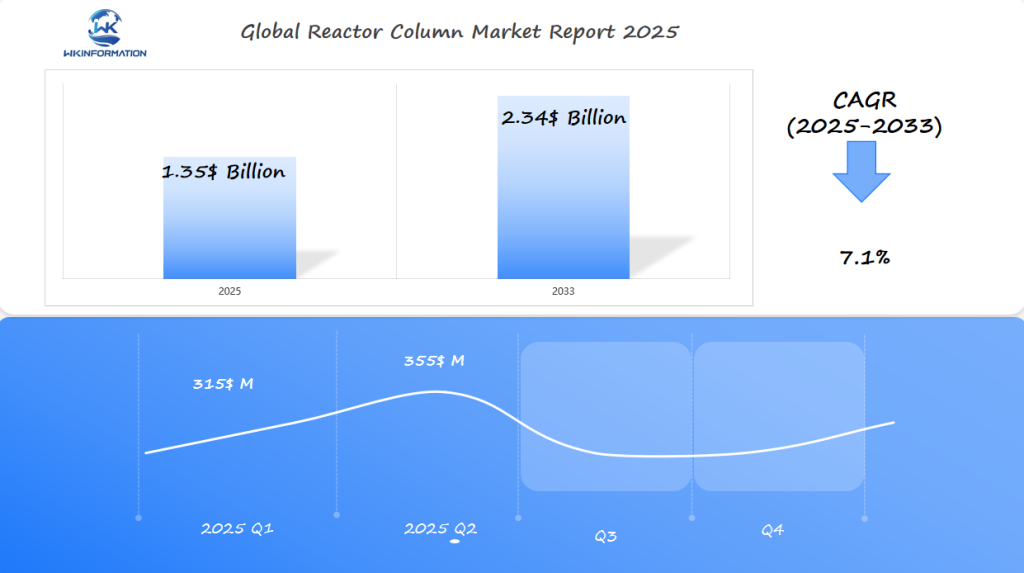

Reactor Column Market on Track for $1.35 Billion Global Valuation by 2025: Key Trends in the U.S., South Korea, and Brazil

Reactor Column Market poised for $1.35 billion global growth by 2025 – get insights on the latest trends and forecasts for this sector.

- Last Updated:

Reactor Column Market in Q1 and Q2 of 2025

The global Reactor Column market is projected to reach $1.35 billion in 2025, growing at a CAGR of 7.1% through 2033. Q1 revenues are expected to be near $315 million, with Q2 figures climbing to approximately $355 million, driven by rising investments in petrochemical and chemical process industries.

Key Drivers by Region

- United States: The refinery and specialty chemicals sector continues to modernize, fueling demand for high-efficiency distillation and absorption columns.

- South Korea: Focus on semiconductor and battery chemical manufacturing supports steady growth in compact and modular reactor designs.

- Brazil: Emerging as a key player in bio-refineries and ethanol production, boosting demand for corrosion-resistant and thermally stable reactor columns.

Understanding the Reactor Column Market: Upstream and Downstream Perspectives

Analyzing the Reactor Column market from both upstream and downstream perspectives provides valuable insights into its supply chain dynamics. The Reactor Column market analysis reveals a complex interplay of factors influencing the industry’s overall performance.

Upstream Perspective: Raw Material Suppliers and Manufacturers

The upstream segment of the Reactor Column market involves raw material suppliers and manufacturers. Key players in this segment include companies that produce high-grade materials used in the construction of Reactor Columns, such as stainless steel and exotic alloys. The availability and cost of these materials significantly impact the overall cost and quality of Reactor Columns.

Downstream Perspective: End-Users of Reactor Columns

On the downstream side, the focus shifts to the end-users of Reactor Columns, including industries such as refining, petrochemicals, and industrial processing. The demand from these sectors drives the growth and development of the Reactor Column market. Understanding the needs and trends in these industries is crucial for suppliers and manufacturers to tailor their products and services.

Understanding the supply chain dynamics

The supply chain dynamics of the Reactor Column market are influenced by various factors, including the availability of raw materials, manufacturing capacity, and the demand from end-users. Efficient supply chain management is crucial to ensure the timely delivery of high-quality Reactor Columns.

Some of the key challenges in the supply chain include:

- Managing the lead times for raw materials

- Maintaining flexibility in manufacturing to accommodate different client needs

- Ensuring compliance with stringent industry standards

By understanding these dynamics, stakeholders in the Reactor Column market can better navigate the complexities of the industry and make informed decisions to optimize their operations and improve their market position.

Emerging trends in chemical processing and Reactor Column demand

New technologies and emerging trends in chemical processing are having a profound impact on the demand for Reactor Columns. As the chemical industry continues to evolve, driven by advancements in technology and changing market requirements, the design and functionality of Reactor Columns are being reshaped.

The influence of emerging trends can be seen in several areas, including:

- The adoption of more efficient and sustainable processes

- The integration of advanced materials

- The incorporation of digital technologies for enhanced monitoring and control

Impact of new technologies on Reactor Column demand

The introduction of new technologies in chemical processing is directly affecting the demand for Reactor Columns. Innovations such as advanced reactor designs, modular reactors, and intensified processes are creating a need for Reactor Columns that can support these advancements.

In addition, the shift towards more sustainable and environmentally friendly processes is driving the development of Reactor Columns that can handle new, potentially more corrosive or high-temperature processes.

Advances in chemical processing and their influence on Reactor Column design

Improvements in chemical processing are not only increasing the demand for Reactor Columns but also shaping their design. Contemporary Reactor Columns are being created to be more adaptable, efficient, and capable of accommodating a broader spectrum of chemical processes.

Some notable design improvements include:

- Enhanced materials and coatings to resist corrosion and fouling

- Modular designs for easier maintenance and flexibility

- Upgraded monitoring and control systems for better process management

The impact of these trends on Reactor Column design can be seen in the following table, which highlights some of the key advancements and their benefits:

| Design Advancement | Benefit |

| Advanced materials and coatings | Improved resistance to corrosion and fouling, reducing maintenance needs |

| Modular designs | Easier to maintain and upgrade, reducing downtime and increasing flexibility |

| Enhanced monitoring and control systems | Better process control, leading to improved efficiency and reduced waste |

The integration of new technologies and emerging trends in chemical processing is expected to continue driving demand for advanced Reactor Columns. As the industry moves towards more sustainable and efficient processes, the role of Reactor Columns will become increasingly important.

Key constraints facing Reactor Column suppliers and users

Understanding the constraints facing Reactor Column suppliers and users is crucial for navigating the complexities of this market. The Reactor Column industry is influenced by various factors that impact the supply chain, from raw material availability to regulatory compliance.

The supply chain for Reactor Columns is complex, involving multiple stakeholders and requiring precise coordination. Challenges in the supply chain can lead to delays, increased costs, and reduced efficiency.

Challenges in the Reactor Column Supply Chain

One of the primary challenges in the Reactor Column supply chain is the availability of raw materials. The quality and cost of these materials can significantly impact the production of Reactor Columns.

Regulatory compliance is another significant constraint. Suppliers and users must adhere to stringent regulations and standards, which can be challenging, especially in a global market with varying requirements.

| Constraint | Impact on Suppliers | Impact on Users |

| Raw Material Availability | Increased costs, potential delays | Higher procurement costs, potential shortages |

| Regulatory Compliance | Additional costs for compliance, risk of non-compliance | Risk of using non-compliant products, potential downtime |

| Supply Chain Disruptions | Delays, loss of business | Delays in receiving products, potential loss of production |

By analyzing these constraints and their impacts, stakeholders in the Reactor Column market can work towards mitigating these challenges and improving overall market dynamics.

Geopolitical influences on Reactor Column trade and infrastructure

Geopolitical tensions and trade policies are reshaping the global Reactor Column trade landscape. The Reactor Column industry, being a critical component of the chemical and petrochemical sectors, is particularly vulnerable to changes in international trade dynamics.

The impact of geopolitical influences on Reactor Column trade is multifaceted. Trade policies, including tariffs and export controls, can significantly affect the cost and availability of Reactor Columns. For instance, tariffs imposed on imported steel or other critical materials can increase the production costs of Reactor Columns, making them more expensive for end-users.

Impact of trade policies on Reactor Column imports and exports

Trade policies play a crucial role in determining the flow of Reactor Columns across borders. Export controls and tariffs can either facilitate or hinder the trade of Reactor Columns, depending on their nature and the countries involved.

- Tariffs on imported Reactor Columns can protect domestic manufacturers but may also increase costs for local buyers.

- Export controls can limit the availability of Reactor Columns in certain regions, potentially driving up prices.

- Free trade agreements, on the other hand, can reduce or eliminate tariffs, making Reactor Columns more competitive in the global market.

The ongoing geopolitical tensions between major economies have led to a shift towards protectionism in some regions, affecting the Reactor Column trade. The industry must navigate these challenges to ensure a stable supply chain.

By type: segmenting the Reactor Column market by configuration and material

Segmenting the Reactor Column market by configuration and material reveals a complex landscape of different types and applications. The Reactor Column market is characterized by a variety of configurations, including fixed-bed, fluidized-bed, and trickle-bed reactors, each designed to serve specific industrial needs.

Analysis of different Reactor Column configurations and materials

The configuration of a Reactor Column is crucial in determining its efficiency and suitability for specific applications. Fixed-bed reactors, for instance, are widely used in the petrochemical industry due to their simplicity and effectiveness in handling large volumes.

Fluidized-bed reactors, on the other hand, offer superior heat and mass transfer rates, making them ideal for reactions that require intense mixing and uniform temperature distribution.

Market share of various Reactor Column types

The market share of different Reactor Column types varies based on their configuration and material. According to industry reports, stainless steel Reactor Columns dominate the market due to their corrosion resistance and durability.

A breakdown of the market share is as follows:

- Stainless Steel Reactor Columns: 40%

- Carbon Steel Reactor Columns: 30%

- Glass-lined Reactor Columns: 15%

- Other materials: 15%

Application analysis: refining, petrochemicals, and industrial usage

The Reactor Column market is experiencing significant growth due to its wide range of applications in refining, petrochemicals, and industrial usage. Reactor Columns play a vital role in numerous industrial processes, serving important functions that improve efficiency and productivity.

Reactor Column applications in refining and petrochemicals

In the refining and petrochemical sectors, Reactor Columns are used for various processes, including catalytic cracking and hydrotreating. These applications require Reactor Columns that can withstand high temperatures and pressures, making material selection and design critical.

Key requirements for Reactor Columns in refining and petrochemicals

- High-pressure resistance: Reactor Columns used in refining and petrochemical applications must be designed to withstand extreme pressures.

- Corrosion resistance: The materials used for Reactor Columns in these industries are chosen for their ability to resist corrosion from the chemicals used in the processes.

Other industries that utilize Reactor Columns

Beyond refining and petrochemicals, Reactor Columns are used in various industrial applications, including chemical processing, pharmaceuticals, and power generation. The versatility of Reactor Columns makes them a crucial component in many different industries.

- Chemical processing: Reactor Columns are used to facilitate chemical reactions, enhancing the efficiency of production processes.

- Pharmaceuticals: In the pharmaceutical industry, Reactor Columns are utilized for the production of active pharmaceutical ingredients (APIs).

The demand for Reactor Columns is expected to continue growing as industries evolve and new applications are developed.

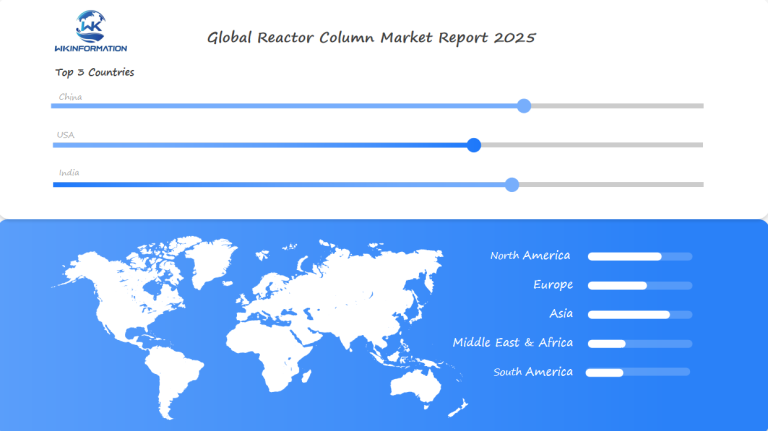

Reactor Column market by global region: performance and forecasts

Regional factors are important in determining how well the Reactor Column market is doing and what its future looks like. The worldwide Reactor Column market is varied, with different regions playing their own unique roles in its growth.

Regional analysis of the Reactor Column market

The Reactor Column market’s regional analysis reveals a complex landscape influenced by factors such as economic conditions, technological advancements, and regulatory frameworks. North America, Europe, and Asia-Pacific are the key regions driving the market forward.

North America

In North America, the Reactor Column market is driven by the presence of a well-established chemical and petrochemical industry. The region’s focus on innovation and adoption of advanced technologies further boosts market growth.

Europe

Europe is another significant market, with a strong emphasis on sustainability and environmental regulations. The region’s stringent policies encourage the adoption of efficient Reactor Column technologies.

Asia-Pacific

The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing demand for chemicals, and expanding refining capacities in countries like China and India.

Market forecasts

Market forecasts indicate varying growth rates across regions. The Asia-Pacific region is anticipated to lead in terms of growth rate, driven by industrial expansion and increasing investments in chemical and petrochemical sectors.

- North America: Steady growth driven by technological advancements and a strong industrial base.

- Europe: Moderate growth influenced by environmental regulations and a focus on sustainable practices.

- Asia-Pacific: High growth rate due to rapid industrialization and increasing demand.

Understanding these regional trends and forecasts is crucial for stakeholders to make informed decisions and capitalize on emerging opportunities in the Reactor Column market.

The U.S. market outlook for Reactor Column technologies

The U.S. Reactor Column market is set to grow significantly, driven by advancements in Reactor Column technologies. This growth reflects the larger trends in the chemical processing and energy sectors, where Reactor Columns are essential.

The U.S. Reactor Column market is experiencing a shift towards more efficient and sustainable technologies. This change is driven by the need for better process efficiency, less environmental impact, and compliance with strict regulations.

Trends shaping the U.S. Reactor Column market

Several trends are shaping the U.S. Reactor Column market, including the adoption of advanced materials and designs that enhance performance and durability. Additionally, there is a growing focus on digitalization and the use of simulation tools to optimize Reactor Column design and operation.

Key trends include:

- Increased use of advanced materials for Reactor Column construction

- Growing adoption of digital technologies for design and operation optimization

- Rising demand for sustainable and environmentally friendly Reactor Column solutions

The U.S. Reactor Column market is also benefiting from investments in research and development, aimed at improving Reactor Column technologies and addressing industry challenges.

As the market continues to evolve, we can expect to see further innovations in Reactor Column design, materials, and operation. These advancements will be crucial in meeting the future needs of the chemical and energy sectors.

South Korea’s role in Reactor Column design and export

South Korea has become a key player in the global Reactor Column industry, thanks to its advanced design and manufacturing skills. The country’s Reactor Column industry has seen significant growth recently, driven by the increasing need for top-notch reactor columns.

The Reactor Column industry in South Korea is known for its strong emphasis on research and development, which allows the country to stay ahead in technology and innovation. This has enabled South Korean companies to create and export high-quality Reactor Columns that meet the needs of the global market.

Design and manufacturing capabilities

South Korea’s Reactor Column industry is known for its advanced design and manufacturing capabilities. The country’s companies have developed strong expertise in designing and manufacturing Reactor Columns that meet the specific needs of various industries, including refining, petrochemicals, and industrial usage.

The design and manufacturing capabilities of South Korean companies are supported by the country’s strong research and development infrastructure. This enables companies to develop new technologies and improve existing ones, staying ahead of the competition in the global market.

Brazil’s industrial development and Reactor Column adoption

As Brazil continues to industrialize, the adoption of Reactor Columns is becoming increasingly crucial. The country’s industrial growth is driven by various factors, including government initiatives and investments in infrastructure.

Brazil’s Industrial Growth and Its Impact on Reactor Column Demand

The demand for Reactor Columns in Brazil is on the rise, thanks to the country’s growing chemical and petrochemical industries. Key factors driving this growth are the need for efficient processing technologies and the upgrading of existing industrial facilities.

- Increasing investments in the chemical and petrochemical sectors

- Growing demand for efficient and sustainable processing technologies

- Government policies supporting industrial development

The adoption of Reactor Columns is also driven by the need for improved safety and operational efficiency. As industries in Brazil continue to evolve, the demand for advanced Reactor Column technologies is expected to grow.

Challenges Ahead

The main challenges facing the Reactor Column market in Brazil include:

- High initial investment costs

- Technical complexities associated with Reactor Column design and operation

- Regulatory compliance and environmental concerns

Despite these challenges, the future prospects for the Reactor Column market in Brazil are promising, driven by ongoing industrial development and the need for advanced processing technologies.

Future opportunities in Reactor Column systems and services

Future opportunities in Reactor Column systems and services are vast, driven by technological advancements and increasing demand. The Reactor Column industry is evolving rapidly, with innovations in design, materials, and services playing a crucial role.

The growing need for efficient and sustainable chemical processing solutions is a significant driver of growth in the Reactor Column market. As industries such as refining, petrochemicals, and pharmaceuticals continue to expand, the demand for advanced Reactor Column systems is expected to rise.

Emerging opportunities in Reactor Column design and manufacturing

One of the key emerging opportunities in Reactor Column systems is the development of advanced materials and designs that enhance efficiency, safety, and environmental sustainability. Advanced materials such as composites and alloys are being explored for their potential to improve Reactor Column performance.

The integration of digital technologies such as IoT and AI in Reactor Column design and operation is another area of growth. These technologies enable real-time monitoring, predictive maintenance, and optimized performance.

| Opportunity Area | Description | Potential Impact |

| Advanced Materials | Development of new materials for Reactor Columns | Improved efficiency, safety, and sustainability |

| Digital Technologies | Integration of IoT and AI in Reactor Column design and operation | Enhanced performance, predictive maintenance, and real-time monitoring |

| Service Enhancements | Expansion of services including maintenance, repair, and overhaul | Increased customer satisfaction, loyalty, and retention |

The service segment of the Reactor Column market is also expected to witness significant growth. As operators seek to maximize the lifespan and efficiency of their Reactor Columns, the demand for comprehensive service solutions is increasing.

The future of Reactor Column systems and services is promising, with numerous opportunities emerging across design, manufacturing, and services. Companies that innovate and adapt to these trends are likely to lead the market.

Competitive analysis of Reactor Column manufacturers

The global reactor column manufacturing market is highly competitive, with leading players such as Sulzer Chemtech (Switzerland), Koch-Glitsch (USA), and Praj Industries (India) dominating key sectors like petrochemicals, pharmaceuticals, and chemical processing. Sulzer and Koch-Glitsch are known for their expertise in mass transfer and separation technologies, while Praj has a strong foothold in the bioenergy segment.

- GE Hitachi Nuclear Energy – United States

- Holtec International – United States

- X-Energy – United States

- Parr Instrument Company – United States

- Fluitron – United States

- Kobe Steel USA – United States

- Applied Reactor Technologies – United States

- Hach Company – United States

- Paul Mueller Company – United States

- KSB – Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Reactor Column Report |

| Base Year | 2024 |

| Segment by Type |

· Stainless Steel Reactor Columns · Carbon Steel Reactor Columns · Glass-lined Reactor Columns · Other |

| Segment by Application |

· Chemical Processing · Pharmaceuticals · Power Generation |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Reactor Column market is set for significant growth, driven by emerging trends in chemical processing and increasing demand from various industries. A summary of key findings reveals a complex landscape influenced by upstream and downstream dynamics, geopolitical factors, and regional market performance.

Key Trends and Findings

The Reactor Column market is characterized by a shift towards advanced technologies and materials, with South Korea and the U.S. playing significant roles in design, manufacturing, and export. Brazil’s industrial development is also contributing to the growth of the Reactor Column market, driven by increasing demand from the refining and petrochemical sectors.

Future opportunities in Reactor Column systems and services are emerging, driven by the need for efficient and reliable equipment. As the industry continues to evolve, key players will need to adapt to changing market dynamics and technological advancements to remain competitive.

Global Reactor Column Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Reactor Column Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Reactor ColumnMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Reactor Columnplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Reactor Column Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Reactor Column Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Reactor Column Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofReactor ColumnMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected global valuation of the Reactor Column Market by 2025?

The Reactor Column Market is expected to grow significantly, with a projected global valuation of $1.35 billion by 2025, aligning with the broader economic market outlook for 2025.

What are the key trends driving the growth of the Reactor Column Market?

The growth of the Reactor Column Market is driven by emerging trends in chemical processing, advancements in Reactor Column design, and increasing demand from industries such as refining, petrochemicals, and industrial usage.

What are the challenges facing Reactor Column suppliers and users?

Reactor Column suppliers and users face challenges such as supply chain constraints, raw material availability, and regulatory compliance.

How do trade policies impact the Reactor Column Market?

Changes in trade policies and geopolitical tensions can significantly impact the Reactor Column Market, affecting imports and exports, and influencing the global supply chain.

What are the different types of Reactor Columns and their applications?

Reactor Columns can be segmented by configuration and material, with different types being used in various applications such as refining, petrochemicals, and industrial usage.

What is the outlook for the Reactor Column Market in the U.S.?

The U.S. Reactor Column Market is expected to be driven by trends and developments in Reactor Column technologies, with a growing demand from industries such as refining and petrochemicals.

What role does South Korea play in the global Reactor Column Market?

South Korea is a significant player in the global Reactor Column Market, with a strong industry presence in design, manufacturing, and export.

How is Brazil’s industrial development impacting the Reactor Column Market?

Brazil’s industrial growth is driving the demand for Reactor Columns, with the country’s industrial development presenting opportunities for Reactor Column suppliers.

What are the emerging opportunities in Reactor Column systems and services?

Emerging opportunities in Reactor Column systems and services are driven by advancements in Reactor Column design, increasing demand from industries, and the need for efficient and cost-effective solutions.

What are the key findings and trends in the Reactor Column Market?

The Reactor Column Market is experiencing significant growth due to several factors:

- Emerging trends in chemical processing: New technologies and methods are being developed to improve efficiency and sustainability in chemical manufacturing.

- Advancements in Reactor Column design: Ongoing research and development are leading to innovative designs that enhance performance and reduce energy consumption.

- Increasing demand from various industries: Sectors such as refining, petrochemicals, and industrial applications are driving the need for more efficient and effective reactor systems.