$22.7 Billion Metallurgical Engineering Services Market Set to Emerge Strongly in the U.S., China, and India by 2025

Explore trends in the metallurgical engineering services market, including AI, IoT, sustainability, and regional growth, shaping industries worldwide.

- Last Updated:

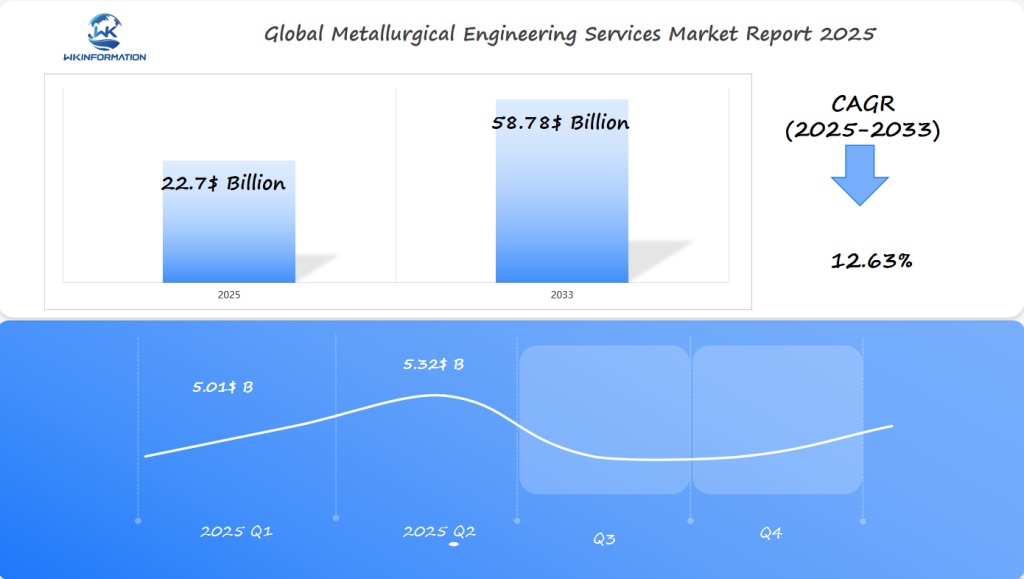

Projected Market Insights for Metallurgical Engineering Services in Q1 and Q2 of 2025

The Metallurgical Engineering Services market is expected to reach $22.7 billion in 2025, with a CAGR of 12.63% from 2025 to 2033. In Q1, the market is projected to generate approximately $5.01 billion, driven by the rising demand for advanced materials and engineering expertise in industries such as automotive, aerospace, and construction. By Q2, the market is anticipated to grow to about $5.32 billion, as innovations in material technology and metallurgy continue to play a key role in product performance improvements and cost savings.

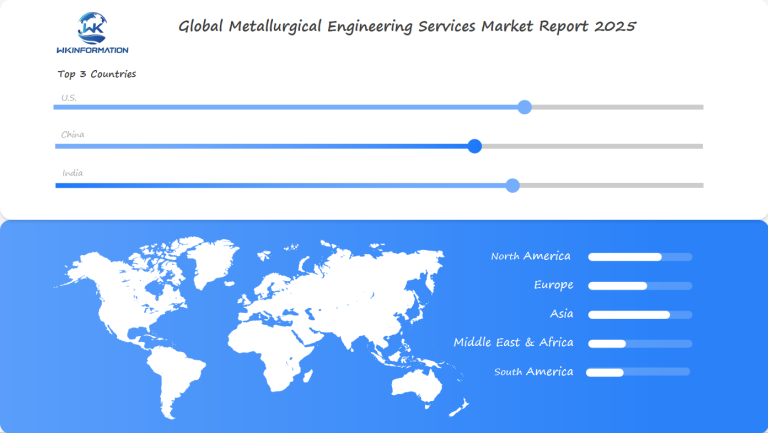

The U.S., China, and India are expected to be the largest contributors to this market. The U.S. leads with high investments in R&D and advanced manufacturing, while China and India’s rapidly growing industries create strong demand for metallurgical engineering services to support their infrastructure and manufacturing capabilities. The combination of industrial expansion and technological advancements will fuel steady growth in this sector.

Understanding the Upstream and Downstream Industry Chains for Metallurgical Engineering Services

Upstream Industry Chain

The upstream industry chain in metallurgical engineering services includes all processes from raw material extraction to initial processing. This phase is crucial as it sets the foundation for quality and efficiency in subsequent stages. It involves mining, refining, and smelting operations where metallurgical engineers play a vital role in optimizing resource utilization and minimizing waste.

Downstream Industry Chain

On the other hand, the downstream industry chain includes activities involved in getting the product to the end consumer. This includes everything from manufacturing the product to distributing it. During this phase, metallurgical processes are used to ensure that materials remain strong and meet industry standards. Important tasks in this stage include designing the product, fabricating it, and conducting quality control checks.

Role of Metallurgical Engineering in Supply Chain Management

Metallurgical engineering plays a crucial role in supply chain management in several ways:

- Ensures optimal material performance across various sectors like automotive, aerospace, and construction.

- Enhances service delivery through precise control over material properties at every supply chain stage.

Impact of Technology on Upstream and Downstream Processes

Metallurgical engineering uses advanced technologies like AI and IoT to improve both upstream and downstream processes. This integration results in better resource management and greater competitiveness in global markets.

Importance of the Interaction Between Industry Chains

The interaction between these industry chains not only affects cost-efficiency but also determines the sustainability of engineering services across various applications.

Emerging Trends in Metallurgical Engineering Services: Innovations and Advances

Technological advancements are transforming the landscape of metallurgical engineering services, driving efficiency and innovation across industries. Automation has become a cornerstone, streamlining processes and reducing human error. This not only accelerates production timelines but also improves quality control.

AI applications in metallurgical engineering services are gaining momentum, offering predictive analytics for material performance and failure rates. AI can predict potential issues before they occur, enabling proactive maintenance strategies. These capabilities help reduce downtime and enhance service reliability, ensuring that operations run smoothly.

IoT applications in metallurgy are also making a significant impact. By integrating IoT devices, companies can monitor equipment conditions in real-time. This connectivity allows for more precise data collection and analysis, leading to optimized resource management and energy consumption.

The future implications of these trends on service offerings are vast:

- Enhanced Customization: Tailored solutions based on data-driven insights.

- Improved Sustainability: Reduction in waste and improved resource efficiency.

- Increased Competitiveness: Firms that adopt these technologies are likely to gain a competitive edge.

Such innovations indicate a dynamic shift towards more intelligent and responsive metallurgical engineering services that cater to evolving industry demands.

Challenges in Providing High-Quality Metallurgical Engineering Services

Delivering high-quality metallurgical engineering services presents several challenges.

1. Quality Control

Ensuring consistent quality across various projects requires meticulous attention to detail, rigorous testing, and validation processes. Any lapse in these areas can lead to significant setbacks, impacting client satisfaction and project success.

2. Resource Allocation

Efficiently allocating skilled personnel and technical resources becomes complex as demand fluctuates. Balancing resource distribution while ensuring each project receives the necessary expertise and attention is crucial for maintaining service standards.

To overcome these obstacles, firms can adopt several strategies:

- Investment in Technology: Utilizing advanced technologies such as AI-driven analytics can enhance quality control by predicting potential issues before they arise. Companies like GM are already leveraging such advancements through their Tech Learning University which focuses on upskilling employees with the latest technological trends.

- Training and Development: Continuous training programs ensure that engineers stay updated with the latest industry standards and technological advancements. This could include metallurgical engineering courses that provide in-depth knowledge and skills.

- Flexible Resource Management: Implementing dynamic resource allocation systems allows for better adaptation to changing project demands.

Addressing these challenges effectively is vital for firms aiming to thrive in the competitive metallurgical engineering services market. Through strategic planning and innovation, companies can uphold high-quality standards, fostering growth and client trust in this evolving industry landscape.

Moreover, expanding the scope of metallurgical engineering services to include chemical engineering aspects can open up new avenues for growth and client satisfaction.

Geopolitical Influences on Metallurgical Engineering Services Demand

Geopolitical factors significantly impact the demand for metallurgical engineering services. Global events, such as political shifts or international conflicts, can alter supply chain dynamics, affecting how and where these services are required.

Key Geopolitical Factors Affecting Demand

- Trade Policies: Regulations and trade agreements directly influence international collaboration within the industry. Tariffs or restrictions on raw materials can lead to changes in sourcing strategies, necessitating adaptation in engineering processes.

- Political Stability: Countries with stable governments tend to attract more foreign investments, enhancing the demand for metallurgical services due to increased infrastructure projects.

- Regional Conflicts: Areas experiencing conflict may see a decline in demand due to instability, while neighboring regions might experience a spike as they absorb increased industrial activities.

The intersection of geopolitics and engineering services underscores the need for firms to develop flexible strategies. This adaptability ensures they remain resilient against these external pressures, allowing them to respond effectively to both opportunities and challenges presented by geopolitical shifts.

Market Segmentation: Types and Applications of Metallurgical Engineering Services

Breaking down the service types offered by metallurgical engineers reveals a diverse range of solutions designed to meet the complex needs of various industries. These services include:

- Consulting Services: Providing expert advice on material selection, failure analysis, and process optimization.

- Design and Development: Creating innovative solutions for metallurgical processes and products.

- Testing and Analysis: Conducting rigorous testing procedures to ensure material integrity and compliance with industry standards.

- Quality Assurance: Implementing systems to maintain high-quality outputs in manufacturing processes.

Exploring the application sectors for metallurgy consulting, several key industries stand out:

- Automotive Industry: Metallurgical services play a critical role in developing lightweight materials that enhance fuel efficiency and safety.

- Aerospace Sector: The demand for high-performance alloys and composites is met through advanced metallurgical engineering techniques.

- Construction Industry: Ensuring durability and sustainability through the use of innovative materials engineered for modern infrastructure demands.

These applications highlight the indispensable nature of metallurgical engineering services across diverse sectors, reinforcing their pivotal role in driving technological advancements and economic growth. Each industry leverages these services to achieve specific goals, whether it’s enhancing performance, ensuring safety, or driving innovation.

Importance of Metallurgical Engineering in Key Industries

Metallurgical engineering is essential in several industries, especially in mining, manufacturing, and energy sectors. Here’s how metallurgists contribute to each of these fields:

Mining

In the mining industry, metallurgists concentrate on:

- Extracting metals from ores

- Processing metals to obtain pure forms

- Implementing sustainable practices for metal recovery

Manufacturing

Metallurgical engineers play a vital role in manufacturing by:

- Designing materials that meet strict quality requirements

- Producing materials using advanced methods like alloy design and heat treatment

Energy

The energy sector depends on metallurgical engineering for:

- Creating materials that can endure harsh environments (e.g., power plants, renewable energy systems)

- Improving efficiency and environmental sustainability through innovative material development

Global Insights into Metallurgical Engineering Services Growth

The global metallurgical engineering services market is experiencing significant growth due to several factors:

- Advancements in technology

- Increased industrial demand

- The push for sustainability

Key Drivers of Growth

- Innovations in Materials Science: The development of high-strength alloys and corrosion-resistant metals is improving product performance across industries.

- Energy-Efficient Processes: There is a growing demand for more energy-efficient processes in manufacturing, which is driving the need for specialized services within metallurgical engineering.

- Sustainable Manufacturing: The focus on sustainability in production methods is leading to an increase in metallurgical engineering services that promote environmentally friendly practices.

Regional Growth Leaders

The growth of the metallurgical engineering services market is being led by the following regions:

- Asia-Pacific: This region, particularly China and India, is at the forefront of this growth.

- North America and Europe: These regions are concentrating on advanced metallurgical solutions that offer high value addition.

U.S. Market Outlook for Metallurgical Engineering Services

The U.S. metallurgical engineering services market is expected to continue its upward trajectory, driven by a strong demand for high-performance materials in industries such as aerospace, automotive, and energy.

Several factors are contributing to this growth:

- The ongoing push for innovation in manufacturing processes

- A focus on reducing carbon footprints

- The growing trend of reshoring manufacturing operations

These factors are creating a greater need for advanced metallurgical solutions and presenting new opportunities for domestic metallurgical engineering services.

With a strong emphasis on research and development, the U.S. market is positioning itself as a leader in cutting-edge metallurgical engineering practices.

China’s Role in the Expansion of Metallurgical Engineering Services

China plays a crucial role in the growth of metallurgical engineering services. This is mainly because it is a global manufacturing center and its industries are growing.

Key Factors Driving China’s Role

- Infrastructure Development: China has made significant investments in infrastructure, which supports various industries and creates a demand for metallurgical solutions.

- Advanced Manufacturing Technologies: The country is embracing advanced manufacturing technologies, leading to more efficient production processes and higher-quality products.

- Sustainability Initiatives: China is actively pursuing sustainability initiatives, such as developing eco-friendly materials and energy-efficient production methods, which further drive the need for innovative metallurgical solutions.

Industries Benefiting from China’s Metallurgical Engineering Services

- Steel Production: The steel industry in China is one of the largest in the world, and there is a constant need for advanced metallurgical techniques to improve production efficiency and reduce environmental impact.

- Automotive Manufacturing: With the rise of electric vehicles and lightweight materials, the automotive industry requires specialized metallurgical expertise to meet new challenges.

- Electronics: As technology advances, the electronics sector demands precise metalworking capabilities for components used in various devices.

As China continues to be a dominant force in global supply chains, its metallurgical engineering services sector will remain vital to the world economy.

India’s Growing Need for Advanced Metallurgical Engineering Solutions

India’s expanding industrial sector is driving up the demand for advanced metallurgical engineering solutions. With more investments in infrastructure, manufacturing, and the energy sector, there’s a greater need for strong, long-lasting materials.

Why Metallurgical Engineering Services Are Important

Metallurgical engineering services play a crucial role in:

- Optimizing production processes

- Enhancing the quality of materials

- Ensuring sustainable energy and manufacturing operations

The Impact of Renewable Energy on Metallurgical Solutions

India’s focus on renewable energy sources like solar and wind is increasing the demand for specialized metallurgical solutions. These solutions are necessary to create materials that can endure extreme environmental conditions.

The changing market in India offers significant opportunities for innovation in metallurgical engineering.

The Future Outlook for Metallurgical Engineering Services Market Growth

The metallurgical engineering services market is about to undergo a significant transformation. Expected trends suggest a shift towards advanced material science and customization, driven by increasing demands in industries such as automotive and aerospace. The integration of artificial intelligence (AI) and Internet of Things (IoT) technologies is set to revolutionize this sector, enhancing efficiency and precision in metallurgical processes.

Impact of Emerging Technologies

1. AI in Metallurgy

AI algorithms are expected to streamline complex metallurgical processes, enabling predictive maintenance and improving quality control measures.

2. IoT Applications

IoT devices will facilitate real-time monitoring of material properties, optimizing resource usage and minimizing waste.

These technological advancements have the potential to disrupt traditional methods and bring about a new era of innovation.

Sustainability Considerations

- Resource Efficiency: Emphasis on sustainable practices will drive the adoption of eco-friendly materials and recycling techniques.

- Carbon Footprint Reduction: Metallurgical engineering services will increasingly focus on reducing emissions during production processes.

The future landscape of the metallurgical engineering services market hinges on these evolving trends, with a keen eye on sustainability. As the industry adapts to these changes, stakeholders must remain proactive in embracing technology and sustainable practices to ensure long-term growth and resilience.

Competitive Landscape in the Metallurgical Engineering Services Market

The metallurgical engineering services market is highly competitive, with key players operating in various regions and industries:

-

Vista Engineering —— USA

-

Modern Group —— USA

-

Stress Engineering Services Inc. —— USA

-

SGS MSI —— Switzerland

-

WJE —— USA

-

ASAP Metal Testing —— USA

-

Colorado Metallurgical Services —— USA

-

HTTE —— USA

-

Eurofins —— Luxembourg

-

GBM Group —— USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Metallurgical Engineering Services Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The metallurgical engineering services market is constantly changing and growing due to factors such as digitalization, sustainability, and advanced technologies. Major companies and regions play a significant role in this growth, while developing countries create new opportunities.

However, there are challenges such as high costs and a lack of skilled professionals. On the bright side, innovations like AI and additive manufacturing offer hope for a better future.

To stay competitive, stakeholders need to keep an eye on market trends and use insights to their advantage. By adopting new technologies and sustainable practices, businesses can set themselves up for long-term success in this ever-evolving industry.

Global Metallurgical Engineering Services Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Metallurgical Engineering Services Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Metallurgical Engineering Services MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Metallurgical Engineering Servicesplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Metallurgical Engineering Services Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Metallurgical Engineering Services Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Metallurgical Engineering Services Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofMetallurgical Engineering Services Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for metallurgical engineering services by 2025?

The metallurgical engineering services market is projected to reach a size of $22.7 billion by 2025, indicating significant growth driven by key regions such as the U.S., China, and India.

How do upstream and downstream industry chains impact metallurgical engineering services?

The upstream and downstream industry chains play a vital role in metallurgical engineering services as they determine how materials and processes move. By effectively managing these chains, we can improve supply chain efficiency and service delivery in different industries.

What are some emerging trends in metallurgical engineering services?

Emerging trends in metallurgical engineering include technological advancements such as automation, AI applications, and IoT integration. These innovations are reshaping service offerings and improving operational efficiencies within the industry.

What challenges do companies face in delivering high-quality metallurgical engineering services?

Companies often encounter quality control issues and resource allocation challenges when providing metallurgical engineering services. Strategies to overcome these challenges include implementing robust quality management systems and efficient resource planning.

How do geopolitical factors influence the demand for metallurgical engineering services?

Geopolitical events significantly shape the demand for metallurgical engineering services globally. Trade policies can affect international collaboration, impacting service availability and project execution within the industry.

What types of applications are available for metallurgical engineering services?

Metallurgical engineering services include various types such as consulting and design, with applications in multiple industries including automotive, aerospace, and manufacturing. Each sector benefits from specialized metallurgy consulting tailored to its needs.