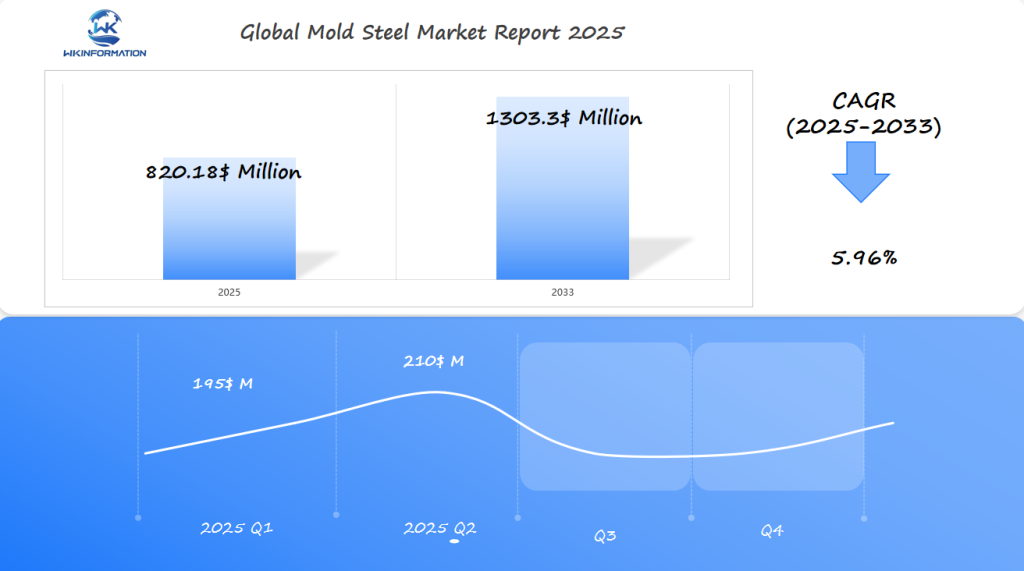

Mold Steel Market Expected to Reach $820.18 Million Globally by 2025 with Leading Growth in Germany, China, and the U.S.

Explore the rapidly growing Mold Steel Market, projected to reach $820.18 million globally by 2025, with leading growth in Germany, China, and the U.S.

- Last Updated:

Mold Steel Market Performance in Q1 and Q2 of 2025 with Regional Focus

The Mold Steel market is expected to reach $820.18 million in 2025, growing at a rate of 5.96% annually until 2033. In the first quarter, revenues are projected to be around $195 million, with an increase to approximately $210 million in the second quarter. This growth is driven by higher industrial production and demand for tooling.

Regional Insights

- Germany’s advanced manufacturing sector continues to drive innovation and demand for high-performance mold steels.

- China’s rapid industrial expansion and modernization efforts are fueling growth.

- The U.S. market benefits from investment in automotive and aerospace tooling.

Factors Supporting Growth

Ongoing improvements in alloy compositions and processing methods are contributing to the growth of this market. These advancements enhance durability and efficiency across various applications, further driving demand for mold steels.

Analyzing the Upstream and Downstream Industry Chain of Mold Steel Market

The upstream and downstream industry chains of the mold steel market are interdependent, influencing its market trends and future outlook. The mold steel industry chain involves various stakeholders, from raw material suppliers to manufacturers and end-users.

Understanding the Mold Steel Industry Chain

The mold steel industry chain can be broadly categorized into upstream and downstream sectors. The upstream sector involves the production of raw materials such as steel and alloys, which are crucial for manufacturing mold steel.

Key Raw Materials in Mold Steel Production

The key raw materials used in the production of mold steel include:

- High-carbon steel

- Alloy steels

- Specialty alloys

These materials are processed and alloyed to create high-quality mold steel, which is then used in various industrial applications.

Key Players in the Mold Steel Industry Chain

The mold steel industry chain involves several key players, including:

- Raw material suppliers: Companies that supply steel and alloys.

- Mold steel manufacturers: Companies that produce mold steel using the raw materials.

- Mold manufacturers: Companies that use mold steel to manufacture molds for various industries.

These players work together to ensure a smooth supply chain, from raw material production to the manufacturing of final products using mold steel.

Understanding the roles and interdependencies of these key players is essential for analyzing the mold steel market’s dynamics and identifying opportunities for growth.

Key Trends Driving Mold Steel Market Expansion

The mold steel industry is about to undergo a significant change due to several key trends. The growing need for highly accurate molds, improvements in materials, and the use of Industry 4.0 technologies are all reshaping the industry.

Emerging Trends in Mold Steel Market

Several emerging trends are driving the mold steel market forward. Increased demand for precision molds is one of the primary drivers, as manufacturers seek to produce complex components with high accuracy.

Advanced materials are another significant trend. The development of new steel grades with enhanced properties, such as higher hardness and better wear resistance, is enabling the production of more durable molds.

The adoption of Industry 4.0 technologies is also impacting the mold steel market. Technologies like AI, IoT, and additive manufacturing are improving mold design, production, and maintenance.

| Trend | Description | Impact |

| Increased Demand for Precision Molds | Growing need for complex components with high accuracy | Higher demand for high-precision mold steel |

| Advanced Materials | Development of new steel grades with enhanced properties | Improved mold durability and performance |

| Industry 4.0 Technologies | Adoption of AI, IoT, and additive manufacturing | Enhanced mold design, production, and maintenance |

These emerging trends are expected to continue shaping the mold steel market, driving innovation and growth.

Market Restrictions and Regulatory Challenges in Mold Steel Industry

The mold steel industry faces numerous regulatory challenges that impact its global market dynamics. These challenges are multifaceted, involving environmental regulations, trade policies, and industry standards that mold steel manufacturers must comply with.

Regulatory Challenges Facing the Mold Steel Industry

The mold steel industry is subject to various environmental regulations aimed at reducing its ecological footprint. These regulations include emissions controls, waste management practices, and energy efficiency standards. Compliance with these regulations can be costly and requires significant investment in technology and process adjustments.

Trade policies also play a crucial role in shaping the mold steel industry. Tariffs, quotas, and other trade barriers can affect the availability and cost of raw materials, thereby influencing the production costs and competitiveness of mold steel manufacturers.

Impact of Regulations on Mold Steel Market

The impact of regulations on the mold steel market is significant. Environmental regulations can lead to increased production costs due to the need for cleaner technologies and waste reduction measures. Trade policies can affect the global supply chain, making it challenging for manufacturers to source raw materials at competitive prices.

| Regulatory Challenge | Impact on Industry | Compliance Measures |

| Environmental Regulations | Increased production costs | Adoption of cleaner technologies |

| Trade Policies | Disruption in supply chain | Diversification of supply sources |

| Industry Standards | Enhanced quality and safety | Implementation of quality management systems |

To navigate these challenges, mold steel manufacturers are adopting various strategies, including investing in research and development to improve efficiency and reduce environmental impact. They are also diversifying their supply chains to mitigate the effects of trade policies.

Geopolitical Impact on the Mold Steel Market

The mold steel market is significantly influenced by geopolitical factors, including trade policies and economic sanctions. These factors can alter the global supply chain, affecting the availability and pricing of mold steel.

Geopolitical Factors Influencing Mold Steel Market

Geopolitical tensions between major economies can lead to trade wars, impacting the mold steel industry. For instance, tariffs imposed on steel imports can increase the cost of raw materials for mold steel manufacturers.

Key geopolitical factors influencing the mold steel market include:

- Trade policies and agreements

- Economic sanctions on steel-producing countries

- Political stability in major mold steel-consuming regions

These factors can create uncertainty and volatility in the market, affecting the profitability of mold steel producers and suppliers.

To mitigate these risks, companies in the mold steel industry are adopting strategies such as diversifying their supply chains and investing in local production capacities.

Mold Steel Market Segmentation by Type

The mold steel market is diverse, with various types catering to different industrial needs. This diversity is driven by the unique properties and applications of each type of mold steel.

Types of Mold Steel

Mold steel can be broadly categorized into several types, including plastic mold steel, die-cast mold steel, and others. Each type has its specific characteristics and is suited for particular applications.

Characteristics of Different Mold Steel Types

Plastic mold steel is used for manufacturing molds for plastic injection molding. It is known for its high polishability, corrosion resistance, and ability to withstand high pressures. Die-cast mold steel, on the other hand, is used for die-casting processes and is valued for its high thermal conductivity and resistance to thermal fatigue.

The characteristics of mold steel types are crucial in determining their suitability for various industrial applications. For instance, plastic mold steel is often used in the production of consumer goods, while die-cast mold steel is commonly used in the automotive and aerospace industries.

The market share of each type of mold steel varies based on factors such as demand from different industries and regional market trends. Understanding these factors is essential for manufacturers and suppliers to tailor their products and strategies to meet the evolving needs of the market. This involves a careful selection of mold steel types to match specific requirements and optimize performance.

Applications and Industrial Uses of Mold Steel

Mold steel is crucial in shaping the modern industrial landscape. Its unique properties make it an essential material in various manufacturing processes, driving innovation and efficiency across different sectors.

Here are some key applications and industrial uses of mold steel:

- Injection Molding: Mold steel is widely used in the production of injection molds, which are essential for manufacturing plastic parts and components.

- Die Casting: In die casting processes, mold steel is employed to create molds for producing metal parts with high precision and intricate designs.

- Blow Molding: Mold steel plays a significant role in blow molding applications, where it is used to create molds for hollow plastic products such as bottles and containers.

- Thermoforming: In thermoforming processes, mold steel is utilized to manufacture molds for shaping thermoplastic sheets into various products.

- Compression Molding: Mold steel is also used in compression molding applications, where it serves as the material for creating molds used in the production of rubber and composite parts.

- 3D Printing: With the rise of additive manufacturing, mold steel is being explored as a material for 3D printing molds, enabling rapid prototyping and production of complex geometries.

The versatility of mold steel makes it a critical component in these industries, contributing to the advancement of manufacturing techniques and the creation of innovative products.

Industrial Applications of Mold Steel

Mold steel is widely used in the production of automotive parts, consumer electronics, and medical devices. Its high durability and resistance to wear make it an ideal material for manufacturing complex components.

Key Industries Utilizing Mold Steel

- Automotive Industry: Mold steel is used to produce various automotive parts, such as engine components, gearboxes, and body panels.

- Consumer Electronics: The precision and durability of mold steel make it suitable for manufacturing electronic components, including smartphone casings and laptop parts.

- Medical Devices: Mold steel is used in the production of medical devices, such as surgical instruments and implantable devices, where high precision and sterility are crucial.

Emerging Applications of Mold Steel

The demand for mold steel is also driven by emerging applications in industries such as aerospace and renewable energy. As technology advances, the need for high-quality mold steel with specialized properties is on the rise.

The use of mold steel in emerging applications is expected to drive market growth, as industries continue to seek materials that can meet their demanding requirements.

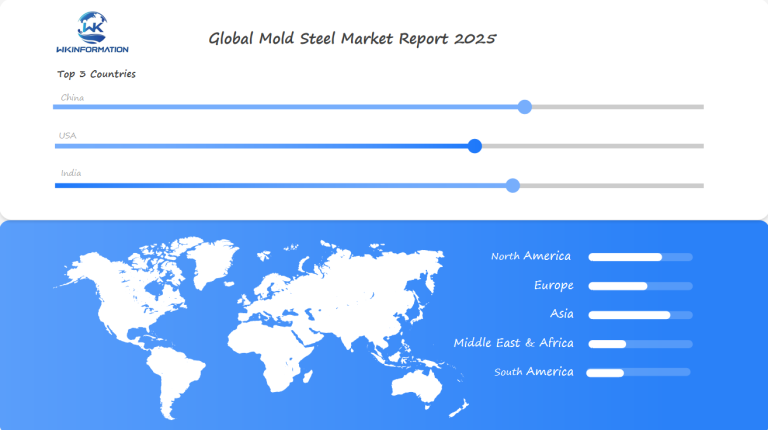

Global Regional Overview of Mold Steel Market

The global mold steel market has different regional factors that greatly affect its overall growth. Each region has its own market trends influenced by things like industrialization, technological progress, and demand from various industries that use molds.

Regional Mold Steel Market Trends

Regional variations in demand and supply play a crucial role in shaping the mold steel market worldwide. In regions with robust manufacturing sectors, such as Asia-Pacific and Europe, the demand for high-quality mold steel is particularly strong.

1. Asia-Pacific Region

This region is expected to witness significant growth in the mold steel market, driven by rapid industrialization and the presence of a large number of manufacturing facilities in countries like China, Japan, and South Korea.

2. European Region

Europe is another significant market for mold steel, with countries like Germany, Italy, and France having well-established automotive and machinery industries that drive the demand for mold steel.

3. North American Region

The North American mold steel market is primarily driven by the United States, where there is a strong presence of industries such as automotive, aerospace, and consumer goods, all of which require high-quality mold steel.

Emerging Trends in Regional Markets

Emerging trends in regional markets include the increasing adoption of advanced materials and technologies, such as additive manufacturing, which is expected to create new opportunities for mold steel manufacturers.

- Increased focus on sustainability and environmental regulations

- Growing demand for customized mold steel products

- Rising importance of digitalization and Industry 4.0

Understanding these regional market trends is crucial for industry players to navigate the complex global mold steel market landscape effectively.

Growth Drivers and Challenges in the Germany Mold Steel Market

The Germany mold steel market is expected to grow significantly, mainly due to the country’s strong automotive industry. There is a rising demand for high-quality mold steel because vehicles require components that are precisely engineered.

The growth of the mold steel market in Germany is also affected by the country’s solid manufacturing foundation and its skills in precision engineering. Industries like automotive, aerospace, and consumer goods are the main drivers behind the need for mold steel.

Germany Mold Steel Market Trends

Several trends are shaping the Germany mold steel market. These include:

- Increasing demand for advanced materials and coatings

- Growing adoption of Industry 4.0 technologies

- Rising focus on sustainability and environmental regulations

The competitive landscape of the Germany mold steel market is characterized by the presence of several key players. These companies are adopting strategies such as product innovation, mergers and acquisitions, and partnerships to gain a competitive edge.

The market is expected to witness significant investments in research and development, driven by the need for innovative solutions and technologies.

Some of the key challenges facing the Germany mold steel market include:

- Fluctuations in raw material prices

- Stringent environmental regulations

- Increasing competition from low-cost producers

China Mold Steel Market: Insights and Opportunities

The China mold steel market plays a crucial role in the global mold steel industry, thanks to its large production capacity and increasing demand. Several factors, such as the growth of the automotive and consumer electronics industries, are driving the country’s mold steel market.

Emerging Trends

The China mold steel market is witnessing several emerging trends. One of the key trends is the increasing demand for high-performance mold steel, driven by the need for precision and quality in mold manufacturing.

in mold steel production, such as the use of advanced materials and manufacturing processes, are also gaining traction.

China Mold Steel Market Trends

The market is also influenced by government initiatives aimed at promoting the development of the manufacturing sector. These initiatives include investments in infrastructure and technology upgrades.

Competitive Landscape

The China mold steel market is highly competitive, with several domestic and international players operating in the market. Key strategies adopted by industry players include:

- Investing in research and development to improve product quality and performance.

- Expanding production capacity to meet growing demand.

- Developing strategic partnerships with suppliers and end-users.

Overall, the China mold steel market presents significant opportunities for growth and investment. Industry players who can adapt to the changing market dynamics and capitalize on emerging trends are likely to succeed in this competitive landscape.

U.S. Mold Steel Market: Current Trends and Strategic Outlook

The U.S. is a significant player in the global mold steel market, with its market driven by the demand from various industrial sectors. The country’s strong manufacturing industry, particularly in the aerospace and automotive sectors, has been a key driver of the mold steel market.

U.S. Mold Steel Market Trends

The U.S. mold steel market has several key players who are using different strategies to take advantage of the opportunities in the market. They are using technological advancements and innovative manufacturing processes to improve product quality and lower production costs.

The demand for mold steel in the U.S. is also being driven by the increasing need for high-precision tools and dies in various industries. The aerospace industry, in particular, requires high-quality mold steel for making complex components.

Factors Driving the U.S. Mold Steel Market

- Increased adoption of advanced materials and technologies

- Growing demand from the automotive and aerospace sectors

- Rising focus on sustainability and environmental regulations

Industry players are also paying attention to sustainability and following environmental regulations, which is becoming more important in the U.S. mold steel market.

Future Development Trends in Mold Steel Market

The mold steel industry is constantly evolving, and there are several key trends that are expected to drive its growth. In the coming years, the mold steel market is likely to see significant advancements, thanks to new trends and technologies that are emerging.

Emerging Trends in Mold Steel Market

The adoption of advanced materials is one of the significant trends shaping the mold steel market. These materials offer improved durability and performance, catering to the increasing demand for high-quality mold steel.

The integration of Industry 4.0 technologies is another emerging trend. This includes the use of automation, artificial intelligence, and data analytics to enhance manufacturing processes, improve efficiency, and reduce costs.

The growing demand for sustainable products is also influencing the mold steel market. Manufacturers are focusing on developing eco-friendly products and processes, aligning with global sustainability goals.

Impact of Emerging Trends

- Increased adoption of advanced materials for improved product quality.

- Enhanced manufacturing efficiency through Industry 4.0 technologies.

- Growing focus on sustainability and eco-friendly products.

These emerging trends are expected to create new opportunities and challenges for industry players. Companies that adapt to these trends and invest in innovative technologies are likely to stay ahead in the competitive mold steel market.

Competitive Landscape of Mold Steel Industry Leaders

- Böhler-Uddeholm – Austria

- Daido Steel – Japan

- Hitachi Metals – Japan

- Aichi Steel – Japan

- Carpenter Technology – United States

- SCHMOLZ + BICKENBACH – Switzerland

- Crucible Industries – United States

- JFE Steel – Japan

- Nippon Steel – Japan

- Kobe Steel – Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Mold Steel Report |

| Base Year | 2024 |

| Segment by Type |

· Plastic Mold Steel · Die-Cast Mold Steel · Others |

| Segment by Application |

· Injection Molding · Die Casting · Blow Molding · Thermoforming · Compression Molding |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The mold steel market is set to grow significantly, driven by increasing demand from various industries. As discussed earlier, the market is influenced by factors such as upstream and downstream industry chains, key trends, and geopolitical impacts.

Market Outlook and Future Prospects

The global mold steel market is expected to reach $820.18 million by 2025, with leading growth in Germany. Understanding the mold steel industry chain and emerging trends is crucial for industry players to capitalize on market opportunities. The market outlook indicates a positive trajectory, with opportunities arising from technological advancements and increasing demand from end-use industries.

To stay competitive in the global mold steel market, industry players must be aware of the challenges and opportunities presented by geopolitical factors, regulatory challenges, and market trends. By doing so, they can make informed decisions and develop strategies to drive growth and expansion.

Global Mold Steel Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Mold Steel Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Women’s ActivewearMarket Segmentation Overview

Chapter 2: Competitive Landscape

- GlobalMold Steel players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Mold Steel Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Mold Steel Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Mold Steel Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWomen’s ActivewearMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the expected global value of the mold steel market by 2025?

The mold steel market is projected to reach $820.18 million globally by 2025.

Which country is leading the growth in the mold steel market?

Germany is leading the growth in the mold steel market.

What are the key trends driving the expansion of the mold steel market?

The key trends driving the expansion of the mold steel market include:

- The increasing demand for high-precision molds

- The growing use of advanced materials

- The rising adoption of Industry 4.0 technologies

What are the regulatory challenges facing the mold steel industry?

The mold steel industry is subject to various regulations and standards, including environmental regulations, trade policies, and industry standards.

How do geopolitical factors impact the mold steel market?

Geopolitical factors, such as trade tensions and economic sanctions, can significantly impact the mold steel market, creating potential risks and opportunities for industry players.

What are the different types of mold steel?

The mold steel market can be segmented by type, including plastic mold steel, die-cast mold steel, and others.

What are the industrial applications of mold steel?

Mold steel has various industrial applications, including the production of automotive parts, consumer electronics, and medical devices.

What is the outlook for the mold steel market in Germany?

Germany is a significant market for mold steel, driven by the country’s strong automotive and manufacturing industries.

What are the emerging trends in the mold steel market?

The emerging trends in the mold steel market include:

- The adoption of advanced materials

- The use of Industry 4.0 technologies

- The growing demand for sustainable products

What is the current state of the mold steel market in China?

China is a major player in the global mold steel market, with a large production capacity and a growing demand for mold steel.

What are the growth drivers and challenges facing the U.S. mold steel market?

The U.S. mold steel market is driven by the country’s strong manufacturing industry, particularly in the aerospace and automotive sectors.