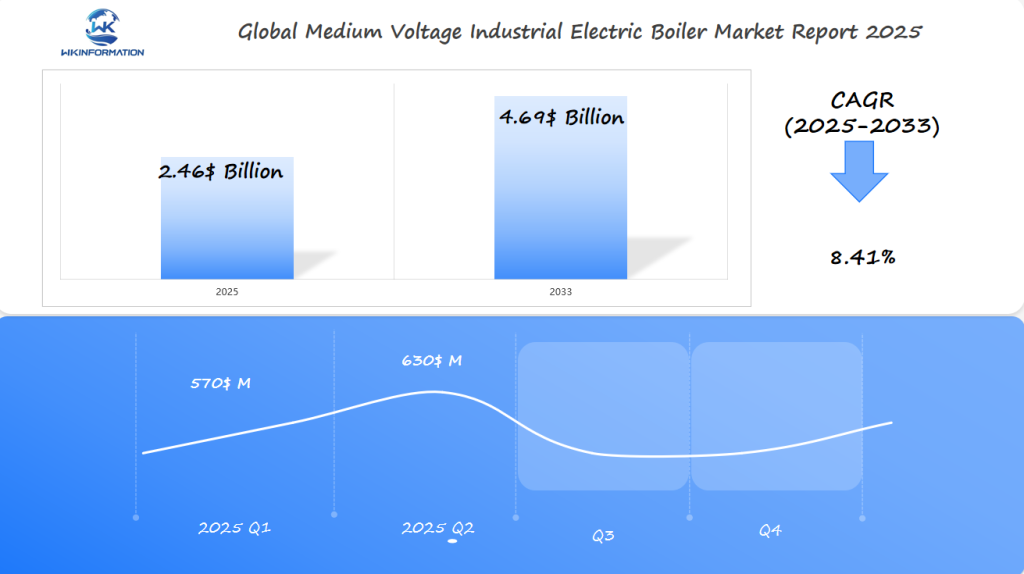

Medium Voltage Industrial Electric Boiler Market Forecasted to Reach $2.46 Billion by 2025 with Key Momentum in the U.K., U.S., and South Korea

The Medium Voltage Industrial Electric Boiler Market is forecasted to reach $2.46 Billion by 2025

- Last Updated:

Growth of Medium Voltage Industrial Electric Boiler Market in Q1 and Q2 2025

The Medium Voltage Industrial Electric Boiler market is projected to reach $2.46 billion in 2025, with a compound annual growth rate (CAGR) of 8.41%. This indicates a clear upward trend for the industry.

Sales Estimates

Sales for Q1 2025 are estimated to be around $570 million, while Q2 is expected to see an increase to approximately $630 million. This growth can be attributed to the ongoing industrial decarbonization and electrification efforts.

Factors Driving the Market

Several factors are contributing to the positive outlook for the Medium Voltage Industrial Electric Boiler market:

- Stricter emissions standards

- Increasing demand for energy efficiency

- Transition away from fossil fuel-based heating systems

Key Markets

The U.K., U.S., and South Korea are identified as key markets for this industry. Each of these countries is investing in electrified process heating solutions to achieve their climate goals. As a result, they are likely to lead in innovation and adoption throughout the forecast period.

Mapping Upstream and Downstream Supply Chains in Electric Boiler Ecosystem

The electric boiler ecosystem relies heavily on a well-coordinated supply chain to meet industrial demands. Understanding the intricacies of this supply chain is vital for stakeholders to make informed decisions.

Understanding the Electric Boiler Supply Chain

The electric boiler supply chain is complex, involving various stakeholders across different stages. From raw material suppliers to manufacturers and distributors, each player has a crucial role.

Key Components of the Supply Chain:

- Raw material sourcing

- Manufacturing and assembly

- Distribution and logistics

- Installation and maintenance

The Growing Trend of Electrification in Industrial Heating Processes

As industries work towards reducing their carbon footprint, electrification in industrial heating is becoming more popular. This change is driven by the need for energy efficiency and lower emissions, making electric boilers an appealing solution for industrial heating requirements.

The Shift to Electrification

The industrial sector is undergoing a major change with the rise of electric boilers. This shift is mainly driven by the need to cut down on greenhouse gas emissions and boost energy efficiency. Electric boilers provide a cleaner option compared to traditional heating systems that rely on fossil fuels.

Key reasons for this shift include:

- Growing regulatory pressures to lower emissions

- Increasing energy costs associated with fossil fuels

- Technological advancements in electric boiler design

Benefits of Electrification

Switching to electric heating in industries brings several advantages, such as better energy efficiency and lower operational costs. Electric boilers can achieve higher efficiency rates compared to conventional systems, resulting in long-term cost savings.

Furthermore, the use of electric boilers helps reduce greenhouse gas emissions, supporting industries in their sustainability objectives. As the energy transition progresses, electrification will play a crucial role in shaping the future of industrial heating.

Limitations in Power Supply Infrastructure and Regulatory Barriers

The Medium Voltage Industrial Electric Boiler Market faces significant hurdles due to limitations in power supply infrastructure and stringent regulatory frameworks. Despite the growing demand for electric boilers, the existing power supply infrastructure in many regions is not equipped to handle the increased load, leading to potential grid instability and reliability issues.

Infrastructure Challenges

A key challenge lies in the upgrade and modernization of the grid to accommodate the increased electricity demand. Many industrial areas still rely on aging infrastructure that isn’t designed to support the high-capacity demands of modern electric boilers.

Regulatory Hurdles

Regulatory frameworks governing the adoption of electric boilers vary significantly across regions, creating inconsistencies in market dynamics. Compliance with these regulations can be complex and costly, deterring some businesses from transitioning to electric boilers.

To overcome these challenges, stakeholders must collaborate on infrastructure upgrades and advocate for supportive regulatory policies. This includes investing in grid modernization and developing standardized regulations that facilitate the adoption of electric boilers.

Geopolitical Factors Influencing Energy Transition and Industrial Electrification

As the world moves towards cleaner energy, geopolitical factors are reshaping the landscape of industrial electrification. The Medium Voltage Industrial Electric Boiler Market is leading this transition, influenced by a complex interaction of global events, trade policies, and government regulations.

Geopolitical Influences

Geopolitical factors significantly impact the energy transition and the adoption of industrial electric boilers. These influences can be seen in several areas:

- Trade Policies: Tariffs and trade agreements can either hinder or facilitate the import and export of electric boilers and their components.

- Government Regulations: Policies aimed at reducing carbon emissions and promoting clean energy can drive the demand for electric boilers.

- Global Events: Political instability and conflicts can disrupt supply chains and impact the global energy market.

Impact on Energy Transition

The energy transition is a critical aspect of global efforts to combat climate change. Geopolitical drivers play a crucial role in this transition by influencing the availability and adoption of clean energy technologies, including industrial electric boilers.

The shift towards electrification in industrial processes is not just a technological or economic decision but also a geopolitical one. Countries with favorable policies and resources are likely to lead in the adoption of electric boilers.

The Medium Voltage Industrial Electric Boiler Market is expected to benefit from geopolitical drivers that support energy transition. Companies that navigate these geopolitical influences effectively will be better positioned to capitalize on the growing demand for electric boilers.

Segmented Analysis by Voltage Ratings, Boiler Capacities, and Configurations

The Medium Voltage Industrial Electric Boiler Market is complex and multifaceted, with various factors influencing its dynamics. Segmenting the market by voltage, capacity, and configuration reveals the complexities of the Medium Voltage Industrial Electric Boiler Market, allowing for a nuanced understanding of its different segments.

Market segmentation is crucial for understanding the diverse needs and trends within the industry. By analyzing voltage ratings, boiler capacities, and configurations, stakeholders can better navigate the market and make informed decisions.

Market Segmentation

The market can be segmented into different categories based on voltage ratings, including low, medium, and high voltage boilers. Each category has its unique applications and growth prospects.

- Low voltage boilers are typically used in smaller industrial setups.

- Medium voltage boilers are the most common, catering to a wide range of industrial needs.

- High voltage boilers are used in heavy industries requiring high energy output.

Segment-wise Analysis

A detailed analysis of each segment reveals the factors driving demand and the competitive landscape. For instance, the demand for medium voltage boilers is driven by their versatility and efficiency in various industrial applications.

Similarly, the segmentation by boiler capacities and configurations provides insights into market trends and growth areas. Understanding these segments is crucial for manufacturers and suppliers to tailor their offerings to meet specific industrial needs.

| Segment | Voltage Rating | Boiler Capacity |

| Low Voltage | Up to 1kV | Small to Medium |

| Medium Voltage | 1kV to 35kV | Medium to Large |

| High Voltage | Above 35kV | Large |

Application Overview in Food, Chemical, and Textile Processing Industries

Electric boilers are versatile and suitable for various industrial applications, such as food processing and chemical manufacturing. They offer precise temperature control and efficient heating, making them an excellent choice for multiple industries.

Industry Applications

Electric boilers are being increasingly adopted in the food processing industry due to their ability to maintain precise temperatures, which is crucial for processes like sterilization, pasteurization, and cooking. They provide clean steam essential for these processes.

In the chemical processing industry, electric boilers are used for heating reactors and for various chemical reactions that require controlled temperatures. The precise temperature control they offer is critical for achieving desired results in chemical reactions.

In the textile processing industry, electric boilers are utilized for dyeing, drying, and fixing fabrics. The high degree of temperature control ensures that textiles are processed consistently, enhancing product quality and reducing energy consumption.

Applications of Electric Boilers in Various Industries

- Food Processing: Electric boilers are valued for their ability to provide clean steam, which is essential for processes like cooking and sterilization.

- Chemical Processing: The use of electric boilers in chemical processing helps achieve precise temperature control, which is critical for chemical reactions.

- Textile Processing: The textile industry benefits from the use of electric boilers through improved fabric quality and reduced energy consumption.

The adoption of electric boilers across these industries is driven by the need for efficient heating solutions and precise process control. As industries continue to evolve, the demand for electric boilers is expected to grow, driven by their benefits in enhancing product quality and reducing operational costs.

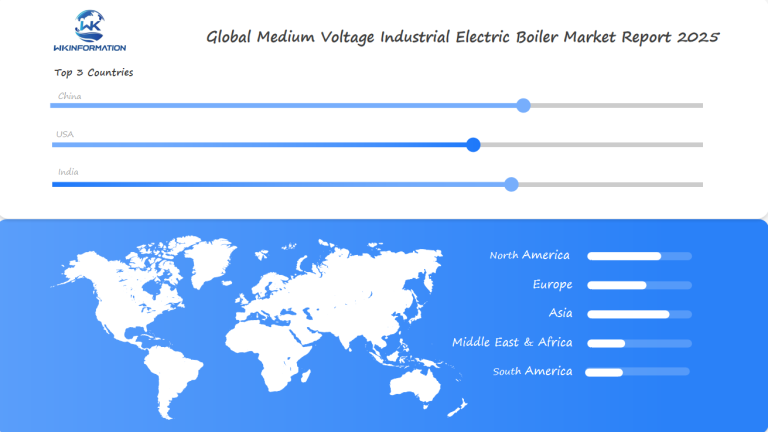

Global Regional View on Electrification and Boiler Adoption

As the world moves towards cleaner energy solutions, the role of electric boilers in industrial applications is gaining significant traction across different regions. The adoption of electric boilers varies widely, influenced by factors such as regional energy policies, industrial infrastructure, and economic conditions.

Regional Trends

Regional trends in electrification and boiler adoption are influenced by local industrial requirements, environmental regulations, and the accessibility of renewable energy sources. For example, areas with plentiful renewable energy are more inclined to embrace electric boilers as a greener substitute for fossil fuels.

A closer look at regional variations shows different adoption patterns. In areas with well-established industrial infrastructure, the shift towards electric boilers is often motivated by the necessity to upgrade existing heating systems and adhere to strict environmental regulations.

| Region | Electrification Trend | Boiler Adoption Rate |

| North America | High | Moderate |

| Europe | Very High | High |

| Asia Pacific | Moderate | High |

The regional analysis emphasizes the significance of customized approaches to encourage the adoption of electric boilers, considering local circumstances and industry requirements.

The U.K.’s Industrial Decarbonization and Electric Boiler Demand

The U.K. is focusing on reducing industrial carbon emissions and is turning to electric boilers as a key solution. The country’s commitment to decarbonizing its industrial sector is leading to a significant shift towards cleaner energy sources.

U.K. Market Analysis

The U.K. market is seeing a significant rise in the use of electric boilers, driven by government policies and the need for sustainable industrial practices. Electric boilers provide a practical solution to conventional heating systems that rely on fossil fuels, supporting the U.K.’s environmental goals.

Decarbonization Efforts in the U.K.

The U.K. is taking a comprehensive approach to reducing carbon emissions, with both government initiatives and industry-led innovations playing a role. One important part of this strategy is promoting electric boilers for industrial use.

- Government incentives are being offered to encourage the adoption of cleaner heating technologies.

- Industries are investing in electric boiler technology to reduce their carbon footprint.

U.S. Market Shifts Toward Energy-Efficient Heating Solutions

With the help of government support and advancements in technology, the U.S. is now embracing energy-efficient heating solutions like never before. This change is primarily driven by government programs designed to lower carbon emissions and encourage sustainable practices in various industries.

Market Dynamics

The U.S. market for energy-efficient heating is experiencing significant growth, driven by the need to reduce energy consumption and lower operational costs. Electric boilers are becoming an important part of this trend, offering high efficiency and reliability.

Energy Efficiency Initiatives

Several initiatives are underway to promote energy efficiency in heating solutions. These include:

- Incentives for adopting energy-efficient technologies

- Stricter regulations on energy consumption

- Investments in research and development of new heating technologies

These initiatives are expected to drive the demand for electric boilers, contributing to the overall growth of the energy-efficient heating market in the U.S.

South Korea’s High-Tech Manufacturing and Electrified Process Heating

The South Korean market is experiencing a major shift towards electrified process heating in high-tech manufacturing. This change is being driven by the demand for efficient and precise heating solutions in different industrial processes.

South Korean Market Analysis

South Korea is known for its high-tech manufacturing capabilities, with industries such as electronics and automotive driving the demand for advanced heating solutions. Electrified process heating offers a cleaner and more efficient alternative to traditional fossil-fuel-based heating methods.

The adoption of electrified process heating in South Korea’s high-tech manufacturing sector is driven by several factors, including the need for precision temperature control and the desire to reduce carbon emissions. Key applications include:

- Semiconductor manufacturing

- Electronics assembly

- Advanced materials processing

As the South Korean market continues to evolve, the demand for electrified process heating solutions is expected to grow, driven by the ongoing need for efficient and sustainable industrial heating solutions.

Future Pathways Toward Net Zero and Innovation in Boiler Control Systems

Integration with Renewable Energy Sources

-

Hybrid systems combining traditional boilers with solar thermal or biomass inputs are being explored.

-

Control systems are evolving to optimize energy input sources based on availability and efficiency.

Advanced Sensing and Automation

-

IoT-enabled sensors provide real-time data on temperature, pressure, and emissions.

-

Smart control algorithms adjust combustion parameters dynamically to reduce fuel consumption and emissions.

Predictive Maintenance and AI Integration

-

Use of machine learning to predict component failures and schedule maintenance before breakdowns.

-

Reduces downtime and improves efficiency, contributing to overall carbon footprint reduction.

Low-NOx and Hydrogen-Compatible Burners

-

Boilers are being redesigned with low-NOx burners to meet strict emission regulations.

-

Emerging control systems are being adapted for hydrogen or hydrogen blend fuels, key for decarbonization.

Cloud-Based Control Platforms

-

Remote monitoring and control through cloud-connected systems enable centralized energy management.

-

These platforms support data analytics, benchmarking, and long-term efficiency improvements.

Competitive Overview of Leading Boiler Manufacturers and Innovators

The industrial electric boiler market is highly competitive, with several key players in the industry. This competition is fueled by the increasing demand for energy-efficient heating solutions and technological advancements in boiler manufacturing.

Market Competitiveness

Market competitiveness is driven by factors such as innovation, pricing strategies, and the ability to meet diverse customer needs. Leading boiler manufacturers are investing heavily in research and development to improve their product offerings and stay ahead of the competition.

Innovators in the field are introducing new technologies that enhance the efficiency and reliability of electric boilers. For instance, some companies are developing boilers with advanced control systems that optimize energy consumption.

Here are some of the key players in the boiler manufacturing industry:

- Cemline Corp. – United States

- Thermal Solutions Products LLC – United States

- SUSSMAN Electric Boilers (Diversified Heat Transfer, Inc.) – United States

- Fulton – United States

- Chromalox, Inc. – United States

- Hurst Boiler & Welding Company – United States

- Cleaver-Brooks – United States

- Miura America Co. – United States (subsidiary of Miura Co., Ltd. – Japan)

- Superior Boiler Works, Inc. – United States

- Clayton Industries – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Medium Voltage Industrial Electric Boiler Report |

| Base Year | 2024 |

| Segment by Type |

· Low Voltage · Medium Voltage · High Voltage |

| Segment by Application |

· Food Processing · Chemical Processing · Textile Processing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Medium Voltage Industrial Electric Boiler Market is expected to grow significantly due to the increasing demand for energy-efficient heating solutions. As industries continue to embrace electrification, the market is projected to expand considerably.

Emerging Trends

Key industry trends, including the shift towards electrification and decarbonization, will shape the market’s future. The adoption of electric boilers in various industries, such as food processing and textiles, is expected to drive market growth.

Future Directions

As the market evolves, stakeholders can expect opportunities in emerging regions and industries. The focus on energy-efficient solutions and reducing carbon footprint will continue to drive innovation and investment in the medium voltage industrial electric boiler market, influencing the market outlook and future pathways.

Global Medium Voltage Industrial Electric Boiler Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Medium Voltage Industrial Electric Boiler Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Women’s ActivewearMarket Segmentation Overview

Chapter 2: Competitive Landscape

- GlobalMedium Voltage Industrial Electric Boiler players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Medium Voltage Industrial Electric Boiler Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Medium Voltage Industrial Electric Boiler Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Medium Voltage Industrial Electric Boiler Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWomen’s ActivewearMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Medium Voltage Industrial Electric Boiler Market?

The market is driven by the increasing demand for energy-efficient heating solutions in industrial processes, as industries transition towards electrification.

What are the key challenges facing the Medium Voltage Industrial Electric Boiler Market?

The market faces challenges related to power supply infrastructure and regulatory frameworks, which can hinder market growth.

How is the market segmented?

The market can be segmented based on voltage ratings, boiler capacities, and configurations, with each segment having its own market size, growth prospects, and trends.

What are the applications of electric boilers in various industries?

Electric boilers have various applications across industries, including food, chemical, and textile processing, with benefits and challenges specific to each industry.

How is the adoption of electric boilers varying across regions?

The adoption of electric boilers varies across regions, influenced by factors such as energy policies, industrial infrastructure, and economic conditions.

What is the outlook for the Medium Voltage Industrial Electric Boiler Market?

The market is expected to reach $2.46 Billion by 2025, driven by the increasing demand for energy-efficient heating solutions and the shift towards electrification in industrial processes.

What are the benefits of electrification in industrial heating processes?

Electrification offers several benefits, including energy efficiency and reduced carbon emissions, making it an attractive option for industries looking to reduce their environmental impact.

Who are the key players in the Medium Voltage Industrial Electric Boiler Market?

The market is competitive, with several leading manufacturers and innovators, including companies that specialize in electric boilers and related technologies.

What is the role of government regulations in shaping the market?

Government regulations play a significant role in shaping the market, with policies and initiatives influencing the adoption of electric boilers and the overall growth of the market.

What are the future pathways for the Medium Voltage Industrial Electric Boiler Market?

The Medium Voltage Industrial Electric Boiler Market is expected to continue growing, driven by the increasing demand for energy-efficient heating solutions and the shift towards electrification, with opportunities for stakeholders to capitalize on emerging trends and technologies.