Prefabricated Balcony Market Expected to Reach $982.15 Million by 2025: Modular Construction Advances in Germany, the U.K., and the U.S.

Explore the Prefabricated Balcony Market trends, driven by urbanization and sustainable construction demands. Get insights on growth projections, key players, and market dynamics.

- Last Updated:

Prefabricated Balcony Market Forecast for Q1 and Q2 2025

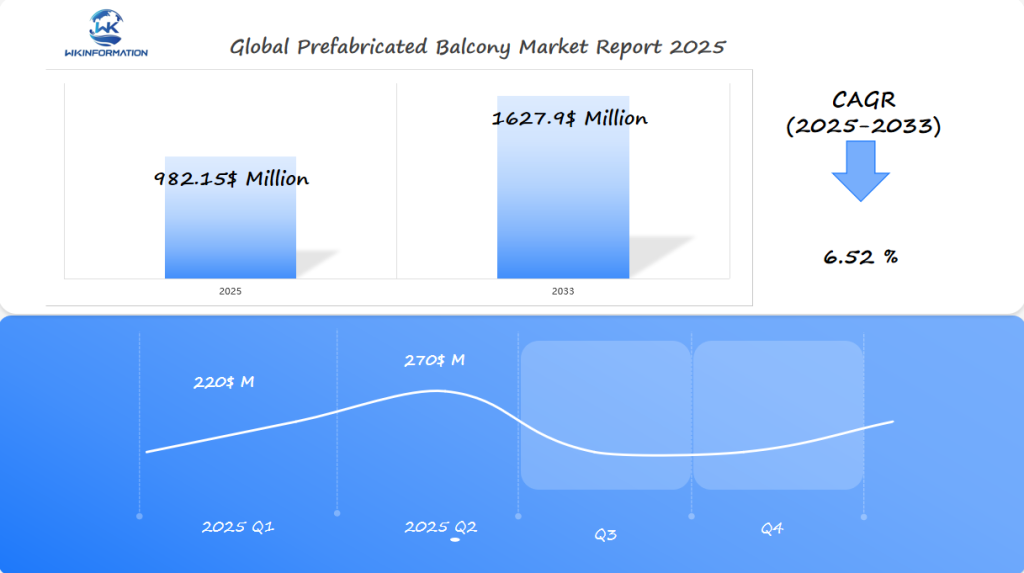

The Prefabricated Balcony market is projected to reach $982.15 million in 2025, underpinned by a steady CAGR of 6.52% expected through 2033. The market size for Q1 2025 is estimated at approximately $220 million, reflecting a moderate start shaped by seasonal construction slowdowns and ongoing supply chain optimizations. In Q2, the market is forecasted to grow to around $270 million, driven by heightened construction activities, especially in urban residential and commercial projects.

Key Takeaways

- Prefabricated balcony market projected to reach $982.15 million by 2025

- Modular construction techniques revolutionizing urban development

- Increased efficiency and reduced construction timelines

- Technological innovations driving market expansion

- Sustainable building solutions gaining widespread adoption

Upstream and Downstream Industry Chain Analysis of the Prefabricated Balcony Market

The prefabricated balcony market is a complex web of players. They work together to bring new ideas and efficiency to building design. This analysis shows how suppliers and buyers are connected in this process.

Upstream Suppliers

Upstream suppliers are key in the prefabricated balcony market. They include:

- Raw material manufacturers specializing in steel

- Aluminum production companies

- Concrete and composite material suppliers

- Specialized engineering component providers

Downstream Buyers

Downstream buyers are a wide range of construction players. They include:

- Residential property developers

- Commercial building contractors

- Urban housing management firms

- Architectural design studios

The relationship between suppliers and buyers is dynamic. Technological advancements and material innovations lead to better balcony systems. This makes building faster and cheaper.

Working together, manufacturers, suppliers, and builders create top-notch balcony solutions. These solutions meet the latest design and engineering needs.

Trends in off-site construction and time-saving solutions

The construction world is changing fast with off-site construction leading the way. Prefabricated balconies are a big step forward. They are made in factories, improving how buildings are built.

Off-site construction brings many benefits:

- Less need for workers on-site

- Better quality control

- Less delay from weather

- Projects finish faster

Time-saving in making balconies is changing the game for homes and businesses. New tech helps make balcony parts quickly. Then, they can be put together fast on-site.

This method saves a lot of money. Projects can be up to 40% faster with prefabricated balconies. It cuts down on waste and makes schedules more reliable.

Modern tech makes sure each balcony is top-notch. It also lets architects and developers be more creative. Digital models and precise engineering have made off-site construction a smart choice for today’s buildings.

Market restrictions due to design limitations and regulatory approvals

The prefabricated balcony market has big hurdles. Design limits and strict rules are major challenges. These rules make it hard for makers to bring new ideas to the table.

Some big problems with design limits are:

- Following local and national building codes

- Ensuring structures are strong

- Meeting material standards

- Handling seismic and wind forces

Companies need smart design plans to get past these rules. Adaptive modular approaches help meet different building needs while keeping things safe and working well.

Safety rules really affect how balconies are made. Makers spend a lot on research to make products that fit strict rules everywhere.

The top companies in the balcony market know how to handle design limits and rules. They create solutions that grow and fit many different buildings.

Geopolitical factors influencing construction practices and labor costs

The prefabricated balcony market faces many challenges due to geopolitical factors. These factors greatly affect how buildings are made and the cost of labor. Different regions bring their own set of problems for companies trying to make and sell balconies.

Several key geopolitical factors shape the global prefabricated balcony industry:

- Trade policies affecting raw material imports

- International economic regulations

- Regional labor market variations

- Construction standards and building code differences

Companies must find ways to work well in different economic settings. Strategic localization of manufacturing processes is seen as a key strategy to deal with these changes.

| Region | Labor Cost Impact | Construction Practice Adaptation |

| North America | High skilled labor costs | Advanced modular design techniques |

| Europe | Moderate labor regulations | Sustainable prefabrication methods |

| Asia-Pacific | Lower labor expenses | Rapid scalability in production |

Construction methods are always changing as companies find new ways to handle global challenges. Being able to quickly adjust to economic changes is key to staying ahead in the prefabricated balcony market.

Segmentation by Type: Steel, Concrete, and Timber Prefabricated Balconies

Prefabricated balconies are a big step forward in building design. They come in steel, concrete, and timber, each suited for different needs and places. These materials help meet various architectural and environmental demands.

Building experts pick balcony materials based on what the project needs. They look at how well the material works, its looks, and how it holds up. Each type has its own strengths for design and strength.

Steel Prefabricated Balconies

Steel balconies are known for their strength and flexibility. They are selected for:

- High load-bearing capacity

- Corrosion resistance

- Lightweight structural profile

- Design flexibility

Concrete Prefabricated Balconies

Concrete balconies are known for their toughness and durability. They are great for:

- Excellent fire resistance

- Sound insulation properties

- Thermal mass regulation

- Long-term structural stability

Timber Prefabricated Balconies

Timber balconies are loved for their natural look and eco-friendliness. They offer:

- Renewable material source

- Warm visual appearance

- Natural insulation properties

- Adaptable design potential

| Material | Strength Rating | Cost Efficiency | Sustainability Score |

| Steel Balconies | High | Medium | Low |

| Concrete Balconies | Very High | Low | Medium |

| Timber Balconies | Medium | High | High |

Each material has its own benefits. This lets architects choose the best one for each project and setting.

Segmentation by Application: Residential Apartments, Commercial Buildings, and Hospitality Structures

Prefabricated balconies have changed how we design buildings. They work well for homes, offices, and hotels. These modular parts help create spaces that are both useful and beautiful.

- Residential applications: supporting urban living solutions

- Commercial buildings: seeking efficient design strategies

- Hospitality structures: requiring unique architectural features

Residential Apartments: Expanding Living Spaces

More people want outdoor spaces in cities. Prefabricated balconies offer a quick way to add these areas. They make homes more valuable and happier for those who live there.

Commercial Buildings: Functional Design Solutions

Commercial spaces use prefabricated balconies to stand out. Offices, shops, and mixed-use buildings use them for their looks and efficiency.

Hospitality Structures: Enhancing Guest Experiences

Hotels and resorts are using prefabricated balconies more. They give guests amazing views and a smooth transition from inside to outside.

| Application Sector | Key Benefits | Market Growth Potential |

| Residential | Increased living space | High |

| Commercial | Architectural flexibility | Medium-High |

| Hospitality | Enhanced guest experiences | Medium |

Global regional analysis of the Prefabricated Balcony market

The global market for prefabricated balconies shows different trends in each region. These trends affect how buildings are made and how the market grows. The regional market analysis points out big differences in various areas.

Asia Pacific: Leading the Market

Asia Pacific leads the prefabricated balcony market. Fast growth in cities and new buildings drive the market. Countries like China and India are growing fast in construction, thanks to their economies and city plans.

North America: Advanced Building Techniques

North America uses advanced ways to build modules.

Europe: Focus on Green Designs

European markets focus on green designs.

New Markets: Special Building Challenges

New markets face special building challenges.

More people want quick and efficient building methods. The prefabricated balcony market meets this need. It offers new ways to build that save time and reduce the need for workers on site.

| Region | Market Growth Potential | Key Drivers |

| Asia Pacific | High | Urbanization, Infrastructure Development |

| North America | Moderate | Technological Innovation |

| Europe | Steady | Sustainability Focus |

Technological progress and economic changes are changing the prefabricated balcony market worldwide. Companies need to adjust to local building rules, design tastes, and building ways to succeed in different markets.

Germany's Leadership in Modular Construction Techniques

The German construction industry leads in modular construction, introducing new ways to build. With a strong engineering background, Germany is a top prefabricated building provider in Europe. It sets high standards for efficiency and green building.

Advanced Modular Building Methods

German makers have come up with advanced modular building methods. These methods cut down building time and boost project quality. Experts in Germany use top-notch manufacturing to build complex structures fast and accurately.

- Precision engineering with automated production systems

- High-performance sustainable materials

- Energy-efficient design principles

- Streamlined manufacturing workflows

Tech Innovation and New Building Solutions

Germany’s focus on tech innovation makes it a leader in modular building. German companies keep pushing the limits with new building solutions. They use digital tech, robotics, and smart manufacturing to achieve top architectural results.

Prefabrication for Homes and Business Buildings

German prefabrication works for homes and business buildings alike. Its ability to make quality, custom building parts makes Germany a top name in green building.

The U.K.'s adoption of prefabricated solutions in urban housing

The British construction market is changing fast with prefabricated housing. This new way is helping solve housing shortages and make cities denser.

Benefits of Prefabricated Balcony Systems

Prefabricated balcony systems are getting popular in big cities like London, Manchester, and Birmingham. They bring many benefits:

- Reduced construction time

- Lower overall project costs

- Enhanced architectural flexibility

- Improved sustainability metrics

Urban Developers and Prefabricated Housing

Urban developers are using prefabricated housing to make homes more efficient. The modular construction approach allows for faster deployment of housing units. This is key in solving the UK’s housing crisis.

Support for New Building Methods

Rules are now helping these new building methods. The British construction market sees the value of off-site manufacturing. It helps make housing development faster and meets urban needs.

Focus on Prefabricated Solutions in Big Cities

Big cities are focusing on prefabricated solutions. They can be quickly added to the city. This helps solve housing shortages and supports green building.

The U.S. market's focus on cost-effective building methods

The US construction market is changing fast. Cost-effective building methods are becoming more popular. Prefabricated balconies are leading this change, offering new ways to build homes and commercial spaces.

What’s driving this change in American housing trends? It’s all about:

- Reducing construction time

- Lowering labor costs

- Improving construction quality

- Dealing with a shortage of builders

Developers in big cities are turning to prefabricated balconies. These modular solutions are changing the game for multi-family homes, student housing, and mixed-use projects. They make building faster and better, without sacrificing design or safety.

Companies are pushing the limits of prefabrication. They’re making balcony modules in factories. This way, they can:

- Save on materials

- Build more precisely

- Save money on projects

- Finish buildings faster

The US construction market sees prefabricated balconies as a smart choice. They help solve big building problems while keeping costs down and quality high.

Future development prospects in the Prefabricated Balcony market

The prefabricated balcony market is set for big changes. New technologies and strategies are leading the way. These changes are opening up new possibilities for architects and builders.

Key areas of innovation include:

- Smart balcony integration with IoT technologies

- Advanced lightweight composite materials

- Energy-efficient design solutions

- Customizable architectural adaptations

New discoveries in materials science are changing balcony design. High-strength composite materials make structures lighter and stronger. They can be made and put up fast, saving time and keeping buildings safe.

| Innovation Category | Potential Impact | Market Readiness |

| Smart Sensor Integration | Structural Health Monitoring | Near-Term Implementation |

| 3D Printed Components | Rapid Customization | Emerging Technology |

| Sustainable Materials | Reduced Environmental Footprint | High Market Potential |

Urban design trends are driving prefabricated balcony makers towards tech-driven solutions. The future looks bright, with a growing need for adaptable, green building parts that fit modern styles.

Competitor Analysis and Market Share Distribution

Key players in the prefabricated balcony market are focusing on technological advancements to improve construction efficiency and sustainability. They are expanding operations in rapidly urbanizing regions such as Asia-Pacific, where the demand for cost-effective and time-saving building solutions is increasing. Strategic collaborations with construction firms and investments in innovative design and manufacturing processes are enabling these companies to enhance their market presence and drive the adoption of prefabricated balcony systems in modern architectural projects.

Key Players:

-

Lendlease (Australia)

-

Permasteelisa Group (Italy)

-

AluK Group (Luxembourg)

-

Schüco International (Germany)

-

YKK AP (Japan)

-

Kawneer (United States)

-

Oldcastle BuildingEnvelope (United States)

-

W&W Glass (United States)

-

Hunter Douglas (Netherlands)

-

Kingspan Group (Ireland)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Prefabricated Balcony Market Report |

| Base Year | 2024 |

| Segment by Type | · Steel

· Concrete · Timber |

| Segment by Application |

· Residential Apartments · Commercial Buildings · Hospitality Structures |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Prefabricated Balcony Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Prefabricated Balcony Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Prefabricated Balcony Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Prefabricated Balcony Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Prefabricated Balcony Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Prefabricated Balcony Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Prefabricated Balcony Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Prefabricated Balcony Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a prefabricated balcony?

A prefabricated balcony is made in a factory and then put up at a building site. They are designed to fit quickly into homes, offices, and hotels. This makes building faster and easier.

What are the main materials used in prefabricated balconies?

The primary materials used in prefabricated balconies are:

- Steel: known for its strength and flexibility

- Concrete: valued for its durability and fireproof properties

- Timber: appreciated for its beauty and eco-friendliness

How do prefabricated balconies benefit construction projects?

They save time and money. They need less work on site and are built to last. This means projects can start sooner and cost less.

Are prefabricated balconies customizable?

Yes, they can be made to fit many styles and needs. New ways of making them allow for more choices while keeping costs down.

Which regions are at the forefront of adopting prefabricated balconies?

Germany, the UK, and the US are leading the way in adopting prefabricated balconies. These countries are pushing the boundaries of what can be achieved with these innovative structures, placing a strong emphasis on design and finding solutions to urban challenges.

How do geopolitical factors impact prefabricated balcony markets?

Factors such as trade regulations and labor costs have an impact on the market. Companies need to find solutions to navigate these challenges. This may involve producing goods locally and forming partnerships with other entities.

What future technologies might impact prefabricated balconies?

New tech like advanced materials and smart sensors could change things. 3D printing might also play a big role. These could make balconies better and more personal in the future.

Are prefabricated balconies environmentally sustainable?

Many prefabricated balconies are designed with the environment in mind. They use less waste during production and can be made from recycled materials. Additionally, these balconies can incorporate energy-saving features, further reducing their environmental impact.

What applications use prefabricated balconies?

They are used in many places. This includes apartments, offices, hotels, and more. Each place has its own needs, and these balconies can meet them.

How do building codes affect prefabricated balcony design?

Codes and safety rules shape how prefabricated balconies are made. Companies must follow these rules while still being flexible and efficient. This balance is important for accommodating different building styles.