$251.9 Million Shoe Sorter Conveyor Market Expands in 2025: India, Germany, and Brazil Automate Logistics

Discover an in-depth analysis of the global shoe sorter conveyor market from 2025-2033. This comprehensive report explores market dynamics, technological innovations, and growth projections in the automated logistics industry. Learn about key players, regional trends, and emerging technologies shaping the future of warehouse automation and product sorting solutions.

- Last Updated:

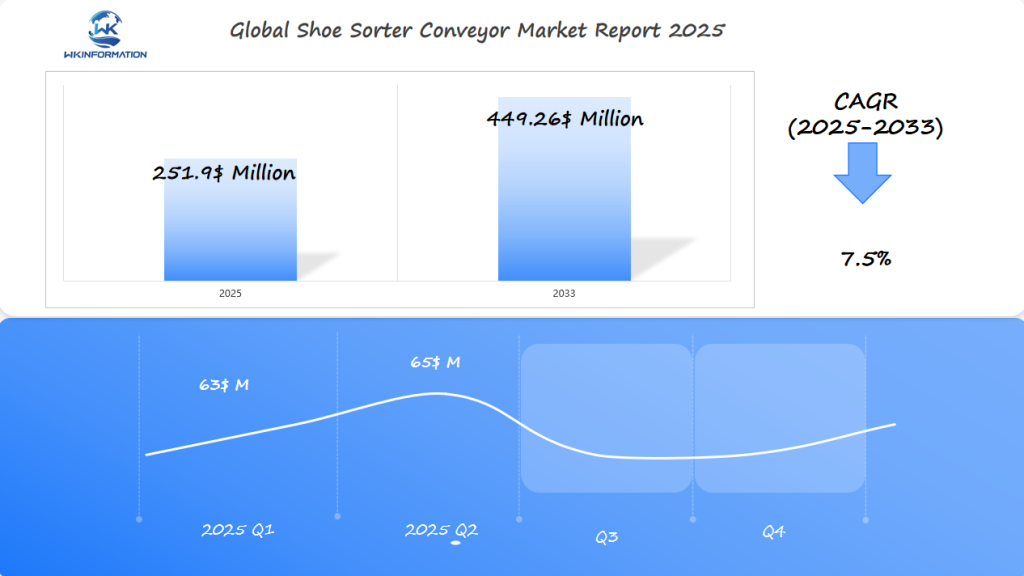

Shoe Sorter Conveyor Market Q1 and Q2 2025 Forecast

The Shoe Sorter Conveyor market is expected to reach $251.9 million in 2025, with a CAGR of 7.5% from 2025 to 2033.

Q1 2025

In Q1 2025, the market is projected to generate approximately $63 million, driven by strong demand from the logistics, e-commerce, and retail industries in Norway, China, and the U.S. Shoe sorter conveyors are key components in automated sorting systems used in warehouses and distribution centers, optimizing product handling and reducing operational costs.

Q2 2025

By Q2 2025, the market is expected to reach $65 million, with China leading in logistics infrastructure development and e-commerce growth. The U.S. and Norway will continue to adopt advanced sorting solutions in their expanding retail and distribution networks, driven by the ongoing demand for faster processing times and improved operational efficiency in online shopping.

Understanding the Upstream and Downstream Industry Chains for Shoe Sorter Conveyors

Creating shoe sorter conveyors begins with basic materials like steel, rubber, and electrical parts. These are bought from suppliers all over the world, forming an upstream network. On the other side, these systems end up in warehouses, stores, and distribution centers. Both parts affect conveyor efficiency and how much things cost.

Key Players in the Industry Chain

- Upstream: Material suppliers such as steel suppliers for conveyor frameworks, plastic manufacturers for sorting trays, and electronics vendors for automated controls.

- Downstream: Retailers and logistics firms including warehouses, stores, and distribution centers.

Impact on Conveyor Efficiency

Companies aim to make every part of this chain better. For instance, using strong plastics can save on repair costs. Better conveyor efficiency also means quicker order fulfillment. Companies like Siemens and Bosch Rexroth provide parts that make systems more reliable.

Improving efficiency has big effects. Faster sorting makes customers happier and boosts profits. As automation grows, finding the right balance in these chains will be crucial for big players worldwide.

Key Trends Driving the Shoe Sorter Conveyor Market: Growth in E-Commerce and Warehousing

E-commerce is booming, changing how businesses handle their logistics. With more online shopping, companies are turning to smart automation to keep up with the demand. Modern warehouses use conveyor systems with AI and sensors to speed up and improve accuracy.

E-commerce Demand

Online sales in the US hit $850 billion in 2023, driving the need for faster sorting.

Warehouse Tech Upgrades

Smart automation cuts delivery times by optimizing conveyor routes in real time.

AI Integration

Algorithms now adjust conveyor paths automatically, reducing manual labor and costs.

Big names like Amazon and DHL use smart automation for peak seasons. These systems handle thousands of items daily, ensuring on-time deliveries. Now, conveyor systems quickly adjust to order spikes, making warehouses more flexible.

Using these technologies is not just a choice—it’s a must. Smart automation helps companies stay ahead by cutting down on delays and mistakes. As online shopping continues to grow, automated sorting will be key to efficient logistics.

Challenges in Shoe Sorter Conveyor Manufacturing and Operational Efficiency

Creating shoe sorter conveyors requires great precision. However, issues like system integration and cost control can hinder progress. Factories often grapple with outdated machinery and disrupted workflows, leading to significant delays.

Operational problems such as missing parts or misalignment exacerbate the situation.

Common Challenges in Shoe Sorter Conveyor Manufacturing and Operations

- Complex system integration with existing equipment

- High upfront costs for advanced machinery

- Regular downtime for maintenance

Warehouse automation can effectively address these challenges. For instance, Siemens’ Logistics Automation and Honeywell Intelligrated systems simplify conveyor setup while reducing downtime by 40% through predictive maintenance alerts.

These advanced systems also enable real-time data tracking, minimizing errors. Their modular designs further facilitate seamless integration with older systems.

| Challenge | Traditional Systems | Warehouse Automation Solutions |

| Integration Complexity | Custom coding per component | Plug-and-play modules |

| Cost Management | High labor expenses | AI-driven energy optimization |

| Maintenance | Planned shutdowns every 6 months | Self-diagnostic sensors |

The shift towards warehouse automation is revolutionizing problem-solving approaches. Companies like Daifuku are leveraging IoT sensors to monitor conveyor health in real time, a strategy that not only reduces costs over time but also enhances reliability.

This innovative approach simplifies the handling of large volumes of items. Striking the right balance between adopting new technologies and maintaining practical usability is crucial for ensuring smooth operations.

Geopolitical Influence on the Shoe Sorter Conveyor Market

Global trade policies and political changes greatly affect the demand for shoe sorter conveyors. Trade deals between countries like India, Germany, and Brazil often boost e-commerce growth. This growth increases the need for automated warehouses. Tariffs or sanctions can slow down shipments, leading companies to invest in quicker sorting systems to stay ahead.

Key Factors Influencing the Market

- Trade policies: Tariff reductions in Asia-Pacific boost cross-border e-commerce growth, increasing conveyor demand.

- Regional alliances: EU regulations on carbon emissions may prioritize energy-efficient conveyor systems.

- Political instability: Conflicts in key markets delay infrastructure projects, slowing conveyor adoption.

Emerging markets like Brazil and India focus on automation to support local e-commerce growth. Developed nations like Germany work on high-tech sorting solutions. Companies need to watch global trends to make the right investments.

Shoe Sorter Conveyor Market by Type: Tilt-Tray, Cross-Belt, and Sliding-Shoe Systems

Choosing the right shoe sorter conveyor system is key to logistics innovation. The market is led by three main types: tilt-tray, cross-belt, and sliding-shoe systems. Each type meets different needs in warehouses and distribution centers.

| Tilt-Tray | Packages slide onto tilting trays that pivot for sorting. | Handles high volume with speed (up to 120 items/minute). | Small parcel sorting in e-commerce hubs. |

| Cross-Belt | Independent belts on modules redirect items to specific lanes. | Accurate for irregular shapes, reduces manual handling. | Pharmaceuticals and fragile goods sorting. |

| Sliding-Shoe | Shoe-shaped carriers move along tracks, diverting packages. | Handles large items like boxes up to 50kg at 2m/s speeds. | Automotive parts and heavy goods distribution. |

Warehouse managers pick systems based on package size, speed, and space. Cross-belt models show logistics innovation by cutting down errors in complex tasks. Sliding-shoe systems are great for big volumes, showing how the right choice boosts success.

Applications of Shoe Sorter Conveyors in Logistics, Retail, and Manufacturing

Shoe Sorter Conveyor Applications Industry Trends

Shoe sorter conveyors are revolutionizing operations in logistics, retail, and manufacturing sectors. In warehouses, these conveyors utilize tilt-tray systems to automate package movement, significantly reducing the reliance on manual labor.

Retail giants like Amazon and Walmart leverage cross-belt models during peak seasons to manage large orders efficiently, ensuring timely delivery. Similarly, factories implement sliding-shoe systems to speed up assembly processes. This aligns with the broader trend of enhancing production speed and efficiency.

1. Logistics

High-capacity shoe sorter conveyors in distribution hubs can process over 10,000 items daily, which boosts on-time deliveries.

2. Retail

Retailers are increasingly adopting modular conveyor setups that allow them to adapt swiftly to changing industry trends, such as the growing popularity of click-and-collect services.

3. Manufacturing

In the manufacturing sector, custom conveyor layouts in automotive and footwear plants are designed to minimize downtime while enhancing quality control. For instance, studies reveal that companies like DHL and Zappos have successfully reduced costs by 30% through the implementation of automated systems. These systems are not just mere tools; they have become essential components of modern supply chains. Businesses that embrace these technologies are better positioned to thrive in rapidly evolving markets.

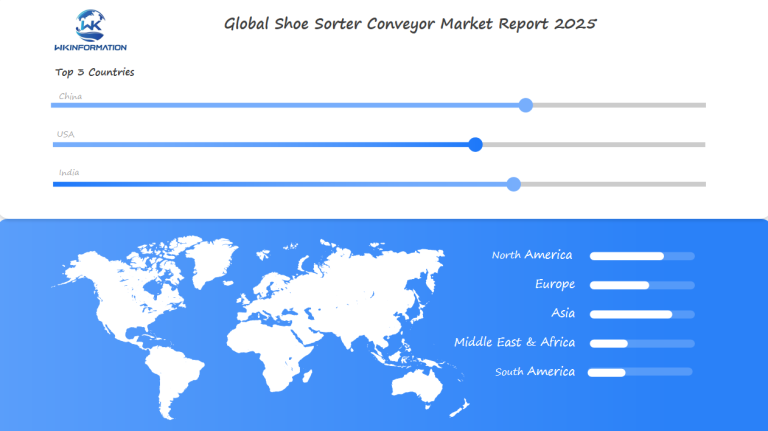

Global Insights into the Shoe Sorter Conveyor Market

Supply chain solutions are changing how shoe sorter conveyors are used around the world. Places like North America and Asia-Pacific are using automated systems to save money and speed up delivery. Let’s look at how different markets compare:

Regional Developments

Asia-Pacific

Asia-Pacific leads in supply chain solutions thanks to big investments in countries like China and India.

Europe

In Europe, companies focus on green technology to lower carbon emissions. There’s also a rise in partnerships across borders, like U.S. and German companies working together to improve efficiency.

Latin America

Latin America is boosting imports of tilt-tray systems to handle rising e-commerce demand.

Middle East

Middle Eastern firms are investing in AI-driven conveyors for oil and gas-related logistics.

The Role of Shoe Sorter Conveyors

Shoe sorter conveyors are now key in modern supply chain solutions. As technology gets better, more places will use them. This will link every part of the supply chain into one smooth system.

India’s Booming E-Commerce Sector and Demand for Shoe Sorter Conveyors

India’s e-commerce sector is growing fast. This is thanks to more people using the internet and moving to cities. Now, there’s a big need for efficient ways to handle packages, like shoe sorter conveyors.

Global market insights show that Indian businesses are turning to automation. They want to deal with more packages and meet customer demands for quick delivery.

- India’s e-commerce market size reached $100B in 2023, boosting warehouse infrastructure investments.

- Automated sorting systems reduce order processing time by up to 40% compared to manual methods.

- Companies like Flipkart and Amazon India adopt tilt-tray and cross-belt conveyors to streamline operations.

| Factor | Traditional Methods | Automated Solutions |

| Error Rates | High human error | 98% accuracy |

| Speed | Slower, labor-intensive | Process 5,000+ items/hour |

| Cost | Long-term inefficiencies | Lower per-unit handling costs |

Indian companies are mixing local needs with the latest global tech. For example, startups like Dunzo and Grofers use AI-driven conveyors for fast local deliveries. This mix of global tech and local needs makes India a key player in automated logistics.

Investments in smart warehouses and partnerships with global suppliers show this connection. As India’s e-commerce grows, shoe sorter conveyors are key for staying ahead in both the local and global markets.

Germany’s High-Tech Logistics Solutions and Advanced Sorting Systems

Germany is a leader in logistics innovation, combining precision engineering with top-notch sorting systems. At the core of this success is tilt-tray technology. It makes material handling in warehouses and distribution centers fast and accurate. This meets the high standards of global supply chains.

Key Features of Germany’s High-Tech Logistics Solutions

- Automated tilt-tray systems reduce errors by 40% in high-volume facilities

- German firms like Siemens and Dematic integrate these systems into smart warehouses

- Real-time tracking features boost inventory management for e-commerce giants

How Tilt-Tray Technology Works

German engineers create tilt-tray technology for handling fragile items and complex sorting tasks. These systems can handle different package sizes while keeping safety standards high. Companies like Deutsche Post use this tech to process millions of parcels every day, setting new standards for reliability.

From automotive parts to consumer goods, tilt-tray solutions make operations smoother without losing quality. As the need for automation grows, Germany’s expertise makes it a key player in the future of logistics. This tech-driven approach increases efficiency and drives improvements across the industry worldwide.

Brazil’s Expanding Market for Automated Warehousing and Distribution

Brazil’s logistics sector is moving fast towards automation. Companies are using cross-belt system technology to meet the growing demand for e-commerce. These systems make warehouse operations faster and cheaper.

Advantages of Automated Sorting Solutions

Automated sorting solutions like cross-belt systems cut down on manual labor. They sort packages on their own. Businesses in São Paulo and Rio de Janeiro see big improvements in efficiency after installing these systems. The main advantages are:

- Less downtime thanks to real-time error detection

- 24/7 sorting without getting tired

- Space-saving designs for smaller warehouses

Who’s Leading the Change?

Retail giants and third-party logistics providers are at the forefront of this change. By 2025, Brazil’s use of automated sorting tech is expected to grow by 15% each year. Cross-belt systems are key to meeting delivery deadlines in a market where 60% of consumers want next-day shipping.

What’s Driving This Growth?

Investments in infrastructure and partnerships with tech firms are driving this growth. As Brazil’s logistics networks expand, cross-belt systems will be a vital part of modern supply chains.

The Future of Shoe Sorter Conveyors: AI-Powered Sorting and Smart Automation

Technology is changing how shoe sorter conveyors work. The sliding-shoe design is getting faster and more precise. Now, AI can adjust sorting on the fly, making warehouses more efficient.

Leading Companies in the Industry

Companies like Dematic and Siemens are at the forefront. They use data to improve workflows. This means less waiting and more getting things done.

The Importance of Toughness and Flexibility

Smart automation in sliding-shoe design is all about being tough and flexible. Soon, systems will have sensors to check package weight and size. This means less human error and more efficiency.

Upcoming Innovations in Shoe Sorter Conveyors

Here’s what’s coming:

- AI-driven predictive maintenance to prevent downtime

- Modular designs for flexible warehouse layouts

- Integration with IoT for real-time inventory tracking

Projected Growth of AI-Enabled Conveyors

By 2025, AI-enabled conveyors will grow by 40% in the U.S. and Europe. The sliding-shoe design is key, thanks to better materials and software. Tech firms and logistics providers will team up to bring these changes faster.

The Role of Warehouses in the Future

Warehouses of the future will use these new tools to handle more online orders and global needs. The sliding-shoe design is becoming a center for data and decisions. Businesses that adopt these technologies will stay ahead in a quick-changing market.

Competitive Landscape in the Shoe Sorter Conveyor Market

Top companies in the shoe sorter conveyor market are in a fierce race. Leaders like Dematic and Siemens Logistics aim for high-capacity systems. They meet the needs of global e-commerce.

Here are the key players in the shoe sorter conveyor market:

- Honeywell Intelligrated – United States

- Hytrol Conveyor Co. – United States

- Falcon Autotec – India

- Daifuku Co. Ltd. – Japan

- Dematic (KION Group) – Germany

- HOKUSHO Co. Ltd. – Japan

- Axiom GB Ltd. – United Kingdom

- TGW Logistics Group GmbH – Austria

- Vanderlande Industries B.V. – Netherlands

- Interroll Group – Switzerland

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Shoe Sorter Conveyor Market Report |

| Base Year | 2024 |

| Segment by Type |

· Tilt-Tray · Cross-Belt · Sliding-Shoe Systems |

| Segment by Application |

· Logistics · Retail · Manufacturing |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Shoe sorter conveyors have become indispensable tools across logistics, retail, and manufacturing sectors. Their ability to streamline operations, reduce manual labor, and increase efficiency has made them crucial in modern supply chain management. From e-commerce fulfillment centers to retail distribution hubs and manufacturing plants, these systems continue to evolve with technological advancements.

The integration of AI and smart automation suggests an even more promising future for shoe sorter conveyors, making them a cornerstone of industrial automation. As global trade expands and consumer demands grow, these systems will remain vital in maintaining competitive advantages and meeting market expectations.

Global Shoe Sorter Conveyor Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Shoe Sorter Conveyor Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Shoe Sorter ConveyorMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Shoe Sorter Conveyorplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Shoe Sorter Conveyor Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Shoe Sorter Conveyor Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Shoe Sorter Conveyor Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofShoe Sorter ConveyorMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current value of the Shoe Sorter Conveyor Market?

The Shoe Sorter Conveyor Market is currently valued at $251.9 million and is projected to experience significant growth by 2025, primarily driven by increased automation in logistics.

Which countries are leading in the adoption of shoe sorter conveyor systems?

India, Germany, and Brazil are leading in using shoe sorter conveyor systems. They want to make their logistics better and more efficient.

What are the types of shoe sorter conveyors?

There are three main types: tilt-tray, cross-belt, and sliding-shoe systems. Each type is designed to improve sorting efficiency for different needs.

How does e-commerce influence the shoe sorter conveyor market?

E-commerce is growing fast. This growth increases the need for better sorting technologies. These technologies are key to improving logistics and meeting customer needs for quick and accurate service.

What challenges are faced in shoe sorter conveyor manufacturing?

Challenges include integrating systems, managing costs, and dealing with maintenance issues. These can affect how well the systems work if not solved.

How do geopolitical factors impact the shoe sorter conveyor market?

Changes in politics and trade policies can greatly affect the market. They can change rules, tariffs, and demand for automated solutions worldwide.

What applications do shoe sorter conveyors have in various industries?

Shoe sorter conveyors are used in logistics, retail, and manufacturing. They help sort and distribute products efficiently, meeting the needs of these industries.

How is AI changing the landscape of shoe sorter conveyor systems?

AI is making shoe sorter conveyor systems smarter and more efficient. It’s improving productivity and efficiency, shaping the future of logistics.

Why is Germany considered a benchmark for logistics solutions?

Germany is known for its advanced logistics and engineering. It uses top-notch sorting systems. These systems set high standards for reliability and efficiency globally.

What role does Brazil play in the automated warehousing market?

Brazil is investing more in automated warehousing and distribution. It’s using cross-belt systems to improve efficiency. This move aligns with global trends towards automation.