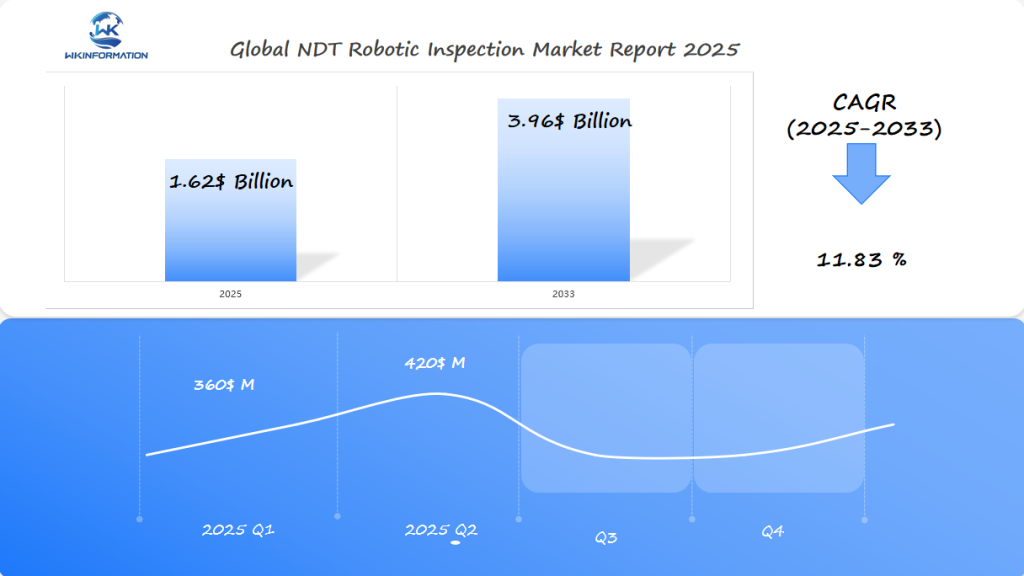

NDT Robotic Inspection Market Expected to Grow to $1.62 Billion Globally by 2025: Advanced Quality Control in the U.S., Germany, and Japan

The NDT Robotic Inspection Market continues to expand with technological advancements, driving efficiency in industrial inspections across aerospace, manufacturing, and oil & gas sectors through 2025

- Last Updated:

NDT Robotic Inspection Market Forecast for Q1 and Q2 2025

The NDT Robotic Inspection market is projected to reach $1.62 billion in 2025, with an impressive CAGR of 11.83% through 2033. Q1 2025 market size is estimated at approximately $360 million, reflecting gradual adoption in aerospace, automotive, and energy sectors as automation technologies gain traction. By Q2, the market is expected to expand robustly to around $420 million, driven by increasing safety regulations and demand for precise, real-time inspection capabilities.

Key Takeaways

- The global NDT robotic inspection market is expected to reach USD 44.1 billion by 2032.

- Technological innovations are driving the growth of the market.

- There is a growing demand in the manufacturing, aerospace, and energy sectors.

- Robotic solutions are enhancing the accuracy and safety of inspections.

- There is a significant opportunity for automation in quality control processes.

Upstream and Downstream Industry Overview in NDT Robotic Inspection

Upstream Industry Overview

- Increasing Demand for Automation in Manufacturing

- Increasing Safety Concerns and Regulatory Compliance

- Technological Advancements in AI and Machine Learning

Downstream Industry Overview

- Key Applications of NDT Robotic Inspection Across Industries:

- Aerospace and Defense Inspection

- Oil and Gas Testing

- Manufacturing and Automotive Quality Control

- Regional Analysis of the NDT Robotic Inspection Market:

- North American Market: Technology Leadership

- European Market: Regulatory Dominance

- Asia-Pacific: Rapid Growth Trajectory

Key Drivers Fueling the Growth of NDT Robotic Inspection Market

The Non-Destructive Testing (NDT) robotic inspection market is changing fast. New technologies and industry needs are changing how we check quality and safety.

Several key factors are driving the growth of NDT robotic inspection systems in many industries:

Increasing Demand for Automation in Manufacturing

Manufacturers are quickly adopting automation to boost productivity and precision. Robotic inspection systems offer unmatched consistency in finding defects with high accuracy. The main benefits are:

- Less human error

- 24/7 operation

- Quicker inspection

- Better quality control

Increasing Safety Concerns and Regulatory Compliance

Safety regulations in industries such as aerospace, oil and gas, and manufacturing are becoming more stringent. NDT robotic inspection systems assist in meeting these challenging safety requirements by providing:

- Comprehensive risk evaluation

- Accurate documentation

- Reduced danger for individuals in hazardous locations

Technological Advancements in AI and Machine Learning

AI is changing NDT robotic inspection in big ways. Machine learning helps spot defects, predict maintenance, and analyze data in real-time. Advanced AI systems can find tiny flaws that humans can’t see.

Challenges Facing the NDT Robotic Inspection Market

The Non-Destructive Testing (NDT) robotic inspection market has big hurdles. These challenges slow down its growth and adoption. Despite new tech, many problems still exist in making inspection processes better.

Companies face many barriers when they try to use robotic inspection. These issues fall into three main areas:

- High costs are a big financial problem

- Technical issues limit how well it works

- Lack of skilled workers makes it hard to use

High Initial Costs and Implementation Barriers

High costs are a big problem for many companies. Small and medium-sized businesses find it hard to afford the cost of advanced NDT robotic systems. They have to pay for the equipment, software, making changes to their setup, and training.

Technical Limitations and Environmental Adaptability

Current robotic inspection technology has limited adaptability in tough industrial settings. It struggles with extreme temperatures, tight spaces, and uneven surfaces. To solve this issue, manufacturers need to create more robust systems that can operate effectively in various environments.

Skilled Workforce Shortage

There’s a big shortage of skilled people to use and fix NDT robotic inspection gear. Schools and training programs need to work together to fill this gap. They must prepare the next generation of technical experts.

Geopolitical Influences Shaping the NDT Robotics Market

The geopolitical landscape plays a crucial role in shaping the NDT robotics market. Factors such as trade policies, international regulations, and global economic conditions impact market dynamics and growth trends. Here are some key geopolitical influences:

Trade Policies and Tariffs

Trade policies between countries can affect the import and export of NDT robotic equipment. Tariffs imposed on foreign goods may impact market prices and competitiveness.

International Regulations

Harmonization or divergence in regulatory standards across regions can create challenges for NDT robotics manufacturers. Compliance with different regulations may require additional resources and investments.

Global Economic Conditions

Economic stability, currency exchange rates, and overall market demand influenced by geopolitical events can impact investment decisions in the NDT robotics market.

Geopolitical Alliances and Conflicts

Collaborative efforts between countries in technological innovation or geopolitical tensions that disrupt supply chains can have implications for the NDT robotics industry.

Resource Availability and Access

Geopolitical factors can also influence access to critical resources needed for manufacturing NDT robotic systems, such as rare earth minerals or advanced technology components.

Understanding these geopolitical influences is essential for stakeholders in the NDT robotics market to navigate challenges and seize opportunities for growth.

Emerging Technologies in NDT Robotic Inspection

The world of non-destructive testing (NDT) is changing fast with new technologies. These advancements are changing how we inspect, check quality, and keep things safe in many fields.

New tech is making robots better at inspecting things. These updates help find problems early and keep structures strong.

Advanced Sensors and Imaging Systems

Modern NDT robots use advanced sensors for better details and accuracy. Some key advancements include:

- High-resolution ultrasonic imaging technologies

- Multi-spectral sensor arrays

- Compact electromagnetic scanning systems

IoT Integration and Cloud Computing

IoT is changing NDT by letting robots collect and analyze data in real-time. Cloud computing makes it easy to share and monitor data from anywhere.

| Technology | Key Benefits | Industry Applications |

| Advanced Sensors | Increased precision | Aerospace, Manufacturing |

| IoT Integration | Real-time monitoring | Oil & Gas, Energy |

| Cloud Computing | Data accessibility | Multiple Sectors |

Development of Collaborative Robots (Cobots)

Cobots work with humans to make inspections better and faster. They use smart sensors and learn from their work, making inspections more flexible and effective.

Key Applications of NDT Robotic Inspection Across Industries

Non-destructive testing (NDT) robotic inspection has changed how we check quality in many fields. These new tech tools give us important info about materials and structures without harming them.

The world of industry has seen big changes in how we inspect things. Now, robots are key in making sure we get accurate and reliable results in many areas.

Aerospace and Defense Inspection

In the aerospace industry, NDT robots play a crucial role in ensuring safety and performance. They are used for thorough inspections of aircraft and engines, as well as for identifying minute defects in materials.

Here are some key applications of NDT robots in aerospace and defense:

- Comprehensive analysis of aircraft structures

- In-depth examination of engine components

- Accurate detection of microscopic defects in materials

Oil and Gas Testing

Testing in the oil and gas industry must be extremely comprehensive. NDT robots play a significant role in this process. They inspect pipelines and detect corrosion in areas that are difficult to access.

- Pipeline integrity assessments

- Corrosion detection in challenging environments

- Remote monitoring of critical infrastructure

Manufacturing and Automotive Quality Control

In car making, robots have made a big difference. They help spot problems and check parts as they’re made. This makes cars better and safer.

Key Benefits of Robotics in Manufacturing

- Automated defect recognition systems

- Real-time production line monitoring

- Enhanced precision in component evaluation

Industry Key NDT Applications Primary Benefits Aerospace Structural Component Analysis Enhanced Safety Oil and Gas Pipeline Integrity Testing Risk Mitigation Automotive Manufacturing Quality Control Defect Prevention

These new ways of inspecting things are changing how we make sure things are good. They make our work more accurate and efficient in many important areas.

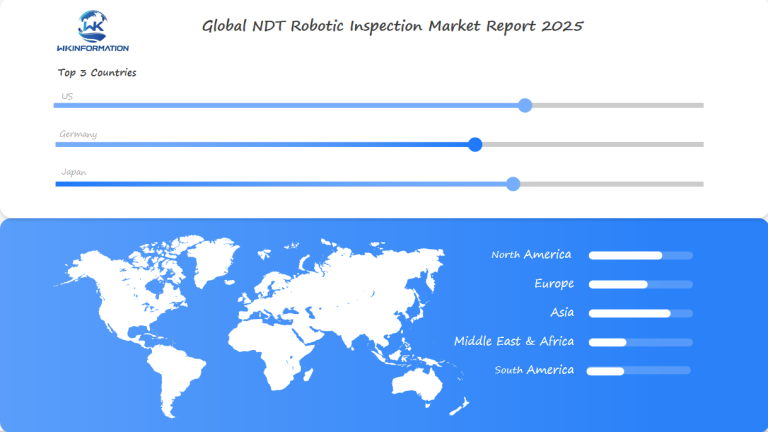

Regional Analysis of the NDT Robotic Inspection Market

The global Non-Destructive Testing (NDT) robotic inspection market shows significant differences in growth and technology across regions. Each area has its own unique characteristics and opportunities for growth in North America, Europe, and Asia-Pacific.

North American Market: Technology Leadership

The North American market leads in NDT robotic inspection tech. Growth is driven by:

- Strong industrial base

- Big investments in research and development

- Wide use of new tech solutions

European Market: Regulatory Dominance

Europe leads in NDT robotic inspection thanks to strict quality rules and top-notch manufacturing. It’s expected to see over 35% of market growth in the forecast period.

Asia-Pacific: Rapid Growth Trajectory

The Asia-Pacific region is growing the fastest in NDT robotic inspection. With a 12.9% CAGR, China and India are leading the way with big investments in infrastructure and manufacturing.

U.S. Investment in Automation and NDT Robotics

The United States is a key player in the advancement and adoption of automation and non-destructive testing (NDT) robotics, driven by its technology leadership in the North American market. U.S. investments focus on several critical areas:

- Technological Innovation: Significant funds are directed towards developing advanced sensors, high-resolution imaging systems, and integrating AI and machine learning capabilities to enhance the accuracy and efficiency of NDT robotic inspections.

- Addressing Implementation Barriers: Investments aim to reduce high initial costs through scalable solutions tailored for small and medium-sized enterprises, alongside funding for training programs to combat the skilled workforce shortage essential for operating sophisticated NDT systems.

- Enhancing Environmental Adaptability: Research funding targets creating robust robotic platforms capable of functioning in extreme industrial conditions such as high temperatures, confined spaces, and uneven surfaces prevalent in sectors like aerospace, oil & gas, and manufacturing.

- Strategic Partnerships and Collaborations: U.S. companies actively pursue collaborations with academic institutions and technology firms to accelerate innovation cycles, facilitate product launches, and maintain regulatory compliance.

- Market Growth and Resilience Post-COVID-19: Capital infusion supports the acceleration of automation trends triggered by the pandemic, ensuring long-term market resilience through autonomous inspection system development.

- Venture Capital and Private Equity Involvement: The U.S. sees a vibrant investment landscape where venture capitalists back startups specializing in IoT integration, cloud computing solutions for data management, and collaborative robots (cobots) designed for NDT tasks.

Germany’s Leadership in Precision Inspection Technology

Germany stands at the forefront of precision inspection technology, showcasing excellence in innovation and implementation. The country’s commitment to quality control and safety has propelled it to a leadership position in the global market. Leveraging advanced sensors, AI, and machine learning, German industries have embraced automation to enhance efficiency and accuracy in inspections. This strategic approach has not only improved manufacturing processes but also ensured compliance with stringent safety regulations. With a focus on technological advancements and skilled workforce development, Germany continues to set high standards in precision inspection technology, driving growth and success across various industries.

Japan’s Advancements in Robotics and Quality Control

Japan has long been a global leader in robotics technology, driven by its commitment to precision engineering, innovation, and quality control. The country’s advancements in robotics have significantly influenced the development and adoption of Non-Destructive Testing (NDT) robotic inspection systems, enhancing manufacturing and industrial quality control on multiple fronts.

Key Contributions of Japan in Robotics and Quality Control:

- Pioneering Automation Integration: Japanese industries have been at the forefront of integrating robotics into manufacturing lines to improve productivity and consistency. This has translated into advanced robotic inspection systems that perform precise, repeatable quality checks with minimal human error.

- Focus on Precision Engineering: Japan’s expertise in precision machinery enables the creation of highly sensitive sensors and imaging technologies used in NDT robotic inspection. These tools can detect microscopic defects, ensuring superior product reliability and safety.

- Collaborative Robots (Cobots): Japan has contributed significantly to the development of cobots that can safely work alongside humans. These cobots enhance inspection processes by combining machine accuracy with human oversight, leading to improved flexibility and efficiency in quality control.

- AI and Machine Learning Integration: Japanese companies are actively incorporating AI-powered algorithms into robotic systems for real-time defect detection and predictive maintenance. This approach optimizes manufacturing workflows while reducing downtime.

- Regulatory Compliance and Safety Standards: With stringent domestic safety regulations, Japan has fostered a regulatory environment that pushes forward the adoption of advanced NDT robotic technologies. This ensures high standards in industries such as automotive, aerospace, and electronics.

- Robust R&D Ecosystem: The synergy between academic institutions, government agencies, and private enterprises in Japan accelerates innovation in robotics. Continuous research leads to breakthroughs in sensor technology, autonomous operations, and IoT connectivity within quality control applications.

Future Trends and Opportunities in NDT Robotic Inspection

The NDT robotic inspection market is going through big changes. New technologies and growing industries are driving this shift. As the world builds more and fixes old stuff, the need for better inspection tools grows.

New ways of inspecting are changing how we check quality and keep things running. New tech is opening doors in many fields.

Expansion into Emerging Industries

New industries are offering big chances for NDT robotic inspection. Key areas include:

- Renewable energy, like wind power

- Electric car making

- Advanced manufacturing

- Aerospace and defense

Integration of Artificial Intelligence and Machine Learning

AI is changing how we use NDT robotic inspection. Machine learning helps find tiny problems better. Now, smart systems can spot tiny flaws with great accuracy.

Development of Autonomous Inspection Systems

Autonomous systems are a big step forward in NDT robotic inspection. These systems can do tough checks on their own. This makes work safer and more efficient in factories.

Key Players and Competitive Landscape in NDT Robotic Inspection

Key players in the NDT robotic inspection market are focusing on technological advancements to enhance inspection accuracy, efficiency, and safety across various industries. They are expanding operations in regions such as North America, Europe, and Asia-Pacific, where demand for automated, non-destructive testing solutions is growing due to the need for increased efficiency, safety, and precise quality assessments. Strategic collaborations with manufacturing firms and investments in AI-driven automation, advanced sensor integration, and real-time data analysis are enabling these companies to strengthen their market presence and contribute to improved asset integrity and compliance with stringent industry standards.

Key Players:

-

GE Inspection Robotics (United States)

-

Olympus Corporation (Japan)

-

Eddyfi Technologies (Canada)

-

RVI Group (United Kingdom)

-

Inuktun Services (Canada)

-

Waygate Technologies (United States)

-

Mistras Group (United States)

-

TWI Ltd (United Kingdom)

-

Cyberhawk Innovations (United Kingdom)

-

KUKA Robotics (Germany)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global NDT Robotic Inspection Market Report |

| Base Year | 2024 |

| Segment by Type |

· Advanced Sensors · IoT Integration · Cloud Computing |

| Segment by Application |

· Aerospace · Oil and Gas · Automotive |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global NDT Robotic Inspection Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: NDT Robotic Inspection Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- NDT Robotic Inspection Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global NDT Robotic Inspection Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: NDT Robotic Inspection Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: NDT Robotic Inspection Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: NDT Robotic Inspection Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of NDT Robotic Inspection Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is NDT Robotic Inspection?

NDT (Non-Destructive Testing) Robotic Inspection uses robots to check materials without damaging them. It helps find defects in industrial parts.

Which industries primarily use NDT Robotic Inspection?

Industries such as aerospace, oil and gas, manufacturing, automotive, and defense primarily use NDT Robotic Inspection. These industries rely on this technology to ensure the quality and safety of their parts.

How do AI and machine learning improve NDT robotic inspection?

AI and machine learning make inspections more accurate. They help predict maintenance needs and analyze data better. This makes systems learn and adapt faster.

What are the primary challenges in NDT Robotic Inspection?

The main challenges in NDT Robotic Inspection are:

- High costs

- Technical issues

- Lack of skilled workers

- Need for ongoing training

How has COVID-19 impacted the NDT Robotic Inspection market?

The pandemic has led to a greater need for automation, which could result in a higher demand for robotic systems. However, it has also caused some delays in supply chains.

What are the emerging technologies in NDT Robotic Inspection?

New tech includes better sensors, IoT, cloud computing, and AI. Also, collaborative robots and advanced inspection tools are coming.

What is the projected market growth for NDT Robotic Inspection?

The market is expected to grow significantly, potentially reaching $1.62 billion globally by 2025. This growth can be attributed to increased automation and technological advancements.

How do robotic inspection systems improve safety?

Robotic inspection systems make environments safer by reducing human risk. They perform precise and consistent checks, ensuring compliance with strict safety regulations.

Which regions are leading in NDT Robotic Inspection technology?

- North America leads in innovation.

- Europe has the biggest market share.

- The Asia-Pacific region, especially China and India, is growing fast.

Are NDT robotic inspection systems fully autonomous?

Most systems are not fully autonomous yet. They still need human help. But, new tech is making them more independent.