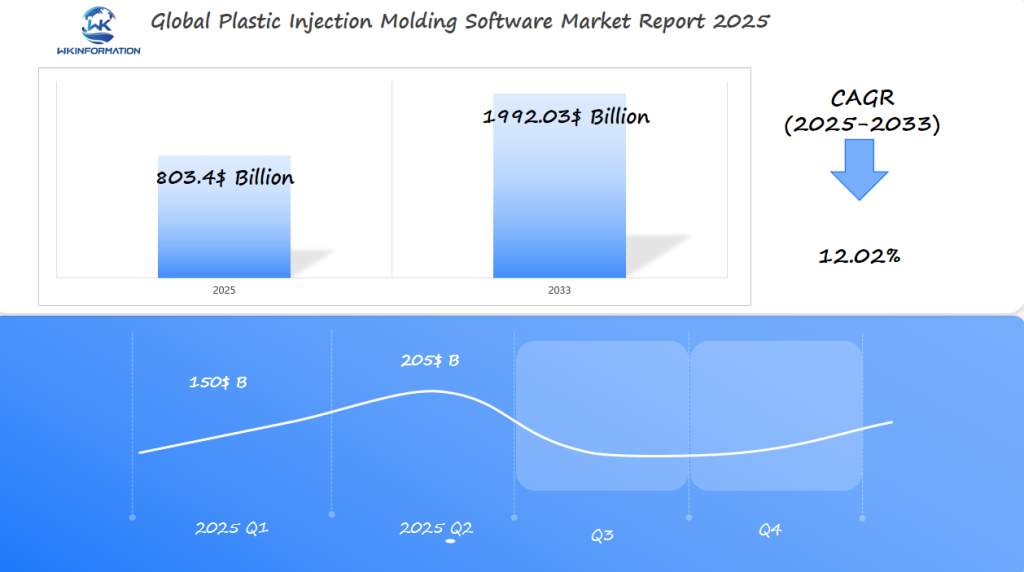

Plastic Injection Molding Software Market Expected to Surpass $803.4 Million Globally by 2025: High Growth in the U.S., Germany, and Japan

Explore key trends, challenges, and market insights in the Plastic Injection Molding Software industry. Discover how global trade policies, regional trends, and technological advancements are shaping the future of this market. Learn about leading companies and industry drivers in this competitive landscape.

- Last Updated:

Plastic Injection Molding Software Market Q1 and Q2 2025 Performance Insights

The Plastic Injection Molding Software market is expected to reach $803.4 million by the end of 2025, with a CAGR of 12.02% during the 2025–2033 period. Estimated Q1 revenue stands at $150 million, increasing to approximately $205 million in Q2, driven by higher demand from the automotive, consumer electronics, and packaging industries. The surge in Q2 reflects increased investment in digital transformation, which sees more manufacturing businesses adopting advanced simulation and optimization software.

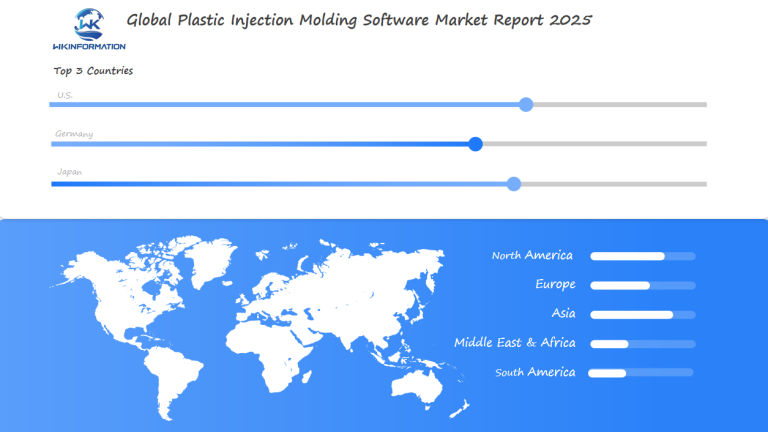

The United States leads in market share, propelled by the high demand for injection molding in the automotive, consumer goods, and packaging industries. In Germany, the automotive sector and industrial manufacturing continue to drive the need for these software solutions. Japan follows closely, with the electronics industry fueling growth as manufacturers look for software tools that improve the precision and efficiency of their molding processes.

Key Takeaways

- The global Plastic Injection Molding Software Market is expected to witness significant growth.

- Advancements in technology are driving market expansion.

- Increasing demand from automotive and healthcare industries.

- Improved efficiency and reduced costs are key benefits.

- The market is anticipated to surpass $803.4 million by 2025.

Upstream and Downstream Chain Analysis of the Plastic Injection Molding Software Market

A comprehensive analysis of the plastic injection molding software market involves understanding its upstream and downstream chains. This analysis is crucial for identifying key players, potential bottlenecks, and areas for improvement within the supply chain.

Understanding the Supply Chain Dynamics

The supply chain dynamics of the plastic injection molding software market are complex, involving various stakeholders from raw material suppliers to end-users. Effective supply chain management is critical for ensuring the timely delivery of high-quality software solutions.

The supply chain can be broadly categorized into upstream and downstream segments. The upstream segment includes raw material suppliers and software developers, while the downstream segment involves manufacturers of injection molding machines and end-users.

Key Players in the Supply Chain

Key players in the supply chain include:

- Software developers who design and develop plastic injection molding software.

- Manufacturers of injection molding machines who integrate the software into their products.

- Raw material suppliers who provide the necessary materials for the production of components used in injection molding.

| Supply Chain Segment | Key Players | Role in the Market |

| Upstream | Raw Material Suppliers, Software Developers | Provide essential materials and software solutions. |

| Downstream | Injection Molding Machine Manufacturers, End-users | Integrate software into machines and utilize the software for production. |

Trends and Technological Advancements in Plastic Injection Molding Software

The injection molding software industry is undergoing a significant change with new trends and technologies emerging. This transformation is driven by the need for more efficient, accurate, and cost-effective manufacturing processes.

One of the key trends is the integration of artificial intelligence (AI) and machine learning (ML) into injection molding software. These technologies enable predictive maintenance, quality control, and process optimization, leading to improved product quality and reduced production costs.

Emerging Trends in Injection Molding Software

One of the significant emerging trends is the adoption of cloud-based software for plastic injection molding. Cloud-based solutions offer scalability, flexibility, and reduced IT costs, making them attractive to manufacturers.

Another trend is the use of simulation tools to optimize injection molding processes. Simulation software allows manufacturers to model and analyze the injection molding process, identifying potential issues before they occur.

The industry is also seeing a rise in the use of data analytics to drive decision-making. By analyzing data from injection molding processes, manufacturers can identify areas for improvement and optimize their operations.

Furthermore, the integration of Internet of Things (IoT) technology is enhancing the capabilities of injection molding software. IoT enables real-time monitoring and control of injection molding machines, improving efficiency and reducing downtime.

- Predictive maintenance through AI and ML

- Cloud-based solutions for scalability

- Simulation tools for process optimization

- Data analytics for informed decision-making

- IoT integration for real-time monitoring

These emerging trends and technological advancements are transforming the plastic injection molding software market, enabling manufacturers to improve efficiency, reduce costs, and enhance product quality.

Key Challenges and Market Limitations in Plastic Injection Molding Software

The Plastic Injection Molding Software Market is expected to grow, but it faces significant challenges that could slow down its progress. The industry has high development costs, complex software, and a lack of skilled workers, among other problems.

Challenges Faced by Industry Players

Industry players in the plastic injection molding software market encounter several obstacles. High development costs are a significant barrier, as creating sophisticated software requires substantial investment in research and development. Additionally, the complexity of the software itself can be a challenge, as it demands a high level of technical expertise to design and implement effectively.

Another critical issue is the lack of skilled personnel. The industry requires professionals with specialized knowledge in both plastic injection molding and software development, a combination that is not always readily available. This scarcity can lead to increased labor costs and project delays.

Overcoming Market Limitations

To overcome these challenges, industry players must adopt strategic approaches. One potential solution is to invest in training and development programs that can help bridge the skills gap. Companies can also explore collaborations and partnerships that can share the burden of development costs and expertise.

A detailed analysis of the challenges and potential solutions is provided below:

| Challenge Description Potential Solution High Development Costs | Significant investment required for R&D | Collaborations and partnerships |

| Complexity of Software | Requires high technical expertise | Simplification of software design |

| Lack of Skilled Personnel | Shortage of professionals with specialized knowledge | Training and development programs |

Geopolitical Considerations Shaping Plastic Injection Molding Software Markets

Global trade policies and geopolitical tensions are having a profound impact on the plastic injection molding software market. The industry is experiencing a significant shift due to changes in trade agreements, tariffs, andother geopolitical factors.

Impact of Global Trade Policies

The plastic injection molding software industry relies heavily on global supply chains, which are being disrupted by changing trade policies. Tariffs imposed on imported goods are increasing costs for manufacturers, making it essential for them to optimize their production processes using advanced software.

This shift is driving demand for plastic injection molding software that can help manufacturers improve efficiency and reduce costs.

The impact of global trade policies on the plastic injection molding software market can be seen in several areas:

- Increased costs due to tariffs

- Disruptions to global supply chains

- Greater demand for software that can help manufacturers optimize production

To mitigate these effects, manufacturers are turning to advanced plastic injection molding software that can help them streamline their production processes and improve product quality.

Regional Trade Agreements

Regional trade agreements, such as the United States-Mexico-Canada Agreement (USMCA), are also influencing the plastic injection molding software market. These agreements can affect the flow of goods and services across borders, making it essential for manufacturers to have software that can help them navigate these changes.

By understanding the impact of geopolitical considerations on the plastic injection molding software market, manufacturers can make informed decisions about their investments in software and technology.

Type-Based Segmentation Insights in Plastic Injection Molding Software

Type-based segmentation is crucial for understanding the dynamics of the Plastic Injection Molding Software market. This segmentation helps in identifying the various software types that cater to the diverse needs of the industry.

Segmentation by Software Type

The Plastic Injection Molding Software market can be segmented into several software types, including CAD software, CAE software, and CAM software. Each of these software types has itsunique features and applications in the plastic injection molding process.

1. CAD Software

CAD software is used for designing and modeling the products to be manufactured through plastic injection molding. It allows for precise design and modification of product models, which is crucial for the production of complex plastic parts.

2. CAE Software

CAE software, on the other hand, is utilized for simulating and analyzing the injection molding process. It helps in predicting potential issues such as warping, sink marks, or air traps, thereby optimizing the manufacturing process.

3. CAM Software

CAM software is essential for controlling the machinery involved in the plastic injection molding process. It generates the necessary instructions for the manufacturing equipment, ensuring efficient and accurate production.

The demand for these software types varies based on factors such as industry requirements, product complexity, and manufacturing scale. Understanding these demands is crucial for software developers and industry stakeholders to tailor their offerings and strategies effectively.

Application-Specific Demand Drivers in Plastic Injection Molding Software

The Plastic Injection Molding Software market is driven by diverse industry needs. Various industries such as automotive, healthcare, and consumer goods have specific requirements that influence the demand for this software. For instance, the automotive industry often requires high precision and durability in the parts produced, which drives the need for advanced plastic injection molding software. Similarly, the healthcare sector demands strict compliance with safety and quality standards, further influencing software requirements. In the consumer goods sector, the focus is often on cost-effectiveness and rapid production times, which again shapes the demand for specific software features.

Demand Drivers in Different Industries

Plastic Injection Molding Software is in high demand across various industries due to specific needs and requirements. Here are the key drivers of demand in different sectors:

1. Automotive Industry

The automotive industry plays a significant role in driving the demand for Plastic Injection Molding Software. This is primarily because:

- The automotive industry requires software that can handle complex designs and simulations.

2. Healthcare Industry

In the healthcare sector, the demand for Plastic Injection Molding Software is driven by:

- The healthcare industry demands software that meets stringent regulatory requirements.

This is essential for ensuring the manufacturing of high-precision molding for medical devices and equipment, which must comply with strict regulations.

3. Consumer Goods Industry

The consumer goods industry also contributes to the demand for this software through its need for:

- The consumer goods industry needs software that can facilitate innovative product design.

Plastic Injection Molding Software enables manufacturers to produce intricate designs and customize products according to consumer preferences, thereby reducing production costs.

Other Contributing Industries

In addition to the above industries, there are other sectors such as aerospace and electronics that also contribute to the demand for Plastic Injection Molding Software. These industries require high-quality, precise parts, further fueling the growth of the market.

As industries continue to evolve and adapt to changing market dynamics, the demand for advanced software solutions like Plastic Injection Molding Software is expected to grow steadily.

Regional Trends and Global Spread of Plastic Injection Molding Software Market

The global spread of the Plastic Injection Molding Software Market is characterized by distinct regional trends. As the market continues to evolve, understanding these regional dynamics is crucial for stakeholders to make informed decisions.

The Plastic Injection Molding Software Market is witnessing significant growth across different regions, including North America, Europe, and Asia-Pacific. Each region has its unique market trends and drivers. For instance, North America is driven by the presence of key industry players and technological advancements, while Europe is influenced by stringent regulations and a strong automotive sector.

Regional Market Analysis

North America

The North American market is characterized by a high adoption rate of advanced technologies and a strong presence of industry leaders. The region’s focus on innovation and quality is driving the demand for sophisticated plastic injection molding software.

Europe

Europe’s market is shaped by its robust automotive and industrial sectors. The region’s emphasis on sustainability and regulatory compliance is also influencing the demand for plastic injection molding software that can help companies meet these requirements.

Asia-Pacific

The Asia-Pacific region is emerging as a significant growth hub due to rapid industrialization, increasing manufacturing activities, and a growing demand for consumer goods. Countries like China, Japan, and South Korea are at the forefront of this growth, driven by investments in manufacturing technologies and infrastructure.

The regional trends in the Plastic Injection Molding Software Market highlight the importance of understanding local market dynamics and tailoring strategies to meet specific regional needs. As the market continues to grow, companies that can adapt to these regional trends are likely to gain a competitive edge.

U.S. Plastic Injection Molding Software Market: Developments and Forecasts

The U.S. plastic injection molding software market is experiencing growth due to innovation and industry demand. This growth can be attributed to the presence of major industry players and advancements in technology.

Market Developments in the U.S.

The U.S. market is witnessing significant developments in plastic injection molding software, driven by the need for increased efficiency and precision in manufacturing processes. Technological advancements such as AI and IoT integration are playing a crucial role in this development.

Market forecasts indicate a positive trajectory for the U.S. plastic injection molding software market, with an expected increase in adoption across various industries.

The growth in the U.S. market can be attributed to several factors, including the increasing demand for customized plastic products and the need for cost-effective manufacturing solutions.

Germany’s Growing Influence in Plastic Injection Molding Software Market

Germany’s growing influence in the Plastic Injection Molding Software Market is driven by its strong industrial base. The country’s robust manufacturing sector, combined with its technological advancements, positions Germany as a key player in this industry.

Germany’s market trends show a steady increase in the adoption of plastic injection molding software. This growth is due to the rising demand for precision-engineered plastic components across various industries such as automotive, medical devices, and consumer goods.

Germany’s Market Trends

The German Plastic Injection Molding Software Market is characterized by several key trends. Innovation is a driving force, with companies investing heavily in research and development to improve software capabilities and manufacturing processes.

The demand for advanced software solutions is also on the rise, driven by the need for greater efficiency, precision, and customization in plastic injection molding.

Key Market Trends:

- Increased adoption of Industry 4.0 technologies

- Growing demand for simulation and analysis software

- Rise in the use of cloud-based software solutions

Japan’s Innovation in Plastic Injection Molding Software Sector

Japan’s plastic injection molding software sector is undergoing a significant change, thanks to new technological advancements.

The country’s industry leaders are leading the way in creating advanced simulation tools and software, greatly improving the efficiency and accuracy of plastic injection molding processes.

Technological Advancements

Japan’s technological advancements in this sector are multifaceted, including improvements in simulation accuracy, integration of AI and machine learning, and development of more user-friendly interfaces.

These advancements are not only improving existing processes but also enabling the creation of complex products that were previously difficult or impossible to manufacture.

The impact of these innovations is being felt across various industries, from automotive to consumer goods, where plastic injection molding plays a crucial role.

As Japan continues to innovate and push the boundaries of what is possible with plastic injection molding software, the global industry is likely to benefit from these advancements.

Future Development Trends for Plastic Injection Molding Software

- Integration of AI and Machine Learning

The incorporation of artificial intelligence (AI) and machine learning into plastic injection molding software is revolutionizing the industry. These technologies enable predictive analytics, optimize process parameters, and reduce defects through intelligent automation. This trend facilitates smarter decision-making and adaptive manufacturing processes. - Development of More User-Friendly Interfaces

Enhancing usability through intuitive interfaces is a key focus area. Simplified and interactive software designs allow operators with varying skill levels to efficiently manage complex molding tasks, reducing training time and minimizing operational errors. - Advanced Simulation Tools

New simulation capabilities are improving accuracy and efficiency in molding process design. Enhanced virtual prototyping enables manufacturers to predict potential issues before physical production, saving time and resources while boosting product quality. - Support for Complex Product Manufacturing

Innovations are enabling the creation of intricate plastic components that were previously difficult or impossible to produce. This expands application possibilities across industries such as automotive, consumer goods, healthcare, and electronics.

Competitive Overview and Leading Companies in Plastic Injection Molding Software

The Plastic Injection Molding Software industry has several major companies competing against each other. In this section, we’ll take a closer look at how these companies compete with each other, including their market share and the strategies they use to stay ahead.

Key Players:

Autodesk Inc. (Moldflow) – United States

Siemens Digital Industries Software (NX, Simcenter Moldex3D) – Germany

PTC Inc. (Creo with mold design extensions) – United States

Dassault Systèmes (SOLIDWORKS Plastics, CATIA) – France

CoreTech System Co., Ltd. (Moldex3D) – Taiwan

Simcon kunststofftechnische Software GmbH (Cadmould) – Germany

Altair Engineering Inc. (Inspire Mold) – United States

SolidCAM Ltd. (CAM software with mold-making modules) – Israel

Autodesk Moldflow Insight (via Moldflow Australia Pty Ltd) – Australia / United States

MSC Software (Digimat, Simufact) – United States (part of Hexagon AB, Sweden)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Plastic Injection Molding Software Market Report |

| Base Year | 2024 |

| Segment by Type | ·CAD Software

·CAE Software ·CAM Software |

| Segment by Application | ·Automotive Industry

·Healthcare Industry ·Consumer Goods Industry |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The plastic injection molding software market is set for significant growth, driven by technological advancements and increasing demand from various industries. As the industry continues to evolve, emerging trends and innovations are expected to shape the market.

Our analysis highlights the importance of staying ahead of the curve in terms of technological advancements and industry trends. By understanding the key drivers and limitations of the plastic injection molding software market, businesses can make informed decisions and capitalize on emerging opportunities.

Global Plastic Injection Molding Software Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Plastic Injection Molding Software Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Plastic Injection Molding Software Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Plastic Injection Molding Software Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Plastic Injection Molding Software Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Plastic Injection Molding Software Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Plastic Injection Molding Software Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Plastic Injection Molding Software Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the expected global value of the Plastic Injection Molding Software Market by 2025?

The Plastic Injection Molding Software Market is expected to reach $803.4 million worldwide by 2025.

What are the key industries driving the demand for Plastic Injection Molding Software?

The demand for Plastic Injection Molding Software is driven by various industries, including:

- Automotive

- Healthcare

- Consumer goods

What technological advancements are being seen in the Plastic Injection Molding Software Market?

The Plastic Injection Molding Software Market is seeing significant technological advancements, including the integration of artificial intelligence and machine learning, as well as emerging trends such as cloud-based software and simulation tools.

What are the key challenges faced by industry players in the Plastic Injection Molding Software Market?

Industry players face several challenges, including:

- High development costs

- Complexity of software

- Lack of skilled personnel

How do global trade policies impact the Plastic Injection Molding Software Market?

Changes in global trade policies can affect the supply chain, pricing, and demand for injection molding software.

What are the different software types used in Plastic Injection Molding?

The Plastic Injection Molding Software Market can be segmented based on software type, including CAD software, CAE software, and CAM software.

Which regions are experiencing significant growth in the Plastic Injection Molding Software Market?

The Plastic Injection Molding Software Market is experiencing significant growth across various regions, including North America, Europe, and Asia-Pacific.

What is driving the demand for Plastic Injection Molding Software in the U.S. market?

The U.S. market is driven by the presence of major industry players and technological advancements.

Why is Germany becoming an important player in the Plastic Injection Molding Software Market?

Germany is becoming an important player because of its strong manufacturing industry and technological expertise.

What is Japan’s contribution to the Plastic Injection Molding Software Sector?

Japan is driving technological advancements, including the development of advanced simulation tools and software.

Who are the leading companies in the Plastic Injection Molding Software Market?

The market is highly competitive, with several leading companies competing for market share, including Autodesk, Siemens, and Dassault Systèmes.

What is the future outlook for the Plastic Injection Molding Software Market?

The future outlook for the industry is promising, with emerging trends and innovations expected to shape the market.