Riveting Tool Market to Surpass $753.19 Million by 2025: Strategic Growth in the U.S., Germany, and South Korea

Explore the expanding Riveting Tool Market as it reaches $753.19M by 2025. Rising demand in manufacturing sectors drives growth across the U.S., Germany, and global regions.

- Last Updated:

Riveting Tool Market Performance in Q1 and Q2 of 2025

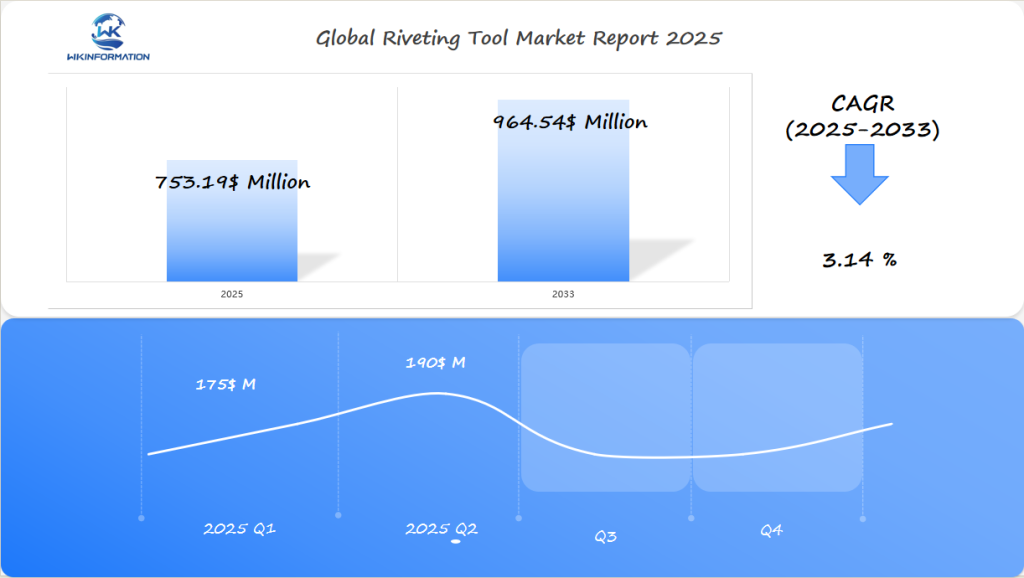

The Riveting Tool market is projected to reach $753.19 million in 2025, with a CAGR of 3.14% from 2025 to 2033. Q1 market size is estimated to be around $175 million, and Q2 will likely increase to approximately $190 million as demand continues from industries such as automotive manufacturing and aerospace. The demand for riveting tools is driven by the need for durable, long-lasting, and secure joint fastening solutions in these industries.

The U.S., Germany, and South Korea are key players, with the U.S. leading in automotive and aerospace applications, Germany focusing on precision tools for industrial use, and South Korea expanding in electronics and automotive sectors. As global manufacturing demands rise, the market for riveting tools will continue to benefit from innovations in automation and process efficiency.

Key Takeaways

- The market is expected to reach $753.19 million by 2025.

- Significant growth is driven by the automotive and aerospace industries.

- Technological advancements are stimulating market development.

- The U.S., Germany, and South Korea are emerging as key strategic markets.

- A projected CAGR of 3.14% is expected from 2025 to 2033.

Understanding the Upstream and Downstream Factors of the Riveting Tool Industry

The riveting tool supply chain is a complex web of processes that boost global manufacturing. It shows how these tools go from raw materials to their final use. This understanding is key to seeing how the industry works.

Key Components of the Riveting Tool Supply Chain

The main parts of the riveting tool supply chain are:

- Raw material procurement

- Manufacturing processes

- Distribution channels

- End-user industries

How Upstream Factors Influence the Riveting Tool Market

Upstream factors shape the riveting tool market a lot. Costs of materials, manufacturing tech, and production power affect product prices and availability. Manufacturers need to find the best sources to stay ahead.

The Impact of Downstream Factors on the Industry

Downstream factors also play a big role. Industries like automotive, aerospace, and construction have their own needs. These needs push for new and better fastening solutions.

The Importance of Adaptability in a Changing Market

Changes in one part of the market can affect the whole supply chain. Being able to adapt quickly is crucial for businesses to grow in this fast-changing market.

Key Trends Shaping the Riveting Tool Industry

The riveting tool market is evolving rapidly, driven by advancements in technology. Manufacturers are striving to develop innovative solutions that cater to the demands of various sectors.

Here are some significant trends influencing the riveting tool industry:

- Adoption of advanced pneumatic and robotic riveting technologies

- Increased focus on lightweight material applications

- Integration of enhanced precision and automation capabilities

- Development of environmentally sustainable riveting solutions

Leading Industries Driving Innovation

The automotive and aerospace sectors are at the forefront of driving innovation in riveting tools. These industries are investing heavily in research and development to create tools that not only perform optimally but also align with sustainability goals.

Performance Improvements Through Technology

New technologies are significantly enhancing the performance of riveting tools:

| Technology Performance Improvement Robotic Riveting | +45% Precision |

| Pneumatic Tools | +30% Efficiency |

| Lightweight Material Compatibility | +25% Versatility |

These advancements indicate a clear trajectory towards more intelligent, versatile, and eco-friendly riveting solutions across multiple industries.

Regulatory and Operational Barriers Impacting Market Momentum

The riveting tool market is facing big challenges. These include strict safety rules and quality standards. These rules affect how products are made and how they enter the market.

Some major challenges are:

- Stringent safety compliance requirements

- Environmental policy constraints

- Increasing competition from alternative fastening technologies

- Skilled labor shortages in manufacturing

Riveting tool rules are getting more complex. This means companies need to spend on new tech. The market also faces competition from new methods like adhesive bonding.

| Regulatory Area | Impact on Market | Compliance Difficulty |

| Safety Standards | High Production Costs | Moderate to High |

| Environmental Policies | Design Modifications | High |

| Quality Control | Increased Testing | Moderate |

Companies need to keep innovating to beat these hurdles. Strategic adaptation is key to staying ahead in the riveting tool world.

How Geopolitical Changes Are Redefining Riveting Tool Supply Chains

The world of riveting tools is undergoing significant transformation due to intricate global politics. Businesses are swiftly adapting their manufacturing and distribution strategies for these tools, as international relations now heavily influence production and commerce.

Challenges Shaping the Industry

Several major issues are reshaping the global landscape for riveting tool manufacturing and sales:

- Heightened trade conflicts between key economic powers

- Growing regional economic protectionism

- Disrupted manufacturing networks

- Emergence of regional manufacturing hubs

Strategies for Staying Competitive

In response to these challenges, companies are proactively seeking new methods to maintain their competitive edge:

- Broadening supplier networks across various regions

- Investing in localized production facilities

- Building more robust supply chain infrastructures

- Exploring alternative manufacturing destinations

The automotive and aerospace sectors are particularly impacted by these shifts, as they rely on precise riveting tools and require meticulous management of their supply chains.

The Role of Technology and Local Policies

The future of riveting tool supply chains will continue to be influenced by technological advancements and local economic policies. Those companies capable of navigating these intricate changes will emerge as leaders in the industry.

Market Breakdown by Tool Type: Manual, Pneumatic, and More

The riveting tool market is full of new technologies and special tools. Knowing about the different types is key for those who make things and work in industry. They want the best performance and efficiency.

There are many types of riveting tools, each with its own strengths. People pick the right tool based on what they need. This includes how well it works, how versatile it is, and what it’s used for.

Pneumatic Rivet Tools: Leading the Market

Pneumatic riveting tools are the top choice for many industries. They are known for their:

- High precision and consistent quality

- Strong design for tough environments

- Fast speed and efficiency

Battery-Powered Rivet Tools: The Rising Star

Battery-powered riveting tools are changing the game. They are becoming more popular because of:

- Being easy to move around

- Not needing a power source

- Being easier on the body

Other Tool Types: Specialized Solutions

There are also other types of riveting tools. They are made for specific needs:

| Tool Type | Key Characteristics | Primary Applications |

| Hydro-pneumatic | High-pressure precision riveting | Aerospace, automotive manufacturing |

| Lazy Tong | Manual leverage mechanism | Construction, small-scale fabrication |

| Hand-Held Lever | Compact and lightweight design | Maintenance, repair operations |

The market for riveting tools keeps getting better. New tech leads to more options. Makers are working on tools that are good for many uses and work well.

Applications of Riveting Tools Across Industries: A Demand-Based View

Riveting tools are key in many industries, leading to market growth and new tech. They help make strong connections in complex settings. This makes them vital for manufacturers.

There’s a big need for special riveting tools in different fields. These tools are crucial for keeping things strong and making production better. They help in many types of manufacturing.

Automotive and Aerospace: Driving Market Growth

The automotive and aerospace industries have a high demand for riveting tools. These industries require tools that can perform effectively in challenging environments and consistently deliver precise results.

- Car manufacturers utilize riveting tools for assembling body panels.

- Aircraft manufacturers employ specialized riveting techniques in the construction of aircraft.

- There is a need for tools specifically designed for working with materials such as carbon fiber and aluminum.

Building and Construction: Rising Demand

The building and construction industry is rapidly expanding. As more buildings and cities are constructed, there is an increasing demand for robust joining techniques.

Industries Benefiting from Riveting Tools

| Industry Sector | Riveting Tool Application | Growth Potential |

| Automotive | Body Panel Assembly | High |

| Aerospace | Structural Connections | Very High |

| Construction | Steel Framework | Moderate |

Other Industries: Transportation, Woodworking, and More

Riveting tools are also used in transportation, woodworking, and making decorative items. This shows how versatile modern riveting tech is.

The wide use of riveting tools shows tech progress and the complexity of making things worldwide.

Global Hotspots: Regional Market Comparisons for Riveting Tools

The world of riveting tools is always changing. It’s a place where new ideas meet old ones. People who make these tools and those who use them are always looking at what’s new.

Looking at different places shows us how things vary. Some places grow faster, while others are more advanced. Knowing this helps companies plan their moves worldwide.

Asia Pacific: The Dominant Market Force

Asia Pacific is the top spot for riveting tools. It’s because of:

- Fast growth in China and India

- A big car-making industry

- More projects to build things like roads and buildings

- People quickly adopting new tech

North America: Steady and Strategic Growth

The North American market keeps growing. It’s because of:

- Strong car and plane making

- Big investments in new riveting tech

Europe: The Hub of Technological Innovation

Europe is at the forefront of technological innovation, with Germany and Switzerland leading the way. These countries are known for their expertise in creating specialized tools that are highly efficient for specific tasks.

Middle East & Africa: Emerging Market Potential

The Middle East and Africa are full of opportunities for growth. There’s a lot of construction and manufacturing happening, and businesses are investing to support development.

Examining these markets reveals their interconnectedness. It’s crucial to understand the unique aspects of each region when strategizing for business.

U.S. Industrial Demand and the Rise of Automation in Riveting Tools

The U.S. riveting tool market is changing fast thanks to new tech and automation. The aerospace and automotive industries are leading this change. They are making manufacturing more precise and efficient.

Automated riveting systems are changing the game for U.S. makers. These advanced tools are super accurate and fast. They cut down on mistakes and boost production.

- Aerospace industry adopting advanced riveting technologies

- Automotive manufacturers investing in precision automation

- Reduced labor costs through intelligent riveting solutions

Automated riveting systems bring big benefits. Here are some:

| Feature | Impact on Manufacturing |

| Precision Placement | 99.9% accuracy in rivet positioning |

| Speed | Up to 300% faster than manual processes |

| Cost Efficiency | 20-40% reduction in production expenses |

The U.S. riveting tool market keeps growing. Makers are working on smarter, more flexible automated systems. Technological innovation is key to staying ahead in this fast-changing world.

Germany's Manufacturing Dominance and Its Impact on the Riveting Tool Market

The Germany riveting tool industry leads in European manufacturing innovation. It drives big steps in precision engineering. Germany is a top global leader in riveting tool technology.

Germany’s manufacturing sector has key strengths:

- Exceptional precision engineering capabilities

- Advanced technological infrastructure

- Strong research and development investments

- Robust automotive and aerospace manufacturing ecosystems

Germany’s focus on Industry 4.0 has changed the riveting tool market. It has pushed the limits of automation and smart manufacturing. German manufacturers show unmatched skill in using advanced technologies in production.

| Industry Sector | Riveting Tool Demand | Innovation Level |

| Automotive | High | Advanced |

| Aerospace | Medium-High | Cutting-Edge |

| Construction | Medium | Emerging |

Germany manufacturers focus on making high-performance riveting tools. They are key players in the global market. Their dedication to quality, precision, and innovation sets new industry standards.

South Korea's Tech-Focused Market for Advanced Riveting Systems

South Korea is a major player in the world of riveting technology. It leads in innovation with its advanced systems. The country’s strong electronics and car industries drive this progress.

The South Korean riveting technology sector shows great strength in many areas:

- Sophisticated IoT-enabled riveting tools with real-time data analytics

- Seamless integration of robotics and automation in manufacturing processes

- High-precision engineering for complex industrial applications

South Korean makers invest a lot in research and development. This puts them at the top of advanced riveting systems. They mix precision engineering with smart tech to solve complex industrial needs.

Some key innovations include smart riveting tools that:

- Monitor real-time performance metrics

- Automatically adjust pressure and alignment

- Provide predictive maintenance insights

The Asia Pacific, with South Korea leading, controls the global riveting tools market. Experts say growth will keep going because of tech advancements and more industries expanding.

Innovation and Expansion: What Lies Ahead for Riveting Tools

The riveting tool market is about to undergo a significant transformation. With the advent of new technologies, the way we manufacture products is evolving, leading to improvements in these tools. This shift is creating opportunities for innovative manufacturing methods across various industries.

Key Areas of Development

Some of the key areas where we can expect advancements include:

- Smart IoT-enabled riveting systems: These systems will leverage Internet of Things (IoT) technology to enable real-time monitoring and control of riveting processes, enhancing efficiency and productivity.

- AI-assisted precision riveting processes: Artificial intelligence (AI) algorithms will be employed to optimize riveting operations, ensuring consistent quality and reducing defects.

- Eco-friendly and sustainable tool designs: There will be a growing emphasis on designing riveting tools that are environmentally friendly and sustainable, using materials and manufacturing techniques that minimize ecological impact.

- Advanced lightweight materials integration: The integration of advanced lightweight materials in riveting applications will lead to stronger yet lighter structures, benefiting industries such as aerospace and automotive.

Future Trends

Looking ahead, we can anticipate a significant shift towards smart, connected riveting tools. Manufacturers are investing heavily in research and development to create tools that are not only precise but also capable of communicating with other machines and systems.

| Innovation Category | Key Technological Advancement | Potential Impact |

| IoT Integration | Real-time performance monitoring | Enhanced predictive maintenance |

| AI Precision | Machine learning algorithms | Improved quality control |

| Sustainable Design | Energy-efficient mechanisms | Reduced environmental footprint |

Recent Example of Innovation

In February 2025, Rivit launched the RIV943—a new hydropneumatic riveting tool specifically designed for rivet nuts. This product exemplifies the type of innovation we can expect in the coming years.

Industries Benefiting from Riveting Tool Innovations

The aerospace, automotive, and construction sectors are actively seeking opportunities to implement these cutting-edge tools into their manufacturing processes. The potential impact of such advancements on production methods is substantial.

As we move forward into this new era of manufacturing, it becomes increasingly important for businesses within these industries to stay abreast of technological developments. By embracing innovative solutions like IoT-enabled systems or AI-driven processes, companies can gain a competitive edge while also contributing towards sustainability goals.

With ongoing investments being made into research initiatives focused on improving existing technologies as well as developing entirely new ones—such as eco-friendly designs or advanced material integrations—we can expect many exciting changes ahead.

Competitive Dynamics and Brand Positioning in the Riveting Tool Space

The riveting tool market has seen a lot of competition lately. Big players are coming up with smart strategies to get ahead. They’re using new ways to stand out in a busy market.

Being strategic in the riveting tool world means a few key things:

- Creating new products that meet specific needs

- Improving customer service and tech support

- Targeting specific groups with marketing

- Putting money into research and development

Key Players:

-

Stanley Black & Decker – United States

-

Atlas Copco AB – Sweden

-

Illinois Tool Works Inc. (ITW) – United States

-

Bosch Power Tools – Germany

-

Makita Corporation – Japan

-

Snap-on Incorporated – United States

-

Ingersoll Rand Inc. – United States

-

DeWalt (Stanley Black & Decker) – United States

-

Hilti AG – Liechtenstein

-

Metabo – Germany

Smaller companies are also making a mark by focusing on specific products. They compete by offering:

- Custom riveting solutions

- Quick responses

- Flexible manufacturing

How you sell and support your products is also key. Companies that offer great support and tech solutions are leading the way in the riveting tool market.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Riveting Tool Market Report |

| Base Year | 2024 |

| Segment by Type |

· Hydro-pneumatic · Lazy Tong · Hand-Held Lever |

| Segment by Application |

· Automotive · Aerospace · Construction · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The riveting tool market is complex, with new tech and growth chances. It’s expected to grow at 3.14% from 2025 to 2033. Leaders must face tough challenges and grab new chances in global making sectors.

For success, companies need to be flexible and use new tech. They should focus on making better pneumatic and battery tools. The auto, aerospace, and building sectors need tools that are precise and efficient.

Expanding the market means focusing on green tech and new products. Companies should make tools that are better for the planet and work better. They need to keep improving their tools, especially with automation and smart making.

The market’s future is tied to how companies handle new tech and changes. Those that go digital, adapt quickly, and see what’s coming will lead. They’ll grab more of the market in North America, Europe, and Asia Pacific.

Global Riveting Tool Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Riveting Tool Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Riveting ToolMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Riveting ToolPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Riveting Tool Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Riveting Tool Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Riveting Tool Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Riveting ToolMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for riveting tools by 2025?

The market for riveting tools is expected to hit $753.19 million by 2025. This growth is fueled by rising needs in the automotive and aerospace fields. It’s also driven by fast urban growth and new tech advancements.

What are the key technological trends in riveting tools?

Some major trends in riveting tools include:

- The use of pneumatic and robotic tools

- A shift towards lighter materials

- An emphasis on energy-saving and environmentally-friendly tools

Which industries have the highest demand for riveting tools?

The car and plane industries lead the demand. This is because of new tech and specific needs in making these products.

What types of riveting tools are most popular in the market?

Pneumatic tools are the top choice. Battery-powered tools are gaining fans for being easy to carry and having the latest tech.

How are global events impacting the riveting tool market?

Global changes are affecting supply lines. Companies are responding by finding new suppliers, moving production, and exploring new markets.

Which regions are leading in the riveting tool market?

The Asia Pacific, especially China, is leading. North America is growing steadily. Europe is innovating with new tech.

What challenges does the riveting tool market face?

The market faces competition from other fastening methods. There’s a shortage of skilled workers. Safety rules and the need for new ideas are also challenges.

What emerging technologies are shaping the future of riveting tools?

New tech includes smart tools with IoT, AI in riveting, and green solutions.

How are manufacturers adapting to market changes?

Manufacturers are innovating their products, automating processes, and utilizing new technologies such as IoT and data analysis. They are also addressing emerging industry requirements.

What role do countries like the U.S., Germany, and South Korea play in the riveting tool market?

These countries are key players:

- The U.S. is pushing for automation in the riveting tool industry.

- Germany excels in precision manufacturing of riveting tools.

- South Korea is innovating in riveting technology.