Remote Visual Inspection Market Set to Reach $2.5 Billion by 2025: Key Trends from the U.S., Germany, and Japan

In 2025, the global market reached an estimated value of USD 1.45 billion, with projections indicating growth to USD 2.65 billion by 2033 at a compound annual growth rate (CAGR) of 7.85%. This growth is driven by increasing demand for remote inspection technologies across various industries, including manufacturing, oil and gas, and infrastructure, as companies seek to enhance safety, reduce operational costs, and improve inspection efficiency.

- Last Updated:

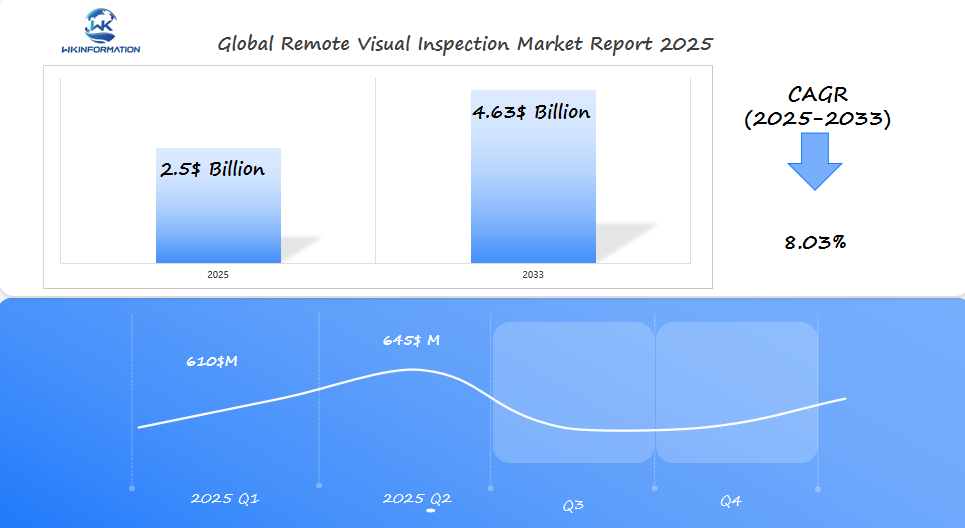

Remote Visual Inspection Market Forecast for Q1 and Q2 2025

The remote visual inspection (RVI) market is set to reach $2.5 billion in 2025, with an 8.03% CAGR projected through 2033. Estimated Q1 revenue stands at $610 million, increasing to about $645 million in Q2 as demand rises in manufacturing and infrastructure sectors.

The U.S. leads with widespread use in aerospace, oil & gas, and utilities for safety and compliance. Germany benefits from its precision manufacturing and robust automation ecosystem, fostering strong RVI adoption.

Japan contributes significantly through innovation in robotics and endoscopic technologies. The growing integration of AI and 3D imaging in inspection tools is expected to accelerate future market development.

Key Takeaways

- The RVI Market is expected to reach $2.5 billion by 2025.

- Key trends driving growth are observed in the U.S., Germany, and Japan.

- Increasing demand for efficient inspection solutions is a major growth factor.

- RVI technologies are being adopted across various industries.

- The need for cost-effective inspection processes is driving market growth.

Understanding the Upstream and Downstream Dynamics in Remote Visual Inspection

The remote visual inspection market is influenced by various upstream dynamics that shape its growth and development. To understand the complexities of this market, it’s essential to delve into the factors that drive its upstream dynamics.

Upstream Dynamics in Remote Visual Inspection

The upstream dynamics in remote visual inspection are characterized by the development and advancement of inspection technologies. These technologies are crucial for enhancing the efficiency and accuracy of remote visual inspections.

Several factors contribute to the upstream dynamics, including:

- Technological advancements in imaging and sensing technologies.

- Increased demand for remote inspection solutions in various industries.

- The need for cost-effective and efficient inspection methods.

Factors Influencing Upstream Dynamics

The upstream dynamics in remote visual inspection are influenced by several key factors. These include:

- Advances in artificial intelligence and machine learning, which enhance the capabilities of inspection technologies.

- The growing adoption of remote visual inspection technologies in industries such as oil and gas, aerospace, and manufacturing.

- The need for improved safety and reduced risk in inspection processes.

Understanding these factors is crucial for stakeholders to make informed decisions and drive growth in the remote visual inspection market.

Emerging Trends in the Remote Visual Inspection Industry

Emerging trends in the remote visual inspection industry are set to reshape the future of industrial inspection. The integration of advanced technologies is changing how inspections are carried out, making them more efficient and precise.

Trends Shaping the Future of Remote Visual Inspection

Several key trends are driving the evolution of RVI. One significant trend is the adoption of AI-powered inspection tools, which enhance the accuracy and speed of inspections. Additionally, the increasing use of drones for inspection purposes is revolutionizing the way visual inspections are carried out, especially in hard-to-reach areas.

The use of augmented reality (AR) and virtual reality (VR) in remote visual inspection is another emerging trend. These technologies provide inspectors with a more immersive and detailed view of the inspection area, improving decision-making.

| Trend Description Impact AI-Powered Inspection Tools | Utilize artificial intelligence to analyze inspection data | Enhanced accuracy and speed of inspections |

| Drones for Inspection | Use drones equipped with high-resolution cameras for visual inspections | Increased accessibility to hard-to-reach areas |

| AR and VR in RVI | Employ augmented and virtual reality to enhance inspection visualization | Improved decision-making through detailed visualization |

These emerging trends are not only enhancing the capabilities of remote visual inspection but are also opening up new opportunities for industries that rely on inspection services. As technology continues to evolve, we can expect to see further innovations in the RVI industry.

Challenges and Barriers to Growth in Remote Visual Inspection

As the remote visual inspection market continues to evolve, it is confronted with numerous challenges that require innovative solutions. The industry’s growth is influenced by various factors, including technological advancements and the need for skilled personnel.

Challenges Facing the Remote Visual Inspection Market

The remote visual inspection market faces several challenges, including high initial investment costs and the requirement for specialized training for personnel operating inspection equipment. High-quality equipment and skilled operators are crucial for accurate inspections, but they come at a cost.

1. Complexity of Technology

The complexity of remote visual inspection technology also poses a barrier, as it demands a certain level of technical expertise.

2. Integration Issues

Moreover, the integration of remote visual inspection with existing systems can be challenging, requiring significant adjustments.

3. Cost Factors

High initial investment costs can deter potential users from adopting this technology.

To overcome these barriers, companies in the remote visual inspection market are focusing on reducing costs through technological advancements and improving the user experience. Training programs are being developed to enhance the skills of personnel, making the technology more accessible.

Furthermore, the development of more user-friendly and integrated systems is underway, aiming to simplify the adoption process for new users. By addressing these challenges, the remote visual inspection market is poised to achieve significant growth.

The industry’s ability to adapt to these challenges will be crucial in determining its future success. As companies continue to innovate and improve their offerings, the barriers to growth are likely to diminish, paving the way for expanded adoption of remote visual inspection technologies.

Geopolitical Impacts on Remote Visual Inspection Solutions

As global politics continue to change, the remote visual inspection industry faces new challenges and opportunities that can impact its growth. The complex interactions of international politics and trade policies are increasingly influencing the market for remote visual inspection solutions.

Geopolitical Factors Influencing Remote Visual Inspection

Several geopolitical factors are affecting the remote visual inspection market.

Negative Impacts

Trade tensions and sanctions can disrupt the supply chain, impacting the availability of critical inspection technologies. Furthermore, regional conflicts and political instability can deter investment in infrastructure, thereby affecting the demand for remote visual inspection solutions.

Positive Impacts

On the other hand, geopolitical factors can also drive the adoption of remote visual inspection technologies. For instance, the need for enhanced security and surveillance in politically volatile regions can accelerate the deployment of advanced inspection solutions.

Some specific geopolitical factors to consider include:

- Trade policies and tariffs affecting the import/export of inspection equipment

- Regional conflicts influencing infrastructure investment and inspection needs

- Sanctions and export controls impacting the availability of certain technologies

The remote visual inspection industry must navigate these complex geopolitical landscapes to ensure resilience and growth. By understanding the geopolitical factors at play, stakeholders can better anticipate challenges and capitalize on emerging opportunities.

Remote Visual Inspection Market Segmentation: Industries and Technologies

Understanding the segmentation of the remote visual inspection market is crucial for identifying industry trends and technological advancements. The market is broadly categorized into various industries and technologies, each presenting unique growth opportunities and challenges.

Industry Segmentation in Remote Visual Inspection

The remote visual inspection market is segmented into several key industries, including oil and gas, aerospace, and power generation. Each of these industries utilizes remote visual inspection technologies for different purposes, such as predictive maintenance, quality control, and safety inspections.

Key Industries:

- Oil and Gas: Utilizes remote visual inspection for pipeline inspection, rig inspection, and equipment monitoring.

- Aerospace: Employs remote visual inspection for aircraft inspection, engine inspection, and component analysis.

- Power Generation: Uses remote visual inspection for turbine inspection, equipment monitoring, and predictive maintenance.

Technological Segmentation in Remote Visual Inspection

The technological segmentation of the remote visual inspection market includes advancements in camera technologies, robotics, and software solutions. These technologies enhance the capabilities of remote visual inspection, making it more efficient and accurate.

| Technology | Description | Application |

| High-Resolution Cameras | Advanced cameras providing high-resolution images for detailed inspection. | Used in oil and gas, aerospace, and power generation for detailed visual inspections. |

| Robotics | Robotic systems that can navigate complex environments for remote inspection. | Applied in industries requiring inspection in hazardous or hard-to-reach areas. |

| Software Solutions | Advanced software for image analysis, defect detection, and reporting. | Used across industries for enhancing inspection accuracy and efficiency. |

The segmentation of the remote visual inspection market into industries and technologies highlights the diverse applications and growth prospects of this technology. As industries continue to adopt remote visual inspection solutions, the market is expected to witness significant advancements and expansions.

Applications Driving the Growth of Remote Visual Inspection

Remote visual inspection is transforming industries with its diverse applications, including infrastructure inspection and aerospace. The flexibility of RVI technology is a key reason behind its increasing use in different sectors.

Key Applications of Remote Visual Inspection

Several key applications are driving the growth of the remote visual inspection market. These include the inspection of pipelines, storage tanks, and aircraft engines. The use of RVI in these areas enhances safety, reduces inspection time, and minimizes costs.

Remote Visual Inspection Applications

In the aerospace industry, RVI is used for the inspection of aircraft engines and other critical components. This helps in reducing downtime and improving the overall efficiency of maintenance operations.

The following table highlights some of the key applications of remote visual inspection across different industries:

| Industry Application Benefits Oil & Gas | Pipeline Inspection | Enhanced safety, reduced environmental impact |

| Aerospace | Aircraft Engine Inspection | Reduced downtime, improved maintenance efficiency |

| Energy | Storage Tank Inspection | Improved safety, reduced maintenance costs |

These applications are driving the growth of the RVI market, as industries continue to seek more efficient and safe inspection methods. As technology advances, we can expect to see even more innovative applications of remote visual inspection.

The remote visual inspection technology is revolutionizing various sectors by providing a safer and more efficient alternative to traditional inspection methods.

Regional Insights: Key Global Markets for Remote Visual Inspection

The global remote visual inspection market is diverse, with several key regions driving growth. Regional insights into the market reveal a complex landscape influenced by technological advancements, industry demands, and geographical factors.

Regional Market Analysis

The remote visual inspection market can be segmented into several key regions, each with its unique characteristics and growth drivers. North America, Europe, and Asia-Pacific are among the leading regions in this market.

1. North America

Driven by technological advancements and a strong industrial base, North America is a significant market for remote visual inspection.

2. Europe

Europe’s market is characterized by a strong emphasis on industrial safety and regulatory compliance.

3. Asia-Pacific

This region is experiencing rapid growth due to increasing industrialization and infrastructure development.

The diversity in regional markets is also reflected in the varying adoption rates of remote visual inspection technologies.

Growth prospects in these regions are influenced by factors such as investment in infrastructure, technological innovation, and the presence of key industry players.

Understanding these regional dynamics is crucial for stakeholders looking to capitalize on the opportunities in the remote visual inspection market.

U.S. Remote Visual Inspection Market: Key Drivers and Trends

The presence of key industries in the U.S. is driving the demand for remote visual inspection solutions. The U.S. market is a significant hub for various industries, including oil and gas, aerospace, and power generation, which are increasingly adopting remote visual inspection technologies.

Drivers of the U.S. Remote Visual Inspection Market

Several factors are driving the growth of the remote visual inspection market in the U.S. Technological advancements and the need for efficient inspection methods are key drivers. The oil and gas industry, for instance, is leveraging remote visual inspection to enhance the safety and efficiency of operations.

The aerospace sector is another significant contributor, using remote visual inspection for the maintenance and inspection of aircraft. This not only reduces downtime but also improves safety standards.

Trends in the U.S. Remote Visual Inspection Market

One of the emerging trends in the U.S. remote visual inspection market is the adoption of artificial intelligence (AI) and machine learning (ML) technologies. These technologies are enhancing the capabilities of remote visual inspection systems, allowing for more accurate and efficient inspections.

Another trend is the increasing use of remote visual inspection in infrastructure projects. With the U.S. investing heavily in infrastructure development, the demand for remote visual inspection solutions is expected to rise.

- The integration of AI and ML in remote visual inspection systems.

- Growing demand from the oil and gas and aerospace industries.

- Increased adoption in infrastructure projects.

Germany’s Innovation in Remote Visual Inspection Technologies

With its strong engineering background, Germany is leading the way in creating remote visual inspection technologies. The country’s strong industrial foundation, combined with its focus on research and development, has made Germany a top player in the remote visual inspection industry.

Advancements in Inspection Technologies

Germany’s contributions to remote visual inspection are diverse, including improvements in hardware, software, and methods. High-resolution cameras, sophisticated sensors, and advanced data analytics are some of the key areas where German innovation is making a significant impact.

Integration of AI and ML

The integration of artificial intelligence (AI) and machine learning (ML) in remote visual inspection technologies is another area where Germany is making notable progress. By using AI and ML, inspection processes are becoming more efficient, accurate, and reliable.

“The use of remote visual inspection technologies is changing the way industries do inspections, making it safer, more efficient, and cost-effective.”

Development of Standards and Best Practices

Germany’s innovation in remote visual inspection technologies is not limited to the technology itself but also includes the development of standards and best practices. This is crucial for ensuring the widespread adoption and effective implementation of these technologies across various industries.

Key Areas of Innovation

- Advanced imaging technologies

- AI and ML integration

- Enhanced data analytics capabilities

- Development of industry-specific inspection solutions

| Innovation Area | Description | Impact |

| Advanced Imaging | High-resolution cameras and sensors | Improved inspection accuracy |

| AI and ML Integration | Automated defect detection and analysis | Increased efficiency and reduced costs |

| Data Analytics | Advanced data processing and insights | Enhanced decision-making capabilities |

Germany’s commitment to innovation in remote visual inspection technologies is expected to continue driving growth and advancements in the field. As industries increasingly adopt these technologies, Germany’s contributions are likely to play a crucial role in shaping the future of remote visual inspection.

Japan’s Expanding Remote Visual Inspection Market

Japan’s remote visual inspection market is experiencing rapid growth, driven by technological advancements and increasing demand across various industries. The country’s strong manufacturing base and focus on technological innovation are key factors contributing to this growth.

The growth prospects in Japan’s remote visual inspection market are significant, with industries such as manufacturing, power generation, and oil & gas driving the demand for RVI technologies. These industries require efficient and safe inspection methods, which RVI solutions provide.

Growth Prospects in Japan’s Remote Visual Inspection Market

The increasing adoption of RVI technologies in Japan is due to their ability to improve inspection efficiency and lower costs. Key industries driving this trend include manufacturing, where RVI is used for quality control and predictive maintenance, and power generation, where it is used for inspecting equipment and infrastructure.

| Industry Application of RVI Benefits Manufacturing | Quality control, predictive maintenance | Enhanced efficiency, reduced downtime |

| Power Generation | Equipment inspection, infrastructure inspection | Improved safety, reduced maintenance costs |

| Oil & Gas | Pipeline inspection, rig inspection | Increased safety, reduced risk of accidents |

The future of Japan’s RVI market looks promising, with ongoing advancements in technology and increasing adoption across industries. As the market continues to grow, we can expect to see more innovations and applications of RVI technologies.

Future Outlook for Remote Visual Inspection

Remote visual inspection is on the brink of a major change, with new technologies ready to reshape the industry. The future outlook for remote visual inspection looks very promising, driven by advancements in technologies such as AI, robotics, and drones. These innovations are expected to improve the efficiency, accuracy, and safety of visual inspections in various industries.

Emerging Opportunities in Remote Visual Inspection

The combination of AI and machine learning algorithms with remote visual inspection technologies is creating new opportunities for predictive maintenance and defect detection. This integration allows for the analysis of complex data sets, providing insights that can prevent equipment failures and reduce downtime.

Another emerging opportunity is the use of drones equipped with high-resolution cameras for remote visual inspection in industries such as construction, oil and gas, and infrastructure. Drones can access hard-to-reach areas, reducing the need for manual inspections and enhancing safety.

Key Emerging Trends:

- Advancements in AI and machine learning for enhanced data analysis

- Increased adoption of drones for remote inspections

- Integration of robotics for improved inspection efficiency

The future of remote visual inspection will also be influenced by the development of more advanced software solutions. These improvements will enable better data management, analysis, and visualization, further enhancing the capabilities of remote visual inspection technologies.

| Industry | Emerging Opportunities | Potential Impact |

| Construction | Use of drones for site inspections | Improved safety and reduced inspection time |

| Oil and Gas | AI-powered predictive maintenance | Reduced downtime and increased efficiency |

| Infrastructure | Robotics for bridge and road inspections | Enhanced inspection accuracy and safety |

Competitive Landscape in the Remote Visual Inspection Market

- Baker Hughes Company (Waygate Technologies) —— Houston, Texas, USA

- EVIDENT (Olympus) —— Tokyo, Japan

- Eddyfi Technologies —— Québec City, Québec, Canada

- Gradient Lens —— Rochester, New York, USA

- Nexxis —— Perth, Western Australia, Australia

- VISCOY —— Singapore

- Lenox Instrument Company —— Trevose, Pennsylvania, USA

- KARL STORZ —— Tuttlingen, Germany

- WOHLER —— Bad Wünnenberg, Germany

- JIREH Industries —— Ardrossan, Alberta, Canada

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Remote Visual Inspection Market Report |

| Base Year | 2024 |

| Segment by Type | · Robotic Systems

· Drones · Automated Devices |

| Segment by Application | · Industrial Tank Inspection

· Offshore Oil Rigs · Underwater Pipelines · Infrastructure Monitoring · Aerospace Components |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The remote visual inspection market is set for significant growth, driven by advancements in technology and increasing demand across various industries. As discussed, the market is expected to reach $2.5 billion by 2025, with key trends emerging from the U.S., Germany, and Japan.

Market Outlook

The future prospects of the remote visual inspection market look promising, with emerging opportunities in industries such as aerospace, oil and gas, and manufacturing. The adoption of remote visual inspection technologies is expected to drive industry growth, improve efficiency, and reduce costs.

As the market continues to evolve, key players are likely to focus on innovation and strategic partnerships to stay competitive. The increasing demand for remote visual inspection solutions is expected to drive further investment in research and development, leading to new and innovative applications.

Global Remote Visual Inspection Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Remote Visual Inspection Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Remote Visual InspectionMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Remote Visual Inspectionplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Remote Visual Inspection Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Remote Visual Inspection Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Remote Visual Inspection Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofRemote Visual InspectionMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Remote Visual Inspection?

Remote Visual Inspection (RVI) is a technique used to inspect and examine equipment, infrastructure, or other assets without direct human intervention, often using cameras, drones, or other technologies.

What are the benefits of Remote Visual Inspection?

The benefits of RVI include:

- Reduced costs

- Increased efficiency

- Improved safety

- Enhanced accuracy

RVI eliminates the need for physical presence in hazardous or hard-to-reach areas, making it a valuable tool in various industries.

What industries use Remote Visual Inspection?

RVI is used in various industries, including oil and gas, aerospace, power generation, manufacturing, and construction, among others, to inspect equipment, infrastructure, and assets.

What technologies are used in Remote Visual Inspection?

RVI employs various technologies, including:

- Cameras

- Drones

- Robotics

- Artificial Intelligence (AI)

- 3D Modeling

These technologies are used to capture and analyze visual data.

How does Remote Visual Inspection improve safety?

RVI improves safety by reducing the need for personnel to enter hazardous or confined spaces, thereby minimizing the risk of accidents and injuries.

What is the role of AI in Remote Visual Inspection?

AI is used in RVI to analyze visual data, detect defects, and predict potential failures, enabling proactive maintenance and reducing downtime.

Can Remote Visual Inspection be used for predictive maintenance?

Yes, RVI can be used for predictive maintenance by identifying potential issues before they become major problems, allowing for scheduled maintenance and reducing unplanned downtime.

What are the limitations of Remote Visual Inspection?

The limitations of RVI include:

- The need for high-quality visual data

- Potential interference or distortion

- The requirement for skilled personnel to interpret the data

How is Remote Visual Inspection used in the oil and gas industry?

In the oil and gas industry, RVI is used to inspect pipelines, storage tanks, and equipment, helping to detect corrosion, damage, or other potential issues.

What is the future of Remote Visual Inspection?

The future of RVI is expected to be shaped by advancements in technologies such as AI, drones, and robotics, leading to increased adoption and applications across various industries.