2025 Pillow Plate Heat Exchangers Market Surge: Exceeding $1.2 Billion with Increasing Industrial Demand in U.S., China & Japan

Explore the evolving landscape of Pillow Plate Heat Exchangers market through 2025, with focus on U.S., China, and Japan’s leadership in sustainable heat transfer solutions. Discover key trends, technological innovations, and market dynamics shaping the industry’s future.

- Last Updated:

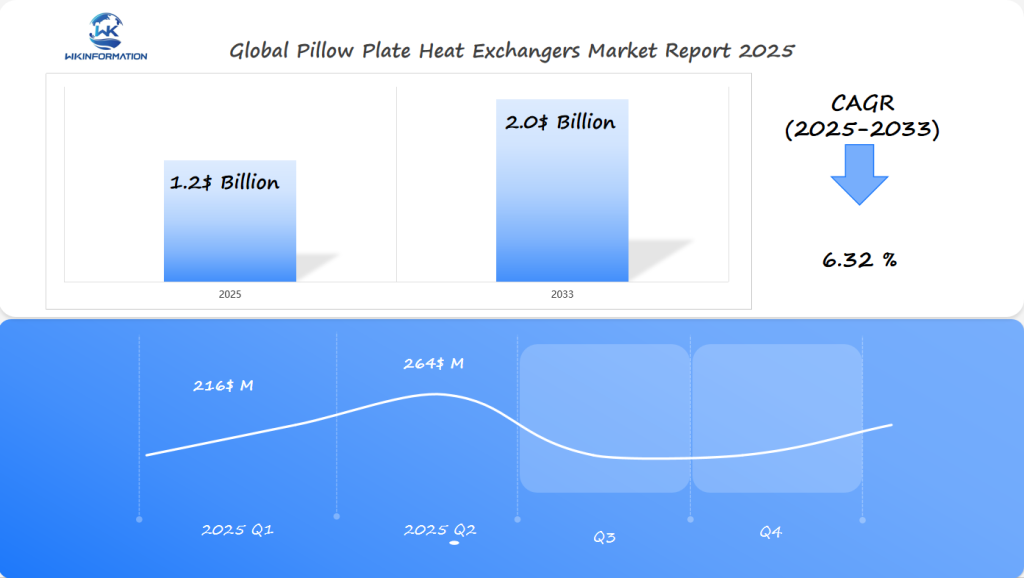

Pillow Plate Heat Exchangers Market: Q1 and Q2 2025 Predictions

The Pillow Plate Heat Exchangers market is expected to reach USD 1.2 billion in 2025, driven by the growing demand for efficient heat transfer solutions across various industries. With a projected CAGR of 6.32% through 2033, Q1 2025 is forecasted to account for around 18% of the total market, approximately USD 216 million. Q2 is expected to show a slightly stronger performance, contributing around 22% of the total market, or USD 264 million, as industries ramp up investments in heat transfer technologies.

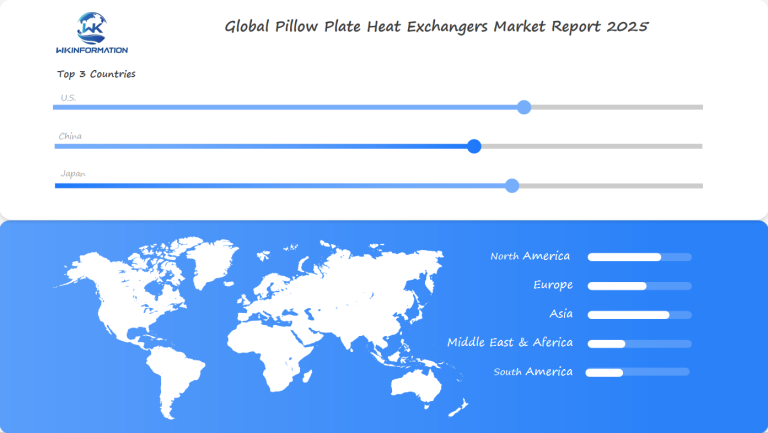

The U.S., China, and Japan are expected to be the most influential countries in shaping market trends. The U.S. is anticipated to lead, with significant demand from the food and beverage and chemical industries. China and Japan will also play key roles, with China seeing a strong push from manufacturing sectors and Japan’s industrial focus driving demand for innovative heat exchange solutions. These regions are expected to be critical in shaping the market landscape in 2025.

Upstream and Downstream Industry Chain Analysis: Understanding the Pillow Plate Heat Exchangers Supply Chain

The supply chain for pillow plate heat exchangers is complex, involving both upstream and downstream processes.

Upstream Processes

- Raw Materials: The production begins with sourcing high-quality raw materials such as stainless steel, which is essential for fabricating durable and efficient pillow plates.

- Manufacturing: Advanced manufacturing techniques, including laser welding and forming, create the distinctive dimpled structure of pillow plates, enhancing thermal performance.

Downstream Applications

Pillow plate heat exchangers have various uses in different industries:

- Food and Beverage: Critical in processes like pasteurization and fermentation where precise temperature control is paramount.

- Pharmaceuticals: Used extensively for maintaining stringent temperature regulations during drug production.

- Chemicals and Energy: These sectors benefit from the energy-efficient heat transfer capabilities of pillow plates, integral to their operational efficiency.

Understanding this supply chain reveals how each component plays a vital role in delivering effective heat transfer solutions, meeting the increasing industrial demand for energy-efficient systems. By examining both upstream inputs and downstream outputs, one gains insights into the strategic importance of pillow plate heat exchangers across multiple industries.

Trend Analysis: Emerging Trends in Pillow Plate Heat Exchangers Technology

The pillow plate heat exchangers market is witnessing a wave of technological advancements that are reshaping its landscape.

1. Integration of IoT Capabilities

One of the most notable trends is the integration of IoT capabilities into pillow plate designs. This innovation allows for real-time monitoring and data collection, enhancing operational efficiency and predictive maintenance. Companies can now optimize heat transfer processes by leveraging data analytics, leading to improved performance and reduced downtime.

2. Focus on Sustainability Initiatives

Another key innovation trend centers around sustainability initiatives. Industries are increasingly focusing on energy conservation as they align with global environmental goals. Pillow plate heat exchangers are at the forefront of this movement due to their superior thermal efficiency. The design of these exchangers minimizes energy consumption while maximizing heat transfer, making them a preferred choice for industries seeking eco-friendly solutions.

3. Emphasis on Energy Efficiency

In addition to IoT integration and sustainability, there is an emphasis on energy efficiency within the industry. Advanced manufacturing techniques and material innovations are being employed to further reduce energy losses during heat exchange processes. These developments not only address the growing demand for cost-effective solutions but also support industries in achieving their sustainability targets.

This combination of technological innovation, focus on sustainability, and drive for energy efficiency positions pillow plate heat exchangers as a pivotal component in modern industrial applications.

Restriction Analysis: Challenges in the Pillow Plate Heat Exchangers Market

The Pillow Plate Heat Exchangers Market faces several challenges that could hinder its growth trajectory. A primary concern is the high initial costs associated with manufacturing and installation. The intricate design and specialized materials required for pillow plates contribute to these elevated expenses, potentially deterring smaller businesses from adopting this technology.

Another significant challenge is the competition from alternative heat exchange technologies. Traditional heat exchangers, such as shell-and-tube or plate-and-frame systems, have established a strong foothold in various industries. Their proven reliability and cost-effectiveness make them formidable competitors to pillow plate designs.

Fluctuations in raw material prices also impact market dynamics. Materials like stainless steel, crucial for pillow plate construction due to its thermal properties and durability, are subject to price volatility. These fluctuations can lead to unpredictable production costs and ultimately affect pricing strategies within the market.

Understanding these challenges is crucial for stakeholders aiming to navigate the evolving landscape of the Pillow Plate Heat Exchangers Market. By addressing these obstacles through innovation and strategic planning, companies can better position themselves for sustained growth amidst an increasingly competitive environment.

Geopolitical Analysis: How Global Politics Influence Pillow Plate Heat Exchangers Production and Trade

Geopolitical factors significantly shape the production and trade of pillow plate heat exchangers. Political stability, international relations, and trade policies directly impact global market dynamics. Ongoing trade tensions between major economies can lead to fluctuations in tariffs and import restrictions, affecting the supply chain and pricing strategies for these heat exchangers.

Governmental policies play a pivotal role in promoting clean technologies, which aligns with the rising demand for energy-efficient solutions like pillow plates. Countries prioritizing sustainability initiatives often provide incentives or subsidies to industries adopting such technologies. This encouragement not only boosts market growth but also fosters innovation in design and manufacturing processes.

Examples of Geopolitical Influences on the Market

- The U.S.-China trade relations are an example of geopolitical influences that create uncertainties in the global market. Tariff adjustments can alter competitive landscapes, affecting market accessibility for manufacturers.

- In Europe, the Green Deal aims to make the continent climate-neutral by 2050, offering a favorable environment for technologies that contribute to energy conservation and reduced carbon footprints.

By understanding these geopolitical factors, stakeholders can better navigate the complexities of international markets while leveraging opportunities presented by supportive governmental policies.

Segmentation Type Market Analysis: Pillow Plate Heat Exchangers Market Segmentation by Type and Application

Market segmentation for pillow plate heat exchangers revolves around two primary aspects: types and application sectors.

Types of Pillow Plates:

- Welded Pillow Plates: These are commonly used due to their robust construction, making them suitable for high-pressure applications. The welding process enhances durability and thermal efficiency.

- Laser-Welded Plates: Known for precision, these plates offer excellent heat transfer capabilities and are often employed in applications requiring intricate designs.

The demand trends within each type reflect their unique advantages. Welded plates are favored in industries where durability is critical, while laser-welded plates find applications in sectors that prioritize precision.

Application Sectors:

- Food and Beverage: Essential for processes such as pasteurization and fermentation, where maintaining precise temperature control is crucial.

- Pharmaceuticals: Utilized to regulate temperature during drug production, ensuring product efficacy and safety.

- Chemicals: Deployed in reactions where effective heat management can significantly impact process efficiency.

Each application sector demonstrates distinct demand patterns. The food and beverage industry leads in volume due to the continuous need for efficient thermal management. Pharmaceuticals follow closely, driven by stringent regulatory requirements for temperature control. The chemical sector benefits from the adaptability of pillow plate heat exchangers in various reaction processes.

Application Market Analysis: The Role of Pillow Plate Heat Exchangers in Industrial Processes

Pillow Plate Heat Exchangers play a crucial role in enhancing process efficiency across various industrial applications. Their unique design allows for effective temperature control, which is paramount in industries such as food processing and pharmaceuticals.

Applications of Pillow Plate Heat Exchangers

1. Food Processing

Pillow plates are extensively used in processes like pasteurization and fermentation. Precise temperature control is essential here to ensure the quality and safety of food products. These heat exchangers provide the necessary thermal management to maintain optimal conditions, improving both product consistency and energy efficiency.

2. Pharmaceuticals

In drug production, maintaining strict temperature controls is vital to ensure the integrity and efficacy of pharmaceuticals. Pillow Plate Heat Exchangers offer reliable solutions for this challenge, allowing for consistent temperature regulation during various stages of drug manufacturing. This enhances the overall quality of products while supporting compliance with industry standards.

These applications demonstrate the significant impact Pillow Plate Heat Exchangers have on operational efficiency and output quality. Their adoption aligns with the broader market trend towards energy-efficient technologies, responding to an increasing demand for sustainable industrial solutions within the Pillow Plate Heat Exchangers Market.

Regional Analysis of the Global Pillow Plate Heat Exchangers Market

The global market for pillow plate heat exchangers is experiencing significant growth in various regions, driven by industrial advancements and sustainability efforts. Among these regions, the Asia Pacific stands out as a key player due to its rapid industrialization. The increasing number of industrial plants and the adoption of energy-efficient technologies underscore this region’s significant contribution to market expansion.

Asia Pacific

This region’s rapid industrialization is a major factor fueling demand for pillow plate heat exchangers. Countries like China and India are at the forefront, investing heavily in manufacturing and energy sectors, which necessitate efficient heat management solutions.

North America

With a strong emphasis on sustainability and stringent environmental regulations, North America remains a crucial market. The drive towards clean technologies is promoting the adoption of innovative heat exchange solutions.

Europe

Known for its advanced technological landscape, Europe continues to prioritize sustainable practices. This focus aligns well with the benefits offered by pillow plate heat exchangers, supporting their widespread integration into industrial processes.

These regional trends highlight the significance of pillow plate heat exchangers in meeting global demands for efficient thermal management. As industries increasingly prioritize energy conservation and sustainability, these regions are pivotal in shaping future market trajectories.

Country One: United States Pillow Plate Heat Exchangers Market Analysis

In the United States, the pillow plate heat exchangers market is experiencing robust growth driven by various industrial demands. Key sectors contributing to this expansion include:

- Food and Beverage: This industry remains a significant consumer due to the need for precise temperature control in processes like pasteurization and fermentation. The emphasis on energy-efficient systems aligns with sustainability initiatives prevalent across the U.S.

- Pharmaceuticals: The demand for sophisticated thermal management solutions is crucial in drug production, where maintaining optimal temperatures directly impacts product quality.

- Chemical Industry: With a focus on enhancing process efficiency and reducing energy consumption, pillow plate heat exchangers offer viable solutions.

Several factors are shaping market dynamics:

- Technological Advancements: U.S. companies are investing in R&D to develop innovative designs that integrate IoT capabilities for improved monitoring and efficiency.

- Government Policies: Supportive regulations promoting clean technologies further energize market growth, encouraging industries to adopt more sustainable practices.

Challenges remain, such as high initial costs and competition from alternative technologies. Yet, opportunities for innovation persist, with advancements promising to refine efficiency and cost-effectiveness in industrial applications. The U.S. market stands poised for continued development in response to these evolving needs and technological possibilities.

Country Two: Europe Pillow Plate Heat Exchangers Market Analysis

The European market for pillow plate heat exchangers is growing strongly. This growth is mainly due to the high demand for energy-efficient solutions in various industries. Industries like food and beverage, pharmaceuticals, and chemicals are playing a crucial role in adopting pillow plate technology in this region. Precise control of temperature is extremely important for these industries, which is why they find pillow plates appealing because of their superior heat transfer abilities.

Key Factors Driving Growth:

1. Regulatory Environment

Europe has strict regulations on energy efficiency and emissions, which have pushed industries to adopt advanced heat exchange technologies. This regulatory push aligns with the region’s commitment to sustainability and clean energy.

2. Technological Advancements

The integration of IoT (Internet of Things) and smart manufacturing practices has made it possible to develop more efficient and adaptable pillow plate systems. These innovations are designed to meet the specific needs of European manufacturers who are looking for ways to improve their operations.

3. Economic Influences

The economic policies of the European Union encourage investment in sustainable technologies, which further increases the growth potential of the market.

Despite these advantages, there are still challenges that need to be overcome. High production costs and competition from other technologies pose significant obstacles. However, the region’s focus on sustainability and technological innovation puts it in a good position for continued growth in the pillow plate heat exchangers market.

Country Three: Japan Pillow Plate Heat Exchangers Market Analysis

Japan’s market for pillow plate heat exchangers is experiencing a notable surge, driven by the country’s emphasis on technological innovation and energy efficiency. As one of the foremost leaders in industrial technology, Japan continually seeks advanced solutions to enhance operational efficiencies and reduce environmental impact.

1. Technological Innovation

Japanese manufacturers are at the forefront of integrating IoT capabilities into pillow plate designs. This integration allows for real-time monitoring and optimization of heat exchange processes, significantly enhancing overall system performance.

2. Sustainability Goals

With strong governmental support for clean technology initiatives, Japan’s industrial sector is motivated to adopt energy-efficient equipment. The use of pillow plate heat exchangers aligns with national sustainability goals, promoting reduced energy consumption across various industries.

3. Key Industries

The food and beverage industry in Japan heavily relies on precise temperature control provided by pillow plates, especially in fermentation processes critical to the production of traditional beverages like sake. Pharmaceuticals also represent a significant market segment, where stringent temperature management is essential during drug manufacturing.

4. Market Dynamics

Despite the high initial investment costs, the long-term benefits of operational efficiency and compliance with environmental standards drive demand. Competitive pricing and technological advancements are pivotal factors influencing purchasing decisions within Japan’s industrial landscape.

Japan’s commitment to innovation and sustainability positions its market as a significant player in the global pillow plate heat exchanger industry.

Future Development Analysis: The Future of Pillow Plate Heat Exchangers in Energy Efficiency

The future of pillow plate heat exchangers is set to be shaped by innovations in design and a strong focus on energy efficiency. As industries around the globe strive to align with sustainability goals, the demand for advanced thermal management solutions is rising.

Key predictions for future developments include:

- Enhanced Thermal Performance: New materials and refining the geometry of pillow plates could significantly improve heat transfer efficiency.

- Integration of IoT and Smart Technologies: By embedding IoT capabilities, these systems can enable real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency.

- Customization for Industry-Specific Needs: Advanced manufacturing techniques will allow for highly customized designs that cater to specific industry requirements, from pharmaceuticals to food processing.

- Sustainable Manufacturing Practices: Adoption of eco-friendly production methods and materials will help reduce the carbon footprint associated with manufacturing processes.

These advancements are expected to drive the market forward, offering industries versatile solutions that not only meet energy demands but also contribute to broader environmental objectives. Pillow plate heat exchangers are poised to play a pivotal role in achieving efficient energy use across diverse industrial applications.

Competitor Analysis: Major Players in the Pillow Plate Heat Exchangers Market

In the competitive landscape of the Pillow Plate Heat Exchangers Market, several key players are leading the charge with innovative strategies and robust growth plans. Understanding these major manufacturers provides insight into market dynamics and future trends.

- FIC – Italy

- Anthermo GmbH – Germany

- Gesmex – Germany

- LOB GmbH – Germany

- Mazurczak GmbH – Germany

- Cenerge Engineering Solutions – India

- Boucheng Corp – China

- Shanghai Heat Transfer Equipment Co – China

- Sehenstar – China

- Omega Thermo Products – Netherlands

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Pillow Plate Heat Exchangers Market Report |

| Base Year | 2024 |

| Segment by Type |

· Welded Pillow Plates · Laser-Welded Plates |

| Segment by Application |

· Food and Beverage · Pharmaceuticals · Chemicals |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Pillow Plate Heat Exchangers Market is about to grow significantly, driven by a strong demand for energy-efficient thermal management solutions in industries such as food processing, pharmaceuticals, and chemicals.

Key Factors Driving Growth

Several factors are contributing to this growth:

- Technological Advancements: Innovations like IoT integration and smart manufacturing are improving efficiency and sustainability.

- Geopolitical Influences: Policies that support clean technologies are helping the market expand.

- Regional Growth: The rapid industrialization of Asia Pacific is making it a leader in market share.

Challenges Ahead

However, there are still challenges to overcome:

- High initial costs and competition from other technologies.

- Fluctuations in raw material prices affecting cost structures.

To stay competitive, industry players are focusing on innovation and strategic expansion. The push towards sustainable practices aligns with global efforts to reduce environmental impact while improving industrial processes.

As industries place greater importance on conserving energy and managing heat efficiently, pillow plate heat exchangers will play a crucial role in achieving these objectives. The future looks promising, with plenty of opportunities for those willing to invest in innovation and adaptability.

Global Pillow Plate Heat Exchangers Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Pillow Plate Heat Exchangers Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Pillow Plate Heat ExchangersMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Pillow Plate Heat Exchangersplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Pillow Plate Heat Exchangers Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Pillow Plate Heat Exchangers Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Pillow Plate Heat Exchangers Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofPillow Plate Heat ExchangersMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key components of the supply chain for pillow plate heat exchangers?

The supply chain for pillow plate heat exchangers includes key upstream components such as raw materials and manufacturing processes, as well as downstream applications which involve end-users in various industries like food and beverage, pharmaceuticals, and chemicals.

What emerging trends are influencing pillow plate heat exchanger technology?

Current emerging trends in pillow plate heat exchanger technology include technological advancements such as the integration of IoT capabilities, a strong focus on sustainability initiatives, and energy conservation efforts within the industry.

What challenges does the pillow plate heat exchangers market face?

The pillow plate heat exchangers market faces several challenges including high initial costs associated with manufacturing and installation, competition from alternative heat exchange technologies, and fluctuations in raw material prices that impact market dynamics.

How do geopolitical factors affect the production and trade of pillow plate heat exchangers?

Global political landscapes significantly influence the production and trade of pillow plate heat exchangers. Governmental policies promoting clean technologies can drive market growth while trade policies may impose restrictions or tariffs that affect international trade.

How is the pillow plate heat exchangers market segmented by type and application?

The market for pillow plate heat exchangers is segmented by type, including variations such as welded pillow plates, and by application sectors which encompass industries like food processing, pharmaceuticals, and chemicals. Demand trends vary within each segment based on specific industrial needs.

What is the future outlook for pillow plate heat exchangers regarding energy efficiency?

The future of pillow plate heat exchangers is expected to focus on innovations that enhance energy efficiency. Predictions indicate a trend towards designs that align with sustainability goals while improving process efficiency across various industrial applications.