2025 Ripcord Yarn Market: Exploring $1.5 Billion Global Innovations, Fueled by Developments in China, India, and US

Explore the dynamic growth of the global ripcord yarn market, focusing on key regions like China, India, and the US. This comprehensive analysis examines market trends, technological innovations, and sustainability initiatives shaping the future of telecommunications infrastructure and fiber optic cable manufacturing.

- Last Updated:

Ripcord Yarn Market Outlook for Q1 and Q2 2025

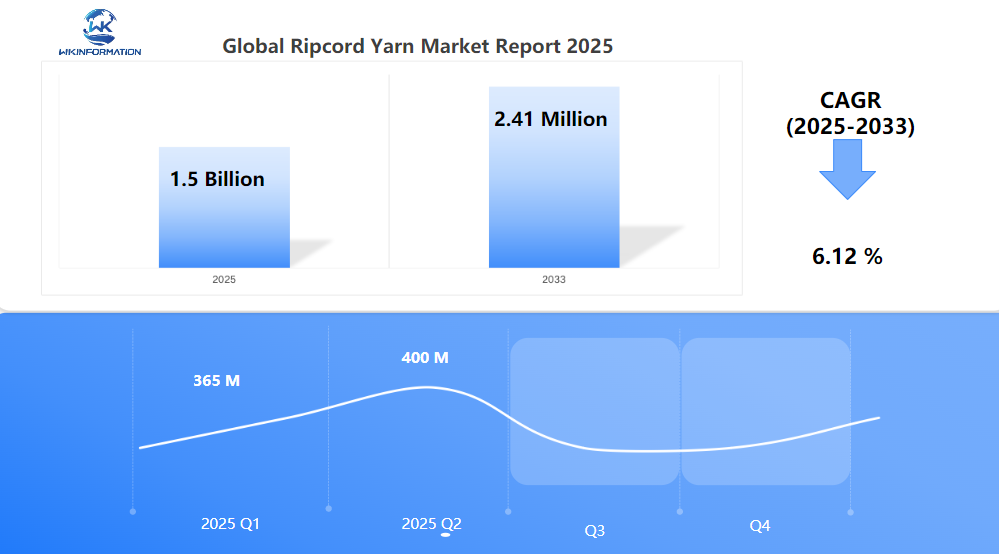

The global Ripcord Yarn market is on a robust growth trajectory, with an estimated valuation of USD 1.5 billion in 2025. Based on current trends and seasonal demand patterns, Q1 and Q2 of 2025 are projected to achieve market sizes of USD 365 million and USD 400 million, respectively, showcasing a non-linear yet steady expansion.

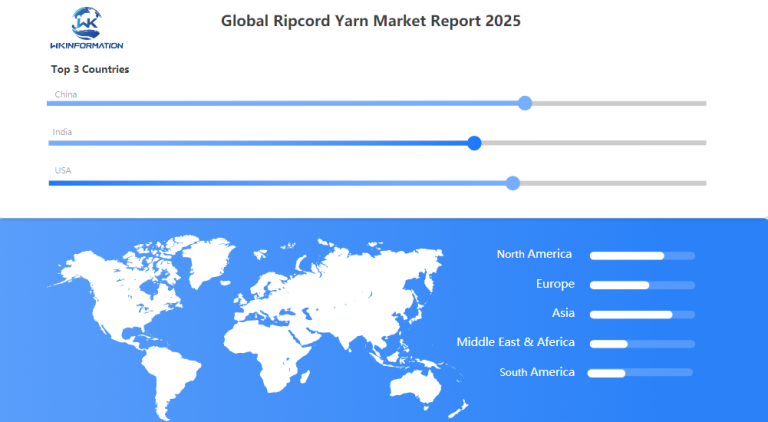

Among the key markets, China, India, and the USA are leading the charge, collectively contributing over 60% of the global demand. These countries are driving growth through advancements in telecommunications, infrastructure development, and industrial applications. For a detailed breakdown of market dynamics, regional insights, and future projections, explore the Wkinformation Research sample and full report. Unlock the complete analysis to stay ahead in this rapidly evolving market!

Key Takeaways

- China, India, and the US control over 60% of the global ripcord market production and consumption

- The ripcord yarn market is growing at 5-7% annually with acceleration expected

- Telecommunications expansion serves as the primary driver for market growth

- Each nation brings distinct advantages: China (scale), India (expertise), US (innovation)

- Sustainability practices are reshaping manufacturing processes across all three countries

- Trade policies significantly impact cross-border market dynamics in the ripcord sector

Upstream and Downstream Industry Chain Analysis: The Ripcord Yarn Supply Chain Explained

The ripcord yarn industry has a complex network of suppliers, manufacturers, and distributors. It starts with getting raw materials and ends with delivering finished products. This chain is different in each part of the world.

Raw Material Sourcing and Initial Processing

Fiber sourcing is the first step in making yarn. Natural fibers like cotton, wool, and silk come from farms. Synthetic materials need petrochemical processing.

Where these materials come from affects how they are sourced. China uses its own cotton, India has a lot of natural fibers, and the US often imports.

Distribution Networks and End-User Integration

After yarn is made, it goes to cable makers, textile producers, and industrial clients. The way it gets there varies by region. China has a lot of infrastructure, India is improving its logistics, and the US uses advanced tracking.

Value Addition at Each Supply Chain Stage

The supply chain adds value at every step. From preparing fibers to delivering yarn, each step makes the product better and more valuable.

Trend Analysis: Innovations and Trends in Ripcord Yarn Technology

The world of ripcord yarn technology is changing fast. New production methods are making things better and faster. These changes are affecting how ripcord yarns are made, sold, and used in many fields.

Sustainable and Eco-Friendly Production Methods

More companies are focusing on green manufacturing in ripcord yarn production. They use recycled polyester and biodegradable materials for eco-friendly options. Water use has dropped by up to 30% in new factories.

More people want yarns made in a sustainable way. This is making manufacturers look into cleaner production methods.

Automation and Digital Integration in Manufacturing

Smart factories are leading the way in ripcord yarn making. Automated systems check thread quality and tension as it’s made. This has cut down on mistakes by 25%.

Virtual models of production lines let engineers test changes without stopping work. This helps small makers compete by improving quality and saving on labor costs.

Advanced Material Science Developments

Material scientists have made hybrid yarns that are incredibly strong yet light. New coatings make them better at keeping moisture out and resisting UV rays. Some yarns even change color in certain conditions.

These advancements are opening up new uses in aerospace, medical textiles, and protective gear.

Restriction Analysis: Challenges Facing the Ripcord Yarn Industry

The global ripcord market faces big challenges that affect growth and profits. These issues vary by region but shape the industry’s future and competition.

Regulatory Hurdles and Compliance Issues

Manufacturers in the ripcord yarn sector deal with strict environmental rules. They must adjust operations to meet these rules, which change in China, India, and the US. This leads to uneven costs and barriers to market entry.

Raw Material Availability and Price Volatility

The textile industry relies on steady raw material supplies. But, ripcord producers face unpredictable price changes and supply issues. Costs for cotton, polyester, and specialty fibers have changed a lot, forcing companies to either absorb these costs or raise prices to customers.

Competitive Pressures and Market Saturation

Market saturation is a big worry as production grows faster than demand in some areas. This makes prices drop and narrows profit margins for big players. Many producers focus on specialized areas where their skills are hard to match.

Geopolitical Analysis: The Impact of Global Politics on Ripcord Yarn Production and Trade

Geopolitical tensions change the global ripcord market every day. They affect production chains and trade relationships. National security concerns now shape trade policies, with ripcord yarn at the center of these issues.

Trade Policies and International Agreements

Recent tariffs have changed how ripcord yarn is traded. The US textile industry now faces 25% duties on some yarn imports from China. This has led manufacturers to look for new sources.

At the same time, agreements like RCEP boost supply chains in Asia. This helps the China textile market reach more countries. It also helps counter restrictions from Western markets.

Regional Political Dynamics Affecting Manufacturing

Stable politics are key for making ripcord yarn. The China textile market gets support from clear policies. This helps it focus on improving technical textiles.

In contrast, the US textile industry sees changes with each new government. This makes it hard for manufacturers to plan for the future.

Shifting Global Alliances and Market Access

Global alliances now decide who gets to trade where in the global ripcord market. Countries with close ties trade more with each other. This creates two main supply chains.

One is led by China and its partners. The other is led by Western countries looking to diversify. These systems change where manufacturers invest, trying to reach both markets despite political differences.

Segmentation Type Market Analysis: Ripcord Yarn Market Segmentation by Material and Application

The ripcord yarn industry has clear market segmentation patterns. These help makers focus on what customers need. Segments are based on materials, how well they perform, and where they’re used.

Natural vs. Synthetic Ripcord Yarn Segments

The main split is between natural and synthetic fibers. Natural fibers like cotton, jute, and silk are good for the environment. They also have traditional benefits.

Synthetic fibers, such as polyester, nylon, and aramid, are stronger and more uniform. They also stand up better to the weather than natural fibers.

Performance-Based Classification Systems

Ripcord yarns are sorted by strength, breaking force, and how well they keep their shape. High-strength ripcords have ratings over 180 N. Standard ones are between 100-180 N.

This sorting helps pick the right yarn for different ripcord applications. It ensures the yarn meets the needed performance.

Emerging Specialty Categories and Niche Markets

New segments have emerged for special uses. Fire-resistant ripcords are for places where safety is key. Eco-friendly yarns are made from recycled materials, focusing on sustainability.

Ultra-thin yarns are for tiny electronics. These special types often cost more but meet exact needs.

Knowing these segments helps makers make products that meet customer needs. It also lets buyers find the best yarn for their projects.

Application Market Analysis: The Diverse Applications of Ripcord Yarn in Textiles

Ripcord yarn is key in many industries, from traditional cable making to advanced technical textiles. Its versatility has grown its use in the textile world. This has opened up new markets and solved tough manufacturing problems.

Traditional Applications in Fiber Optics and Cables

In telecom, ripcord yarn makes it easy to get to cable parts quickly and safely. It’s placed inside cables so techs can remove outer layers without harming the fiber optics.

Emerging Uses in Technical Textiles

Ripcord yarn is changing fields like aerospace, auto, and building. It makes safety gear stronger and helps in composite materials. It also boosts drainage and soil stability in geotextiles.

Innovation-Driven Applications in Consumer Products

Ripcord yarn is in many everyday items, though you might not see it. It’s in easy-open packaging and sportswear that can tear away. It’s also in smart clothes, helping them work with electronics.

Global Ripcord Yarn Market Region Analysis: Regional Market Dynamics

The global ripcord market shows different patterns in each region. Production centers around the world create a complex system. Here, old markets compete with new ones.

Manufacturers focus on what each area needs. This makes each region unique in its own way.

Established Markets vs. Emerging Regions

Western Europe and Japan lead in the ripcord market. They use new tech and focus on quality. This keeps them ahead in the game.

New areas like Southeast Asia and Latin America are growing fast. They have lower costs and a big demand for yarn.

Comparative Analysis of Production Costs and Quality

Costs vary a lot around the world. Labor in new places is 40-60% cheaper. This gives them a big edge in making yarn.

Energy costs also play a big role. Places that use coal face more environmental issues. Quality of yarn also differs. European and Japanese places usually make better yarn.

Cross-Regional Trade Flows and Dependencies

The textile world depends on complex trade networks. These connect raw materials to factories. Expertise moves from old to new markets through partnerships.

Trade deals shape how goods move and costs. But, economic stability can be a problem. It affects how yarn is made and sold.

China Ripcord Yarn Market Analysis

China is the world leader in making ripcord yarn, producing over 60% of it. The country has grown its textile industry by investing in new machines and factories. These are mainly in places like Zhejiang and Jiangsu provinces.

Production Capacity and Manufacturing Advantages

Chinese makers have big advantages in making ripcord yarn. They have easy access to cheap raw materials like polyester, nylon, and aramid fibers. Their big factories can make more yarn than smaller places can.

Chinese yarn makers have also improved their technology. They use automated spinning and quality checks to keep rejection rates low. This helps them keep prices down even as labor costs go up.

Domestic Consumption Trends and Export Markets

The demand for special ripcord yarns in China is growing. This demand is mainly for technical textiles. It helps manufacturers stay stable while they focus on selling more abroad.

Chinese yarn exports are becoming more valuable. They are focusing on making flame-retardant and high-tenacity yarns. These are needed for tough industrial uses.

Government Policies Shaping the Industry

Beijing’s policies help the yarn industry a lot. They offer incentives for new technology and innovation. Also, new rules on the environment have made yarn making cleaner, with 30% less water used since 2018.

The Belt and Road Initiative has also helped. It has opened new paths for Chinese yarn to reach more markets. This has helped them grow their share of the global yarn market.

India Ripcord Yarn Market Analysis

India is a major player in the global ripcord materials market. It combines traditional textile skills with modern manufacturing. Over the last ten years, India’s yarn production has grown a lot. This makes India a strong competitor in the world market.

Traditional Expertise and Growing Production Capabilities

The Indian textile industry is great at making ripcord yarn. This is thanks to the skills passed down through generations. These skills are now mixed with new technology, giving India an edge.

India makes about 15% of the world’s ripcord yarn. Its production is growing at over 7% each year.

Domestic Market Dynamics and Export Orientation

The demand for ripcord materials in India is going up. This is because India’s industrial sector is growing. Local makers use these yarns for things like tire cord and technical textiles.

India also exports a lot of these materials. Most of these exports go to Asia-Pacific and Africa.

Big buyers from around the world are choosing Indian suppliers. They like the good prices and quality. Many Indian producers have gotten international certifications to show they are reliable.

Infrastructure Challenges and Development Initiatives

Despite its growth, India’s ripcord materials sector faces big challenges. Problems with transport, power, and water affect production. The government is working to fix these issues.

US Ripcord Yarn Market Analysis

The United States stands out in the global ripcord yarn market. It focuses on quality, not just quantity. The US textile industry has shifted to specialized, high-value production. This uses advanced technology and skilled workers.

High-Tech Production and Innovation Leadership

American makers are at the forefront in ripcord yarn technology. They invest heavily in research and development. Their advanced factories use robots, computer systems, and quality checks to make precise products.

Reshoring Trends and Domestic Manufacturing Renaissance

A big change is happening in the US textile industry. Companies are moving their production back from abroad. This is due to higher shipping costs, concerns about intellectual property, and a desire for domestic products.

The pandemic made people realize the importance of local production. This has sped up the move back to American factories.

Market Specialization and Premium Positioning

US makers focus on specific, high-demand areas. They serve the defense, aerospace, and medical fields. These sectors need top-quality products, which justifies higher prices.

US companies innovate with products like antimicrobial yarns and ultra-strong materials. They also create custom solutions for technical needs.

Even with higher costs, the US stays competitive. Automation, specialized skills, and a focus on quality help. This strategy lets American producers excel in high-value markets, leaving mass production to others.

Future Development Analysis: The Future of Ripcord Yarn in Modern Textile Manufacturing

The world of ripcord yarn technology is changing fast. Manufacturers are using new materials and ways to make things. Labs are working on plant-based yarns that are strong but gentle on the planet. These yarns come from things like agricultural waste, showing a big change in how we think about being green.

Soon, ripcord yarns might carry data. They could track things like the weather or how long a product has been used. By adding things like carbon nanotubes and graphene, these yarns will be even stronger and lighter.

New tech is changing how we make clothes. Robots and AI help find tiny flaws and use materials better. They also let us test ideas online before making them real, saving time and money.

Working together, textile makers and tech companies are making big leaps in yarn tech. Medical and aerospace fields are getting in on the action too. They’re making smart bandages and super-strong airplane parts with these new yarns.

Competitor Analysis: Major Players in the Ripcord Yarn Market

- Avient

- DuPont, Roblon

- FIL-TEC, Gurfil

- DijitalPort

- LongVision

- Beidou

- Shinyuan Technologies

- Coats Group

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Ripcord Yarn Market Report |

| Base Year | 2024 |

| Segment by Type | · Polyester Ripcord Yarn

· Aramid Ripcord Yarn · Others |

| Segment by Application | · Automotive Industry

· Sports Equipment · Medical Devices · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Innovation in the Ripcord Yarn Market is essential for its growth. With the increasing demand for fiber optic cables due to technological advancements and connectivity requirements, there is a significant opportunity to create eco-friendly alternatives. By prioritizing sustainable materials, companies can attract environmentally conscious consumers and stand out in a competitive market.

It is also important to address challenges such as fluctuating raw material prices. Manufacturers must find ways to innovate not only in product development but also in cost management strategies to stay competitive against alternative materials.

Regional opportunities, particularly in rapidly urbanizing countries like China and India, can provide a strategic advantage. These areas have growing markets because of infrastructure development and increased technology use. The U.S., with its focus on sustainability and technological progress, also presents opportunities for growth.

By effectively navigating these factors, businesses can position themselves as leaders in the promising future of the ripcord yarn industry.

Global Ripcord Yarn Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Ripcord Yarn Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Ripcord Yarnplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Ripcord Yarn Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Ripcord Yarn Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Ripcord Yarn Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofRipcord Yarn Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is ripcord yarn and why is it important in the textile industry?

Ripcord yarn is a special type of yarn used in many textiles. It’s key in making fiber optic cables, technical textiles, and consumer goods. It adds strength, durability, and makes it easy to get to what’s inside. This makes it vital for many industries.

How do the ripcord yarn markets in China, India, and the United States differ in terms of production, consumption, and trade dynamics?

China, India, and the United States have unique features in their ripcord yarn markets. China has a huge production capacity and low costs. India uses its textile know-how and growing factories. The United States focuses on high-tech and quality, leading in premium ripcord yarns.

What are the key trends and innovations shaping the future of the ripcord yarn industry?

The ripcord yarn industry is changing with new trends and innovations. These include eco-friendly production, smart textiles, and automation. These changes are creating new uses and driving growth in the industry.

What are the major challenges and restrictions facing the global ripcord yarn industry?

The industry faces many challenges like rules and regulations, raw material issues, and competition. Overcoming these needs careful planning and teamwork among industry players.

How do geopolitical factors and international trade dynamics impact the ripcord yarn market?

Global politics and trade greatly affect the ripcord yarn industry. Changes in trade policies and alliances can impact production and market access. Businesses need to understand these global factors.