2025 Remote Inspection Software Market Booming Unlocking $11.01 Billion Opportunities in US, UK, and Germany

Discover comprehensive insights into the Remote Inspection Software Market, projected to reach USD 11.01 billion by 2025. This market analysis explores key growth drivers, including automation adoption, regulatory compliance demands, and technological advancements across US, UK, and German markets. Learn about emerging trends, industry challenges, and future innovations shaping this rapidly evolving sector.

- Last Updated:

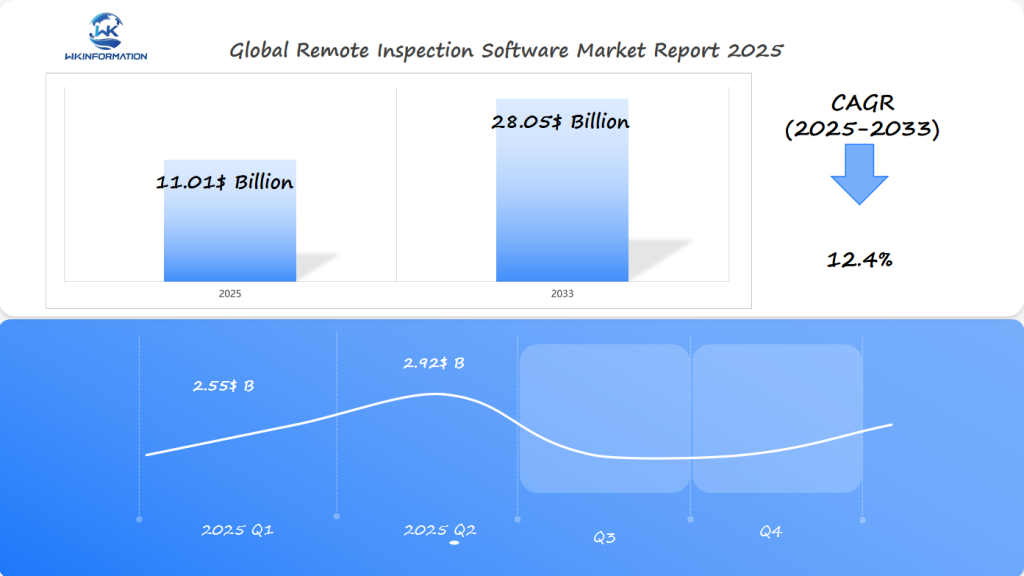

Remote Inspection Software Market Projection for Q1 and Q2 2025

The global remote inspection software market is expected to be valued at USD 11.01 billion in 2025, growing at a CAGR of 12.4% from 2025 to 2033.

In Q1 2025, the market is forecasted to reach approximately USD 2.55 billion, while Q2 2025 is projected to expand to around USD 2.92 billion. The US, UK, and Germany are leading this market expansion, driven by increasing demand for AI-powered remote inspection solutions across industries such as manufacturing, construction, and infrastructure management. The US remains at the forefront due to widespread adoption in industrial automation and regulatory compliance. The UK’s emphasis on smart infrastructure and digital transformation fuels significant growth, while Germany’s expertise in engineering and industrial applications positions it as a key contributor to market development.

Remote Inspection Software Market Supply Chain and Industry Dynamics

The supply chain for remote inspection software is a complex network that supports the efficient deployment and operation of various technological tools. At its core, this supply chain involves multiple layers, starting from software developers who design and create the tools, to distributors who manage the logistics of delivering these solutions to end-users.

Key Stakeholders in the Market

- Software Providers: These are companies specializing in developing comprehensive solutions for remote inspections. They play a crucial role in innovating features such as real-time data analytics and integration with other enterprise systems.

- End-Users: This group includes industries like manufacturing, healthcare, construction, and automotive sectors. End-users drive demand by implementing these solutions to enhance their inspection processes, aiming for increased operational efficiency and compliance with safety standards.

Dynamics Affecting Industry Performance

Several dynamics shape the performance of the remote inspection software market:

- Technological Advancements: Innovations in AI, drones, and augmented reality are continuously redefining what’s possible in remote inspections. These advancements allow for more precise and efficient inspection processes.

- Regulatory Compliance: The need to adhere to local and international regulations regarding safety and quality standards pushes companies toward adopting advanced software tools that ensure compliance.

- Market Demand: As industries grow more reliant on technology for operational excellence, the demand for robust and scalable remote inspection solutions is expected to surge. This demand drives competition among software providers to offer superior functionalities at competitive prices.

Understanding these elements is essential for stakeholders aiming to navigate the complexities of this expanding market efficiently.

Emerging Trends and Market Growth Drivers for Remote Inspection Software in 2025

The remote inspection software market is undergoing significant changes due to several important trends and factors driving its growth. One of the main influences is the increasing use of automation processes, which are transforming how inspections are carried out in various industries. Automation not only makes operations more efficient but also improves accuracy, making it an essential tool for modern businesses.

Key Factors Shaping the Remote Inspection Software Market

1. Growing Focus on Regulatory Compliance

A major factor propelling this market is the rising importance placed on regulatory compliance, particularly regarding health and safety standards. As regulations become stricter, organizations are turning to remote inspection software to ensure they meet these requirements and avoid potential penalties. This trend underscores the software’s role in maintaining operational integrity while prioritizing employee well-being.

2. Impact of COVID-19 on Market Dynamics

When discussing market dynamics, we cannot ignore the influence of COVID-19. The pandemic hastened the transition towards software-based inspection management as companies sought ways to continue their operations while adhering to social distancing measures. This unexpected catalyst has resulted in a surge in demand for solutions that enable remote work, thereby driving market growth.

3. Technological Advancements Enhancing Capabilities

Innovations such as artificial intelligence (AI), augmented reality (AR), and big data analytics are further enhancing the capabilities of remote inspection software, allowing for more comprehensive analyses and real-time decision-making.

4. Industry Applications Driving Demand

Industries like manufacturing, healthcare, construction, and automotive are increasingly implementing these technologies, driving demand for advanced solutions that cater to their unique requirements.

As these trends continue to develop, the remote inspection software market is expected to grow significantly, creating lucrative opportunities for stakeholders who are aware of technological advancements and changing regulatory landscapes.

Challenges and Market Barriers Impacting Remote Inspection Software Expansion

Entering the Remote Inspection Software Market can be tough for new companies. Here are some of the main challenges they face:

1. Competition from Established Players

One of the biggest challenges is the barriers to entry caused by the competitive landscape. Existing companies with advanced technology have a significant advantage over newcomers. To stand out in this crowded market, new businesses need to invest heavily in research and development to provide innovative solutions.

2. Complex Regulations

Another major challenge is dealing with regulatory hurdles. Companies creating remote inspection software must comply with various international standards and local laws, which can be complicated and expensive. For example, different safety and data protection rules in regions like the US, UK, and Germany require customized solutions that meet specific regulations. This complexity can slow down software development and deployment, affecting how quickly products can be launched.

3. Resistance to Change

The expansion of the market is also hindered by resistance to change in traditional inspection practices. Many industries that depend on inspections have established processes and may be reluctant to embrace new technologies due to concerns about reliability, training costs, or potential disruptions. Convincing stakeholders of the benefits of automation and digital solutions requires strong evidence of improved efficiency and cost savings.

Understanding these market challenges is crucial for companies aiming to succeed in the remote inspection software field. By efficiently addressing regulatory compliance issues and demonstrating clear advantages over traditional methods, businesses can overcome these obstacles and tap into the growing opportunities within this dynamic market.

Geopolitical Factors Reshaping the Remote Inspection Software Market Landscape

Geopolitical factors are playing an increasingly critical role in shaping the remote inspection software market landscape. As countries navigate complex international relations, technology adoption can be significantly influenced by these dynamics.

Influence of Geopolitical Tensions on Technology Adoption

- Trade Wars and Tariffs: Trade disputes, such as those between major economies like the US and China, can lead to increased tariffs and restrictions. These trade tensions may affect the cost and availability of remote inspection technologies, impacting their adoption.

- Data Sovereignty Concerns: Nations are becoming more protective of their data, which can influence how software solutions are developed and deployed internationally. For instance, strict data localization laws may limit the use of cloud-based remote inspection solutions in certain regions.

Regulatory Differences Across Regions

- United States: The US regulatory environment is often characterized by its focus on innovation and flexibility, facilitating rapid adoption of new technologies. However, compliance with federal standards remains crucial for market entry.

- United Kingdom: The UK emphasizes stringent health and safety regulations, encouraging the use of remote inspection software to meet compliance requirements efficiently.

- Germany: Known for its robust industrial base, Germany’s regulatory framework supports technological integration while maintaining high standards for quality assurance.

Impact of International Relations on Market Dynamics

International relations can directly impact market dynamics by altering trade agreements and affecting cross-border collaborations:

- Export Controls: Restrictions on technology exports can limit access to advanced inspection tools in certain markets.

- Investment Flows: Diplomatic relations influence foreign direct investment (FDI), which can either bolster or hinder the growth of remote inspection software firms depending on geopolitical climates.

These geopolitical factors collectively shape how remote inspection solutions are adopted globally, necessitating strategic navigation by stakeholders across different regions.

Remote Inspection Software Market Segmentation by Type and Key Demand Areas

Market segmentation within the remote inspection software sector reveals notable diversity in type of software solutions, particularly when considering deployment modes and demand areas. Two primary deployment modes stand out: on-premise and cloud-based solutions.

Deployment Modes

- On-Premise Solutions: Traditionally favored for their perceived security advantages, on-premise solutions have dominated the market. These systems are installed directly on a company’s local hardware, offering full control over data management and privacy. This mode is often preferred by industries with stringent regulatory standards, such as finance or defense, where data sensitivity is paramount.

- Cloud-Based Solutions: Gaining traction rapidly, cloud-based solutions offer flexibility and scalability that on-premise systems might lack. Such platforms enable remote access to inspection tools and data from anywhere with internet connectivity. As businesses shift towards remote operations, cloud-based solutions are expected to witness significant growth, driven by their ability to seamlessly integrate with other digital processes.

Key Demand Areas Across Industries

The adoption of remote inspection software spans various sectors, each presenting unique demands:

- Manufacturing: In this sector, the focus is on enhancing productivity and ensuring compliance with industrial standards. Remote inspection tools enable real-time monitoring of equipment and processes, reducing downtime and improving efficiency.

- Healthcare: Driven by the necessity for strict adherence to health regulations, healthcare institutions are increasingly utilizing remote inspection software to maintain operational integrity. These tools facilitate regular facility checks without disrupting patient care services.

This segmentation underscores the varied applications of remote inspection software across industries, each leveraging specific features according to their operational needs and regulatory environments.

Application Scope of Remote Inspection Software and Industry Adoption

Remote inspection software has found significant applications across various sectors, each leveraging this technology to enhance operational efficiency and ensure compliance with industry standards.

1. Construction Sector

In construction, remote inspection software is utilized for real-time site inspections and monitoring. It allows project managers to oversee multiple sites from a centralized location, ensuring adherence to safety standards and project timelines. Tools like drones are often integrated with the software to provide aerial views and detailed site analyses, reducing the need for on-site visits.

2. Automotive Industry

The automotive sector benefits from remote inspection software by streamlining vehicle inspections during manufacturing. This technology facilitates quality control processes, enabling manufacturers to detect defects early in the production line. AI-driven analytics within the software assist in predictive maintenance, reducing downtime and enhancing vehicle reliability.

Across these industries, the adoption rates of remote inspection software are rising due to its ability to lower costs and improve accuracy. The shift towards digital solutions is propelled by the need for efficient data management and regulatory compliance. Small and medium enterprises (SMEs) are increasingly adopting these tools as they offer scalable solutions that fit diverse operational needs.

The versatility of remote inspection software ensures it remains integral to sectors focused on maintaining high-quality standards while optimizing resources. As more industries recognize its advantages, adoption rates are poised to escalate, further cementing its role in modern industrial practices.

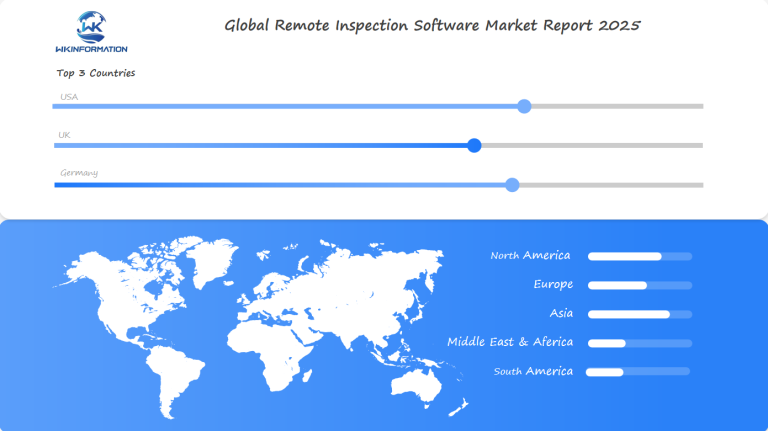

Global Remote Inspection Software Market Regional Growth and Forecast

The global market analysis for remote inspection software highlights significant regional disparities in growth rates and adoption levels. The United States, in particular, serves as a powerhouse due to its investment in automation and regulatory compliance.

In Europe, the UK and Germany are pivotal players shaping the market landscape. These countries benefit from advanced technological frameworks and supportive regulations that encourage remote inspection practices. Germany’s manufacturing prowess combined with the UK’s innovation-driven economy propels their roles in this sector. Both nations exhibit strong growth trajectories, underpinned by investments in AI and IoT technologies that enhance remote inspection capabilities.

Key Regional Insights:

- North America:

- Projected to maintain a leading position with significant investments in AI-driven inspection tools.

- Key industries include aerospace, automotive, and manufacturing sectors.

- Europe:

- The UK focuses on leveraging data analytics and cloud-based solutions for broader application scope.

- Germany emphasizes integration with existing industrial processes to optimize efficiency.

Looking towards 2033, these regions are expected to continue driving innovation within the remote inspection software market. The focus will likely remain on integrating emerging technologies such as drones and augmented reality to further enhance inspection accuracy and efficiency across various industries.

This evolving landscape presents substantial opportunities for growth as companies seek to capitalize on technological advancements while navigating complex regulatory environments.

US Remote Inspection Software Market Trends and Competitive Strategies

Key Market Drivers

Several factors are driving this market’s growth:

-

Automation: Many industries are increasingly adopting automation to improve efficiency in inspection processes.

-

Regulatory Compliance: Stricter regulatory standards are pushing companies to seek advanced software solutions to ensure compliance.

-

Technological Integration: The integration of AI, IoT, and cloud computing is enhancing the capabilities of remote inspection software, making it more efficient and capable of handling complex tasks.

-

Regional Leadership: The US continues to lead in this market, driven by technological advancements and a strong regulatory environment.

Market Dynamics and Growth Factors

Current Market Trends

-

Digital Transformation: Cloud-based solutions are becoming more prevalent, and mobile-first approaches in software development are gaining traction. Additionally, real-time data analytics integration allows for more effective and timely decision-making.

-

Industry Adoption: The manufacturing sector is currently leading in the implementation of remote inspection software, but the construction industry is also growing rapidly in this area. Furthermore, the healthcare sector is emerging as a key adopter, utilizing remote inspection for equipment maintenance and monitoring.

Competitive Landscape

-

Market Leaders: Established software providers dominate the market, often securing large shares through strategic partnerships that foster innovation. These leaders focus on offering comprehensive, all-in-one solutions for industries.

-

Emerging Players: Smaller, niche market specialists and innovation-driven startups are entering the field, particularly by targeting specific regional needs or specialized market demands.

Future Outlook and Opportunities

Technology Advancements

Several emerging technologies will play a critical role in shaping the future of the remote inspection software market:

-

AI and Machine Learning integration will enable more intelligent analysis and decision-making.

-

Augmented Reality (AR) applications will enhance the inspection process by providing real-time overlays and interactive guidance.

-

Drone technology will increasingly be incorporated for remote inspections in areas like construction and infrastructure.

-

IoT sensor integration will further streamline inspections by providing real-time data from connected devices.

Growth Opportunities

-

Industry-Specific Solutions: Tailored software solutions for different industries will become more common. Companies will develop customized features for unique requirements and offer solutions that ensure regulatory compliance in specific sectors.

-

Regional Expansion: There is significant growth potential in emerging markets. Companies can capitalize on this by forming cross-border collaborations and developing local partnerships to better meet regional needs.

Challenges and Considerations

Market Barriers

Several challenges persist, including:

-

Complex regulatory environments, which require companies to navigate strict compliance guidelines.

-

High initial investment in technology and infrastructure, making adoption more difficult for smaller organizations.

-

Technical infrastructure needs, such as robust internet connectivity, which can be a barrier in some regions.

-

Training and implementation challenges as businesses transition to new software systems.

UK Remote Inspection Software Market Performance and Market Demand

The UK’s market shows particular strength due to several key factors, such as a robust technological infrastructure, an advanced regulatory framework, and the increasing implementation of industrial automation. Additionally, the growing focus on workplace safety compliance is driving demand for digital inspection solutions.

Key Market Performance Indicators

The market’s performance is largely shaped by:

-

A strong technological infrastructure that supports the widespread adoption of remote inspection software.

-

An advanced regulatory framework, which promotes the shift towards digital inspection solutions to meet safety and quality standards.

-

A high rate of industrial automation implementation, streamlining inspection processes across various sectors.

-

A growing emphasis on workplace safety compliance, particularly in industries like manufacturing and construction.

Market Demand Drivers

The demand for remote inspection software in the UK is being driven by the ongoing digital transformation across industries. The increasing adoption of automation processes is enhancing operational efficiency, while the integration of AI and machine learning capabilities enables real-time data analysis and decision-making. Furthermore, the rising demand for cloud-based inspection solutions provides businesses with the flexibility and scalability to manage vast amounts of inspection data. The shift toward remote work environments, accelerated by the global pandemic, has further heightened the need for remote inspection capabilities, enabling industries to maintain productivity despite physical distance limitations.

Regulatory compliance also plays a crucial role in driving the demand for remote inspection software. As health and safety standards become stricter, industries are under pressure to continuously monitor and report their operations. This has led to an increased adoption of remote inspection tools to ensure compliance with safety regulations. Additionally, quality assurance and environmental compliance are growing concerns, prompting businesses to implement systems that can ensure products meet safety standards while adhering to environmental sustainability guidelines. With the tightening of data protection regulations, there is also a greater focus on securing sensitive inspection data, further pushing the need for advanced remote inspection technologies.

Market Growth Sectors

Several sectors are driving the market growth of remote inspection software. In manufacturing and industrial, it enhances quality control, equipment maintenance, and safety compliance monitoring. In construction and infrastructure, it supports building inspections, site safety monitoring, and project tracking. In healthcare and pharmaceuticals, it ensures facility inspections, equipment monitoring, and regulatory compliance. These applications help improve efficiency, reduce downtime, and ensure adherence to safety and quality standards, making remote inspection solutions essential across industries.

Germany Remote Inspection Software Market Expansion and Investment Trends

The German remote inspection software market is experiencing substantial growth, positioning the country as a key player in the European market. This expansion is fueled by various factors, such as Germany’s strong manufacturing base, government initiatives supporting digital transformation, and a solid regulatory framework. The country’s well-developed technological infrastructure further supports the rapid adoption of digital inspection solutions across various sectors.

Market Growth Drivers

Key drivers of market growth in Germany include a strong manufacturing base, particularly in automotive and heavy machinery sectors, which creates consistent demand for advanced inspection solutions. The German government’s Industry 4.0 initiatives support digital transformation in traditional manufacturing industries. Strict regulatory frameworks require robust inspection tools for compliance with quality, safety, and environmental standards. Additionally, Germany’s well-established technological infrastructure, including advanced cloud computing and mobile technology, facilitates the seamless implementation of remote inspection software across various industries.

Key Market Segments

The demand for remote inspection software in Germany is driven by several key sectors. In manufacturing, the automotive sector relies on production line monitoring and vehicle inspections, while heavy machinery inspections ensure compliance with safety and operational standards. Quality control automation and production line monitoring help identify issues early and maintain consistent product quality.

In infrastructure, building inspections ensure structural integrity and safety compliance, while public works monitoring focuses on bridges, roads, and tunnels to prevent maintenance delays. Additionally, transportation system checks and utility infrastructure assessments enhance the reliability and safety of critical systems.

Technology Focus Areas

Germany is focusing on several key technological areas to enhance remote inspection capabilities:

-

AI Integration:

Predictive maintenance, powered by AI algorithms, helps predict when equipment requires maintenance, reducing downtime and costs. Automated defect detection uses AI to automatically identify defects during inspections, enhancing accuracy. Real-time analysis capabilities offer immediate insights into inspection data, while machine learning algorithms enable systems to learn from previous inspections, continuously improving detection accuracy and efficiency.

-

IoT Implementation:

IoT-enabled sensor networks monitor equipment and infrastructure, providing real-time data for remote inspections. Data collection systems gather inspection data for further analysis and reporting, while remote monitoring capabilities allow real-time data collection from distant locations. Connected device ecosystems integrate various IoT devices, enhancing inspection capabilities and improving overall efficiency.

Market Opportunities

Growth opportunities in the German remote inspection software market include software customization for specific industries, integration services with legacy systems, training programs to upskill workers, and consulting services for effective implementation and optimization of inspection technologies.

Future Innovations and AI Integration in Remote Inspection Software

Potential Future Innovations

Remote inspection software continues to evolve with potential future innovations poised to transform the industry. The integration of artificial intelligence (AI) is at the forefront, enhancing capabilities by providing predictive analytics and automated anomaly detection. AI technologies are expected to revolutionize inspections by enabling real-time decision-making and reducing human errors.

Role of AI Technologies

AI’s role in remote inspections is vast; it facilitates enhanced data processing capabilities and offers insights that improve efficiency and accuracy. Machine learning algorithms contribute to more sophisticated analysis, allowing systems to learn from data patterns and suggest optimal inspection routes or identify potential issues before they escalate.

Predictions for Technological Advancements

Looking ahead, technological advancements are likely to include increased use of augmented reality (AR) for immersive inspection experiences and drone technology for accessing hard-to-reach areas safely. These innovations aim to streamline processes further while ensuring comprehensive inspection coverage.

Major Players in the Market

Key players such as ABB Ltd., Siemens AG, and General Electric dominate the competitive landscape. Each company employs distinct strategies, with some focusing on expanding their product portfolios and others investing heavily in research and development.

Competitive Landscape and Key Market Players in Remote Inspection Software

The competitive landscape is shaped by strategic partnerships, mergers, and acquisitions.

-

SafetyCulture – Australia

-

OptimaTech Limited – United Kingdom

-

InventoryBase – United Kingdom

-

Property Inspect – United Kingdom

-

SightCall – United States

-

TeamViewer – Germany

-

Microsoft Dynamics 365 – United States

-

VRMedia – Israel

-

VuSpex – United States

-

Avatour – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Remote Inspection Software Market Report |

| Base Year | 2024 |

| Segment by Type | · Cloud-based Remote Inspection Software

· On-premises Remote Inspection Software |

| Segment by Application | · Equipment Inspection

· Facility Inspection · Infrastructure Inspection · Remote Monitoring · Others |

| Geographies Covered | · North America(United States,Canada)

· Europe(Germany,France,UK,Italy,Russia) · Asia-Pacific(China,Japan,South Korea,Taiwan) · Southeast Asia(India) · Latin America(Mexico,Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast,company share,competitive landscape,growth factors and trends |

The remote inspection software market is rapidly evolving, presenting a wealth of opportunities for stakeholders. As the industry moves towards a projected market value of USD 11.01 billion by 2025, there lies potential for significant returns on investment through strategic engagement in emerging trends and technologies.

Key Takeaways for Stakeholders:

- Leverage Automation and AI: By embracing automation and artificial intelligence, companies can enhance their inspection capabilities, ensuring compliance with ever-evolving health and safety standards.

- Capitalize on Regional Growth: With North America holding a substantial share of the market, and Europe following closely, positioning your business in these regions could yield substantial growth.

- Adopt Flexible Solutions: The shift towards cloud-based solutions promises scalability and flexibility, crucial for staying competitive in this dynamic landscape.

For those interested in an in-depth analysis and further insights into the future of the remote inspection software market, it is advisable to explore the comprehensive Wkinformation Research report. This document provides detailed forecasts and strategic guidance essential for navigating this burgeoning sector.

Global Remote Inspection Software Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Remote Inspection Software Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Remote Inspection Software Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Remote Inspection Software players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Remote Inspection Software Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Remote Inspection Software Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Remote Inspection Software Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Remote Inspection Software Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the Remote Inspection Software Market by 2025?

The Remote Inspection Software Market is projected to grow to USD 11.01 billion by 2025, driven by automation, regulatory compliance, and geographical factors.

What are the key stakeholders in the Remote Inspection Software supply chain?

Key stakeholders in the Remote Inspection Software supply chain include software providers and end-users who utilize these solutions across various industries.

What are the emerging trends driving market growth for Remote Inspection Software?

Emerging trends include increased adoption of automation processes, a strong emphasis on regulatory compliance regarding health and safety standards, and the impact of COVID-19 accelerating software adoption.

What challenges do companies face when entering the Remote Inspection Software market?

Companies face several challenges such as regulatory hurdles affecting software development, barriers to entry due to competitive landscapes, and resistance to change from traditional inspection practices.

How do geopolitical factors influence the Remote Inspection Software market?

Geopolitical factors affect technology adoption through regulatory differences across regions like the US, UK, and Germany, as well as how international relations shape overall market dynamics.

What is the application scope of Remote Inspection Software across different industries?

Remote Inspection Software has a wide application scope in sectors such as construction and automotive, with varying industry adoption rates reflecting its versatility and effectiveness in enhancing inspection processes.