the future. This balance is crucial for lasting success.

Strategic Investment and Development Areas

Invest in pressure sensor investment opportunities in IoT and energy-saving designs. Companies that use sensor market strategy with AI and predictive maintenance will lead. Team up with tech startups to bring new fabrication techniques to the market.

Preparing for Future Market Evolution

To stay ahead, focus on adapting to Industry 4.0 and meeting sustainability goals. Innovators who improve materials and follow global rules will lead in new markets. Keep talking to end-users to make sure your products meet their needs.

Global Silicon Micro Melt Pressure Sensor Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Silicon Micro Melt Pressure Sensor Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Silicon Micro Melt Pressure Sensor Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Silicon Micro Melt Pressure Sensor players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Silicon Micro Melt Pressure Sensor Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Silicon Micro Melt Pressure Sensor Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Silicon Micro Melt Pressure Sensor Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Silicon Micro Melt Pressure Sensor Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are silicon micro melt pressure sensors used for?

Silicon micro melt pressure sensors are used in many areas. They help in plastic extrusion, injection molding, and aerospace. They provide accurate pressure readings for better quality and efficiency.

How is the silicon micro melt pressure sensor market expected to grow by 2025?

The market is expected to grow to $1,455 million by 2025. This growth is due to better sensor technology, automated manufacturing, and more demand in different industries.

What are the main regions contributing to the growth of this market?

The United States, China, and Germany are key players. They contribute through their tech advancements, manufacturing skills, and industry needs.

What challenges does the silicon micro melt pressure sensor market currently face?

The market faces challenges like technical issues and cost pressures. It also deals with regulatory compliance across markets.

How are geopolitical factors impacting the silicon micro melt pressure sensor market?

Geopolitical factors like trade policies and tariffs affect the market. They impact supply chains and prices, especially between the US and China.

What trends are transforming the silicon micro melt pressure sensor market?

Trends include miniaturization and integration with Industry 4.0 and IoT. There’s also a focus on sustainability and energy efficiency in sensor designs.

Are there different types of silicon micro melt pressure sensors available?

Yes, sensors vary by technology and configuration. They include strain gauge and piezoresistive types, as well as wired and wireless options. Each is suited for different uses and environments.

How are domestic innovations influencing the silicon micro melt pressure sensor market in China?

China’s domestic innovations are leading to big advancements in sensor tech. Companies are moving from manufacturing to developing their own designs, backed by government support like Made in China 2025.

What role does the automotive industry play in the demand for these sensors?

The automotive industry is a big driver for silicon micro melt pressure sensors. They are used in fuel injection systems, tire pressure monitoring, and other critical vehicle systems that need precise pressure measurements.

How do companies competitive in this market ensure they stay ahead?

Companies stay competitive by forming strategic partnerships and investing in new technologies. They also adapt their offerings to meet changing market needs and customer demands.