Pneumatic Market Set to Reach $34.99 Billion by 2025: Key Trends from the U.S., Germany, and China

In 2025, the global market reached an estimated value of USD 7.48 billion, with projections indicating growth to USD 11.75 billion by 2033 at a compound annual growth rate (CAGR) of 5.81%. This growth is driven by increasing automation in manufacturing processes, the rising demand for pneumatic systems in various industries, and advancements in technology that enhance the efficiency and reliability of pneumatic equipment.

- Last Updated:

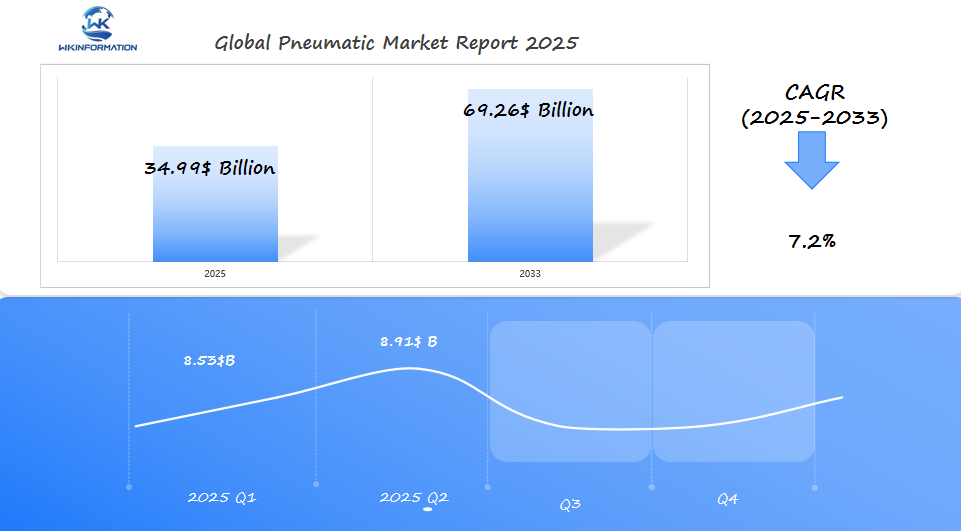

Pneumatic Market Forecast for Q1 and Q2 2025

The pneumatic market is projected to reach $34.99 billion by 2025, registering a CAGR of 7.2% from 2025 to 2033. Estimated revenue for Q1 2025 is around $8.53 billion, increasing to approximately $8.91 billion in Q2 due to growing industrial automation and demand for energy-efficient systems.

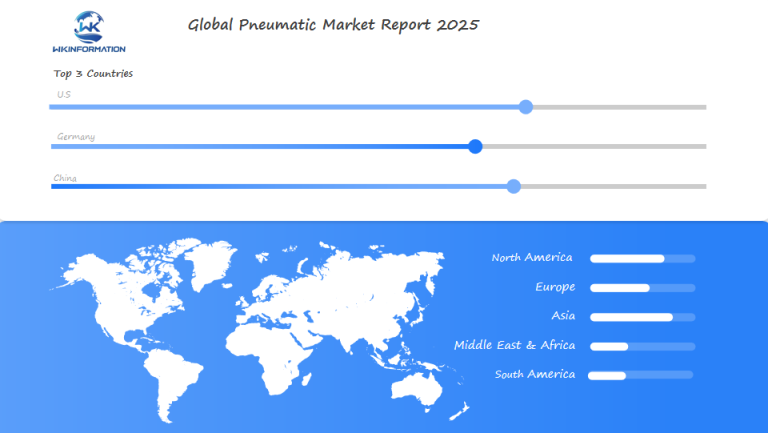

In the U.S., the market benefits from the expansion of manufacturing and logistics sectors. Germany shows strong adoption of pneumatic technologies in automotive and precision engineering.

China’s growth is fueled by large-scale infrastructure projects and smart factory investments. Emerging trends include integration of IoT in pneumatic components and development of compact, high-speed actuators.

Key Takeaways

- The global pneumatic market is expected to reach $34.99 billion by 2025.

- Key regions driving growth include the U.S., Germany, and China.

- Pneumatic systems play a crucial role in industrial automation and other sectors.

- Market trends in these regions will shape the industry’s future.

- The adoption of automation technologies is driving demand for pneumatic systems.

Upstream and Downstream Market Trends in Pneumatic Solutions

To understand the dynamics of the pneumatic solutions market, we need to closely examine both upstream and downstream trends. The pneumatic industry is a complex system where the supply chain is crucial in determining market growth and profitability.

Upstream Market Trends

The upstream market in pneumatic solutions involves the supply of raw materials and components necessary for manufacturing pneumatic equipment. This segment is crucial as it lays the foundation for the production of pneumatic systems.

Raw Material Suppliers

Raw material suppliers are key players in the upstream market, providing essential materials such as metals, plastics, and other components. The quality and cost of these materials significantly impact the overall production cost and efficiency of pneumatic equipment manufacturing.

Key raw materials used in pneumatic equipment manufacturing include:

- Aluminum

- Steel

- Copper

- Plastics

The availability and pricing of these materials are influenced by global market trends, trade policies, and geopolitical factors. For instance, fluctuations in metal prices can directly affect the production costs of pneumatic components.

| Raw Material | Impact on Production Cost | Market Trend |

| Aluminum | Moderate | Stable |

| Steel | High | Fluctuating |

| Copper | High | Volatile |

| Plastics | Low | Steady |

The downstream market for pneumatic solutions involves the application of pneumatic systems in various industries such as automotive, manufacturing, and healthcare. The demand from these industries drives the growth of the pneumatic market.

The Key Factors Driving the Growth of Pneumatic Systems

As industries evolve, the demand for pneumatic systems is rising, fueled by key factors such as automation and technological innovation. The growth of pneumatic systems can be attributed to the increasing need for efficient, reliable, and cost-effective solutions across various industries.

Increasing Demand for Automation

The demand for automation is a significant driver behind the growth of pneumatic systems. Industries are adopting automated solutions to enhance productivity, precision, and to reduce labor costs. Automation in manufacturing processes not only improves efficiency but also minimizes the risk of human error, leading to higher quality products.

Advancements in Pneumatic Technologies

Advancements in pneumatic technologies are another crucial factor driving the growth of pneumatic systems. Innovations such as improved valve technologies, advanced materials, and more efficient compressor designs are enhancing the performance and reliability of pneumatic systems.

The table below highlights some of the key advancements in pneumatic technologies and their benefits:

| Technological Advancement Benefits Improved Valve Technologies | Enhanced precision, faster response times, and increased durability |

| Advanced Materials | Lightweight, corrosion-resistant, and capable of withstanding extreme temperatures |

| Efficient Compressor Designs | Reduced energy consumption, lower operating costs, and minimized environmental impact |

These advancements are not only improving existing pneumatic systems but are also enabling the development of new applications and industries that can benefit from pneumatic technology.

Challenges Impacting the Pneumatic Market Expansion

Despite the promising outlook, the pneumatic market’s growth is threatened by several key challenges. The industry must address these issues to ensure continued expansion and innovation.

High Maintenance Costs

One of the significant challenges facing the pneumatic market is the high maintenance costs associated with pneumatic systems. Industries that rely heavily on these systems often incur substantial expenses to maintain and repair equipment. Regular maintenance is crucial to prevent system failures and ensure optimal performance, but it can be costly.

According to industry experts, “The cost of maintaining pneumatic systems can be a significant burden for companies, particularly those in industries with high equipment utilization rates.” This highlights the need for more cost-effective maintenance solutions and more durable equipment designs.

Environmental Concerns

Environmental concerns are another challenge impacting the pneumatic market. The industry is under increasing pressure to reduce its environmental footprint, particularly in terms of energy consumption and emissions. Eco-friendly pneumatic solutions are becoming more prominent as companies seek to minimize their environmental impact.

A notable example of this shift is the development of more energy-efficient pneumatic systems. Manufacturers are now focusing on creating systems that not only meet but exceed environmental standards. As noted by a leading industry figure, “The future of pneumatics lies in sustainability and energy efficiency.”

The pneumatic market must navigate these challenges to achieve its projected growth. By addressing high maintenance costs and environmental concerns, the industry can continue to expand and innovate. This involves developing more efficient systems, reducing waste, and implementing cost-effective maintenance strategies.

- Improving equipment durability to reduce maintenance needs

- Developing eco-friendly pneumatic solutions

- Implementing cost-effective maintenance strategies

By tackling these challenges, the pneumatic market can ensure a sustainable and prosperous future. The industry’s ability to adapt to these challenges will be crucial in determining its long-term success.

Geopolitical Impacts on the Global Pneumatic Market

The growth of the global pneumatic market is influenced by several geopolitical factors. Trade policies, tariffs, and regional conflicts play a significant role in shaping market dynamics.

Trade Policies and Tariffs

Trade policies and tariffs imposed by governments can significantly impact the global pneumatic market. For instance, tariffs on imported pneumatic equipment can increase costs for manufacturers, potentially leading to higher prices for end-users.

Regional Conflicts

Regional conflicts can disrupt supply chains and impact the availability of pneumatic equipment. This disruption can lead to delays in production and increased costs for companies operating in affected regions.

| Geopolitical Factor | Impact on Pneumatic Market | Potential Consequences |

| Trade Policies | Increased tariffs on pneumatic equipment | Higher costs for manufacturers and end-users |

| Regional Conflicts | Disruption of supply chains | Delays in production and increased costs |

| Tariffs | Increased costs of imported pneumatic components | Potential for higher prices and reduced demand |

Geopolitical factors such as trade policies, tariffs, and regional conflicts play a crucial role in shaping the global pneumatic market. Companies must navigate these challenges to maintain competitiveness.

Pneumatic Market Segmentation: Types of Pneumatic Equipment and Uses

Understanding pneumatic market segmentation is crucial for identifying opportunities and challenges in the industry. The pneumatic market can be segmented based on the types of pneumatic equipment and their applications in various industries.

Types of Pneumatic Equipment

Pneumatic equipment is diverse, ranging from cylinders and valves to compressors and air dryers. Each type of equipment serves a specific purpose and is used in different industrial applications.

Cylinders are one of the most common types of pneumatic equipment, used to generate force and motion in various industrial processes. Valves, on the other hand, control the flow of compressed air, directing it to the required parts of the system.

Industrial Applications

Pneumatic equipment is used in a wide range of industrial applications, including manufacturing, automotive, and aerospace. In the manufacturing sector, pneumatic systems are used for automation, improving efficiency and productivity.

The table below highlights some of the key industrial applications of pneumatic equipment:

| Industry Pneumatic Equipment Used Application Manufacturing | Cylinders, Valves | Automation, Material Handling |

| Automotive | Compressors, Air Dryers | Tire Inflation, Power Tools |

| Aerospace | Actuators, Valves | Flight Control Systems, Landing Gear |

The use of pneumatic equipment in these industries highlights their versatility and importance in modern industrial processes.

How Applications Are Shaping the Future of Pneumatic Systems

As technology advances, pneumatic systems are finding new roles in emerging sectors. The versatility and efficiency of pneumatic systems make them ideal for a wide range of applications, from industrial automation to healthcare and beyond.

Emerging Applications

The adoption of pneumatic systems in emerging applications is driving innovation and growth in the industry. Sectors such as healthcare, food processing, and renewable energy are increasingly relying on pneumatic technologies to improve efficiency and precision.

Healthcare

Pneumatic systems are used in medical devices such as ventilators and dental equipment, where precision and reliability are critical.

Food Processing

The food processing industry utilizes pneumatic systems for packaging and handling, benefiting from their cleanliness and ease of maintenance.

Renewable Energy

In renewable energy, pneumatic systems are employed in wind turbines to enhance performance and optimize energy generation.

Technological Advancements

Technological advancements are playing a crucial role in the evolution of pneumatic systems. Innovations such as IoT integration, advanced materials, and energy-efficient designs are enhancing the performance and capabilities of pneumatic technologies.

- The integration of IoT with pneumatic systems allows for real-time monitoring and predictive maintenance, reducing downtime and improving overall efficiency.

- Advanced materials and designs are also contributing to the development of more compact, lightweight, and energy-efficient pneumatic components.

| Industry | Application | Benefit |

| Healthcare | Medical Devices | Precision and Reliability |

| Food Processing | Packaging and Handling | Cleanliness and Efficiency |

| Renewable Energy | Wind Turbines | Enhanced Performance |

The future of pneumatic systems looks promising, with continued advancements in technology and expanding applications across various industries. As pneumatic systems become more sophisticated and efficient, they will play an increasingly vital role in shaping the future of industrial automation and beyond.

Regional Insights: Key Markets Driving Pneumatic Growth

Understanding regional insights is essential to grasping the factors driving pneumatic growth. The pneumatic market is a complex ecosystem influenced by various regional dynamics.

Regional Market Trends

The growth of the pneumatic market varies significantly across different regions, driven by factors such as economic conditions, industry demand, and regulatory environments. For instance, the U.S. market is driven by technological advancements, while Germany’s market is influenced by its strong manufacturing base.

China, on the other hand, is emerging as a significant player due to its large-scale manufacturing capabilities and government support for industrial automation. As noted by industry experts, “China’s pneumatic market is poised for substantial growth due to its expanding industrial sector.”

Key Players

Several key players are operating in these regions, shaping the pneumatic market landscape. Some of the notable companies include:

- Companies like SMC Corporation and Festo are leading the market with their innovative pneumatic solutions.

- Other significant players include Parker Hannifin and Bosch Rexroth, known for their high-quality pneumatic equipment.

These companies are not only driving growth but also influencing regional market trends through their strategies and product offerings.

The U.S. Pneumatic Market: Innovations and Future Trends

The U.S. pneumatic market is set to grow significantly in the next few years, thanks to innovations on the rise. This growth is mainly due to the increasing use of automation technologies in various industries such as manufacturing, automotive, and healthcare.

Market Overview

The U.S. pneumatic market has several key players who are driving innovation and competition. The demand for pneumatic systems is increasing because they are efficient, reliable, and cost-effective.

Innovations

The U.S. pneumatic market is seeing significant innovations, especially in smart pneumatic systems and energy-efficient technologies. These advancements are expected to drive market growth and make U.S. industries more competitive.

Some of the key innovations include:

- Integration of IoT technologies with pneumatic systems

- Development of advanced materials for pneumatic components

- Enhanced design and functionality of pneumatic equipment

The future trends in the U.S. pneumatic market will likely be influenced by ongoing innovations and the growing use of automation technologies. As industries continue to evolve, the demand for advanced pneumatic solutions is expected to increase, leading to further market expansion.

Key factors contributing to market growth include:

- Increasing demand for automation

- Technological advancements in pneumatic systems

- Growing need for efficient energy solutions

Germany’s Role in Advancing Pneumatic Technologies

Germany, known for its strong engineering background, is crucial in developing pneumatic technologies. The country’s manufacturing industry plays a major role in this growth, emphasizing innovation and quality.

Industry 4.0 and Automation

Germany’s adoption of Industry 4.0 principles has been a key factor in its leadership in pneumatic technologies. Industry 4.0 emphasizes the integration of automation, data exchange, and manufacturing technologies, creating a highly efficient and flexible production environment. Pneumatic systems are integral to this vision, enabling precise control and automation in various industrial applications.

Germany pneumatic technologies

The integration of pneumatic technologies with Industry 4.0 is driving advancements in areas such as predictive maintenance, smart manufacturing, and cyber-physical systems. This convergence is enhancing the efficiency, reliability, and adaptability of industrial processes, further solidifying Germany’s position in the global pneumatic market.

Key Players

Several German companies are at the forefront of pneumatic technology innovation. Companies like Festo and Bosch Rexroth are leading the way in developing advanced pneumatic systems that meet the demands of Industry 4.0. These companies are investing heavily in research and development, driving the creation of more sophisticated and efficient pneumatic solutions.

- Festo is known for its innovative pneumatic and electromechanical components.

- Bosch Rexroth offers a wide range of pneumatic systems and components, tailored to the needs of modern manufacturing.

These key players, along with others in the German industry, are contributing to the country’s dominance in the global pneumatic market through their commitment to innovation and quality.

China’s Dominance in Pneumatic Equipment Production

With its vast manufacturing capabilities, China is dominating the pneumatic equipment production industry. The country’s large-scale manufacturing base, coupled with competitive advantages such as low labor costs and a comprehensive supply chain, has positioned it as a global leader in the pneumatic market.

Manufacturing Capabilities

China’s manufacturing capabilities are a key driver of its dominance in pneumatic equipment production. The country boasts state-of-the-art production facilities, advanced technology, and a skilled workforce, enabling the production of high-quality pneumatic equipment.

Key aspects of China’s manufacturing capabilities include:

- Advanced production facilities

- Technological innovation

- Skilled workforce

- Comprehensive supply chain

Market Trends

The Chinese pneumatic market is characterized by rapid growth, driven by increasing demand for automation across various industries. Trends shaping the market include the adoption of Industry 4.0 technologies and the integration of smart technologies into pneumatic systems.

The table below highlights key statistics related to China’s pneumatic equipment production:

| Year | Production Volume (Units) | Growth Rate (%) |

| 2020 | 1,000,000 | 10% |

| 2021 | 1,100,000 | 11% |

| 2022 | 1,210,000 | 12% |

China’s pneumatic equipment production is expected to continue growing, driven by increasing demand for automation and advancements in technology.

Looking to the Future: The Growth Trajectory of the Pneumatic Market

The pneumatic market is expected to experience substantial growth driven by key trends. The industry is on the verge of a transformation, driven by technological advancements and changing market demands.

Emerging Trends

The pneumatic market is witnessing several emerging trends that are likely to shape its future. These include the adoption of smart pneumatic systems and the integration of IoT technologies. Such innovations are enhancing the efficiency and reliability of pneumatic systems, making them more attractive to various industries.

- Increased automation in manufacturing processes

- Growing demand for energy-efficient pneumatic systems

- Adoption of Industry 4.0 technologies

The future growth prospects of the pneumatic market appear promising, driven by the increasing demand for automation and the need for more efficient systems. Key industries such as automotive, aerospace, and manufacturing are expected to drive this growth.

- Expansion in emerging markets

- Technological advancements in pneumatic equipment

- Increasing investments in research and development

Overall, the pneumatic market is poised for significant growth, driven by emerging trends and technologies. As industries continue to adopt more efficient and automated systems, the demand for pneumatic solutions is expected to rise.

Competitive Landscape in the Pneumatic Industry

- SMC Corporation —— Tokyo, Japan

- Festo SE —— Esslingen am Neckar, Germany

- Parker Hannifin Corp. —— Cleveland, Ohio, USA

- Emerson Electric Co. —— St. Louis, Missouri, USA

- Bosch Rexroth —— Lohr am Main, Germany

- Camozzi Automation S.p.A. —— Milan, Italy

- CKD Corporation —— Komaki, Aichi, Japan

- AirTAC International Group —— Taipei, Taiwan

- Janatics India Pvt. Ltd. —— Coimbatore, Tamil Nadu, India

- Siemens AG —— Munich, Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Pneumatic Market Report |

| Base Year | 2024 |

| Segment by Type | · Pneumatic Cylinders

· Pneumatic Calves · Air Treatment Components |

| Segment by Application | · Food and Beverage Industry

· Pharmaceutical Industry · Chemical Industry · Mining and Heavy Industries |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The pneumatic market is set for significant growth, driven by trends in automation, Industry 4.0, and emerging applications. As discussed, the U.S., Germany, and China are leading the way in pneumatic technologies, with innovations in pneumatic equipment and systems.

To navigate the competitive landscape and capitalize on emerging trends, industry players must stay informed about market dynamics and challenges. The conclusion is that growth is on the horizon, driven by increasing demand for automation and advancements in pneumatic technologies.

Future Outlook

As the pneumatic market continues to evolve, we can expect to see new applications and innovations emerge. With the right strategies, industry players can position themselves for success in this growing market, ultimately leading to a robust conclusion for the pneumatic market.

Global Pneumatic Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Pneumatic Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- PneumaticMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Pneumaticplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Pneumatic Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Pneumatic Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Pneumatic Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofPneumaticMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the expected size of the pneumatic market by 2025?

The pneumatic market is expected to reach $34.99 billion by 2025.

What are the key regions driving the growth of the pneumatic market?

The U.S., Germany, and China are the key regions driving the growth of the pneumatic market.

What are the main applications of pneumatic systems?

Pneumatic systems are used in various applications, including:

- Industrial automation

- Automotive

- Aerospace

What are the upstream market trends in pneumatic solutions?

The upstream market trends involve the supply of raw materials and components necessary for manufacturing pneumatic equipment.

What is driving the demand for pneumatic systems?

The demand for pneumatic systems is driven by:

- increasing demand for automation

- advancements in pneumatic technologies

- the need for efficient and reliable systems

What are the challenges impacting the pneumatic market expansion?

The pneumatic market faces challenges such as high maintenance costs, environmental concerns, and competition from alternative technologies.

How do geopolitical factors impact the global pneumatic market?

Geopolitical factors, including trade policies, tariffs, and regional conflicts, can significantly impact the global pneumatic market.

What are the different types of pneumatic equipment?

The different types of pneumatic equipment include cylinders, valves, and compressors.

What are the emerging applications shaping the future of pneumatic systems?

Emerging applications, such as healthcare, food processing, and renewable energy, are driving innovation in pneumatic technologies.

Who are the key players in the pneumatic industry?

The key players in the pneumatic industry include manufacturers of pneumatic equipment, such as Festo, SMC Corporation, and Parker Hannifin.

What is the role of Industry 4.0 in advancing pneumatic technologies?

Industry 4.0 principles are driving the development of advanced pneumatic technologies, particularly in Germany.

What is the growth trajectory of the pneumatic market?

The pneumatic market is expected to continue growing, driven by emerging trends and growth prospects, including the adoption of smart pneumatic systems and IoT technologies. This growth trajectory can be visualized in the following chart .