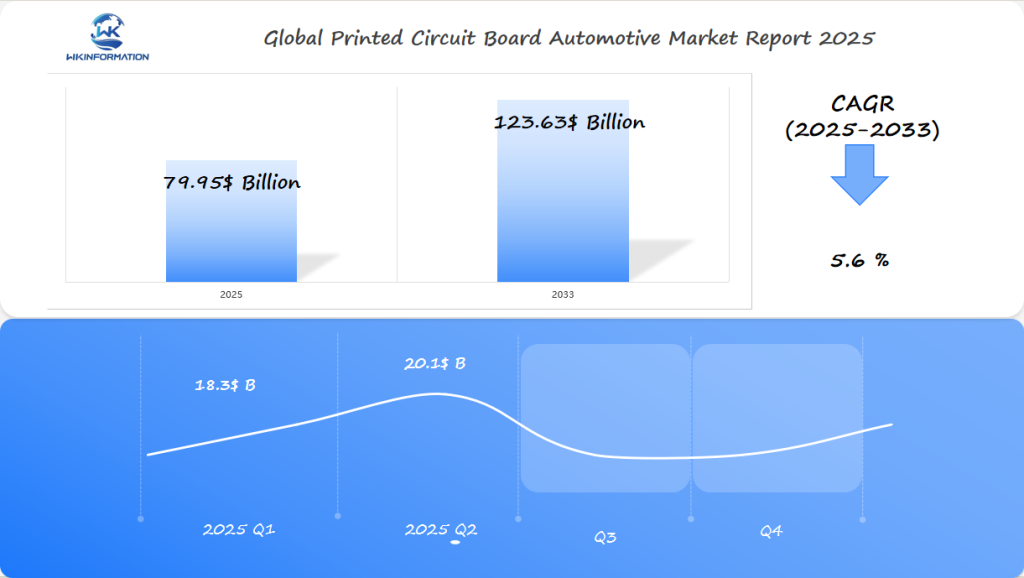

Printed Circuit Board Automotive Market Expected to Surpass $79.95 Billion Globally by 2025: Innovation Driving Smart Vehicles in China, Germany, and South Korea

Explore the latest trends and growth opportunities in the Printed Circuit Board Automotive Market, driven by advanced vehicle electronics and rising demand for electric vehicles.

- Last Updated:

Printed Circuit Board Automotive Market Projections for Q1 and Q2 2025 with Key Countries

The Printed Circuit Board (PCB) Automotive market is forecasted to reach $79.95 billion in 2025, growing at a CAGR of 5.6% through 2033. Q1 estimates position the market at $18.3 billion, supported by rising electric vehicle production and advanced driver assistance system (ADAS) integration in China and South Korea. Q2 expands to $20.1 billion as Germany strengthens its automotive supply chain with innovative PCB technologies focused on lightweight and high-performance modules.

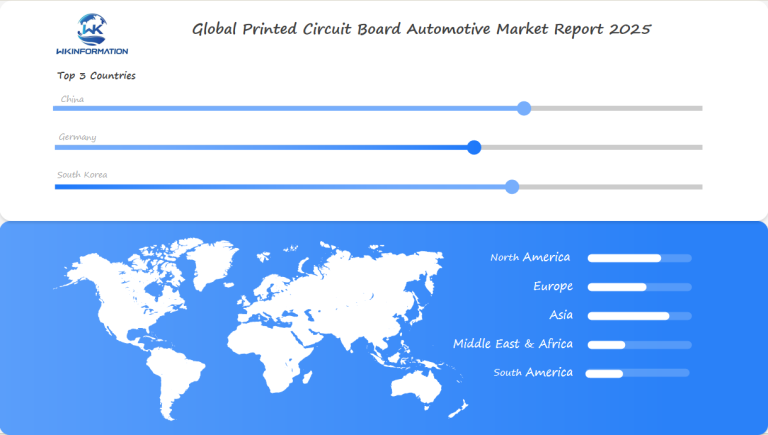

China, Germany, and South Korea represent the most critical markets, offering insights into regional manufacturing trends and regulatory influences. The push toward vehicle electrification and autonomous driving significantly fuels demand for complex PCBs. Additionally, supply chain resilience and component miniaturization remain focal challenges for manufacturers. Collaborative efforts between automotive OEMs and PCB suppliers continue to enhance innovation and quality standards, ensuring market robustness amid evolving consumer expectations.

Key Takeaways

- Global automotive PCB market expected to reach $79.95 billion by 2025

- Smart vehicles driving significant PCB technological innovations

- Increasing demand for advanced electronic automotive systems

- PCBs critical for enabling next-generation vehicle technologies

- Rapid electrification accelerating PCB market expansion

Upstream and downstream value chain analysis of automotive PCBs

The world of automotive electronics is complex. It involves a detailed PCB supply chain with many important players. Component makers are key, turning raw materials into advanced printed circuit boards. These boards power today’s cars.

The value chain for automotive PCBs includes several main steps:

- Raw material procurement

- PCB design and engineering

- Manufacturing processes

- Quality assurance

- Distribution to automotive OEMs

Automotive electronics need precision and reliability. Manufacturers face big challenges like keeping quality high, controlling costs, and keeping up with new tech.

Partnerships between PCB makers and car companies are key. These partnerships help drive innovation, cut down on time to market, and support the growth of advanced car electronics.

Key factors for success in the PCB supply chain are:

- Advanced technological capabilities

- Consistent quality control

- Competitive pricing

- Rapid prototyping

- Flexibility in design

The automotive PCB supply chain keeps changing, thanks to new tech like electric cars and ADAS. To meet the growing needs of the car electronics market, makers must stay quick and creative.

Market trends focusing on miniaturization and multi-layer PCB technologies

The world of automotive electronics is changing fast. This is thanks to PCB miniaturization and new multi-layer PCB technologies. These changes are making vehicle electronics smarter and more compact.

Key trends in automotive PCB development include:

- Reducing PCB footprint while increasing circuit complexity

- Implementing high-density interconnect (HDI) technologies

- Developing more robust multi-layer PCB architectures

Automotive electronics trends are making printed circuit boards smaller and stronger. They can handle tough conditions. Multi-layer PCBs are key for advanced driver assistance systems, electric vehicle power management, and cool infotainment systems.

| PCB Technology | Complexity Level | Automotive Application |

| Single-Layer PCB | Low | Basic electrical systems |

| Multi-Layer PCB | High | Advanced electronic control units |

| HDI PCB | Very High | ADAS and EV control systems |

There are many reasons for the push towards smaller PCBs. More cars are going electric, and people want smarter systems. Also, making cars lighter is important. Companies are working hard to create ultra-compact, high-performance printed circuit boards for modern cars.

Engineers are finding new ways to pack more into smaller spaces. This lets car makers build more advanced, connected, and efficient vehicles.

Restrictions including automotive quality standards and certifications

The automotive PCB industry has strict quality standards. These ensure safety, reliability, and performance. Manufacturers face a complex regulatory landscape to succeed.

Key automotive PCB standards

Key automotive PCB standards are vital for product quality and manufacturing:

- IATF 16949: The core quality management standard for the automotive industry

- AEC-Q100: Qualification and quality standard for electronic components

- ISO/TS 16949: Specific quality management requirements for automotive production

Challenges in regulatory compliance for PCB manufacturers

Meeting regulatory compliance is a big challenge for PCB manufacturers. They must invest a lot in quality standards. The certification process includes:

- Comprehensive testing protocols

- Detailed documentation

- Continuous quality improvement mechanisms

Companies with these certifications have an edge. Showing they follow automotive PCB standards is key in the global market. Automotive electronics need high precision and reliability, making certifications crucial for entry.

Impact of standards on small and medium-sized manufacturers

Meeting these standards can be costly and technical. Small and medium-sized manufacturers find it hard to meet the automotive industry’s quality demands.

Geopolitical factors influencing supply chain and trade of automotive PCBs

The global PCB trade has become more complex due to big changes in world politics. These changes are affecting the automotive electronics world a lot. Automotive supply chain disruptions are a big problem for makers all over, especially in PCBs.

Politics has changed how makers of automotive electronics plan their strategies. Big changes are happening in PCB production and buying plans in different areas.

- US-China trade tensions have created big uncertainty for making things

- Semiconductor shortages have shown weaknesses in global supply networks

- Trade policies in different areas are greatly changing where PCBs are made

Companies are now focusing on making their supply chains stronger. They are setting up factories in different places and finding better ways to buy parts.

| Region | PCB Manufacturing Impact | Supply Chain Resilience |

| North America | Increasing domestic production | High investment in local supply chains |

| Asia-Pacific | Continued manufacturing dominance | Developing alternative sourcing strategies |

| European Union | Emphasizing technological innovation | Strengthening regional manufacturing networks |

Now, makers see that being quick to adapt to politics is not just good—it’s essential in the fast-changing world of automotive electronics.

Segmentation by PCB type and substrate materials

The world of automotive PCBs is full of new technologies. Car makers are always finding new ways to make PCBs better for cars. They create special PCBs to solve problems, such as making cars faster and safer.

There are mainly three types of PCBs for cars:

- Rigid PCBs: These are the usual boards found in cars.

- Flexible PCBs: These are for parts that need to move and bend.

- Rigid-Flex PCBs: These mix both rigid and flexible parts for better performance.

What the PCB is made of is also very important. Each material has its own strengths that affect how well the PCB works.

| Substrate Material | Key Characteristics | Primary Applications |

| FR-4 | Standard epoxy-based material | General automotive electronics |

| High-Temperature FR-4 | Enhanced thermal resistance | Engine control units, power management |

| Ceramic Substrate | Superior heat dissipation | High-performance electronic systems |

The development of PCBs and materials is making car electronics better. Advanced materials and design techniques help make car electronics smaller, more efficient, and reliable.

Application analysis across EVs, ADAS, and infotainment systems

The world of car electronics is changing fast. Printed circuit boards (PCBs) are key in EVs, ADAS, and infotainment systems. These systems are making cars better, safer, and more fun to use.

EV PCBs: Powering the Future

Electric vehicles need special PCBs that can handle high power. EV PCBs manage power, battery systems, and keep things cool. The big challenges are:

- High-temperature resistance

- Enhanced electrical insulation

- Robust power distribution capabilities

ADAS Electronics: Precision and Reliability

ADAS electronics also need advanced PCBs. They need fast signal handling and must be reliable. Important parts include:

- Sensor integration circuits

- Multilayer signal processing boards

- Real-time communication networks

Automotive Infotainment: Connecting Experiences

Automotive infotainment PCBs connect communication, fun, and navigation. They handle complex digital interfaces. They need:

- Advanced signal processing

- Compact, efficient design

- Seamless connectivity features

PCBs are essential in modern car engineering. They drive innovation in electric, autonomous, and connected cars.

Global and regional market dynamics for automotive PCBs

The automotive PCB market is changing a lot worldwide. Different regions have their own special trends and tech levels.

Important areas for the global market include:

- North America: Leading in advanced automotive electronics

- Asia-Pacific: Dominating manufacturing capabilities

- Europe: Focusing on precision engineering

Looking at the trends, we see how tech and making things are key. Technological innovation and making skills are what set places apart. The U.S. and Asia are growing fast in printed circuit board tech.

Each region has its own special traits:

- Manufacturing setup

- Investments in research and development

- Support from governments

- How fast they adopt new tech

New markets are also changing the game. Countries like China, South Korea, and India are growing fast in making car electronics. This opens up new chances for PCB markets.

More investments and new tech will keep changing the PCB market for cars. This will bring new chances for makers and suppliers all over.

China's booming EV market pushing PCB demand

The Chinese EV market is growing fast, leading to more demand for automotive electronics and PCBs. China is getting ahead in electric vehicle making and electronic parts thanks to government support and new tech.

Several factors are boosting PCB demand in China:

- Rapid growth in electric vehicle production

- Big government support for EVs

- More people wanting smart car tech

- Research in car electronics is advancing

The car electronics sector in China is changing fast. Big companies are spending a lot on new PCB tech for electric cars.

The data shows China’s EV market is growing fast, which means more PCBs are needed. Companies are making more advanced PCBs for things like driving help, battery control, and car entertainment.

China is investing in research and development. This keeps China important in the global PCB market, promising more growth and new tech.

Germany's Precision Automotive Manufacturing Leading Innovation

The German automotive industry is leading in PCB innovation. It’s changing the global manufacturing scene. Precision engineering is a big part of German manufacturing. Companies like Volkswagen, BMW, and Mercedes-Benz are leading in electronic integration.

Key areas of PCB innovation in the German automotive sector include:

- Advanced multi-layer PCB technologies for complex vehicle systems

- High-reliability circuit designs for autonomous driving platforms

- Miniaturization of electronic components

- Integration of smart manufacturing techniques

European market leaders are spending a lot on research and development. Industry 4.0 initiatives have made PCB manufacturing more advanced and efficient.

Automotive manufacturers and PCB suppliers are working together. This has led to a strong ecosystem of technological progress. The focus on quality, reliability, and new designs makes the German automotive industry a global leader in electronic system development.

Research shows that German PCB manufacturers are creating advanced solutions. These are for electric vehicles, advanced driver-assistance systems, and next-generation automotive technologies.

South Korea's electronics sector supporting PCB growth

South Korean electronics makers are leading in innovation for automotive PCBs. Their strong electronics base makes them key in developing advanced PCBs for cars. Automotive PCB manufacturers in South Korea are breaking new ground in electronic design and making.

Key developments in South Korea’s electronics sector

Key developments in South Korea’s electronics sector include:

- Advanced flexible PCB technologies for electric vehicles

- Precision manufacturing of multi-layer circuit boards

- Innovative materials for improved automotive electronics

The Asian market trends show South Korea’s smart move in automotive electronics. Big names like Samsung and LG are pouring money into PCB research. These innovations are changing the automotive electronics world, focusing on electric and self-driving cars.

Korean PCB makers and global car brands are working together to speed up tech progress. South Korea’s strong background in semiconductors and electronics helps in making complex electronic systems for today’s cars.

The market is growing, and South Korean companies are becoming world leaders in automotive PCB tech. Their focus on research, precision making, and innovation is setting a new benchmark in car electronics.

Future outlook on next-generation automotive PCB technologies

The world of automotive electronics is changing fast. New PCB technologies are leading this change. They are making electronic systems in cars better and more advanced.

Several key trends are emerging in automotive PCB innovations:

- Advanced substrate materials with enhanced thermal management

- Miniaturized multilayer PCB configurations

- High-density interconnect (HDI) technologies

- Flexible and rigid-flex circuit designs

Graphene-based PCBs are a big step forward in car electronics. They conduct electricity well and keep cool, which is key for electric and self-driving cars.

| Technology | Performance Improvement | Potential Application |

| Graphene PCBs | 90% Better Heat Dissipation | Electric Vehicle Power Systems |

| 3D-Printed Electronics | 40% Reduced Manufacturing Time | Custom Automotive Interfaces |

| Nano-composite Materials | Enhanced Signal Integrity | Advanced Driver Assistance Systems |

Companies are putting a lot of money into research for new PCB technologies. The future of car electronics depends on materials science and new ways to make things.

Competitive landscape overview of key PCB manufacturers

The automotive PCB market is very competitive. Global manufacturers are working hard to innovate and get more market share. They focus on creating advanced technologies for electric vehicles and smart car systems.

Key Players:

-

TTM Technologies – USA

-

Sanmina Corporation – USA

-

Nippon Mektron – Japan

-

Unimicron Technology – China

-

Zhen Ding Technology – China

-

Compeq Manufacturing – China

-

Ibiden – Japan

-

AT&S – Austria

-

Multek – China

-

Kinsus Interconnect Technology – China

Leading companies are using smart strategies to stay ahead. The global printed circuit board market is full of action. Many big players are at the forefront of technology.

- Top PCB makers are spending a lot on research and development.

- Being at the forefront of technology is key to staying competitive.

- Working with car makers helps grow the market.

The competitive scene is complex. It includes both well-known companies and new tech innovators. The competition is especially fierce in areas with lots of car factories.

Overall

The automotive PCB industry is facing big challenges. Modern cars need advanced printed circuit boards that can handle tough conditions. Companies must meet high quality standards, keep costs low, and stay competitive.

Despite these hurdles, the sector has bright growth prospects. The move towards electric and self-driving cars is creating new chances. The automotive PCB industry outlook shows a big increase thanks to advanced tech and connected cars. Markets in Asia Pacific and Latin America are also growing fast.

The industry’s success depends on solving big problems like making things smaller, managing heat, and making them reliable. Companies need to invest in R&D for better, more efficient PCBs. Working together with car makers and PCB suppliers will help drive innovation.

Another big chance for growth is in making things more sustainable. Companies that create green, energy-saving circuit boards will stand out. The shift to electric and smart cars opens up a world of new tech and market chances.

Global Printed Circuit Board Automotive Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Printed Circuit Board Automotive Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Printed Circuit Board Automotive Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Printed Circuit Board Automotive Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Printed Circuit Board Automotive Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Printed Circuit Board Automotive Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Printed Circuit Board Automotive Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Printed Circuit Board AutomotiveMarket Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Automotive PCB Market?

The growth of the automotive PCB market is driven by the need for smart vehicles and advanced electronics. Features like ADAS, infotainment, and vehicle electrification are also key. The market is expected to reach $79.95 billion by 2025.

What are the different types of PCBs used in automotive applications?

Automotive PCBs include rigid, flexible, and rigid-flex types. Each type has its own purpose. Substrate materials vary, depending on the application’s needs.

What quality standards are critical for automotive PCBs?

ISO/TS 16949, AEC-Q100, and IATF 16949 are critical standards for automotive PCBs. These ensure reliability, safety, and consistent performance. They pose challenges for manufacturers.

How are emerging technologies impacting automotive PCB development?

Technologies like graphene-based PCBs and 3D-printed electronics are changing the game. They help with heat dissipation, signal integrity, and miniaturization. This could revolutionize vehicle design and performance.

Which regions are leading in automotive PCB innovation?

China, Germany, and South Korea are at the forefront of automotive PCB innovation. Here’s why:

- China: The country’s electric vehicle market is experiencing rapid growth.

- Germany: Known for its expertise in precision engineering.

- South Korea: Capitalizing on its robust electronics manufacturing industry.

What are the main uses of automotive PCBs?

Automotive PCBs are used in:

- Electric vehicles

- Advanced Driver Assistance Systems (ADAS)

- Infotainment systems

Each of these areas has specific design requirements to ensure optimal performance and reliability.

How do geopolitical factors affect the automotive PCB market?

Geopolitical factors such as trade tensions and tariffs have an impact on the automotive PCB market. Events like the US-China trade war and global semiconductor shortages can disrupt supply chains, making it challenging for companies in the industry.

In response to these challenges, companies in the automotive PCB market must find new strategies to cope with the changing landscape. This may involve exploring alternative sourcing options, diversifying their supply chains, or adapting their business models to navigate through geopolitical uncertainties.

What challenges do PCB manufacturers face in the automotive sector?

Manufacturers face challenges like maintaining quality standards and managing costs. They must ensure timely delivery and meet complex design requirements. Adapting to rapid technological changes is also a challenge.