Milled Carbon Fiber Market on Track to Surpass $2.43 Billion by 2025 with Demand Rising in the U.S., Germany, and Japan

Milled Carbon Fiber Market poised to reach over $2.43 billion by 2025, with the U.S. leading the charge in rising demand.

- Last Updated:

Milled Carbon Fiber Market Q1 and Q2 of 2025

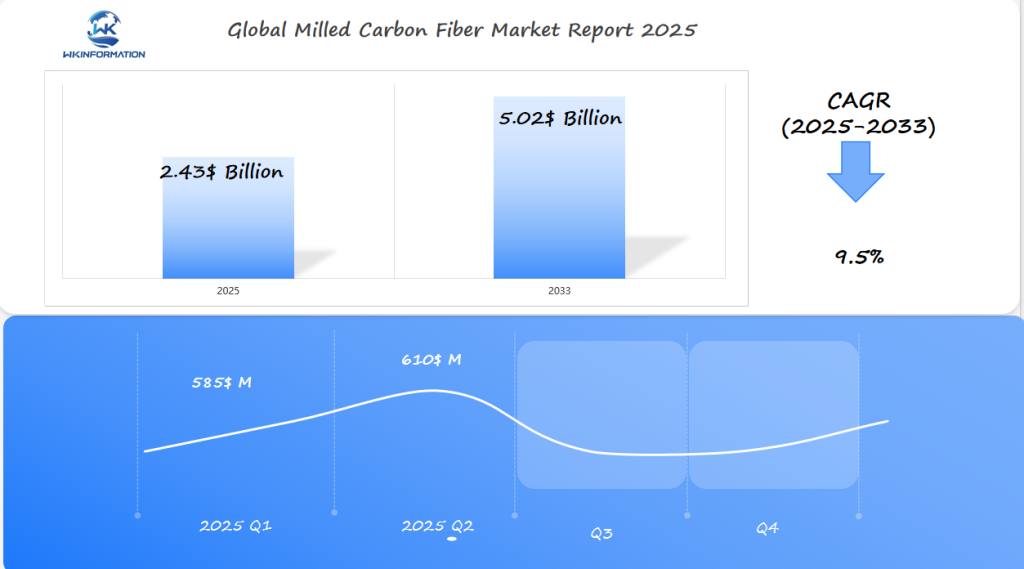

The Milled Carbon Fiber market is forecasted to reach $2.43 billion in 2025, growing at a robust CAGR of 9.5% from 2025 to 2033. In Q1 2025, the market is expected to generate around $585 million, with Q2 showing a moderate increase to $610 million, driven by rising demand in industries such as automotive, aerospace, and sporting goods.

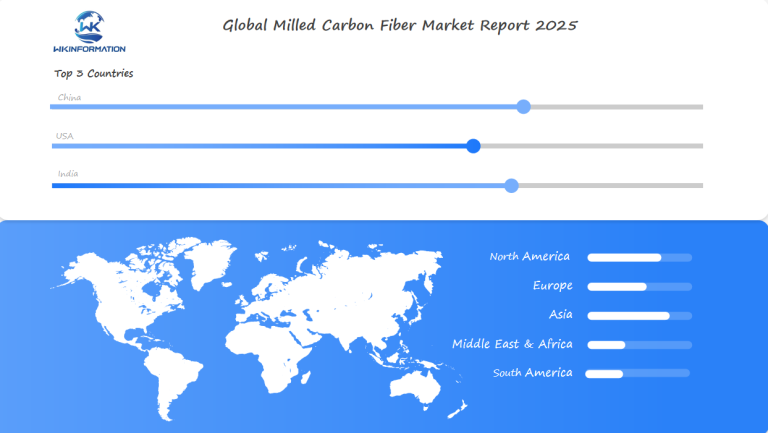

Milled carbon fiber is increasingly being utilized for its lightweight and high-strength properties, which make it an ideal material for applications where performance is critical. The U.S., Germany, and Japan will be key contributors to the market’s growth in 2025. The U.S. remains a leader in automotive innovation and aerospace technology, while Germany’s automotive industry, particularly in lightweight materials, continues to push demand for milled carbon fiber. Japan’s strong manufacturing capabilities in automotive and electronics also support the growth of this market.

As the trend towards sustainable, high-performance materials continues, these countries are set to be at the forefront of the Milled Carbon Fiber market in 2025.

Upstream and Downstream Industry Chain Analysis in the Milled Carbon Fiber Market

Understanding the milled carbon fiber market requires a deep dive into its supply chain, from raw material production to end-use applications. The industry chain analysis is crucial for identifying key drivers, challenges, and opportunities in the market.

Understanding the Supply Chain Dynamics

The supply chain dynamics of the milled carbon fiber market are complex, involving various stages from raw material sourcing to manufacturing. Raw materials such as polyacrylonitrile (PAN) and pitch are crucial for the production of carbon fibers. The quality and cost of these raw materials significantly impact the overall production cost and quality of milled carbon fibers.

Key Steps in Milled Carbon Fiber Production

The production of milled carbon fibers involves several key steps, including:

- Raw material production: PAN and pitch are the primary raw materials used.

- Pre-treatment: Raw materials undergo pre-treatment to prepare them for carbonization.

- Carbonization: The pre-treated materials are then carbonized to produce carbon fibers.

- Milling: The carbon fibers are milled into the desired particle size.

The manufacturing process is energy-intensive and requires significant investment in technology and equipment. Advancements in manufacturing processes are crucial for improving efficiency and reducing costs.

Applications of Milled Carbon Fiber

The downstream segment of the industry chain involves various applications of milled carbon fiber, including:

- Aerospace: Milled carbon fibers are used in aircraft and spacecraft components due to their high strength-to-weight ratio.

- Automotive: The automotive industry uses milled carbon fibers to reduce vehicle weight and improve fuel efficiency.

- Industrial manufacturing: Milled carbon fibers are used in various industrial applications, including coatings, adhesives, and composites.

Emerging trends in carbon fiber composites for aerospace and automotive sectors

Advancements in carbon fiber composites are driving innovation in the aerospace and automotive industries, enabling the creation of more efficient vehicles and aircraft. The use of these composites is becoming increasingly common due to their high strength-to-weight ratio, resistance to fatigue, and potential for reducing overall production costs.

Aerospace applications

The integration of carbon fiber composites in aerospace applications is particularly noteworthy, as they offer significant improvements in fuel efficiency and performance. For instance, the Boeing 787 Dreamliner and Airbus A350 XWB extensively utilize carbon fiber reinforced polymers (CFRP) in their structures, leading to substantial weight reductions and enhanced fuel economy.

Innovations in Composite Materials

Recent innovations in composite materials have focused on enhancing their mechanical properties, thermal stability, and production efficiency. Nanotechnology and advanced manufacturing techniques, such as 3D printing, are being explored to create complex geometries and hybrid materials that offer superior performance characteristics.

The automotive sector is also benefiting from these advancements, with many manufacturers incorporating carbon fiber composites into their vehicle designs to achieve weight reduction and improve fuel efficiency. The use of these materials in high-performance vehicles is becoming more common, with examples including the BMW i8 and Lamborghini Huracán.

As research and development continue to advance, we can expect to see even more innovative applications of carbon fiber composites in these industries, driving further growth in the Milled Carbon Fiber Market.

Challenges and limitations in carbon fiber manufacturing and recycling

As the demand for carbon fiber continues to rise, the industry must address the pressing issues of manufacturing complexities and recyclability. The production of carbon fiber is a complex process that involves several stages, from precursor production to final composite manufacturing.

Overcoming Production Challenges

One of the significant challenges in carbon fiber manufacturing is the high production cost. The process is energy-intensive and requires expensive equipment, making it challenging for manufacturers to reduce costs without compromising quality. Efforts to improve manufacturing efficiency and reduce waste are underway, with companies investing in research and development to create more cost-effective production methods.

The industry is also exploring new technologies to enhance the mechanical properties of carbon fiber, making it more suitable for a wider range of applications. For instance, advancements in nanotechnology are being applied to improve the performance of carbon fiber composites.

Recycling carbon fiber is another significant challenge due to the material’s inherent properties. Unlike metals, carbon fiber composites cannot be melted down and reused directly. Instead, recycling involves breaking down the composite into its constituent parts, a process that is both technically challenging and costly.

Despite these challenges, several companies and research institutions are developing innovative recycling technologies. For example, mechanical recycling methods involve shredding or grinding the composite material into smaller pieces that can be reused in other applications.

| Recycling Method | Description | Application |

| Mechanical Recycling | Involves shredding or grinding carbon fiber composites into smaller pieces. | Reused in construction materials, automotive parts. |

| Chemical Recycling | Breaks down the composite into its chemical constituents. | Potential for reusing carbon fibers in new composites. |

| Thermal Recycling | Involves heating the composite to separate the fibers. | Reused in various industrial applications. |

The development of effective recycling technologies is crucial for the sustainability of the carbon fiber industry. As the demand for carbon fiber continues to grow, so too will the need for environmentally friendly and economically viable recycling solutions.

Geopolitical supply chain dynamics affecting carbon fiber production

The production and distribution of milled carbon fiber are affected by various geopolitical factors and global trade policies. As the demand for carbon fiber continues to rise, particularly in the aerospace and automotive sectors, understanding these dynamics becomes crucial for manufacturers and suppliers.

Global trade policies, including tariffs and trade agreements, can significantly impact the cost and availability of carbon fiber. For instance, tariffs imposed on imported carbon fiber can increase production costs for manufacturers, potentially affecting their competitiveness in the global market. Moreover, these geopolitical supply chain dynamics also play a significant role in shaping the future of carbon fiber production, influencing everything from raw material sourcing to final product delivery.

Impact of Global Trade Policies

Global trade policies play a crucial role in shaping the carbon fiber industry. Trade tensions between major economies can lead to tariffs and other trade barriers, affecting the supply chain. For instance, the trade tensions between the U.S. and China have resulted in tariffs on various goods, including carbon fiber.

The effects of these policies can be observed in the fluctuating prices and availability of carbon fiber. Companies that heavily rely on imported carbon fiber may face increased costs due to tariffs, which can then be passed on to consumers or absorbed by the manufacturers.

To mitigate these risks, companies are adopting various strategies, such as diversifying their supply chains and investing in local production capacities. This not only helps in reducing dependence on imports but also in minimizing the impact of tariffs and other trade barriers.

Regional Trade Agreements and Their Impact

Regional trade agreements can also significantly impact the carbon fiber industry. Agreements that reduce or eliminate tariffs among participating countries can make carbon fiber more competitive in those markets.

| Region | Trade Agreement | Impact on Carbon Fiber |

| North America | USMCA | Reduced tariffs on carbon fiber imports |

| Europe | EU-Japan EPA | Increased competitiveness of carbon fiber in the Japanese market |

| Asia | RCEP | Simplified supply chain dynamics across member countries |

By understanding the geopolitical supply chain dynamics and the impact of global trade policies, companies in the carbon fiber industry can better navigate the complexities of the global market and make informed decisions about their production and distribution strategies.

Segmentation by fiber size and application-specific needs

The versatility of milled carbon fiber is largely attributed to its ability to be segmented into different fiber sizes, meeting specific application requirements. This segmentation enables manufacturers to tailor their products to the unique needs of various industries, including aerospace, automotive, and industrial manufacturing.

Tailoring Products to Specific Applications

Different applications require milled carbon fiber with specific properties and fiber sizes. For instance, aerospace applications often demand high-strength, lightweight materials with precise fiber sizes to ensure optimal performance and safety.

In contrast, automotive applications may prioritize cost-effectiveness alongside performance, necessitating a different set of fiber size specifications. By segmenting their products based on fiber size, manufacturers can better cater to these diverse needs.

The importance of product segmentation is further highlighted by the varying requirements across different industries. The table below illustrates the typical fiber size ranges and their corresponding applications:

| Fiber Size Range | Typical Applications | Industry |

| 1-50 microns | Advanced composites, precision parts | Aerospace |

| 50-100 microns | High-performance automotive parts | Automotive |

| 100-200 microns | Industrial manufacturing, wear-resistant coatings | Industrial |

By understanding and catering to these application-specific needs, manufacturers can drive market growth and expand their customer base. Effective product segmentation not only enhances customer satisfaction but also fosters innovation in the milled carbon fiber market.

Application-driven demand across automotive, aerospace, and industrial markets

Driven by its versatility and performance, milled carbon fiber is increasingly being adopted in automotive, aerospace, and industrial applications. The unique properties of milled carbon fiber, such as its high strength-to-weight ratio and resistance to fatigue, make it an ideal material for various industries. For instance, in the automotive sector, milled carbon fiber is used to create lightweight yet strong components that improve fuel efficiency and performance. Similarly, the aerospace industry benefits from the high strength-to-weight ratio of milled carbon fiber, allowing for the design of more efficient aircraft. In industrial applications, the resistance to fatigue offered by this material makes it a preferred choice for various manufacturing processes.

Market Demand and Trends

The demand for milled carbon fiber is driven by several factors across different markets.

Automotive Sector

In the automotive sector, the need for lightweight materials to improve fuel efficiency and reduce emissions is a significant driver. Milled carbon fiber is used in various automotive parts, including body panels, brake systems, and engine components.

Aerospace Applications

In the aerospace applications, milled carbon fiber is valued for its high strength, stiffness, and resistance to extreme temperatures. It is used in aircraft structures, satellite components, and other aerospace applications where performance and reliability are critical.

Industrial Markets

The industrial markets also benefit from the use of milled carbon fiber, particularly in the production of high-performance composites for machinery, equipment, and infrastructure projects. The material’s ability to enhance durability and reduce weight makes it an attractive choice for various industrial applications.

Some of the key trends driving the demand for milled carbon fiber include:

- Increasing adoption of electric vehicles (EVs) in the automotive sector, driving the need for lightweight materials.

- Growing demand for advanced composites in aerospace applications, driven by the need for improved performance and fuel efficiency.

- Rising investments in infrastructure projects, driving the demand for high-performance materials in industrial markets.

As industries continue to evolve, the demand for milled carbon fiber is expected to grow, driven by its versatility, performance, and the ongoing need for innovation and improvement in various sectors.

The U.S. demand for carbon fiber in aerospace and automotive manufacturing

The U.S. is experiencing a significant increase in demand for carbon fiber, primarily driven by the aerospace and automotive industries. This surge in demand can be attributed to the exceptional qualities of carbon fiber, such as its high strength-to-weight ratio, resistance to corrosion, and capability to endure extreme temperatures.

Regional Market Analysis

The U.S. aerospace industry is a significant consumer of carbon fiber, utilizing it in the manufacture of aircraft components, such as fuselage, wings, and engine parts, to reduce weight and enhance fuel efficiency. Major aerospace manufacturers like Boeing and Lockheed Martin are driving this demand. Similarly, the automotive sector is adopting carbon fiber to produce lightweight vehicle parts, improving performance and reducing emissions. Electric vehicle manufacturers, in particular, are leveraging carbon fiber to optimize battery range and overall vehicle efficiency.

The demand for carbon fiber in these industries is also driven by advancements in manufacturing technologies, making it more feasible to produce complex carbon fiber components. Companies like General Electric (GE) Aviation are at the forefront of adopting advanced carbon fiber composites in their aircraft engine designs. Furthermore, government initiatives and investments in aerospace and automotive research are contributing to the growth of the carbon fiber market in the U.S.

Regional market analysis indicates that the U.S. demand for carbon fiber is not only driven by the existing manufacturing base but also by the emerging trends in sustainable and high-performance materials. The presence of key carbon fiber manufacturers and suppliers in the U.S. is expected to further boost the market. As the aerospace and automotive industries continue to evolve, the demand for carbon fiber is anticipated to grow, driven by its potential to enable innovative designs and improve product performance.

- Increased adoption of carbon fiber in aerospace for weight reduction and fuel efficiency.

- Growing use of carbon fiber in automotive manufacturing for improved performance and reduced emissions.

- Advancements in manufacturing technologies enabling complex carbon fiber component production.

Germany’s leadership in advanced manufacturing and lightweight materials

Germany’s expertise in advanced manufacturing has positioned it as a global leader in the development of lightweight materials. This leadership is particularly evident in the European carbon fiber market, where German companies have made significant advancements in manufacturing technologies.

European Market Insights

The European market for milled carbon fiber is highly competitive, with Germany playing a pivotal role. German manufacturers have invested heavily in research and development, leading to innovations in production processes and material properties.

Key Factors Contributing to Germany’s Success:

- Strong industrial base

- Highly skilled workforce

- Significant investment in R&D

- Favorable business environment

These factors have enabled German companies to maintain a competitive edge in the global market for lightweight materials. The country’s expertise in advanced manufacturing has also led to the development of high-performance carbon fiber products, which are used in various industries, including aerospace and automotive.

| Aerospace | Aircraft components | Reduced weight, increased strength |

| Automotive | Vehicle body parts | Improved fuel efficiency, enhanced performance |

| Industrial | Equipment and machinery | Increased durability, reduced maintenance |

Germany’s leadership in advanced manufacturing and lightweight materials is expected to continue, driven by ongoing innovations and investments in the sector. As the demand for high-performance materials grows, German companies are well-positioned to meet the needs of industries worldwide.

Japan’s focus on innovation in carbon fiber composites for technology

With a strong focus on research and development, Japan is leading the way in advancing carbon fiber technology. The country’s commitment to innovation in carbon fiber composites is driven by significant investments in R&D, aiming to improve material properties and broaden application areas.

The Japanese industry is known for its collaborative approach, bringing together manufacturers, researchers, and end-users to speed up the development of carbon fiber composites. This teamwork encourages the creation of advanced materials with enhanced strength, durability, and sustainability.

Innovation and R&D

Japan’s R&D efforts in carbon fiber composites are focused on several key areas, including the development of new manufacturing processes, enhancement of material properties, and exploration of novel applications. For instance, advancements in carbon fiber recycling technologies are gaining traction, enabling the reuse of materials and reducing production costs.

Innovative manufacturing techniques, such as 3D printing and automated fiber placement, are being adopted to improve production efficiency and reduce waste. These technologies are particularly relevant in the aerospace and automotive sectors, where complex geometries and high-performance materials are required.

carbon fiber composites innovation

The impact of Japan’s innovation in carbon fiber composites is being felt globally, with potential applications extending beyond traditional industries to emerging sectors such as renewable energy and advanced infrastructure.

- Advancements in carbon fiber composites are enhancing the performance and efficiency of various technologies.

- Japan’s R&D initiatives are driving the development of sustainable and cost-effective production methods.

- The global market is expected to benefit from Japan’s innovations, with increased adoption of carbon fiber composites in diverse applications.

As Japan continues to push the boundaries of carbon fiber technology, its emphasis on innovation and R&D is likely to have a lasting impact on the global market, driving growth and adoption across various industries.

Forecast for the Milled Carbon Fiber Market

The Milled Carbon Fiber Market is expected to grow significantly due to increasing demand in various industries. With advancements in technology and expanding applications, the market is projected to experience substantial growth in the coming years.

Factors Driving Growth

The growth of the Milled Carbon Fiber Market can be attributed to:

- Its increasing use in the aerospace and automotive sectors, where it is valued for its lightweight and high-strength properties.

- Emerging trends in carbon fiber composites, which are expected to drive market growth as manufacturers seek innovative materials to enhance product performance.

Market Projections and Trends

Market projections indicate that the Milled Carbon Fiber Market will continue to grow, driven by rising demand from end-use industries. Regional market trends will also play a crucial role, with regions like the U.S. and Asia-Pacific expected to witness significant growth due to their strong manufacturing bases and increasing adoption of advanced materials.

The market is expected to be influenced by factors such as technological advancements and changing consumer preferences. As manufacturers respond to these trends, the Milled Carbon Fiber Market is likely to witness new opportunities and challenges.

Key Drivers of Growth

The growth of the Milled Carbon Fiber Market can be attributed to several key drivers:

- Increasing demand from the aerospace industry

- Growing adoption in the automotive sector

- Emergence of new applications in industrial markets

Overall, the outlook for the Milled Carbon Fiber Market is promising, with growth expected across various regions and applications. As the market continues to evolve, it is likely to be shaped by technological innovations and changing market dynamics.

Forecast for the Milled Carbon Fiber Market

The global milled carbon fiber market is experiencing robust growth, driven by its applications across various industries such as automotive, aerospace, electronics, and sports equipment. The material’s lightweight, high-strength properties make it an attractive choice for manufacturers aiming to enhance performance and fuel efficiency.

Key Drivers of Growth:

-

Automotive Industry: The automotive sector’s push for fuel-efficient and eco-friendly vehicles is increasing the demand for carbon fiber composites.

-

Aerospace Sector: The aerospace industry continues to leverage milled carbon fiber for structural components, benefiting from its strength-to-weight ratio.

-

Technological Advancements: Innovations in milling techniques and the development of hybrid materials are expanding the applications of milled carbon fiber.

-

Sustainability Trends: Growing environmental awareness and the need for sustainable solutions are propelling demand across industries, as milled carbon fiber offers significant weight savings and durability.

Market Segmentation:

-

Fiber Type: The market is segmented into PAN-based and pitch-based fibers, with PAN-based fibers holding a larger share due to their high strength-to-weight ratio and cost-effectiveness.

-

Application Areas: Key applications include automotive, aerospace, electronics, sporting goods, and industrial sectors.

-

End-User Industries: The automotive and aerospace sectors are the leading consumers, driven by the demand for lightweight and high-performance materials.

Competitive environment and key manufacturers in the carbon fiber market

Key manufacturers are driving innovation in the carbon fiber market, leading to a more competitive landscape. The market is characterized by the presence of several established players, as well as new entrants, which is intensifying competition.

Key Players in the Carbon Fiber Market

- Toray Industries, Inc. – Japan

- Mitsubishi Chemical Group Corporation – Japan

- Teijin Limited – Japan

- Daigas Group – Japan

- Stanford Advanced Materials – United States

- Nippon Graphite Fiber Co., Ltd. – Japan

- Easy Composites Ltd – United Kingdom

- Haufler Composites GmbH & Co. KG – Germany

- Procotex – Belgium

- SGL Carbon – Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Milled Carbon Fiber Market Report |

| Base Year | 2024 |

| Segment by Type |

· 1-50 microns · 50-100 microns · 100-200 microns |

| Segment by Application |

· Automotive Sector · Aerospace Applications · Industrial Markets |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Milled Carbon Fiber Market is growing due to increased demand from industries like aerospace, automotive, and industrial applications. Factors such as supply chain dynamics, geopolitical trade policies, and innovations in composite materials also influence the market.

Market Prospects

Looking ahead, the Milled Carbon Fiber Market is expected to continue its growth, driven by the rising demand for lightweight and high-performance materials. The future outlook for the market is promising, with opportunities emerging in new applications and regions. Key manufacturers are likely to focus on developing sustainable and cost-effective production processes to meet the growing demand.

As the market evolves, it is essential to monitor the developments in the industry, including advancements in technology and changes in global trade policies. The Milled Carbon Fiber Market is poised for significant growth, and understanding its dynamics will be crucial for stakeholders to make informed decisions.

Global Milled Carbon Fiber Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Milled Carbon Fiber Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Milled Carbon FiberMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Milled Carbon Fiberplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Milled Carbon Fiber Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Milled Carbon Fiber Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Milled Carbon Fiber Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofMilled Carbon FiberMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is milled carbon fiber?

Milled carbon fiber is a type of carbon fiber that has been processed into a fine powder or milled form, making it suitable for various applications, including aerospace, automotive, and industrial manufacturing.

What are the main factors driving the growth of the Milled Carbon Fiber Market?

The main factors driving the growth of the Milled Carbon Fiber Market include:

- Increasing demand in the aerospace and automotive sectors, particularly in the U.S.

- The unique properties of milled carbon fiber, such as high strength-to-weight ratio and resistance to fatigue.

How do supply chain dynamics affect the Milled Carbon Fiber Market?

Supply chain dynamics, including the production of raw materials such as polyacrylonitrile (PAN) and pitch, as well as manufacturing processes, play a crucial role in the Milled Carbon Fiber Market. These factors impact overall market growth and profitability.

What are the emerging trends in carbon fiber composites for aerospace and automotive sectors?

Emerging trends in carbon fiber composites include the development of new composite materials that offer improved performance and cost-effectiveness, driving growth in the Milled Carbon Fiber Market.

What are the challenges faced by the carbon fiber industry?

The carbon fiber industry faces several challenges, including:

- High production costs

- Difficulty in recycling carbon fiber composites

- Geopolitical factors affecting the supply chain dynamics

How is the Milled Carbon Fiber Market segmented?

The Milled Carbon Fiber Market is segmented based on fiber size and application-specific needs, with different applications requiring specific fiber sizes and properties.

What is the demand for milled carbon fiber in the U.S.?

The U.S. is a significant market for milled carbon fiber, particularly in the aerospace and automotive sectors, driven by the demand for lightweight and high-strength materials.

What is Germany’s role in the European carbon fiber market?

Germany is known for its leadership in advanced manufacturing and the development of lightweight materials, making it a key player in the European carbon fiber market.

How is Japan contributing to the innovation in carbon fiber composites?

Japan has been leading the way in innovation for carbon fiber composites. They have a strong emphasis on research and development, which is driving advancements in carbon fiber technology.

What is the forecast for the Milled Carbon Fiber Market?

The Milled Carbon Fiber Market is expected to surpass $2.43 billion by 2025, driven by increasing demand across various industries, including aerospace, automotive, and industrial manufacturing.

Who are the key manufacturers in the carbon fiber market?

The carbon fiber market is highly competitive, with several key manufacturers including major players who are driving market growth and innovation.

What is the impact of geopolitical supply chain dynamics on carbon fiber production?

Geopolitical factors and global trade policies can significantly impact the supply chain dynamics of the carbon fiber industry, affecting the production and distribution of carbon fiber.