Pneumatic Positioner Market Expected to Reach $1.15 Billion Globally by 2025: Process Automation in Germany, U.S., and China

The Pneumatic Positioner Market shows steady growth driven by rising industrial automation, enhanced control systems, and increased demand in oil & gas, chemical, and manufacturing sectors.

- Last Updated:

Pneumatic Positioner Market Q1 and Q2 2025 Outlook with Country Analysis

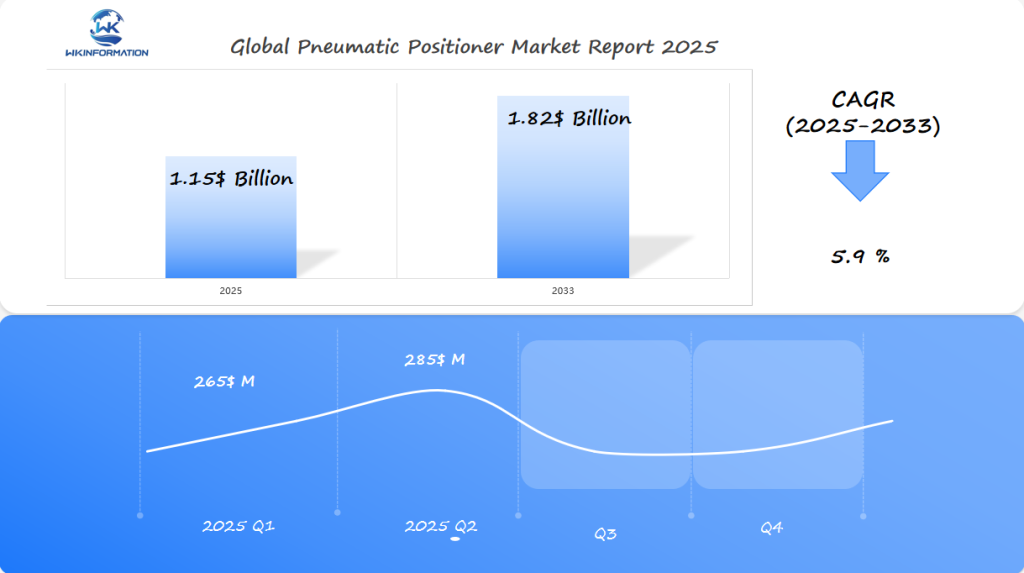

The Pneumatic Positioner market is projected to reach $1.15 billion in 2025, with a CAGR of 5.9%. Q1 sales are estimated at $265 million, led by Germany’s advanced industrial automation sector and U.S. demand in oil & gas and chemical plants. Q2 grows to around $285 million, supported by China’s expanding manufacturing base and infrastructure upgrades. Germany, U.S., and China are crucial countries for market study due to their strong industrial bases and regulatory environments favoring automation efficiency.

Key Takeaways

- Projected market value of $1.15 billion by 2025

- Growing demand for precise industrial automation solutions

- Increasing adoption across manufacturing sectors

- Technological innovations driving market expansion

- Enhanced process control capabilities becoming critical

Analyzing Upstream and Downstream Value Chains of Pneumatic Positioners

The pneumatic positioner market is a complex web of parts and industries. Value chain analysis shows how manufacturers, suppliers, and users work together. This teamwork drives innovation and growth in the market.

Pneumatic positioners are key to industrial automation. They need a network of specialized makers and suppliers. These parts are crucial for their design and how they work.

Key Components and Industry Suppliers

- Precision pressure sensors

- Pneumatic actuators

- Electronic control boards

- Mechanical feedback mechanisms

End-user industries are vital in shaping pneumatic positioner demand. The growth in material handling equipment has opened up new chances for advanced positioning tech.

Critical End-User Industry Requirements

- Oil & Gas: High-precision control in extreme environments

- Chemical Processing: Corrosion-resistant materials

- Manufacturing: Rapid response and consistent performance

The connections between these industries show how pneumatic positioner tech can improve many sectors. This highlights the importance of innovation in these fields.

Trends enhancing precision control and automation efficiency

The pneumatic positioner market is going through a big change. Smart technologies are making precision control and automation better in many industries. Companies are adding advanced digital tools to improve how things work and make things simpler.

Smart pneumatic positioners are changing industrial automation a lot. Some key trends include:

- Advanced sensor integration for real-time monitoring

- Predictive maintenance capabilities

- Enhanced digital communication protocols

- Machine learning-driven control algorithms

Integration of Smart Technologies in Pneumatic Positioners

Today’s pneumatic positioners use the Internet of Things (IoT) for better control. These smart systems can find problems, plan for maintenance, and work better on their own.

| Technology | Performance Impact | Efficiency Gain |

| IoT Sensors | Real-time monitoring | 15-25% improved accuracy |

| AI Algorithms | Adaptive control | 20-30% reduced downtime |

| Digital Communication | Seamless integration | 10-20% faster response |

Advancements in Control Algorithms and Feedback Systems

New control algorithms are making automation much better. Predictive modeling and smart feedback help pneumatic positioners adjust on their own. This ensures they work their best in different settings.

These new technologies are more than just small updates. They are a big change in how control systems work. By using smart pneumatic positioners, companies can reach new heights of precision and success.

Market restrictions including safety and industry compliance

Pneumatic positioner makers face tough challenges with safety and compliance rules. They need to pay close attention to these rules and plan carefully when making products.

Safety is key in making pneumatic positioners for various industries. Companies must follow several important rules:

- Stringent safety protocols for industrial automation equipment

- Comprehensive risk assessment procedures

- Adherence to international regulatory frameworks

Regulatory Challenges in Pneumatic Positioner Implementation

Compliance is a big challenge for engineers and developers. Each industry has its own rules for pneumatic positioners. This means they need to know a lot and be flexible in their designs.

- Oil & Gas Sector: Extreme environmental conditions demand robust safety mechanisms

- Chemical Processing: Strict material compatibility and containment requirements

- Pharmaceutical Manufacturing: Precision control and contamination prevention

Navigating Complex Compliance Landscapes

To succeed, companies must really understand the rules for each industry. They need to spend a lot on research, testing, and keeping up with new rules.

Geopolitical influences on automation equipment trade

The global automation equipment trade is complex, with many geopolitical challenges. These challenges change how companies plan their strategies. Pneumatic positioner makers must deal with international trade policies and regional market trends.

Emerging markets are changing the automation equipment world. They do this by investing in new technologies and adapting to new markets. India is a great example, showing big growth in areas like warehousing and logistics.

Trade Policy Impact on Pneumatic Positioner Markets

Geopolitical factors affect automation equipment trade in several ways:

- Tariff regulations impact the transfer of equipment across borders.

- Restrictions on technology transfer between countries are a big issue.

- Each region has its own rules for industrial automation.

Understanding Regional Market Dynamics and Competitive Strategies

Every global region has its own set of challenges and opportunities for pneumatic positioner makers. Companies need to think about:

- Setting up local manufacturing

- The technology infrastructure in each region

- Different economic policies

Companies must be flexible and adapt to different geopolitical settings. They need to keep innovating and offer good prices to stay competitive.

The global market is connected, so companies must watch for changes in geopolitics. This helps them stay relevant and competitive.

Segmentation by type and control technology

The pneumatic positioner market is complex, with different types and control technologies. This complexity helps industries find the best solutions for precise automation.

Positioner Actuator Types

- Single-acting positioners: Need only one air supply to move

- Double-acting positioners: Use two air supplies for better precision

Control Technology Approaches

- Analog control systems

- Digital control technologies

Single-Acting vs. Double-Acting Pneumatic Positioners

Single-acting pneumatic positioners work with one air supply, good for simple tasks. Double-acting positioners offer more control, perfect for complex industrial needs.

Analog and Digital Control Technologies

Control technology greatly affects how pneumatic positioners work. Digital control is becoming more popular, offering better diagnostics and smart integration.

| Characteristic | Analog Control | Digital Control |

| Signal Processing | Linear, continuous signals | Discrete, programmable signals |

| Diagnostic Capabilities | Limited | Advanced self-monitoring |

| Precision | Standard accuracy | High precision |

Application analysis in oil & gas, chemical, and manufacturing industries

Pneumatic positioners are key to precision and efficiency in many industries. They help control complex processes well. This is especially true in oil & gas, chemical, and manufacturing sectors.

Adding pneumatic positioners has changed how we automate industries. They make it possible to control things precisely in many important areas.

Specific Industry Requirements and Use Cases

Each industry needs something different from pneumatic positioners:

- Oil & gas needs strong gear that can handle very hot and harsh places

- The chemical industry needs very accurate control for complex reactions

- Manufacturing needs precise positioning for complex machines

Growth Prospects and Operational Challenges

Each industry has its own hurdles when using pneumatic positioners:

| Industry | Key Challenges | Growth Potential |

| Oil & Gas | Extreme environmental conditions | High investment in infrastructure |

| Chemical | Precision control requirements | Projected 3% global output increase |

| Manufacturing | Complex automation integration | Increasing automation adoption |

Companies are working hard to make better pneumatic positioners. They focus on making them last longer, work more precisely, and include smart technology.

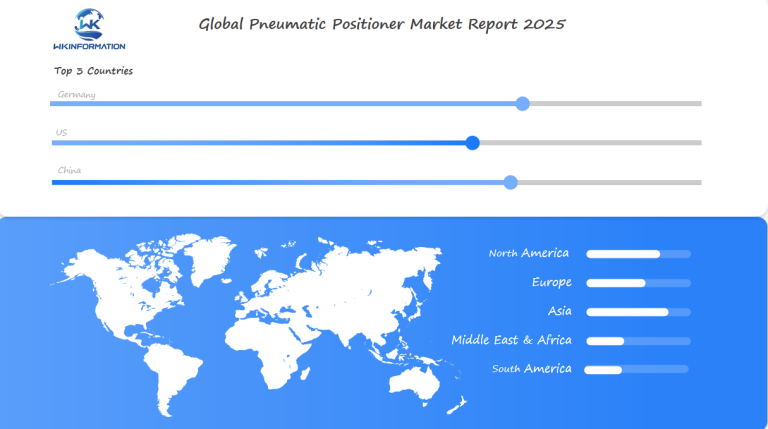

Regional Perspectives on Pneumatic Positioner Market Growth

The global pneumatic positioner market shows different trends in each region. Each area has its own opportunities and challenges. Knowing these trends helps us understand the industry’s changes.

North American Market: Innovation and Technological Leadership

The North American market is known for its advanced technology and well-developed automation. Key factors driving growth include:

- Big investments in new process control technologies

- Strong focus on industrial automation in various sectors

- Active research and development areas

European Market: Sustainability and Energy Efficiency

In Europe, the focus is on energy-saving solutions and strict environmental rules. Sustainable engineering practices are key in the region’s automation.

- Focus on green manufacturing technologies

- Rules supporting eco-friendly industrial practices

- High use of smart control systems

Asia-Pacific Market: Rapid Industrialization

The Asia-Pacific market is growing fast in pneumatic positioner technologies. Countries like India and China are seeing huge industrial growth. This is creating a big demand for these technologies.

- Fast growth in the manufacturing sector

- Government support for modernizing industries

- More investments in automation systems

Germany's engineering excellence driving demand

German engineering is known for its precision and quality, especially in the pneumatic positioner market. The country’s makers are top in industrial automation technologies. They keep improving pneumatic positioner innovation.

The German way of engineering is special:

- Unparalleled precision in manufacturing

- Rigorous quality control processes

- Cutting-edge technological development

- Commitment to sustainable engineering solutions

Innovative Strategies of German Manufacturers

Leading German companies have transformed the design of pneumatic positioners by incorporating advanced control algorithms and intelligent technologies. Through precision engineering, they are able to create products that establish global benchmarks, showcasing remarkable technical expertise.

Global Export Trends

Export trends show Germany’s significant influence in the pneumatic positioner market. German manufacturers have established a presence in international markets, leveraging their reputation for high-quality engineering.

Germany’s pneumatic positioner manufacturers continue to lead in global automation. They are committed to innovation and pursuing excellence.

U.S. Adoption of Smart Process Control

The world of industrial automation is changing fast. Smart process control is making big changes in pneumatic positioner systems. The United States is leading this change, using new IoT and AI tech to make things work better.

Smart process control is making a big difference in how things work. Companies are using IoT integration to make their pneumatic positioner systems smarter and more responsive.

IoT and AI Transformation in Pneumatic Systems

AI in pneumatic positioners brings big benefits:

- Real-time performance monitoring

- Predictive maintenance capabilities

- Enhanced precision in control mechanisms

- Reduced operational downtime

Implementation Case Studies

Many U.S. industries have seen big wins with smart process control. The manufacturing and energy sectors have seen huge boosts in how well they work. This is thanks to advanced pneumatic positioner systems.

| Industry | IoT Integration Benefits | Efficiency Improvement |

| Manufacturing | Automated process control | 15-25% productivity increase |

| Energy | Predictive maintenance | 30% reduction in equipment failures |

| Chemical Processing | Real-time monitoring | 20% improved system reliability |

The future of pneumatic positioner systems is all about keeping up with new tech. Smart process control is leading the way to even more precision and efficiency in all kinds of industries.

China's growing industrial automation sector

The Chinese industrial automation sector is growing fast, changing the world of manufacturing. China, the biggest manufacturing center, is leading in tech and modernizing industries.

The pneumatic positioner market in China is key to this change. Growth comes from:

- Government-backed Made in China 2025 initiative

- Fast growth in manufacturing and process industries

- More investment in smart manufacturing tech

- Higher demand for precise control systems

Domestic Manufacturers Rising to Global Challenges

Chinese companies are quickly improving pneumatic positioner tech. They’re not just competing at home but also taking on global brands with new designs and prices.

The competitive scene shows several important points:

- Big push for research and development

- Partnerships with global tech companies

- Improving product quality

- Aggressive plans to enter new markets

Market Positioning and Future Outlook

Chinese pneumatic positioner makers are set to grab a big share of the market. They use advanced engineering and cost-effective production. Their strategy mixes tech innovation with smart market moves.

Future development prospects for pneumatic positioners

The pneumatic positioner market is at a turning point. New technologies are changing how we automate and control industries.

Now, making pneumatic positioners more sustainable is a big focus. Companies are working on energy-saving and eco-friendly designs. This shift is making systems smarter and greener.

Emerging Technologies Transforming Pneumatic Positioners

- Advanced sensor integration for real-time performance monitoring

- AI-powered predictive maintenance capabilities

- Wireless connectivity for enhanced remote control

- Adaptive learning algorithms for optimal system performance

The pneumatic positioner market research shows a move towards smaller, smarter systems. Intelligent control systems are replacing traditional mechanical approaches, making processes more precise and responsive.

Sustainability and Energy Efficiency Innovations

Key development areas include:

- Reduced air consumption designs

- Enhanced energy recovery mechanisms

- Integration with renewable energy systems

- Modular architectures for improved lifecycle management

Companies are now making pneumatic positioners that save energy and help the environment. The mix of smart tech and green thinking is leading to big changes in this important field.

Competitive landscape analysis of major manufacturers

Key players in the pneumatic positioner market are focusing on technological advancements to enhance precision, reliability, and integration with modern automation systems. They are expanding operations in regions such as Asia-Pacific and North America, where rapid industrialization and the adoption of Industry 4.0 technologies are driving demand for advanced control solutions.

Key Players:

-

Festo (Germany)

-

Emerson Electric (Fisher) (United States)

-

SMC Corporation (Japan)

-

Bürkert (Germany)

-

ASCO Valve (United States)

-

Parker Hannifin (United States)

-

Honeywell (United States)

-

Rotork (United Kingdom)

-

Samson AG (Germany)

-

Metso (Finland)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Pneumatic Positioner Market Report |

| Base Year | 2024 |

|

Segment by Type |

· Analog Control Systems · Digital Control Technologies |

| Segment by Application |

· Oil & Gas · Chemical · Manufacturing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Pneumatic Positioner Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Pneumatic Positioner Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Pneumatic Positioner Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Pneumatic Positioner Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Pneumatic Positioner Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Pneumatic Positioner Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Pneumatic Positioner Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Pneumatic Positioner Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for pneumatic positioners by 2025?

The market for pneumatic positioners is set to grow to $1.15 billion by 2025. This growth is driven by more industrial automation and the need for precise control in various industries.

Which industries commonly use pneumatic positioners?

Pneumatic positioners are widely used in various industries, including:

- Oil and gas

- Chemical processing

- Manufacturing

- Material handling

These industries require precise control and automation for their operations.

How are smart technologies impacting pneumatic positioners?

Smart technologies like IoT and AI are changing pneumatic positioners. They improve control, efficiency, and enable predictive maintenance.

What challenges do pneumatic positioner manufacturers face?

Manufacturers face challenges like complex safety standards and industry-specific regulations. These rules vary across sectors like oil & gas and pharmaceuticals.

What types of pneumatic positioners are available?

The market offers single-acting and double-acting pneumatic positioners. There are also analog and digital control technologies for different industrial needs.

How do geopolitical factors affect the pneumatic positioner market?

Geopolitical factors such as trade policies, tariffs, and technology transfer restrictions have a significant impact on the pneumatic positioner market. These factors can create both challenges and opportunities for manufacturers around the world.

Which regions are leading in pneumatic positioner technology?

North America, Europe, and Asia-Pacific are at the forefront of pneumatic positioner technology. Each region has its own strengths, such as innovation and energy efficiency.

What future developments are expected in pneumatic positioners?

Future developments include:

- Better materials

- Improved control systems

- Enhanced connectivity

There will also be a focus on sustainability and energy efficiency.

How are emerging markets impacting the pneumatic positioner industry?

Countries like China and India are experiencing rapid industrial automation. This growth is creating new opportunities for pneumatic positioner manufacturers.

What role does German engineering play in the pneumatic positioner market?

German manufacturers are known for their engineering excellence and high-quality standards. Their innovations have greatly influenced global expectations for pneumatic positioners.