2025 Rack Anti-Collapse Mesh Market: Capturing $9.8 Billion Global Opportunities, Supported by Markets in U.S., China, and India

Discover the latest trends and key players in the Rack Anti-Collapse Mesh Market, with focus on the U.S., China, and India. Explore how safety regulations, rapid industrialization, and logistics growth drive market expansion. Learn about innovative solutions from industry leaders.

- Last Updated:

Q1 and Q2 2025: Emerging Trends and Key Insights in the Rack Anti-Collapse Mesh Market

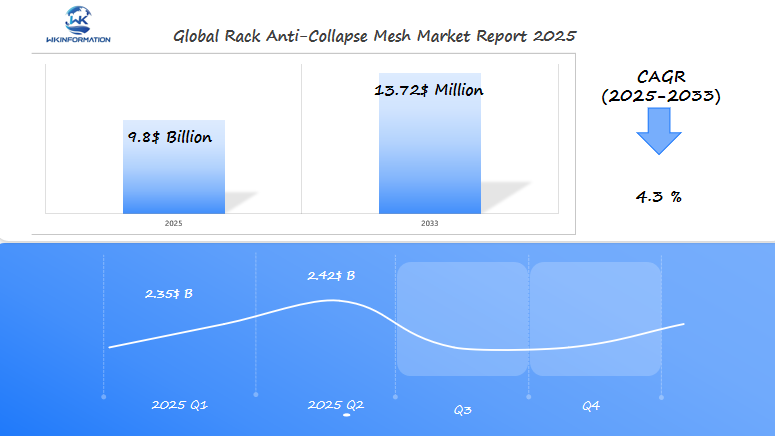

The Rack Anti-Collapse Mesh market is projected to grow significantly, reaching USD 9.8 billion by 2025, driven by a steady CAGR of 4.3%. Preliminary estimates suggest that Q1 2025 will see market revenues of approximately USD 2.35 billion, with Q2 following closely at USD 2.42 billion, reflecting seasonal demand fluctuations and regional growth patterns.

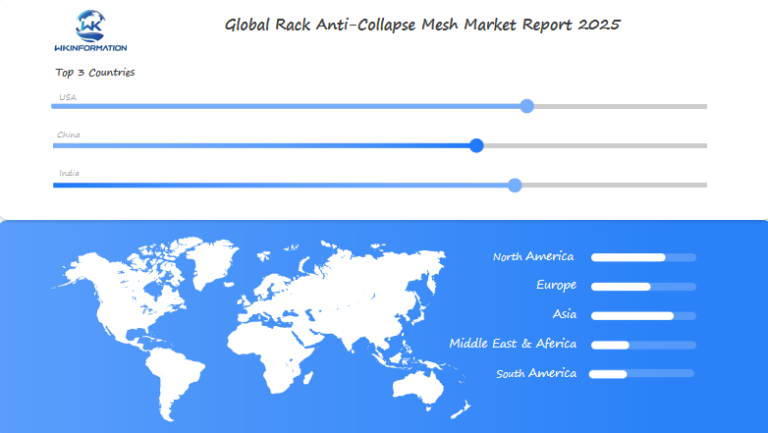

Among the top-performing markets, the USA, China, and India stand out as the most promising regions, accounting for a substantial share of global demand. The USA continues to lead with robust infrastructure investments, while China and India are experiencing accelerated growth due to expanding industrial and logistics sectors. For a comprehensive analysis of market dynamics, including detailed forecasts and regional breakdowns, explore the Wkinformation Research sample and full report. Gain actionable insights to stay ahead in this evolving market landscape. The future of the Rack Anti-Collapse Mesh market is poised for innovation, and understanding these trends is critical for strategic decision-making.

Key Takeaways

- The U.S. market focuses on premium, regulation-compliant rack anti-collapse mesh systems

- China leads in manufacturing volume with cost advantages in global distribution

- India shows the highest growth potential due to rapid industrialization

- E-commerce expansion drives demand across all three major markets

- Custom solutions tailored to local warehouse configurations gain popularity

- Safety regulations increasingly influence product development standards

Upstream and Downstream Industry Chain Analysis: Understanding the Rack Anti-Collapse Mesh Supply Chain

The rack anti-collapse mesh industry has a complex supply chain. It involves many suppliers, manufacturers, and distributors. A detailed analysis shows how raw materials are sourced and products reach the end users.

Steel wire mesh production is key. The quality and gauge of the mesh affect its durability and safety. This is crucial for warehouse rack systems.

Upstream, steel producers supply the raw materials. These materials are then turned into mesh panels by rack safety manufacturers. The panels are made through cutting, welding, and coating.

The quality of these panels is vital. It ensures the mesh meets safety standards for warehouse racks.

Downstream, logistics channels connect manufacturers with warehouse operators and retailers. These channels have faced big challenges, like disruptions. Companies are now working on more resilient supply networks.

Many rack safety manufacturers keep more materials in stock. They also work with several suppliers to avoid delays.

The supply chain goes across many countries. Raw materials come from steel-producing areas, while fabrication happens near the end markets. This global setup brings both chances and risks for companies in the rack safety sector.

There’s a growing need for better supply chain risk management and transparency. This is to handle these challenges effectively.

Trend Analysis: Emerging Trends in Rack Anti-Collapse Mesh Technology

The rack mesh industry is changing fast, thanks to digital technologies. Now, warehouses need more than just basic safety systems. This change opens up new chances for both makers and users of these systems.

Digital tech is leading the way in rack mesh trends. Smart sensors in mesh panels can spot problems before they happen. They send data to a central system, helping to fix issues before they get worse.

Innovations Driving the Future of Warehouse Safety

New materials are making safety meshes stronger and lighter. These materials are also cheaper. This means safer systems that are easier to set up, which is good for warehouse managers.

Custom designs are also big now. Makers offer mesh systems that fit different rack setups. This lets warehouses grow their safety systems as they grow.

But it’s not just about the mesh. New systems also connect with warehouse software. This lets them track loads and warn of dangers before they happen.

The mix of physical mesh and digital monitoring is the future. It offers quick safety and long-term protection. This makes work safer and more efficient.

Restriction Analysis: Challenges in the Rack Anti-Collapse Mesh Market

The rack anti-collapse mesh industry faces big challenges despite its key role in keeping warehouses safe. Companies struggle to introduce these systems into traditional warehouses. Changing these operations is hard.

Cost is a big problem for many businesses. The price of quality mesh systems is high, especially for smaller warehouses with tight budgets. This makes it hard for them to invest in safety measures that could prevent accidents.

Installing these systems is also a big technical challenge. It requires special skills and might mean shutting down operations temporarily. Warehouses that never stop working find these shutdowns very hard to handle.

Overcoming Barriers to Market Growth and Adoption

Safety rules vary a lot around the world, making it hard for big companies to follow them all. In the U.S., OSHA rules are strict, but other countries have different rules. This makes it tough to make and sell these products.

Mesh materials also have to deal with tough environments. Places with extreme weather, high humidity, or corrosive substances need special mesh. It has to stay strong and work well in these conditions.

- Compatibility issues with various racking systems

- Training requirements for proper installation and maintenance

- Supply chain disruptions affecting material availability

- Resistance from facility managers concerned about accessibility

Companies are working to solve these problems. They’re making systems easier to install and teaching people about the benefits. The market is getting better as these solutions are found.

Geopolitical Analysis: How Global Politics Influence Rack Anti-Collapse Mesh Production and Trade

The rack anti-collapse mesh industry is caught in a complex web of international trade policies. These policies shape how production happens and who can sell what. Recently, tensions between the United States and China have led to big tariff hikes on steel. This has made manufacturers rethink their supply chains.

These trade issues have made raw materials 15-30% more expensive for mesh makers. Companies that make things in China but sell to the US are facing big financial challenges. This has forced them to change their strategies.

Trade disputes have raised raw material costs for mesh makers. Companies making things in China but selling to the US are facing big financial challenges. This has forced them to change their strategies.

- Establishment of secondary production facilities in neutral territories

- Formation of joint ventures with local partners to bypass trade barriers

- Investment in automation to offset higher labor costs in domestic production

Navigating International Trade Relations and Tariffs

Cross-border regulations are a big challenge for mesh makers. They try to keep prices low while dealing with these rules. American distributors are now buying more from India and Southeast Asia instead of China.

This change shows a bigger trend in global manufacturing. It’s happening in many industries, not just mesh.

International trade policies are always changing. This brings both risks and chances for companies. Those with flexible supply chains and diverse production bases have an edge. Small and medium businesses find it hard to keep up with these changes. But big companies can adapt faster with their resources.

Segmentation Type Market Analysis: Rack Anti-Collapse Mesh Market Segmentation by Type and Application

The rack anti-collapse mesh market is split into different types for various warehouse safety needs. Knowing these segments helps businesses pick the right safety gear for their specific needs and layouts.

Understanding Different Product Categories and Their Specific Uses

Back-of-rack mesh systems are the biggest segment. They protect against falling items at the back of racks. These panels stop items from falling into walkways or work areas, crucial in busy places.

Side-of-rack mesh acts as a barrier on the sides of racks. It’s especially useful in areas where forklifts move and near work stations or paths.

The market also has custom safety solutions for unique warehouse setups. These include adjustable panels, reinforced corners, and modular systems for odd rack sizes or layouts.

Different industry-specific applications lead to the need for special mesh designs. Retail warehouses need light, flexible solutions. Manufacturing places require strong panels for heavy items. Food and pharmaceutical areas prefer mesh with corrosion-resistant finishes for cleanliness.

Materials vary by segment, with steel wire being common for its strength and cost. Hybrid materials, mixing metal and polymer, are gaining traction for their impact absorption and weight savings in certain uses.

Application Market Analysis: The Role of Rack Anti-Collapse Mesh in Warehouse Safety

Rack anti-collapse mesh systems are key in preventing accidents in warehouses. They keep products on shelves, stopping pallet falls and inventory avalanches. These dangers can harm workers and disrupt operations.Studies show these safety systems work well. Warehouses with them see a 30-45% drop in accidents in the first year. This makes workplaces safer and saves money.

Case Studies of Successful Implementation and Safety Improvements

A big distribution center in Texas became fully OSHA compliant with rack mesh. They had no pallet-related injuries for 18 months after. This was a big change from seven incidents the year before. It also cut their insurance costs by 12%.

Global Rack Anti-Collapse Mesh Market Region Analysis: Regional Market Trends

The rack anti-collapse mesh market varies by region. North America focuses on following rules. Europe puts safety first. Asia grows fast with more factories.

Each area sees safety in its own way. This makes different markets for protecting racks.

Comparing Growth Patterns Across Key International Markets

Southeast Asia is growing fast, with over 7% annual growth. Its factories need more safety gear. Latin America is growing at 5% as its logistics improve.

Europe has strict rules for warehouses. This is different from places where rules are still being made. This means different ways for companies to enter the market.

Places with growing industries and safety focus will grow the most. Eastern Europe and the Middle East are promising. They are building more warehouses and factories.

United States Rack Anti-Collapse Mesh Market Analysis

The United States is a leader in warehouse safety, with rack anti-collapse mesh systems becoming more common. These systems meet strict American warehouse regulations. This ensures high product quality and innovation.

U.S. warehouses have unique needs. They require durable, easy-to-install systems that follow national safety rules.

Regulatory Environment and Industry Best Practices in America

Warehouse managers in the U.S. focus a lot on safety. OSHA sets the minimum safety standards. Insurance companies often ask for even more safety measures.

North American makers have created mesh systems that go beyond the basics. They meet practical needs and safety standards.

ANSI standards MH16.1 and MH16.3 are key for rack safety. They set testing and performance rules. These rules help products get accepted faster by reducing risks.

- West Coast facilities focus on seismic safety.

- Midwest centers want systems that can change with the seasons.

- East Coast places value quick setup for city warehouses.

The market varies by region, showing different needs across the country. This diversity offers chances for makers to tailor their products for specific areas.

China Rack Anti-Collapse Mesh Market Analysis

China leads the world in making rack anti-collapse mesh. It has huge factories that make things cheaply and efficiently. The country is both a big maker and a growing market for these products.

Chinese factories make over 60% of the world’s warehouse safety gear. They have lots of raw materials and good logistics. This makes them very good at making things.

Asian safety standards have changed a lot. New rules in China make sure all warehouses are safe. This has made the market grow fast, with growth rates over 15% a year.

These rules are getting closer to international standards. But China still keeps costs low. This is hard for other markets to do.

Manufacturing Advantages and Domestic Market Growth

China keeps getting better at making things. New factories use robots and new ways of making things. Big companies like Nanjing Dahua and Shanghai Yuanxin are leading this.

They make 5,000-8,000 mesh panels every day. This is more than Western factories, which make 1,000-2,000.

China sends a lot of these products to other countries. It sends 23% more every year. Buyers in North America and Europe like China’s prices and choices.

At the same time, China’s own market is growing. Big online stores need lots of safety gear for their huge warehouses.

India Rack Anti-Collapse Mesh Market Analysis

India is at a key moment in the rack anti-collapse mesh market. The country’s big warehouse growth is opening doors for safety solutions. With over 800 million square feet of warehouse space expected by 2025, India is growing the fastest in South Asia.

Emerging Opportunities in a Rapidly Developing Market

The South Asian market is growing fast, especially in India’s big logistics centers like Mumbai, Delhi NCR, and Bengaluru. Local makers are teaming up with global tech companies to meet the demand. This keeps prices down for buyers who are careful with their spending.

India’s industrial safety adoption has its ups and downs. Safety rules are still being shaped, but some companies are leading the way. They’re adopting international standards. This creates a market where top facilities follow global rules, while smaller ones are slowly improving their safety.

There are big chances for growth beyond just selling products. Companies that offer full solutions, like installation, training, and upkeep, have a big edge. The market wants partners who can help with local supply chains and rules.

- Domestic manufacturing capacity grows at 22% annually

- E-commerce boom drives 35% of new warehouse development

- Government infrastructure initiatives create secondary demand

- Price points average 15-20% lower than western markets

India’s mix of growing safety awareness and cost awareness makes it different from Western markets or China’s focus on making things.

Future Development Analysis: The Future of Rack Anti-Collapse Mesh in Modern Warehousing

Rack anti-collapse mesh is on the verge of a big change. The next five years will see old mesh systems turn into smart safety parts. These new systems will be a big step up in keeping warehouses safe.

Sensors will soon be added to mesh panels, starting a new era in future safety technologies. These sensors will watch over tension, structure, and impacts, sending updates to managers. This will set up a system that warns of possible failures early.

Predicting Industry Evolution and Technological Integration

IoT integration will make rack protection systems talk to other safety parts in the warehouse. By 2025, mesh systems will likely work with automated vehicles. This will create safety zones that change as needed.

The mix of safety and efficiency is pushing innovation in warehouse protection. This is making smarter places that keep things and people safe with less human help.

In places with automated warehousing, mesh systems will change to fit with robotic picking. They will have new ways to attach and designs that can change as the warehouse layout does.

The biggest change will be in predictive safety systems. These use AI to look at rack stress and impact patterns. They will guess when there might be a high-risk situation and adjust picking times to keep things safe and on track.

Competitor Analysis: Key Players in the Rack Anti-Collapse Mesh Market

The rack anti-collapse mesh market is filled with many manufacturers trying to be the best. They compete in different areas, showing who can do things better. The top brands lead by using the best materials and new designs.

- Troax

- GPC Industries

- Manorga

- QTS Ltd

- Actiflip

- EAB

- Axelent

- Stakrak

- Dexion

- Billington Safety Systems

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Rack Anti-Collapse Mesh Market Report |

| Base Year | 2024 |

| Segment by Type | · Carbon Steel Mesh Panel

· Stainless Steel Mesh Panel · Aluminum Mesh Panel |

| Segment by Application | · Storehouse

· Supermarket · Factory · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Forecast unitsUSD million in valueReport coverageRevenue and volume forecast, company share, competitive landscape, growth factors and trends

The global rack anti-collapse mesh market is set for strong growth. It offers exciting investment opportunities and solid strategic planning ahead. The U.S., China, and India will lead as the main market powerhouses.

They will use the latest technologies and best practices to improve warehouse safety and efficiency.

For manufacturers, the future is about smart product development, expanding into new areas, and being competitive. Focus on new mesh designs, automation, and tapping into new markets. This will help you stay ahead.

Distributors and installers should work on better inventory management, improve services, and train customers well. This will help them succeed.

End users and facility managers should think about safety system investments carefully. Make sure they work well together and follow industry standards. By doing regular maintenance and keeping up with new tech, you can make the most of rack anti-collapse mesh solutions. This will protect your warehouse operations.

Global Rack Anti-Collapse Mesh Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Rack Anti-Collapse Mesh Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Rack Anti-Collapse Meshplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Rack Anti-Collapse Mesh Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Rack Anti-Collapse Mesh Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Rack Anti-Collapse Mesh Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofRack Anti-Collapse Mesh Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the three leading countries in the Rack Anti-Collapse Mesh market?

The top countries in the Rack Anti-Collapse Mesh market are the United States, China, and India.

How does the supply chain for Rack Anti-Collapse Mesh work?

The supply chain starts with raw material suppliers. It then moves to manufacturing, distribution, and installation. After-sales support is also part of it. Understanding this chain helps grasp the market’s dynamics.

What are the emerging trends in Rack Anti-Collapse Mesh technology?

New trends include IoT-enabled systems and load-sensing capabilities. Automated alert systems and eco-friendly materials are also on the rise. Modular designs and integration with warehouse systems are becoming more common.

What are the challenges facing the Rack Anti-Collapse Mesh market?

High costs and installation complexities are major hurdles. Safety regulations vary by region. Changing traditional operations and material limitations are also challenges. Durability and compatibility with different systems are concerns.

How do geopolitical factors influence the Rack Anti-Collapse Mesh market?

Global trade tensions and tariffs impact manufacturing and exports. Diplomatic changes can also affect the market.

How is the Rack Anti-Collapse Mesh market segmented?

The market is divided by product types and applications. Products include back-of-rack panels and overhead protection. Industries like retail and manufacturing also play a role.

How do Rack Anti-Collapse Mesh systems improve warehouse safety?

These systems reduce accidents and prevent damage. They improve efficiency and help meet safety standards. They also work well with other safety systems.

What are the key regional trends in the global Rack Anti-Collapse Mesh market?

Growth and adoption rates vary by region. The United States, China, and India lead. Europe, Southeast Asia, and Latin America also show promise.

What is the regulatory environment for Rack Anti-Collapse Mesh in the United States?

The U.S. has strict OSHA and ANSI standards. Insurance also plays a role. American manufacturers lead in innovation.

What are the advantages of the Chinese Rack Anti-Collapse Mesh market?

China benefits from large-scale manufacturing and cost efficiency. The market is growing, driven by domestic demand and safety regulations. Chinese manufacturers influence global markets.

What are the emerging opportunities in the Indian Rack Anti-Collapse Mesh market?

India’s infrastructure and manufacturing sector are growing. This creates demand for safety systems. The market is evolving, with a balance between imports and domestic production.

What is the future outlook for Rack Anti-Collapse Mesh in modern warehousing?

The future includes IoT sensors and AI predictive maintenance. Integration with automated systems will shape the industry. Innovations in materials and installation are expected.

Who are the key players in the Rack Anti-Collapse Mesh market?

The top manufacturers are from the United States, China, and India. The analysis compares their market shares and strengths. It looks at their product strategies and unique offerings.