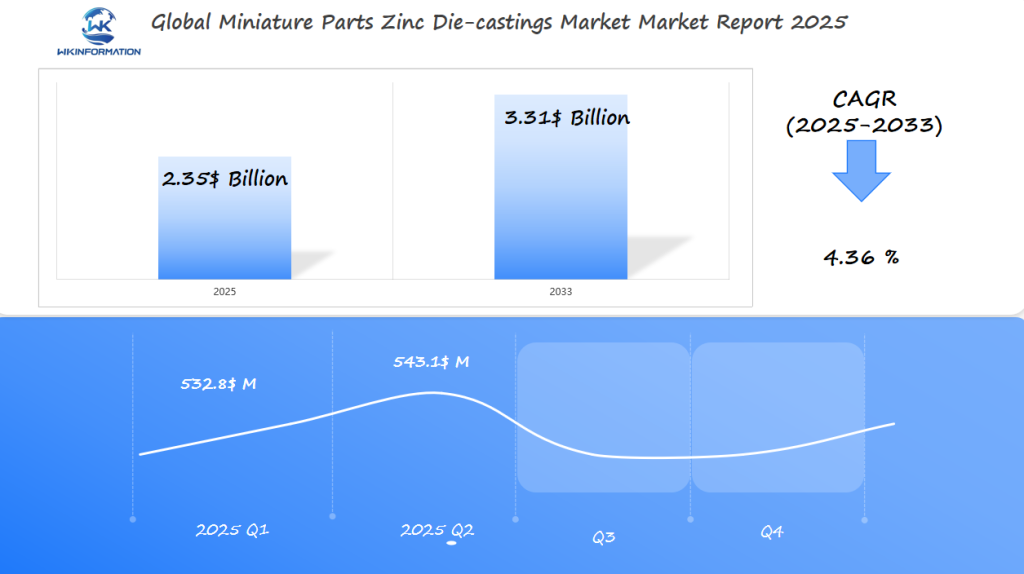

Miniature Parts Zinc Die-castings Market Forecasted at $2.35 Billion by 2025: Driven by the U.S., China, and Germany

Explore the Miniature Parts Zinc Die-castings market, forecasted to reach $2.35 billion by 2025. Discover key industry trends, technological advancements, and the impact of geopolitical factors. Learn how automotive and electronics sectors in the U.S., China, and Germany drive growth through precision manufacturing and innovation. Get insights into market challenges, competitive landscape, and future projections.

- Last Updated:

Miniature Parts Zinc Die-castings Market Q1 and Q2 of 2025

The Miniature Parts Zinc Die-castings market is set to reach $2.35 billion in 2025, with a CAGR of 4.36% during the 2025–2033 period. The Q1 market size is estimated at $532.8 million, increasing to $543.1 million in Q2 2025. Growth is driven by rising demand for precision components in electronics, automotive, and medical devices. The U.S., China, and Germany are major contributors, owing to their advanced manufacturing capabilities and thriving automotive and electronics industries. U.S. manufacturers focus on lightweight and intricate component design. In China, cost-effective production and expanding exports are key factors. Germany emphasizes high-precision parts used in premium vehicles and industrial machinery, supporting steady market expansion.

Key Takeaways

- The global market is driven by demand from the U.S. and China.

- Increasing applications in automotive and electronics sectors.

- Advancements in manufacturing technologies.

- High precision and quality of zinc die-castings.

- Forecasted market value of $2.35 billion by 2025.

Understanding the Miniature Parts Zinc Die-castings Market: Upstream and Downstream

The Miniature Parts Zinc Die-castings market operates within a complex industry chain that involves various stakeholders. This chain is crucial for understanding the dynamics of the market, including trends, challenges, and opportunities.

Understanding the Industry Chain

The industry chain of the Miniature Parts Zinc Die-castings market can be broadly categorized into upstream and downstream segments. The upstream segment involves the supply of raw materials, primarily zinc, which is then processed into die-castings.

“The quality of zinc used in die-castings significantly affects the final product’s properties, such as durability and precision,” as noted by industry experts. The upstream segment is critical for ensuring the quality and consistency of the raw materials.

The downstream segment includes industries that utilize zinc die-castings, such as the automotive and electronics sectors. These industries drive the demand for miniature parts zinc die-castings, influenced by factors like technological advancements and consumer preferences.

Key Players in the Supply Chain

The supply chain of the Miniature Parts Zinc Die-castings market involves several key players:

- Raw material suppliers: Companies that supply zinc and other necessary materials.

- Manufacturers: Firms that produce zinc die-castings using the supplied raw materials.

- End-users: Industries such as automotive, electronics, and healthcare that use zinc die-castings in their products.

Understanding the roles and interactions of these players is essential for analyzing the market’s dynamics and identifying potential opportunities or challenges.

As the market continues to evolve, the importance of a well-coordinated supply chain cannot be overstated. It is crucial for ensuring the timely delivery of high-quality zinc die-castings to meet the growing demands of various industries.

Current trends reshaping the Miniature Parts Zinc Die-castings market

The Miniature Parts Zinc Die-castings industry is going through a significant change due to current market trends. This transformation is mainly driven by advancements in technology and changing consumer demands.

Technological Advancements

Technological advancements are playing a crucial role in reshaping the Die-casting Industry. One of the significant technological advancements is the integration of automation and robotics in the manufacturing process. This has not only improved efficiency but also enhanced the precision and quality of the die-castings.

Impact of 3D Printing

The advent of 3D Printing has revolutionized the Miniature Parts Zinc Die-castings market. 3D Printing technology allows for the production of complex geometries that were previously impossible to achieve through traditional die-casting methods. This has opened up new avenues for innovation and customization in the industry.

The impact of 3D Printing is multifaceted. It enables rapid prototyping, reduces material waste, and allows for the creation of intricate designs. As a result, companies are able to bring products to market faster and with greater precision.

Furthermore, the adoption of 3D Printing is influencing Market Trends by driving demand for more complex and customized miniature parts. This trend is expected to continue as technology advances and becomes more accessible to manufacturers.

- Increased precision and complexity in die-castings

- Rapid prototyping and production

- Reduced material waste and environmental impact

The Miniature Parts Zinc Die-castings market is being reshaped by technological advancements, particularly the integration of 3D Printing. As these trends continue to evolve, they are likely to drive further innovation and growth in the industry.

Barriers to Miniature Parts Zinc Die-castings market expansion

The growth of the Miniature Parts Zinc Die-castings market is hindered by several key challenges, primarily related to manufacturing and environmental sustainability.

Challenges in Manufacturing

Manufacturing miniature parts using zinc die-castings requires high precision and control over the production process. Key challenges include maintaining dimensional accuracy, managing the zinc alloy composition, and ensuring the durability of the die-casting tools.

The zinc die-casting process has several environmental implications, including energy consumption, material waste, and potential emissions. The industry is under growing pressure to adopt more sustainable practices, such as recycling zinc scrap and reducing energy usage through process optimization.

Furthermore, the extraction and processing of zinc, a key raw material, have environmental consequences that need to be addressed through responsible sourcing and supply chain management.

- Improving manufacturing efficiency to reduce waste and energy consumption.

- Adopting sustainable practices, such as recycling and using renewable energy sources.

- Enhancing supply chain transparency to ensure responsible sourcing of raw materials.

Geopolitical factors impacting Miniature Parts Zinc Die-castings production

Geopolitical factors are important in shaping the global Miniature Parts Zinc Die-castings market. The industry is heavily influenced by trade policies, tariffs, and global market dynamics, which can either hinder or support growth.

Trade Policies and Tariffs

Trade policies and tariffs imposed by governments can significantly affect the cost of raw materials and the competitiveness of manufacturers in the Miniature Parts Zinc Die-castings market. For instance, tariffs on zinc imports can increase production costs, potentially leading to higher prices for end-users.

Key impacts of trade policies and tariffs include:

- Increased production costs due to tariffs on raw materials

- Potential for trade wars affecting supply chains

- Competitive disadvantage for manufacturers in regions with stricter trade policies

Global Market Dynamics

Global market dynamics, including fluctuations in demand and supply, also play a critical role in the Miniature Parts Zinc Die-castings market. Changes in global demand can lead to shifts in production levels and pricing strategies.

| Factor | Impact on Production | Impact on Pricing |

| Tariffs on Zinc Imports | Increased production costs | Higher prices for end-users |

| Global Demand Fluctuations | Adjustments in production levels | Variable pricing strategies |

| Trade Agreements | Reduced production costs | More competitive pricing |

The combination of geopolitical factors, trade policies, and global market dynamics creates a complex environment for the Miniature Parts Zinc Die-castings market. Manufacturers must navigate these challenges to remain competitive.

In-depth analysis of Miniature Parts Zinc Die-castings market by type

The Miniature Parts Zinc Die-castings market is diverse, with various types catering to different applications. This diversity necessitates a detailed examination of the market by type to understand the demand dynamics and market share of different zinc die-castings types.

Types of Zinc Die-castings

Zinc die-castings can be categorized into several types based on their application, complexity, and manufacturing process. The primary types include complex geometries, thin-walled castings, and precision castings. Each type has its specific advantages and is suited for particular applications in the miniature parts industry.

Market Share by Type

The market share of different zinc die-castings types varies based on their application and demand. The following table illustrates the market share distribution:

| Type of Zinc Die-castings Market Share (%) Complex Geometries | 35 |

| Thin-walled Castings | 25 |

| Precision Castings | 40 |

The demand for these types is driven by their application in various industries, including automotive, electronics, and healthcare. For instance, precision castings are highly sought after in the electronics industry for their accuracy and reliability.

Applications Driving the Demand for Miniature Parts Zinc Die-castings

The increasing requirement for precision and durability is driving the demand for Miniature Parts Zinc Die-castings. These components are essential in multiple industries because of their excellent precision, durability, and affordability.

Automotive Applications

The automotive sector plays a crucial role in driving the demand for Miniature Parts Zinc Die-castings. These components are utilized in various automotive parts, including engine components, gearboxes, and other complex parts, owing to their capability to endure high temperatures and pressures.

The automotive industry also relies on zinc die-castings to meet the need for lightweight and fuel-efficient vehicles. By reducing the weight of vehicles, zinc die-castings contribute to enhanced fuel efficiency and lower emissions.

Electronics Applications

Apart from the automotive sector, electronics applications are also fueling the demand for Miniature Parts Zinc Die-castings. These components find their use in electronic devices such as smartphones, laptops, and other consumer electronics due to their exceptional precision and durability.

The growing requirement for miniaturized electronic devices further intensifies the need for Miniature Parts Zinc Die-castings. As electronic devices become smaller and more intricate, the demand for precisely engineered components like zinc die-castings is anticipated to rise.

Miniature Parts Zinc Die-castings Applications

The versatility of Miniature Parts Zinc Die-castings makes them suitable for a wide range of applications, from automotive to electronics. As these industries continue to evolve, the demand for high-quality, precision-engineered zinc die-castings is expected to increase.

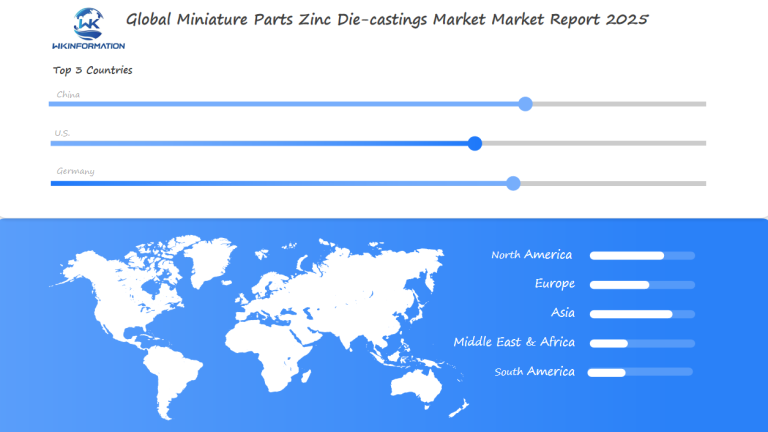

Global Miniature Parts Zinc Die-castings Market Insights by Region

The miniature parts zinc die-castings market has unique characteristics in different regions that affect its growth. Each region has its own market dynamics influenced by factors like economic conditions, technological advancements, and consumer preferences.

Regional Market Trends

Regional trends in the miniature parts zinc die-castings market are shaped by local manufacturing capabilities, demand from key industries, and trade policies. For instance, regions with a strong automotive sector tend to have a higher demand for miniature zinc die-castings.

North America, for example, is a significant market due to its established automotive industry. The region’s demand is driven by the need for high-precision components in vehicle manufacturing.

Emerging Markets

Emerging markets, particularly in Asia-Pacific, are witnessing rapid growth due to industrialization and increasing demand from the electronics and automotive sectors. Countries like China and India are becoming significant players in the global market.

The growth in these emerging markets is attributed to favorable government policies, investments in manufacturing infrastructure, and a growing consumer base.

| Region | Market Trend | Key Drivers |

| North America | Steady demand | Automotive industry |

| Asia-Pacific | Rapid growth | Industrialization, electronics, and automotive sectors |

| Europe | Moderate growth | Manufacturing sector, technological advancements |

Understanding these regional trends and identifying emerging markets are crucial for stakeholders to capitalize on growth opportunities in the global miniature parts zinc die-castings market.

How China’s industrial sector is boosting Miniature Parts Zinc Die-castings growth

China’s manufacturing capabilities are playing a crucial role in the expansion of the global Miniature Parts Zinc Die-castings market. The country’s industrial sector has witnessed significant advancements in recent years, driven by technological innovations and large-scale production capabilities.

The growth of China’s industrial sector can be attributed to its robust infrastructure, skilled workforce, and favorable government policies. These factors have collectively contributed to making China a global hub for the production of Miniature Parts Zinc Die-castings.

China’s Manufacturing Capabilities

China’s manufacturing capabilities are characterized by its ability to produce high-quality Miniature Parts Zinc Die-castings at competitive prices. The country’s manufacturers have adopted advanced technologies, such as automation and precision engineering, to enhance their production processes.

Key factors driving China’s manufacturing capabilities include:

- Advanced technology integration

- Skilled workforce

- Favorable government policies

- Robust infrastructure

As a result, Chinese manufacturers have been able to achieve high levels of efficiency and productivity, making them competitive in the global market.

The Impact of China’s Industrial Sector on the Global Market

The impact of China’s industrial sector on the global Miniature Parts Zinc Die-castings market is significant. The country’s large-scale production capabilities have led to an increase in global supply, which in turn has driven down prices and made Miniature Parts Zinc Die-castings more accessible to a wider range of industries.

The U.S. automotive sector driving Miniature Parts Zinc Die-castings demand

The demand for Miniature Parts Zinc Die-castings is being driven substantially by the U.S. automotive sector. This industry’s need for lightweight, high-precision components is fueling the growth of zinc die-castings.

Automotive Industry Trends

The U.S. automotive industry is experiencing significant trends that are affecting the demand for zinc die-castings. Some of these trends include electrification and precision engineering.

Demand for Zinc Die-castings

The demand for zinc die-castings in the U.S. automotive sector is driven by several factors, including:

- The need for complex geometries that can be achieved through die-casting.

- The requirement for high-precision components that can withstand the rigors of automotive applications.

- The industry’s move towards reducing vehicle weight to improve fuel efficiency.

As the automotive industry continues to evolve, the demand for zinc die-castings is expected to grow. Industry experts predict that the trend towards electrification and precision engineering will continue to drive this demand.

Germany’s manufacturing innovations fostering Miniature Parts Zinc Die-castings adoption

Germany’s expertise in precision engineering is fostering a new era in the adoption of zinc die-castings for miniature parts. The country’s long history of manufacturing excellence, combined with a strong focus on innovation, has positioned it as a leader in the production of high-quality zinc die-castings.

Innovations in Manufacturing

The German manufacturing sector is known for its ability to integrate cutting-edge technology into production processes. This has led to significant advancements in the production of Miniature Parts Zinc Die-castings, enabling the creation of complex components with high precision and reliability.

Some of the key innovations driving this trend include:

- The adoption of advanced materials

- Improved tooling techniques

- The integration of Industry 4.0 technologies such as automation and digitalization

Impact on Adoption

The impact of these innovations on the adoption of Miniature Parts Zinc Die-castings has been substantial. By improving manufacturing efficiency and reducing production costs, German companies have been able to increase the competitiveness of zinc die-castings in various industries, including automotive, electronics, and aerospace.

Furthermore, the enhanced quality and reliability of zinc die-castings produced using these innovative manufacturing techniques have expanded their application in critical components, where precision and durability are paramount.

The specific impacts include:

- Increased precision and complexity in component design

- Improved manufacturing efficiency and reduced costs

- Enhanced quality and reliability of zinc die-castings

- Expanded application in critical industries

Future projections for the Miniature Parts Zinc Die-castings market

The Miniature Parts Zinc Die-castings market is expected to grow significantly due to increasing demand in various industries. With ongoing technological advancements shaping the manufacturing industry, zinc die-castings are becoming more and more essential.

Market Forecast

According to market analyses, the Miniature Parts Zinc Die-castings market is expected to witness substantial growth over the forecast period. Factors such as the expanding automotive and electronics sectors are contributing to this growth.

Key drivers include:

- Increasing demand for miniaturized components

- Advancements in die-casting technology

- Growing automotive and electronics industries

Growth Opportunities

The market presents several growth opportunities, particularly in emerging economies where industrialization is on the rise. Companies can capitalize on these opportunities by investing in research and development and expanding their production capacities.

Competitive overview in the Miniature Parts Zinc Die-castings market

The Miniature Parts Zinc Die-castings market is highly competitive, with numerous players competing for market share. Understanding the competitive landscape is crucial for businesses to stay ahead.

Key Players

- Dynacast International – United States

- Renco Corporation – United States

- Ryobi Limited – Japan

- Zinc Die Casting, Inc. – United States

- Alcast Company – United States

- Gibbs Die Casting Corporation – United States

- Formet Industries – Canada

- MetalTek International – United States

- Die Casting Corporation of Florida – United States

- Matsui Technology Co., Ltd. – Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Miniature Parts Zinc Die-castings Market Report |

| Base Year | 2024 |

| Segment by Type | ·Thin-walled Castings

·Precision Castings |

| Segment by Application | ·Automotive Applications

·Electronics Applications |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Miniature Parts Zinc Die-castings market is characterized by a comprehensive industry chain involving upstream raw materials and downstream applications, primarily in automotive and electronics sectors. Current trends reshaping the market include technological advancements and manufacturing innovations, with barriers such as production challenges and geopolitical factors influencing trade policies and tariffs.

Global Miniature Parts Zinc Die-castings Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Miniature Parts Zinc Die-castings Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Miniature Parts Zinc Die-castings Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Miniature Parts Zinc Die-castings Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Miniature Parts Zinc Die-castings Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Miniature Parts Zinc Die-castings Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Miniature Parts Zinc Die-castings Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Miniature Parts Zinc Die-castings Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Miniature Parts Zinc Die-castings market?

The growth is primarily driven by the demand in the U.S. and China, as well as the increasing use of zinc die-castings in various industries, including automotive and electronics.

What are the key trends reshaping the Miniature Parts Zinc Die-castings market?

Technological advancements and the adoption of 3D printing are improving manufacturing efficiency and enabling the production of complex geometries.

What are the barriers to Miniature Parts Zinc Die-castings market expansion?

Manufacturing challenges and environmental concerns, including high energy consumption and potential environmental hazards, are limiting market growth.

How do geopolitical factors impact the production and trade of Miniature Parts Zinc Die-castings?

Trade policies and tariffs significantly impact the production and trade, affecting the cost of raw materials and the competitiveness of manufacturers in different regions.

What are the main applications fueling the demand for Miniature Parts Zinc Die-castings?

The demand is driven by various applications, including the automotive and electronics sectors, due to their high precision, durability, and cost-effectiveness.

How is China’s industrial sector influencing the Miniature Parts Zinc Die-castings market?

China’s advanced manufacturing capabilities and large-scale production are significantly boosting the market’s growth and influencing global market dynamics.

What is the role of the U.S. automotive sector in driving demand for Miniature Parts Zinc Die-castings?

The U.S. automotive sector plays a crucial role in driving demand for Miniature Parts Zinc Die-castings. This is primarily due to the industry’s ongoing trend towards using lightweight and high-precision components in vehicle manufacturing.

How are Germany’s manufacturing innovations impacting the adoption of Miniature Parts Zinc Die-castings?

Germany’s expertise in precision engineering and manufacturing is driving the use of zinc die-castings in various industries, fostering their adoption.

What are the future projections for the Miniature Parts Zinc Die-castings market?

The market is expected to continue growing, driven by increasing demand from various industries, with opportunities for stakeholders to capitalize on growth prospects.