$8.35 Billion Semiconductor Wafer Cleaning Equipment Market Soars in 2025: U.S., Japan, and South Korea Lead Next-Gen Chip Manufacturing

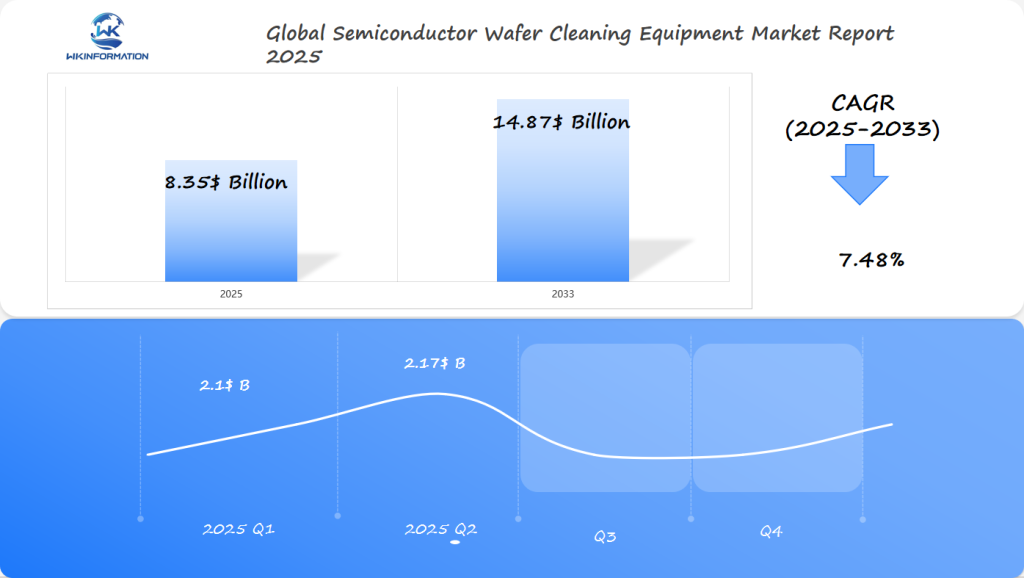

The global Semiconductor Wafer Cleaning Equipment market is valued at USD 8.35 billion in 2025 and USD 14.87 billion in 2033, growing at a compound annual growth rate (CAGR) of 7.48% during the forecast period 2025-2033. The growth is driven by the growing demand for semiconductors in various industries such as electronics and automotive, and the advancement of cleaning technologies such as wet cleaning, dry cleaning, and plasma cleaning. The market is also driven by the increasing complexity of semiconductor equipment and increasingly stringent quality standards, which require effective cleaning solutions to ensure optimal performance and reliability of semiconductor products.

- Last Updated:

Semiconductor Wafer Cleaning Equipment Market Q1 and Q2 2025 Forecast

The Semiconductor Wafer Cleaning Equipment market is projected to reach $8.35 billion in 2025, with a CAGR of 7.48% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $2.1 billion, driven by the continued advancements in semiconductor manufacturing technologies in the U.S., Japan, and South Korea. As demand for advanced semiconductors in 5G, AI, and consumer electronics rises, the need for high-precision cleaning equipment to ensure wafer quality also intensifies.

By Q2 2025, the market is forecast to reach $2.17 billion, supported by increased production capacities for memory chips and logic chips. The ongoing shift towards miniaturized semiconductor devices in the U.S., South Korea, and Japan will further propel growth, as wafer cleaning technology plays a critical role in removing particles and residues at the microscopic level to meet stringent quality standards.

Exploring the Upstream and Downstream Industry Chains for Semiconductor Wafer Cleaning Equipment

The semiconductor manufacturing industry has a complex chain that connects many important sectors. This chain is key to making high-quality wafer cleaning equipment available worldwide.

The semiconductor supply chain has several main stages that work together to support the production of advanced technology:

- Raw material extraction and processing

- Component manufacturing

- Equipment development

- Final product fabrication

Raw Material Suppliers and Component Manufacturers

Raw material suppliers are at the base of the semiconductor industry chain. They offer essential components like ultra-pure chemicals, metals, and ceramics for wafer cleaning equipment.

Component manufacturers create precise parts for semiconductors. They make materials that can handle tough processing and keep things clean.

Equipment Manufacturers and End-Users

Equipment manufacturers use these components to create advanced wafer cleaning systems. They collaborate with semiconductor plants to develop new cleaning technologies that address emerging challenges in the industry.

End-users, such as major tech companies and research institutions, advocate for improved cleaning equipment. Their feedback contributes to enhancing design and performance.

Key Trends Driving the Semiconductor Wafer Cleaning Equipment Market: Increasing Demand for Miniaturization and High-Performance Chips

The semiconductor industry is going through big changes. New technology trends and a need for better electronic parts are leading the way. Miniaturization is key, making devices smaller and more powerful.

There’s also a big push for high-performance chips. This is changing how we make semiconductors. Cleaners are being made to handle the complex needs of new manufacturing methods.

Advancements in Semiconductor Technology

Technology is changing how we make semiconductors:

- Smaller transistors mean more complex chips

- More precise wafer cleaning is needed

- New, advanced cleaning tools are being developed

“The future of semiconductor technology lies in our ability to clean and prepare wafers with unprecedented precision.” – Semiconductor Industry Expert

Growing Demand for IoT and AI Applications

The Internet of Things (IoT) and Artificial Intelligence (AI) are growing fast. They need advanced, miniaturized chips with top performance. This is driving the demand for better semiconductor manufacturing.

Companies are spending a lot on cleaning equipment for these chips. Making smaller, more efficient parts is now a key advantage in the tech world.

Challenges in Semiconductor Wafer Cleaning Equipment Development and Cost Efficiency

The semiconductor industry is facing big challenges in making equipment and keeping costs down. As chips get more complex, makers have to solve tough technical problems while keeping costs in check.

Advanced node cleaning is a big problem for chip makers. The smaller chips get, the more precise cleaning needs to be.

Advanced Node Cleaning Technical Hurdles

Developing equipment for cleaning chips is a big task. It needs new ideas to tackle tiny cleaning tasks. Some big challenges are:

- Getting rid of tiny dirt without harming the chip

- Creating super-accurate cleaning tools for chips smaller than 7nm

- Keeping cleaning quality high as chip designs get more complex

Balancing Performance and Cost Efficiency

Chip makers need to find a balance between keeping costs low and cleaning chips well. Important steps include:

- Investing in the latest cleaning tech

- Designing equipment to work better and faster

- Lowering waste in the cleaning process

Precision and efficiency are the cornerstones of modern semiconductor wafer cleaning equipment development.

| Challenge Category | Key Considerations | Potential Solutions |

| Technical Complexity | Nanoscale contamination removal | Advanced chemical cleaning mechanisms |

| Cost Management | Equipment development expenses | Modular design and process optimization |

| Performance Consistency | Uniform cleaning across chip designs | Adaptive cleaning technologies |

The semiconductor industry is always trying to improve equipment and solve problems. They need new ideas and smart investments to beat these tough challenges.

Geopolitical Influence on the Semiconductor Wafer Cleaning Equipment Market

The semiconductor industry is now a key area of global competition. Trade policies are changing how markets work around the world. Countries see the value of semiconductor tech and are taking steps to control the supply chain.

Geopolitical tensions are affecting the market for semiconductor wafer cleaning equipment. This has made things tough for makers and suppliers everywhere. The big economic powers are racing to keep up with tech, leading to big changes in how things are made and who works together.

Trade Tensions and Supply Chain Disruptions

Big challenges in the semiconductor world include:

- More limits on sharing tech

- Economic sanctions

- Complicated rules for exports

- Less chance for working together across borders

Because of these issues, chip makers are working on strong supply chains. They’re also spreading out their production. Strategic decoupling is a big move, where countries try to not rely so much on others for chips.

Government Initiatives and Subsidies

World governments are stepping up to support their chip industries. They’re investing in tech to:

- Boost their tech skills

- Make their supply chains safer

- Lure in high-tech factories

- Build strong chip ecosystems

The market for cleaning wafers for semiconductors is changing fast because of these global pressures. To grow and stay ahead, innovation and smart planning are key.

Semiconductor Wafer Cleaning Equipment Market by Type: Single-Wafer, Batch, and Scrubber Systems

The semiconductor wafer cleaning equipment market has three main types. Each plays a key role in making advanced chips. They meet the changing needs of chip production.

Manufacturers use different cleaning technologies for top-quality wafer processing. The market has three main cleaning system types:

- Single-wafer cleaning offers precise cleaning for each wafer

- Batch cleaning meets high-volume needs

- Scrubber systems provide deep surface treatment

Single-Wafer Cleaning: Precision at the Forefront

Single-wafer cleaning systems are the most advanced in chip making. They remove particles well and prepare surfaces for new technologies. They handle delicate wafers safely.

Batch Cleaning: Efficiency in Volume Processing

Batch cleaning allows manufacturers to clean multiple wafers simultaneously. It is a cost-effective and efficient solution for large-scale production requirements.

Scrubber Systems: Comprehensive Surface Treatment

Scrubber systems are designed to tackle tough surface dirt challenges. They utilize a combination of chemicals and mechanical processes to achieve deep cleaning at every stage of chip production.

Market Dynamics and Growth Projections

The market for wafer cleaning equipment is growing fast. This is because of the rising need for better microelectronics. New tech in AI, 5G, and IoT drives innovation in cleaning systems.

Applications of Semiconductor Wafer Cleaning Equipment in Logic, Memory, and Foundry Processes

The semiconductor industry needs precise cleaning equipment to keep chip production high. Cleaning wafers is key for quality and performance in logic, memory, and foundry processes.

Cleaning tech has grown more advanced to meet today’s semiconductor needs. Each chip type needs a special cleaning method to keep its tiny details intact.

Cleaning Requirements for Diverse Chip Types

Manufacturers face unique cleaning challenges for different semiconductor parts:

- Logic chips need super-accurate surface prep for best transistor work

- Memory chips get special cleaning to avoid data loss

- Foundry processes require advanced dirt removal

“Precision cleaning is the backbone of semiconductor manufacturing integrity.” – Semiconductor Industry Expert

Emerging Applications in Advanced Packaging

The semiconductor industry is always looking for new packaging solutions. Wafer cleaning tools are now used for complex, three-dimensional chip designs, making devices smaller and more powerful.

Advanced packaging requires even better cleaning techniques that can handle delicate layers without damaging the chip. The growth of cleaning technology is crucial in developing the next major advancement in electronics.

As manufacturers strive for smaller and more efficient chips, wafer cleaning tools play a vital role in supporting logic, memory, and the latest foundry processes.

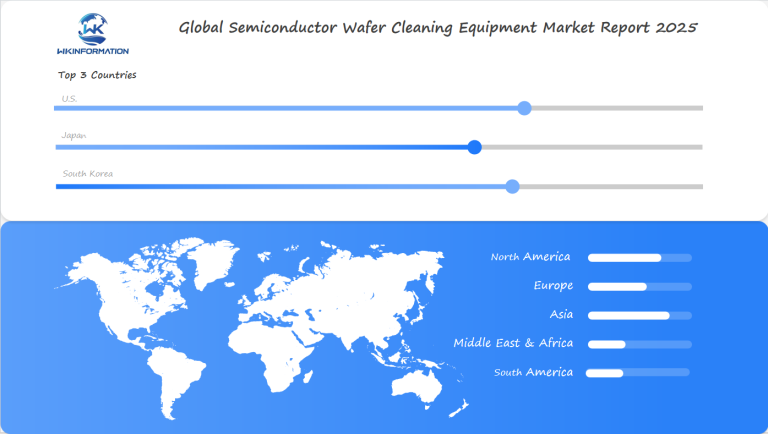

Understanding the Global Semiconductor Wafer Cleaning Equipment Market

The global semiconductor wafer cleaning equipment market is evolving rapidly, driven by emerging technologies and expansion strategies. As the industry expands, various regions around the world are gaining significance.

Semiconductor manufacturers are aiming for global growth, with certain areas emerging as key players in this sector. The market landscape differs significantly across regions and technologies.

Regional Market Shares and Growth Dynamics

Here’s what we found about the semiconductor wafer cleaning equipment market:

- North America leads in technological innovation

- Asia-Pacific dominates production volumes

- European markets focus on specialized cleaning technologies

Emerging Markets and Strategic Opportunities

New markets are opening up for semiconductor wafer cleaning equipment makers. Countries like India, Malaysia, and Vietnam are growing fast. They’re investing in new semiconductor projects.

The global market analysis shows that partnerships and local production are key. Companies need to focus on regional growth in these emerging markets to succeed.

The U.S. Expands Semiconductor Fabrication with Cutting-Edge Cleaning Technologies

The U.S. semiconductor industry is going through a big change. It’s focusing more on making chips at home and using new tech. This includes advanced cleaning methods that make chips better and more precise.

Domestic production is growing thanks to important plans. These plans aim to make the U.S. tech stronger. Key steps include:

- More federal money for chip research

- Team-ups between government and private chip makers

- Investments in new cleaning tech

Investment in Domestic Chip Production

Universities, labs, and chip companies are working together. They’re making new discoveries. These partnerships help create better cleaning tech for chips.

Collaborations between U.S. Companies and Research Institutions

There’s never been more teamwork in the chip world. Schools like MIT and Stanford are teaming up with chip makers. They’re working on new cleaning tech that could help reduce imports.

These efforts are making the U.S. a leader in chip making. They help the U.S. stay ahead in the global tech race.

Japan's Leadership in Precision Wafer Cleaning and Equipment Development

Japanese technology is known for leading in precision cleaning in the semiconductor world. The country’s skill in making new equipment makes it a top player in making semiconductors.

Innovations in Ultra-Clean Processing

Japanese manufacturers have developed new methods for achieving ultra-clean cleanliness. These techniques are so accurate that they guarantee the highest quality and performance of chips.

- Advanced cleaning technologies with sub-nanometer precision

Partnerships with Global Semiconductor Manufacturers

Japan’s success in cleaning equipment comes from working with global partners. Top Japanese companies team up with other manufacturers to create the latest cleaning solutions. These solutions tackle tough tech challenges.

Japanese precision cleaning technologies represent the gold standard in semiconductor equipment innovation worldwide.

Japanese firms keep pushing the limits with their research and advanced cleaning methods. This keeps them ahead in the fast-changing semiconductor world.

South Korea's Growing Investments in Semiconductor Foundries and Equipment Upgrades

The semiconductor industry in South Korea is at a crucial point. Major players like Samsung Electronics and SK Hynix are making significant investments to secure their position as global leaders in technology.

Rapid Changes in South Korea’s Chip Industry

South Korea’s chip industry is undergoing rapid transformation. The country is channeling funds into the establishment of state-of-the-art factories with the aim of becoming the leading manufacturer of memory chips and high-performance chips.

Expansion of Domestic Chip Production Capacity

Here are some big moves in South Korea’s chip production:

- Big money going into new factories

- Upgrading equipment for the latest tech

- Building better places for research and development

The Future of Semiconductor Wafer Cleaning Equipment: Automation and AI-Driven Precision Cleaning

The semiconductor industry is about to undergo a significant transformation. Automation and AI are enhancing cleaning technologies, with new advancements in machine learning and robotics reshaping the way semiconductor wafers are cleaned.

Artificial intelligence is driving substantial advancements in cleaning equipment. Companies are leveraging intelligent algorithms to optimize the cleaning process, resulting in reduced contamination and improved production efficiency.

Integration of Machine Learning and Big Data Analytics

Machine learning can now analyze complex cleaning patterns with great accuracy. These smart systems can:

- Predict where contamination might happen

- Give advice on how to adjust cleaning in real-time

- Lower the chance of human mistakes in cleaning

- Make equipment work better

“AI-driven precision cleaning represents the next frontier in semiconductor manufacturing technology” – Industry Expert

Advancements in Robotics and Process Control

Robotic systems are changing how we automate wafer cleaning. Advanced robots can:

- Make very precise cleaning movements

- Remove contamination consistently

- Need less human help

- Improve quality control

These new technologies are not just making things more efficient. They are changing the way we make semiconductors. Cleaning is becoming smarter and more flexible than ever.

Competitive Landscape in the Semiconductor Wafer Cleaning Equipment Market

The semiconductor wafer cleaning equipment market is highly competitive. Many major players are actively seeking new technologies to gain a significant share of the market through strategic alliances in semiconductor manufacturing.

Key Players:

- SCREEN Holdings Co. Ltd. —— Japan

- Lam Research Corporation —— United States

- Applied Materials Inc. —— United States

- Veeco Instruments Inc. —— United States

- Modutek Corporation —— United States

- Tokyo Electron Limited —— Japan

- Entegris Inc. —— United States

- SEMES Co. Ltd. —— South Korea

- Shibaura Mechatronics Corporation —— Japan

- AP&S International GmbH —— Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Semiconductor Wafer Cleaning Equipment Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The semiconductor wafer cleaning equipment market is at a turning point. It’s expected to grow a lot by 2025. Experts say new technologies and more demand in advanced chip making will lead the way.

Short-term, big investments are coming from the US, Japan, and South Korea. These places will push for better cleaning tech for complex chips. The growth will also come from new uses in AI, IoT, and super-fast computers.

Looking ahead, the market is set to hit $8.35 billion by 2025. Fast tech progress, smaller chips, and more global demand for tech will drive this. Companies must keep innovating to keep up with chip making needs.

Success will depend on partnerships, research, and investing in automation and precision. The ones who offer top-notch cleaning solutions efficiently will stay ahead in the game.

Global Semiconductor Wafer Cleaning Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Semiconductor Wafer Cleaning Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Semiconductor Wafer Cleaning EquipmentMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Semiconductor Wafer Cleaning Equipmentplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Semiconductor Wafer Cleaning Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Semiconductor Wafer Cleaning Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Semiconductor Wafer Cleaning Equipment Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofSemiconductor Wafer Cleaning EquipmentMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for semiconductor wafer cleaning equipment by 2025?

The market for semiconductor wafer cleaning equipment is expected to hit $8.35 billion by 2025. This growth is fueled by new technologies and the need for better chips from top companies in the U.S., Japan, and South Korea.

Why are semiconductor wafer cleaning technologies becoming increasingly important?

The demand for smaller chips is growing due to the Internet of Things (IoT) and Artificial Intelligence (AI). Additionally, there is a need for high-performance chips, which makes wafer cleaning technology essential.

What are the main types of semiconductor wafer cleaning equipment?

There are mainly three types: single-wafer systems, batch systems, and scrubber systems. Each has its own benefits and is used in different ways in making semiconductors.

How do geopolitical factors impact the semiconductor wafer cleaning equipment market?

Trade disputes between major countries can disrupt supply chains and market trends. Government support and subsidies play a crucial role in shaping the global semiconductor industry.

What challenges do manufacturers face in developing advanced wafer cleaning equipment?

Companies face big challenges in cleaning smaller, more complex chips. They need to improve performance while keeping costs down.

Which countries are leading in semiconductor wafer cleaning equipment technology?

The U.S., Japan, and South Korea lead the way. The U.S. excels in new tech, Japan in precision cleaning, and South Korea in memory tech.

What role does automation play in the future of semiconductor wafer cleaning?

Automation will be key in the future. It will use AI, machine learning, and robotics to make manufacturing more efficient and effective.

How do cleaning requirements differ across various semiconductor applications?

Cleaning needs vary by chip type and application. Manufacturers are creating specialized solutions for logic, memory, and foundry processes.

What are the key trends driving growth in the semiconductor wafer cleaning equipment market?

Growth is driven by the need for better chips, tech advancements, IoT and AI growth, and investments in domestic production.