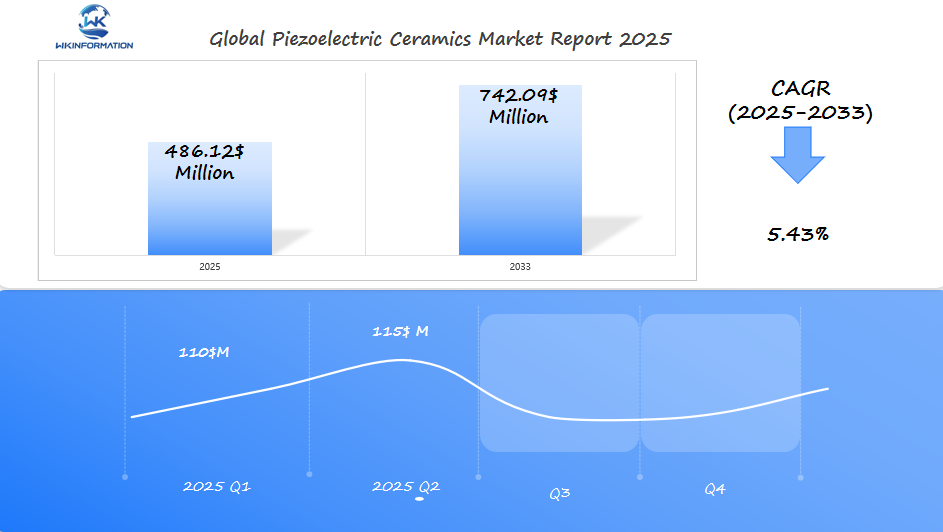

$486.12 Million Piezoelectric Ceramics Market to Enhance Electronics and Automotive in the U.S., Japan, and Germany by 2025

Explore key trends in the piezoelectric ceramics market, including lead-free materials, IoT integration, and regional growth drivers shaping 2025 and beyond.

- Last Updated:

Piezoelectric Ceramics Market Q1 and Q2 2025 Outlook

The piezoelectric ceramics market is estimated to reach $486.12 million in 2025, with a 5.43% CAGR from 2025 to 2033. In Q1 2025, the market is expected to generate about $110 million, as piezoelectric ceramics continue to be critical in sectors such as automotive, medical devices, and industrial automation. With increasing automation in manufacturing processes and a rising demand for precision sensors, the need for piezoelectric ceramics in applications such as pressure sensors, actuators, and medical diagnostic equipment is expanding.

The U.S., Japan, and Germany are expected to be key drivers of growth. In Japan, the demand for high-performance sensors in the automotive industry, particularly for electric vehicles, is contributing significantly to the piezoelectric ceramics market. Germany, with its strong industrial base, continues to invest in automation and precision engineering, further boosting the demand for these materials.

By Q2 2025, the market is forecasted to grow to approximately $115 million, as the adoption of piezoelectric ceramics in advanced medical devices and industrial applications continues to rise in these regions. As industries move toward more advanced and precise technologies, the demand for piezoelectric ceramics is expected to sustain its growth trajectory.

Key Takeaways

- Market growth ties directly to automotive and electronics industry needs.

- Piezoelectric sensors are core to next-gen automotive safety and efficiency systems.

- U.S., Japan, and Germany lead in R&D and manufacturing of these materials.

- Applications in sensors and actuators are expanding rapidly.

- Sustainability and precision are key drivers of market expansion.

Exploring the Upstream and Downstream Industry Chains for Piezoelectric Ceramics

Every ceramic transducer has a complex story. It starts with mining raw materials like barium titanate and lead zirconate titanate. These powders are then mixed into precise formulas, ready for making.

| Stage | Process | Key Players |

| Upstream | Material extraction & purification | Mining companies, chemical suppliers |

| Midstream | Ceramic shaping, firing, and polishing | Material manufacturers, tech firms |

| Downstream | Integration into devices | Automotive, medical, electronics brands |

Companies like TDK and Samsung Electro-Mechanics turn raw powders into ceramic transducers. These parts then go into ultrasound machines or phone vibration motors. A network of distributors makes sure they get to markets all over the world.

Quality control is key at every step. A small mistake in raw materials can harm the final product. This chain’s smooth running is crucial for industries that need precise sensors and actuators. Knowing how these parts are made helps predict market changes and where new ideas will come from.

Key Trends in the Piezoelectric Ceramics Market: Precision and Energy Efficiency

Automotive electronics are at the forefront of using piezoelectric ceramics. This move aims for smarter, greener systems. New advancements in material science allow for precise components that use less power.

This change is transforming how vehicles manage emissions and onboard sensors. It’s a big step towards a more sustainable future.

- Miniaturized sensors for autonomous driving systems

- Lower energy consumption in hybrid and electric vehicle parts

- Integration with IoT for real-time vehicle diagnostics

| Application | Technological Breakthrough | Outcome |

| Automotive Electronics | 3D-printed ceramic structures | Lighter, more responsive components |

| Automotive Electronics | Self-healing coatings | Reduced maintenance in harsh environments |

| Automotive Electronics | AI-optimized material formulas | 20% efficiency gains in energy use |

Companies like Bosch and Continental are adding these upgrades to their automotive electronics. These advancements mean vehicles that are smarter and more eco-friendly. They help meet global emission goals.

As the industry grows, piezoelectric ceramics will continue to improve connected, green transportation.

Challenges in the Development and Application of Piezoelectric Ceramics

Improving piezoelectric ceramics is tough due to technical and logistical problems. Industrial ceramics makers struggle with material purity. Even small impurities can mess up conductivity. Scaling up production without losing quality is a big challenge for companies like Morgan Advanced Materials and CoorsTek.

- Material uniformity: Tiny defects reduce reliability in sensors and actuators

- High production costs limit adoption in cost-sensitive markets

- Environmental regulations increase compliance demands for manufacturers

“Precision is non-negotiable—each micron matters,” explains Dr. Lena Müller of Fraunhofer Institute during a 2023 materials symposium.

| Challenge | Solution Approach |

| Material instability | Advanced sintering techniques |

| Scalability | Automated quality control systems |

| Regulatory hurdles | Global standards collaboration |

Companies like Samsung Corning and Ferro Corporation are using AI to improve industrial ceramics. They aim to balance innovation with keeping costs down. This is crucial as more industries turn to these materials for new technologies.

Geopolitical Influence on the Piezoelectric Ceramics Market

Global politics play a big role in the future of energy efficiency ceramics in piezoelectric technologies. Trade deals and tariffs between the U.S., Japan, and Germany affect costs. For example, U.S. tariffs on Chinese raw materials make companies look for new suppliers, changing how they make things.

“Geopolitical shifts are now a key risk factor for ceramic component supply chains,” said a 2023 industry report by the International Electronics Manufacturing Association.

- EU carbon rules make manufacturers focus on energy efficiency ceramics for green products.

- The U.S.-China tech battle leads to more U.S. investment in ceramic research and development.

- Japan’s export limits on advanced ceramics affect global access to these materials.

Energy efficiency ceramics are under the spotlight with new trade rules. Countries like Germany require local parts for government projects, boosting local production. At the same time, tensions over rare-earth minerals used in these ceramics cause price swings. Companies need to find new suppliers and invest in local factories to keep up.

As policies change, the market’s growth depends on finding a balance between innovation and global politics. The U.S. has passed laws offering tax breaks for making energy efficiency ceramics at home. This shows a move towards being more self-sufficient.

Types of Piezoelectric Ceramics: Materials and Manufacturing Processes

Piezoelectric ceramics come in many types, each with its own makeup and use. You’ll find lead zirconate titanate (PZT), barium titanate, and relaxor-PT among them. Each is crafted with specific materials to boost performance. For instance, PZT is made from lead, zirconium, and titanium. It’s great for sensors and actuators because of its high efficiency.

- PZT-based ceramics are popular because they offer good value and performance. Brands like Samsung Corning and TDK use them.

- Barium titanate is cheaper but not as stable at high temperatures. It’s best for simple sensors.

- Relaxor-PT ceramics are top-notch for medical devices. They’re flexible and durable, making them a favorite of Morgan Advanced Materials.

Creating these ceramics starts with mixing raw oxides like lead oxide and zirconium dioxide. The mixture is ground into powder, shaped, and then baked at high temperatures. New smart material innovations include 3D printing for complex shapes and less waste. Also, better sintering methods help make the materials more uniform, which is key for precise uses.

Recently, there’s a push for lead-free options to meet green standards. Ferroperm Piezoceramics is leading this effort with lithium niobate composites. These are both eco-friendly and functional. Such developments keep piezoelectric ceramics essential in new technologies like health monitors and smart sensors.

Applications of Piezoelectric Ceramics in Sensors, Actuators, and Electronics

Piezoelectric ceramics are key in automotive innovations. They help make cars smarter. Sensors in cars use these materials to detect pressure, vibration, and motion. This improves safety features like airbags and stability control.

Bosch and Toyota use these sensors to make cars better and more reliable.

Actuators powered by piezoelectric ceramics fine-tune engine valves and fuel injectors. This cuts down emissions and boosts efficiency in hybrids. In electronics, they’re crucial for ultrasound devices, smartphone touchscreens, and health monitors.

- Sensors: Monitor vehicle systems in real time.

- Actuators: Optimize engine functions for cleaner energy use.

- Electronics: Power compact, high-performance devices.

Car makers are adding these materials to automotive innovations like self-driving cars. They ensure safe driving. Their ability to work well and last long makes them perfect for new tech.

As more cars need these materials, partnerships will grow. This will lead to smarter, greener vehicles.

Global Insights into the Piezoelectric Ceramics Market

Precision engineering is key to global progress in piezoelectric ceramics. It shapes industries across the world. The U.S., Japan, and Germany are at the forefront, each bringing their unique strengths.

- North America: Companies like Tesla use ceramics for sensors, improving car technology.

- Asia-Pacific: TDK and Murata from Japan lead in material research, focusing on making things smaller for electronics.

- Europe: CeramTec from Germany works on medical and industrial uses, focusing on dependability.

“Precision engineering isn’t just a process—it’s the backbone of market growth,” says a materials scientist at the Fraunhofer Institute. “Without it, scaling advanced ceramics for global use isn’t possible.”

Investment in precision engineering leads to partnerships between Asian makers and U.S. tech companies. Countries like India and Brazil are starting to use these materials for green energy. As the world aims for sustainability, sales are expected to grow. Each region, from Detroit to Munich, has its own needs for precision engineering.

U.S. Market Demand for Piezoelectric Ceramics in Automotive and Consumer Electronics

The U.S. market for piezoelectric ceramics is growing fast. This growth comes from new tech in cars and gadgets. Cars use these materials for sensors and to control vibrations. Gadget makers use them to make devices thinner and more efficient.

- Automotive Use Cases: Engine management systems, tire pressure monitoring, and autonomous vehicle sensors.

- Consumer Electronics Trends: Haptic feedback in smartphones, wearable health monitors, and noise-canceling headphones.

“The U.S. automotive sector could account for 35% of piezoelectric ceramic demand by 2025, fueled by electric vehicle innovations.” — 2023 Industry Analyst Report

Big car makers like Ford and Tesla are adding these materials to their cars. They want to make cars better at using fuel and safer. Tech giants like Apple and Samsung also use them to make gadgets better.

Investments in research and development are showing the growth of this field. The demand for these materials will keep growing. This is because gadgets are getting smaller and cars are getting smarter. The U.S. is leading the way in making these technologies better.

Japan’s Pioneering Role in Piezoelectric Technology for Industrial Use

Japan has been a leader in piezoelectric ceramics for a long time. Companies like TDK and Murata Manufacturing are at the forefront. They make materials that are both precise and durable.

Their research centers, such as the Tokyo Institute of Technology, work closely with manufacturers. Together, they improve production methods.

- TDK’s nanoceramic components enable ultra-precise sensors for automotive safety systems.

- Murata’s low-temperature sintering techniques cut energy use without sacrificing performance.

- Fujikura develops ceramics for industrial robots, boosting automation in manufacturing.

“Innovation in piezoelectric materials isn’t just about numbers—it’s about solving real-world problems.”

These advancements aren’t just in labs. Japanese firms work with Toyota to use ceramics in engine management systems. Medical device makers also use their materials for ultrasound, making images clearer.

Japan is also focused on sustainability. Newer materials reduce waste during manufacturing. As demand increases, Japan’s expertise sets high standards for quality and efficiency. This makes Japan a leader in smart industrial solutions.

Germany’s Innovation in Piezoelectric Ceramics for Medical and Industrial Solutions

Germany is at the forefront of using piezoelectric ceramics in new ways. These materials are crucial in healthcare and manufacturing. They help hospitals and factories achieve new heights.

German engineers are creating tools that are more precise and reliable. This is thanks to their work with piezoelectric ceramics. They make everything from small sensors to big machines better.

- Medical Breakthroughs: Advanced ultrasound systems use German-made ceramics to create clearer images, aiding early disease detection.

- Industrial Precision: Automated assembly lines in automotive plants now use piezoelectric components for error-free part placement.

The Fraunhofer Institute and Siemens Healthineers have made a big impact. They created a device that cuts surgery prep time by 40%. This means surgeons can do less invasive procedures with more accuracy.

German companies also focus on making their products last. CeramTec, for example, makes ceramics that can handle tough conditions. This makes their products a favorite for manufacturers around the world.

Germany is not just keeping up; it’s leading the way. Their innovations are making surgeries safer and factories smarter. They’re improving our lives in big ways.

The Future of Piezoelectric Ceramics: Smart Materials and Sustainability

Piezoelectric ceramics will become key in smart technology as industries grow. We’re seeing the start of self-powered sensors and energy systems. These turn mechanical energy into electricity, perfect for new devices.

- Smart materials could enable adaptive structures that respond to environmental changes.

- Research focuses on reducing production waste and using eco-friendly raw materials.

- Medical and automotive sectors are testing designs that cut energy use by 30% or more.

Companies are focusing on recyclable components to meet green standards. TDK and ROBERT BOSCH are investing in labs for low-temperature methods. This reduces emissions and costs.

Future devices might have piezoelectric layers in solar panels or roads. This could generate power from vibrations. By 2030, these materials will power health monitors and smart city systems. Sustainability is now a must for staying ahead.

Competitive Landscape in the Piezoelectric Ceramics Market

- Kyocera – Kyoto, Japan

- TDK – Nihonbashi, Chuo-ku, Tokyo, Japan

- CeramTec – Plochingen, Germany

- Murata – Nagaokakyo, Kyoto Prefecture, Japan

- PI Ceramic

- Jiangjia

- CTS Corporation – Lisle, Illinois, United States

- Kaili Tech

- Jiakang Electronics – Jiaxing, Zhejiang, China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Piezoelectric Ceramics Market Report |

| Base Year | 2024 |

| Segment by Type |

· Lead Zirconate Titanate (PZT) · Lead Magnesium Niobate (PMN) · Others |

| Segment by Application |

· Industrial &Manufacturing · Automotive · Consumer Electronics · Medical · Military · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Piezoelectric ceramics are leading the way in innovation across many industries. The U.S., Japan, and Germany are at the forefront. These materials are key for car electronics, medical tools, and energy-saving systems.

While they grow, challenges like high production costs and environmental concerns arise. Companies are working hard to make more while harming less. They aim to meet global needs while keeping the planet safe.

Japan is known for its precise sensors, and Germany for its medical tech. The U.S. is pushing for lighter, smarter car parts. The future depends on making these materials in a way that’s good for the planet.

Looking into reports or updates from manufacturers shows how this field is changing. As we need more advanced materials, piezoelectric ceramics will keep playing a big role. They will help us create new, sustainable technologies around the world.

Global Piezoelectric Ceramics Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Piezoelectric Ceramics Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Piezoelectric Ceramics Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Piezoelectric Ceramicsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Piezoelectric Ceramics Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Piezoelectric Ceramics Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Piezoelectric Ceramics Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Piezoelectric Ceramics Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are piezoelectric ceramics?

Piezoelectric ceramics are materials that create an electrical charge when pressed. They are key in many fields, like electronics and cars. They help things work better and use less energy.

How are piezoelectric ceramics manufactured?

Making piezoelectric ceramics starts with picking the right materials. Then, they are shaped and baked. New methods like 3D printing help make them just right for each use.

What are the key applications of piezoelectric ceramics?

They are used in many things like sensors, medical tools, and gadgets. For example, they help in ultrasound and make car parts work better.

What are the challenges in the piezoelectric ceramics market?

Making them better is hard, and making lots of them is tricky. Rules also play a part. Companies must find ways to stay ahead.

How does geopolitics affect the piezoelectric ceramics market?

Politics can change how things are made and sold. This can affect prices and how easy it is to get them. It’s all about supply and demand.

What trends are shaping the future of piezoelectric ceramics?

New trends focus on making things more precise and saving energy. The push for smart materials and green practices is changing the market. It opens up new chances for growth.

Why is Japan a leader in piezoelectric technology?

Japan leads because of its big steps in piezoelectric ceramics, especially in industry. It has a strong research team and companies that make top-notch materials.

What role does Germany play in the piezoelectric ceramics market?

Germany is a big name in medical tech and making things precisely. Piezoelectric ceramics help in these areas, making things better.

What is the market outlook for piezoelectric ceramics in the United States?

The U.S. market is growing, especially in cars and electronics. More money and new ideas are expected to make it even bigger.

How do companies compete in the piezoelectric ceramics market?

Companies compete by being innovative, focusing on quality, and finding their niche. The ones who make the latest tech stand out.