Punching Machine Market to Surpass $1.31 Billion Worldwide by 2025: Industrial Automation Expansion in China, Italy, and the U.S.

Discover comprehensive insights into the punching machine market, including upstream and downstream industry chains, mechanical vs. CNC machines, and applications across automotive, electronics, and metalworking sectors. Explore global trends driven by China’s manufacturing boom, Italy’s precision engineering innovations, and U.S. manufacturing modernization. Learn about emerging technologies like AI and robotics shaping the future, key industry players, market challenges, regulatory compliance, and growth outlooks for enhanced manufacturing efficiency.

- Last Updated:

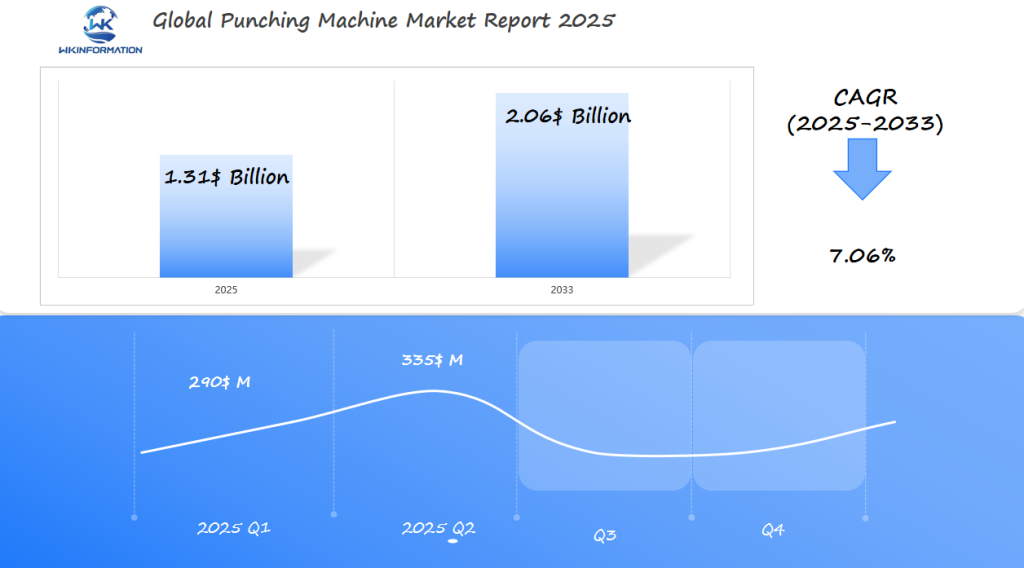

Punching Machine Market Forecast for Q1 and Q2 2025

The Punching Machine market is forecasted to reach $1.31 billion in 2025, supported by a CAGR of 5.83% through 2033. Q1 2025 market size is estimated at roughly $290 million, influenced by cautious capital expenditure in manufacturing sectors and seasonal production cycles. Growth is expected to pick up in Q2, with market size increasing to approximately $335 million, propelled by rising demand for automation and precision metalworking across various industries. China, Italy, and the U.S. dominate this market due to their robust manufacturing ecosystems and ongoing investments in advanced machinery technologies. These regions are crucial to understanding the first half of 2025 market trends and competitive landscape.

Key Takeaways

- The punching machine market is driven by industrial automation.

- Market growth is fueled by the need for precise manufacturing equipment.

- The market is forecasted to surpass $1.31 billion by 2025.

- Technological advancements are driving market expansion.

- Increasingly, the adoption of automated manufacturing solutions is a key growth factor.

Upstream and downstream industry chain insights of punching machines

Understanding the industry chain of punching machines is crucial for stakeholders to identify emerging trends and opportunities. The punching machine industry is part of a larger manufacturing ecosystem, with various sectors influencing its dynamics.

Understanding the Industry Chain

The industry chain of punching machines includes both upstream and downstream parts. Upstream parts are raw materials and equipment manufacturing, while downstream parts involve using punching machines in different industries like automotive, electronics, and metalworking.

Key players in the punching machine industry chain include raw material suppliers, equipment manufacturers, and end-users. These stakeholders are crucial in shaping the market through their interactions and innovations.

- Raw material suppliers provide the necessary inputs for manufacturing punching machines.

- Equipment manufacturers design and produce punching machines, driving technological advancements.

- End-users, such as automotive and electronics manufacturers, apply punching machines in their production processes, influencing demand and application trends.

The collaboration and competition among these players drive the evolution of the punching machine industry, impacting its growth and trends.

Recent trends accelerating punching machine adoption in manufacturing

The rise of Industry 4.0 has brought about a major change in manufacturing, with punching machines playing a crucial role in this transformation. As manufacturers strive to increase efficiency and precision, the demand for advanced punching machines, particularly CNC punching machines, has seen a significant surge.

Trends in Manufacturing

Industry 4.0 technologies, including automation, IoT, and AI, are changing the way manufacturing works. Automation is a key factor, helping manufacturers become more productive and lower labor costs. With the use of IoT devices, manufacturers can now monitor their operations in real-time and predict when maintenance is needed, reducing downtime and improving production efficiency.

“The future of manufacturing is not just about adopting new technologies, but also about transforming the way we work.” – A leading industry expert.

Impact on Punching Machine Adoption

These trends have several effects on the adoption of punching machines:

- There is an increasing demand for CNC punching machines because they are precise and efficient.

- More manufacturers are using automated punching systems to boost productivity.

- Smart technologies are being integrated into punching machines for real-time monitoring and control.

As manufacturers continue to embrace Industry 4.0 technologies, punching machines will play an even more important role. The ability to produce complex parts with high precision will set manufacturers apart in a competitive market.

Market constraints and compliance issues impacting growth

The punching machine market is facing significant challenges due to various market constraints and compliance issues. These challenges are complex and affect the overall growth of the industry.

Regulatory Compliance

Regulatory compliance is a major concern for the punching machine industry. Manufacturers must adhere to strict regulations regarding environmental impact, safety standards, and labor laws. Compliance with these regulations not only affects the operational costs but also influences the overall competitiveness of the companies in the market.

Market Constraints

The punching machine market is constrained by several factors, including high initial investment costs, technological complexities, and fluctuating raw material prices. These constraints can hinder the adoption of punching machines, particularly among small and medium-sized enterprises.

A detailed analysis of the market constraintsand compliance issues is crucial for understanding the industry’s dynamics. The table below summarizes the key constraints and their impact on the punching machine market.

| Constraint | Description | Impact |

| High Initial Investment | Significant upfront costs for machinery and training | Reduces adoption among SMEs |

| Technological Complexities | Difficulty in integrating new technologies | Increases operational challenges |

| Fluctuating Raw Material Prices | Unpredictable costs of raw materials | Affects profit margins |

Addressing these challenges is essential for the sustainable growth of the punching machine market. Companies must innovate and adapt to changing regulatory landscapes and market conditions.

Geopolitical impacts on global punching machine trade and supply

Geopolitical factors significantly influence the global trade and supply of punching machines, affecting manufacturing sectors worldwide. Key impacts include:

- Trade Policies and Tariffs

- Imposition of tariffs and trade barriers between major manufacturing hubs (e.g., China, U.S., EU) can increase costs and disrupt supply chains for punching machines.

- Export restrictions or sanctions may limit the availability of critical components or finished machines in certain regions.

- Supply Chain Disruptions

- Political instability in key raw material-producing countries affects the supply and pricing of steel and other metals essential to punching machine manufacturing.

- Global logistics challenges due to geopolitical tensions can delay shipping times, increasing lead times for machine delivery.

- Regional Manufacturing Strategies

- China’s manufacturing boom drives increased demand for punching machines domestically, influencing global market dynamics and competition.

- Italy’s focus on precision engineering fosters innovation in punching machine technology, impacting export patterns and collaborations.

- The modernization initiatives in the U.S. manufacturing sector boost adoption of advanced CNC punching machines, shifting demand towards high-tech solutions.

- Regulatory Compliance and Standards

- Variations in environmental, safety, and industry standards across countries require manufacturers to adapt machines accordingly, complicating international trade.

- Compliance costs may limit market entry or expansion efforts for some players, especially SMEs.

- Technological Transfers and Intellectual Property

- Geopolitical tensions may hinder technology sharing between countries, slowing innovation diffusion in CNC technologies within the punching machine industry.

- Investment Flows

- Political stability encourages foreign direct investment in manufacturing capabilities related to punching machines, while uncertainty deters capital inflows.

Overall, geopolitical developments shape competitive dynamics by influencing production costs, market access, innovation rates, and strategic partnerships within the global punching machine landscape. Manufacturers must remain agile to navigate these complexities for sustainable growth.

Understanding the Punching Machine Market: Mechanical vs. CNC Machines

The punching machine market can be divided into two main types: mechanical and CNC punching machines. This division is important for understanding how these machines are used in different manufacturing industries and how they operate efficiently.

Mechanical Punching Machines

Mechanical punching machines have been a cornerstone in the manufacturing industry, known for their reliability and efficiency. They operate through a mechanical system that converts rotational motion into linear motion, enabling the punching action. Key advantages include high speed, precision, and the ability to handle large-scale production.

These machines are widely used in industries where high-volume production is required, such as automotive and metalworking. However, they lack the flexibility and programmability offered by their CNC counterparts.

CNC Punching Machines

CNC punching machines represent a significant advancement in punching technology, offering programmability, flexibility, and high precision. They are controlled by computer numerical control (CNC) systems, allowing for complex patterns and designs to be executed with ease.

The adaptability of CNC punching machines makes them ideal for industries requiring customization and rapid prototyping, such as electronics and aerospace. Their ability to be reprogrammed for different tasks reduces downtime and increases production efficiency.

| Mechanical Punching Machines CNC Punching Machines Operational Mechanism | Mechanical system converting rotational motion to linear motion | Computer Numerical Control (CNC) system |

| Precision and Flexibility | High speed and precision, but limited flexibility | High precision and flexibility, with programmability |

| Industry Applications | Automotive, metalworking for high-volume production | Electronics, aerospace for customization and rapid prototyping |

Application analysis across automotive, electronics, and metalworking sectors

Punching machines are now essential in various industries such as automotive, electronics, and metalworking. Their ability to adapt and deliver precise results makes them a vital part of the manufacturing processes in these sectors.

Automotive Sector

The automotive sector is one of the largest consumers of punching machines. These machines are used for producing various components, such as body parts, engine components, and other metal parts. The use of punching machines in the automotive industry is driven by the need for high precision and efficiency.

Key Applications in Automotive:

- Production of body panels and chassis components

- Manufacturing of engine parts and other machinery components

- Creation of precision parts for vehicle assembly

Electronics and Metalworking Sectors

In the electronics sector, punching machines are used to manufacture components such as connectors, contacts, and other precision parts. The metalworking sector also relies heavily on punching machines for cutting, shaping, and forming metal into various shapes and sizes.

Key Applications in Electronics and Metalworking:

| Sector | Application | Benefit |

| Electronics | Manufacturing of connectors and contacts | High precision and accuracy |

| Metalworking | Cutting, shaping, and forming metal | Increased efficiency and productivity |

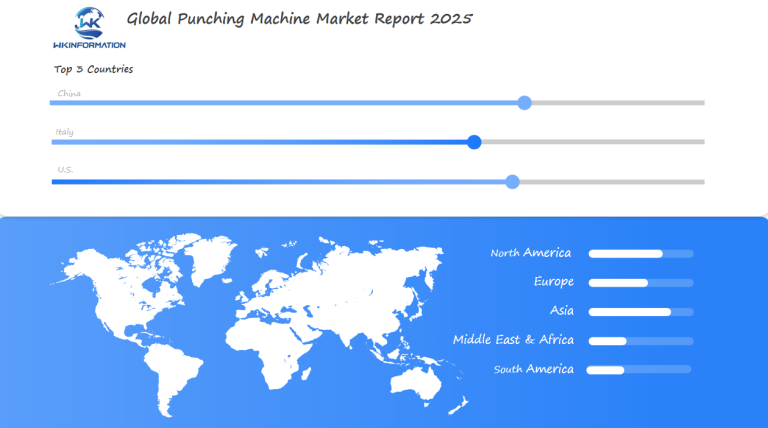

Global and Regional Outlook of the Punching Machine Market

The global punching machine market is experiencing rapid expansion due to the increasing demand for precision and efficiency in various industries. This growth is influenced by several regional factors, such as trends in industrial automation and the specific needs of the manufacturing sector.

Global Market Outlook

The global punching machine market has a wide range of uses in industries like automotive, electronics, and metalworking. According to industry predictions, the market is expected to grow significantly due to the increasing use of CNC punching machines and technological advancements.

Key trends shaping the global market include:

- Increased adoption of automation in manufacturing processes

- Growing demand for precision engineering

As stated by an industry expert, “The future of the punching machine market lies in its ability to adapt to new technologies and manufacturing processes.” This emphasizes the significance of innovation in driving market growth.

Global Punching Machine Market Outlook

The trends and growth patterns of the punching machine market vary across different regions. In North America, the market is being driven by the modernization of the manufacturing sector, while in Asia-Pacific, the growth is being fueled by the expanding industrial base in countries like China and India.

Regional highlights include:

| Region | Market Trend | Growth Driver |

| North America | Modernization of manufacturing | Technological advancements |

| Asia-Pacific | Expanding industrial base | Increasing demand from automotive and electronics sectors |

China’s manufacturing boom driving up punching machine demand

China’s thriving manufacturing sector is driving a surge in punching machine demand. The country’s rapid industrialization and technological advancements have positioned it as a global leader in manufacturing.

China’s Manufacturing Sector

The manufacturing sector in China has experienced significant growth due to government initiatives, investments in technology, and a skilled workforce. This growth has led to an increased demand for machinery and equipment, including punching machines.

Key factors driving China’s manufacturing boom include:

- Increased investment in industrial automation

- Government support for technological innovation

- A large and skilled workforce

Impact on Punching Machine Demand

The growing demand for punching machines in China is largely driven by the need for efficient and precise manufacturing processes. Punching machines are essential in various industries, including automotive, electronics, and metalworking.

The impact of China’s manufacturing boom on punching machine demand is evident in several areas:

- Increased production capacity

- Improved manufacturing precision

- Enhanced operational efficiency

As China’s manufacturing sector continues to expand, the demand for punching machines is expected to rise. This trend is likely to drive innovation and advancements in punching machine technology.

Italy’s precision engineering driving market innovation

Precision engineering, a hallmark of Italy’s manufacturing expertise, is playing a crucial role in innovating punching machines. Italy’s rich history of engineering excellence has positioned it as a leader in the development of advanced manufacturing technologies.

Precision Engineering in Italy

Italy’s precision engineering sector is known for its ability to produce high-quality, intricate components with exacting specifications. This skill is driving innovation in the punching machine market, allowing for the development of more advanced and efficient machines.

Key factors contributing to Italy’s precision engineering success include:

- Advanced manufacturing technologies

- Highly skilled workforce

- Strong focus on research and development

Innovation in Punching Machines

The innovation driven by Italy’s precision engineering sector is leading to significant advancements in punching machine technology. These advancements include improved accuracy, increased efficiency, and the ability to produce complex shapes.

As stated by industry experts, “The integration of precision engineering with punching machine technology is transforming the manufacturing landscape, enabling companies to produce higher quality products with less waste and energy consumption.”

The future of punching machine technology looks bright, with ongoing innovation expected from Italy’s precision engineering sector. As the industry continues to grow, we can expect even more advanced and efficient manufacturing solutions.

U.S. Manufacturing Sector Modernization and Punching Machine Trends

The ongoing modernization efforts in the U.S. manufacturing sector are significantly influencing trends in punching machine technology. As manufacturers adopt more advanced technologies, the demand for sophisticated punching machines is increasing.

This shift towards modernization is not just about adopting new machinery, but also about integrating digital technologies into manufacturing processes. This includes the use of automation, artificial intelligence, and data analytics to enhance efficiency and productivity.

As a result, we are witnessing a surge in demand for advanced punching machines that can meet these new requirements. These machines are not only more efficient but also offer greater precision and flexibility in operations.

Modernization of U.S. Manufacturing

The U.S. manufacturing sector is undergoing a significant transformation, driven by technological advancements and the need for increased efficiency. This modernization is impacting various aspects of manufacturing, including the use of punching machines.

According to industry experts, “The integration of advanced technologies like CNC and automation is revolutionizing the manufacturing landscape.” This shift is driving the demand for more advanced punching machines that can meet the new standards of precision and productivity.

Punching Machine Trends in the U.S.

Several trends are emerging in the U.S. punching machine market as a result of modernization. These include:

- Increased adoption of CNC punching machines for improved precision

- Growing demand for automated punching systems to enhance productivity

- Rise in the use of advanced materials and technologies, such as servo-electric punching machines

As the U.S. manufacturing sector continues to evolve, it is likely that these trends will continue to shape the punching machine market. Manufacturers are looking for machines that can offer high precision, flexibility, and reliability.

The future of punching machines in the U.S. looks promising, with a focus on innovation and technological advancement.

Future development paths in punching machine technology

Emerging technologies are set to transform the punching machine market in profound ways. As manufacturing continues to evolve, the integration of advanced technologies is expected to drive significant improvements in punching machine technology.

Emerging Technologies

The punching machine industry is witnessing a shift towards more sophisticated and automated systems. Artificial intelligence (AI) and machine learning (ML) are being incorporated to enhance precision and efficiency. These technologies enable real-time monitoring and predictive maintenance, reducing downtime and increasing productivity.

Another significant trend is the adoption of Industry 4.0 principles, which involve the integration of cyber-physical systems, the Internet of Things (IoT), and cloud computing. This leads to smarter, more connected manufacturing environments.

Future Developments

Future developments in punching machine technology are expected to focus on further enhancing automation and connectivity. Advancements in robotics will play a crucial role in this area, enabling more complex and flexible manufacturing processes.

The use of advanced materials and 3D printing technologies is also anticipated to influence the design and functionality of punching machines, allowing for more customized and efficient production processes.

- Increased use of AI and ML for predictive maintenance

- Integration of Industry 4.0 principles for smarter manufacturing

- Advancements in robotics for enhanced automation

Competitive players shaping the punching machine industry landscape

Key Players

- Amada – Japan

- Trumpf – Germany

- Komatsu – Japan

- Prima Power – Italy

- LVD Group – Belgium

- JMT USA – United States

- Muratec – Japan

- Euromac – Italy

- Salvagnini – Italy

- Bystronic – Switzerland

The competitive strategies include:

- Investing in research and development to improve product quality and functionality.

- Expanding their global presence through strategic partnerships and acquisitions.

- Enhancing customer service through after-sales support and training programs.

By adopting these strategies, key players in the punching machine industry are not only enhancing their competitive position but also driving the industry forward.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Punching Machine Market Report |

| Base Year | 2024 |

| Segment by Type | ·Mechanical Punching Machines

·CNC Punching Machines |

| Segment by Application | ·Electronics

·Metalworking |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The punching machine market is growing, thanks to the rise of industrial automation and changing manufacturing trends. As discussed earlier, various factors like industry chain insights, recent manufacturing trends, and regional perspectives are influencing the market.

Global Punching Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Punching Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Punching Machine Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Punching Machine Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Punching Machine Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Punching Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Punching Machine Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Punching Machine Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the punching machine market?

The growth of the punching machine market is driven by:

- the expansion of industrial automation

- increasing demand for efficient and precise punching machines

- trends such as Industry 4.0

What are the key segments of the punching machine market?

The punching machine market can be divided into two main segments: mechanical and CNC punching machines. These machines have applications in various industries such as automotive, electronics, and metalworking.

How is China’s manufacturing sector impacting the punching machine market?

China’s manufacturing boom is fueling demand for punching machines, driven by the country’s large-scale industrial production and infrastructure development.

What role is Italy’s precision engineering playing in the punching machine market?

Italy’s precision engineering sector is driving innovation in the punching machine market, with a focus on high-precision and customized solutions.

How is the modernization of the U.S. manufacturing sector influencing punching machine trends?

The modernization of the U.S. manufacturing sector is driving trends in the punching machine market, with a focus on automation, digitalization, and advanced manufacturing technologies.

What are the emerging technologies shaping the future of punching machine technology?

Emerging technologies such as artificial intelligence, robotics, and advanced materials are expected to shape the future of punching machine technology, enabling greater precision, efficiency, and customization.

Who are the key players in the punching machine industry?

The punching machine industry is competitive, with key players including manufacturers of mechanical and CNC punching machines, as well as companies providing related services and solutions.

What are the major challenges facing the punching machine market?

The punching machine market faces challenges such as regulatory compliance, market constraints, and the need for continuous innovation to stay competitive.