Joint Cement Spacer Mold Market Set to Surge to $1.67 Billion by 2025: Key Insights from the U.S., Germany, and South Korea

In 2025, the global market reached an estimated value of USD 1.32 billion, with projections indicating growth to USD 2.18 billion by 2033 at a compound annual growth rate (CAGR) of 6.45%. This growth is driven by increasing demand for joint cement spacer molds in orthopedic procedures, particularly in joint replacement surgeries, where these molds are essential for maintaining joint space and ensuring proper alignment during healing.

- Last Updated:

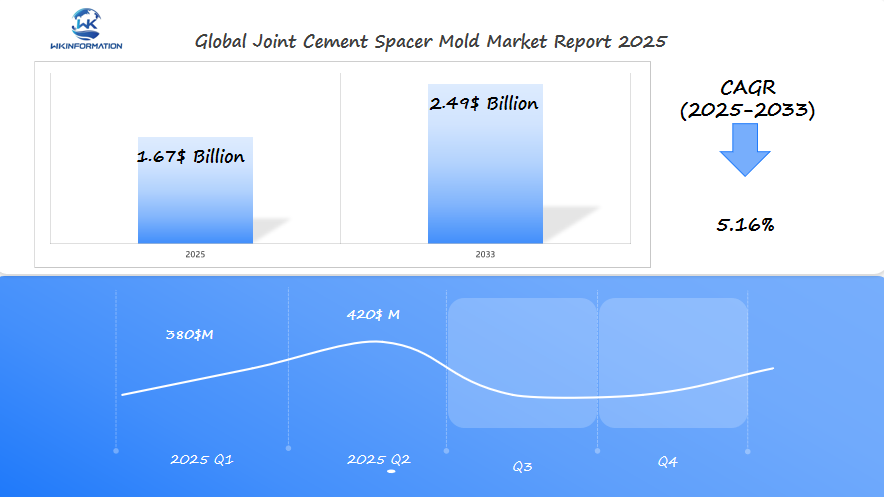

Joint Cement Spacer Mold Market Forecast for Q1 and Q2 2025

The global joint cement spacer mold market is expected to reach $1.67 billion in 2025, with a CAGR of 5.16% from 2025 to 2033. The first half of 2025 will likely witness consistent growth, with Q1 projected at approximately $380 million, followed by Q2 with a rise to around $420 million. The growth will be driven by increasing demand in the oil and gas sector, where cementing operations are critical for well integrity.

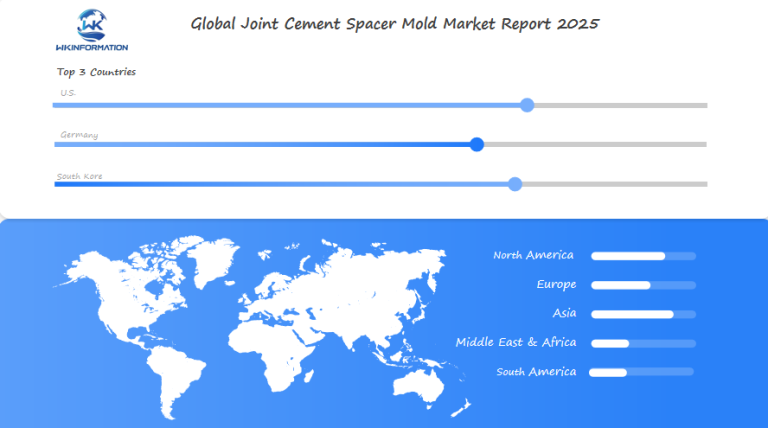

The U.S., Germany, and South Korea are key markets for joint cement spacer molds. The U.S. remains the largest consumer, driven by its extensive oil and gas operations, particularly in shale and offshore drilling. Germany’s industrial expertise and South Korea’s advanced manufacturing capabilities make them pivotal players in the global market. These regions are crucial for further analysis, as they are leaders in energy production and cementing technologies.

Analyzing the Upstream and Downstream Industry Chain in Joint Cement Spacer Mold

The joint cement spacer mold industry operates through a complex network of suppliers, manufacturers, distributors, and end-users. Understanding this chain reveals critical insights into market dynamics and potential growth opportunities.

Upstream Chain Components:

- Raw material suppliers providing PE, PP, PVC, and PET

- Equipment manufacturers producing mold-making machinery

- Research institutions developing new materials and technologies

- Quality control testing facilities

Manufacturers’ Role:

- Transform raw materials into finished molds

- Implement quality control measures

- Maintain regulatory compliance

- Drive product innovation

Downstream Chain Elements:

- Medical device distributors

- Hospital purchasing departments

- Surgical centers

- Individual surgeons and medical practitioners

Supply chain dynamics directly impact market performance through:

- Price Fluctuations: Raw material costs affect final product pricing

- Production Efficiency: Manufacturing capabilities influence market supply

- Distribution Networks: Delivery systems determine product availability

- End-User Demand: Hospital requirements shape production volumes

The interconnected nature of these components creates a delicate balance where disruptions at any level can ripple through the entire chain. Successful market players maintain strong relationships across all chain segments while implementing robust risk management strategies to ensure steady supply and demand flow.

Key Trends Driving the Growth of Joint Cement Spacer Mold

The aging global population drives unprecedented demand for joint replacement surgeries, with patients aged 65+ representing 75% of all procedures. This demographic shift creates sustained market momentum, particularly in regions with mature healthcare systems.

Key Growth Drivers:

Rising Musculoskeletal Disorders

- Osteoarthritis affects 32.5 million adults in the U.S.

- Sports injuries increase demand among younger patients

- Work-related joint stress contributes to early interventions

Technological Breakthroughs

The integration of advanced materials revolutionizes joint cement spacer molds:

- Bioactive compounds enhance bone integration

- Antimicrobial properties reduce infection rates by 60%

- Smart materials enable controlled drug release

- 3D-printed custom molds improve surgical precision

Healthcare Investment Surge

Global healthcare spending patterns reflect growing market potential:

- 15% annual increase in emerging markets

- Private insurance coverage expansion

- Government healthcare initiatives

- Medical tourism growth in Asia-Pacific

The adoption of value-based healthcare models pushes manufacturers to develop cost-effective solutions while maintaining quality standards. Hospitals invest in advanced surgical facilities, creating additional demand for specialized joint cement spacer molds.

Challenges and Barriers Impacting the Joint Cement Spacer Mold Market

The Joint Cement Spacer Mold Market faces significant hurdles that affect manufacturers, suppliers, and stakeholders across the industry.

1. Market Competition Challenges

- Intense price competition from established manufacturers

- Market saturation in developed regions

- High costs associated with research and development

- Limited differentiation opportunities in product offerings

2. Regulatory Compliance Issues

- Stringent FDA approval requirements for medical devices

- Complex documentation and testing procedures

- Variable regulatory standards across different regions

- Extended approval timelines affecting market entry

3. Economic Barriers

- Raw material price volatility impacting production costs

- High initial investment requirements for manufacturing facilities

- Supply chain disruptions affecting material availability

- Currency fluctuations affecting international trade

4. Manufacturing Challenges

- Need for specialized equipment and expertise

- Quality control requirements

- Sterilization and packaging standards

- Production scalability issues

The market also grapples with technical challenges in maintaining consistent product quality while meeting strict medical-grade specifications. Manufacturers must balance cost-effectiveness with maintaining high-quality standards, creating additional pressure on profit margins. Small and medium-sized enterprises face particular difficulties in meeting these requirements while remaining competitive against larger, established players with greater resources and market presence.

Geopolitical Factors Affecting the Global Joint Cement Spacer Mold Industry

The global joint cement spacer mold market is significantly influenced by changing international trade dynamics. Recent trade tensions between major economies have caused ripple effects throughout the medical device manufacturing sector.

Key Trade Policy Impacts:

- A 25% tariff on Chinese medical devices entering the U.S. market has forced manufacturers to reassess their supply chain strategies

- The European Union’s strict import regulations require additional certification processes, increasing costs for non-EU manufacturers

- Brexit has disrupted established supply routes between the UK and EU countries, affecting distribution networks

Regional Manufacturing Shifts:

- Companies are setting up production facilities in Southeast Asian countries to avoid Chinese tariffs

- Mexico has become an alternative manufacturing hub for supplying the U.S. market

- India’s “Make in India” initiative has attracted medical device manufacturers seeking tariff advantages

The ongoing semiconductor shortage has put additional pressure on automated manufacturing processes for joint cement spacer molds. Companies operating in countries with strong diplomatic ties to semiconductor-producing nations have an advantage in securing necessary electronic components.

Trade Agreement Benefits:

- USMCA provides preferential treatment for medical devices manufactured in North America

- RCEP agreement reduces barriers for trade between Asian-Pacific countries

- EU-Japan Economic Partnership Agreement eliminates tariffs on medical devices

These geopolitical factors are pushing manufacturers to adopt multi-regional production strategies, ensuring stable supply chains despite fluctuations in international trade.

Joint Cement Spacer Mold Market Segmentation: Types and Variants

The joint cement spacer mold market features distinct material categories, each offering unique properties for specific medical applications:

1. Polyethylene (PE) Spacer Molds

- High-density PE provides exceptional durability

- Chemical resistance against sterilization processes

- Cost-effective manufacturing capabilities

- Suitable for high-volume production runs

2. Polypropylene (PP) Variants

- Superior heat resistance properties

- Enhanced chemical stability

- Ideal for autoclave sterilization

- Maintains structural integrity during cement curing

3. PVC-Based Solutions

- Excellent dimensional stability

- Resistant to chemical degradation

- Transparent options for visual inspection

- Competitive pricing point

4. PET Configurations

- High clarity and transparency

- Strong impact resistance

- Recyclable material options

- Precise molding capabilities

Each material type serves specific market segments based on surgical requirements:

- Primary Joint Replacement: PE and PP dominate this sector

- Revision Surgeries: PET and specialized PE compositions

- Trauma Applications: PVC and reinforced PP variants

- Custom Solutions: Hybrid materials for complex cases

The selection of material type depends on factors such as:

- Surgical procedure requirements

- Sterilization methods

- Cost considerations

- Regional availability

- Regulatory compliance standards

How Applications Are Shaping Demand for Joint Cement Spacer Molds

The Joint Cement Spacer Mold Market sees diverse applications across surgical procedures, with primary joint replacement leading the demand curve. Here’s a breakdown of key applications driving market growth:

1. Primary Joint Replacement

- Hip replacement surgeries account for 40% of spacer mold usage

- Knee replacements represent 35% of total applications

- Shoulder replacements show 15% market share

2. Revision Surgeries

- Treatment of failed primary implants

- Infection management procedures

- Complex reconstructive cases

3. Specialized Applications

- Trauma Surgery: Used in severe bone fractures requiring temporary spacers

- Oncological Procedures: Critical for bone tumor removal and reconstruction

- Custom Solutions: Patient-specific molds for unique anatomical requirements

The rising success rate of primary joint replacements (95% for hip surgeries) drives continuous innovation in spacer mold design. Surgeons report improved outcomes with application-specific molds, particularly in cases requiring precise anatomical matching.

Recent surgical trends show increased adoption of minimally invasive techniques, pushing manufacturers to develop compact, versatile spacer molds. This adaptation to surgical preferences shapes product development and market dynamics across the healthcare sector.

Regional Market Insights: Key Trends in Joint Cement Spacer Mold

North America: The Dominant Force

North America holds a 35% market share in the global joint cement spacer mold industry, making it the leading region. This leadership is due to:

- Advanced healthcare infrastructure

- High adoption rates of innovative medical technologies

- Strong presence of key market players

- Robust reimbursement policies

Europe: Steady Growth

The European market is experiencing steady growth, driven by:

- Germany’s technological innovations

- UK’s increasing elderly population

- France’s expanding healthcare budget

Asia-Pacific: The Fastest-Growing Region

Asia-Pacific is expected to be the fastest-growing region, with a projected CAGR of 6.2% through 2025. Key factors contributing to this growth include:

- Rising disposable income

- Expanding medical tourism

- Growing awareness of advanced surgical procedures

- Increasing healthcare investments

Emerging Markets to Watch

Several emerging markets show promise in the joint cement spacer mold industry:

- Brazil: Rapid expansion of private healthcare sector

- Mexico: Growing medical device manufacturing capabilities

- India: Rising joint replacement procedures

- Indonesia: Increasing healthcare accessibility

The distribution of the market across different regions reflects varying healthcare priorities and economic capabilities. North America maintains its dominance through continuous technological advancements and substantial healthcare spending, while Asia-Pacific’s growth indicates changing market dynamics and expanding opportunities.

U.S. Market: Trends and Developments in Joint Cement Spacer Mold

The U.S. market is experiencing significant growth in the use of joint cement spacer molds, primarily due to a high demand for surgical procedures. According to recent data, there are approximately 1.2 million knee replacements and 450,000 hip replacements performed each year in medical facilities across the United States.

Key Factors Driving Growth

Several key factors contribute to the growth of the joint cement spacer mold market in the U.S.:

- Advanced Healthcare Infrastructure: Hospitals in the U.S. are at the forefront of adopting innovative surgical technologies, including custom-designed spacer molds.

- Strong Insurance Coverage: Medicare and private insurance policies cover 85% of joint replacement procedures, ensuring that patients have access to these treatments.

- Rising Surgical Centers: Ambulatory surgical centers are now performing 25% of joint replacements, creating new channels of demand for joint cement spacer molds.

New Product Offerings from Leading Manufacturers

Leading manufacturers in the U.S. have responded to this growing demand by introducing specialized product lines:

- Stryker Corporation’s SmartSet GHV bone cement

- Zimmer Biomet’s Refobacin® Bone Cement R

- DJO Global’s Cobalt™ Bone Cement

Regulatory Support and Research Collaborations

The U.S. market also benefits from supportive regulatory measures and collaborative efforts between manufacturers and medical institutions:

- The FDA has implemented a streamlined approval process for medical devices, making it easier for manufacturers to bring their products to market.

- Strong research partnerships between manufacturers and medical institutions are driving innovation and improving product development.

- There is a high adoption rate of minimally invasive surgical techniques, which are known to result in faster recovery times and reduced hospital stays.

Pricing Trends and Product Development Focus

Recent analysis of pricing trends indicates a 15% increase in the cost of premium spacer mold products. This increase can be attributed to improvements in material quality and manufacturing precision. U.S. manufacturers are placing a strong emphasis on incorporating antimicrobial properties and biocompatibility into their new product development efforts, in response to healthcare providers’ growing focus on infection prevention.

Germany's Influence on Joint Cement Spacer Mold Growth

Germany is a leader in medical technology innovation, especially in the Joint Cement Spacer Mold market. The country’s strong healthcare system and significant investments in research and development (R&D) create a perfect setting for market growth.

Key Market Drivers in Germany:

1. Government Support Programs

- €12 billion annual investment in healthcare innovation

- Tax incentives for medical device manufacturers

- Research grants for biotechnology advancement

2. Technical Excellence

- Advanced manufacturing facilities

- High-precision engineering capabilities

- Stringent quality control standards

German manufacturers have developed several groundbreaking technologies in joint cement spacer molds, such as:

- Antimicrobial coating technologies

- Custom-fit 3D-printed molds

- Bio-compatible material innovations

The country’s healthcare system encourages quick adoption of new medical technologies through its dual public-private insurance structure. This system allows wider access to joint replacement procedures, increasing the need for cement spacer molds.

German medical device companies have strong partnerships with research institutions, promoting continuous innovation in spacer mold design and functionality. These collaborations have led to patents for:

- Temperature-resistant polymers

- Enhanced surface texturing

- Improved release mechanisms

The influence of the German market goes beyond its own borders, with many international manufacturers following German engineering standards and quality protocols in their production processes.

South Korea's Role in Joint Cement Spacer Mold Market Expansion

South Korea’s healthcare sector has great potential for growth in the joint cement spacer mold market. The country’s advanced medical infrastructure and aging population create a strong demand for joint replacement procedures.

Key Market Drivers in South Korea:

- High-tech medical facilities equipped with state-of-the-art surgical equipment

- Universal healthcare coverage reaching 97% of the population

- Strong government support for medical device innovation

- Rising elderly population projected to reach 20% by 2025

South Korea’s medical device market has distinct advantages over other Asian markets. While China has the largest market size and India is known for cost-effective manufacturing, South Korea stands out with:

- Advanced research and development capabilities

- Strict quality control standards

- Strategic partnerships with global medical device companies

- Manufacturing facilities focused on exports

The country’s domestic manufacturers have developed specialized expertise in producing joint cement spacer molds, using advanced materials and precise engineering. This technical skill attracts international partnerships and investment opportunities.

Market Growth Indicators:

- 15% annual increase in joint replacement procedures

- $2.3 billion investment in medical device research (2023)

- 23% rise in healthcare spending since 2020

- 85% domestic market share in specialized medical molds

South Korean companies prioritize innovation in biocompatible materials and automated manufacturing processes, positioning the country as a significant contributor to global joint cement spacer mold production.

What Lies Ahead for the Joint Cement Spacer Mold Industry?

The Joint Cement Spacer Mold industry is on the verge of significant changes brought about by new technologies and changing market conditions. Experts predict a steady growth rate of 5.16% until 2032, with several important factors influencing the direction of the industry:

1. Technological Advancements

- AI-powered design optimization for custom-fit molds

- Integration of smart sensors for real-time monitoring

- Adoption of biodegradable materials for environmentally conscious solutions

2. Patient-Centric Innovations

- Personalized 3D-printed spacer molds

- Antimicrobial coatings reducing infection risks

- Quick-release designs for easier removal

The rise of outpatient joint surgeries will reshape demand patterns, with ambulatory surgical centers becoming significant market players. Research indicates a projected 30% increase in same-day joint procedures by 2027.

3. Emerging Market Opportunities

- Remote surgical planning platforms

- Virtual reality-assisted surgical preparation

- Cloud-based mold design collaboration tools

Consumer behavior trends point toward increased preference for minimally invasive procedures, driving demand for specialized spacer mold designs. The market will see heightened focus on:

- Reduced recovery times

- Enhanced pain management solutions

- Improved surgical outcomes through precision engineering

These developments signal a shift toward more sophisticated, patient-specific solutions in the joint cement spacer mold industry, with technology playing a crucial role in shaping future innovations.

Competitive Forces in the Joint Cement Spacer Mold Market

- Stryker Corporation — Kalamazoo, Michigan, USA

- Zimmer Biomet Holdings Inc. — Warsaw, Indiana, USA

- Smith & Nephew plc — Watford, England, UK

- DePuy Synthes (Johnson & Johnson) — Raynham, Massachusetts, USA

- Medtronic plc — Dublin, Ireland

- Arthrex Inc. — Naples, Florida, USA

- Exactech Inc. — Gainesville, Florida, USA

- MicroPort Orthopedics Inc. — Arlington, Tennessee, USA

- Aesculap AG (B. Braun) — Tuttlingen, Germany

- Conformis Inc. — Billerica, Massachusetts, USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Joint Cement Spacer Mold Market Report |

| Base Year | 2024 |

| Segment by Type | · Plastic Molds

· Metal Molds · Composite Materials |

| Segment by Application | · Residential Construction

· Commercial Construction · Oil & Gas Sector · Pipeline Installations |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global joint cement spacer mold market is expected to grow from 2025 to 2033, driven by its importance in the construction and oil & gas industries. These molds play a vital role in maintaining structural integrity and managing resources efficiently.

As cities continue to grow, the need for specialized molds is projected to increase. This growth will be fueled by advancements in technology and material science.

Key Points:

- Technological Advancements: Innovations such as 3D printing are transforming the production of joint cement spacer molds, offering enhanced customization and improved performance.

- Market Dynamics: The need for effective solutions to joint-related infections and infrastructure demands fuels market growth, with antibiotic-loaded cement spacers being a cornerstone of modern treatment protocols.

- Competitive Landscape: Leading manufacturers are navigating challenges such as raw material price volatility and competition from alternative products by leveraging partnerships and strategic acquisitions.

All stakeholders have opportunities to harness these trends, optimizing their strategies to align with future market directions. The industry’s focus on innovation and efficiency continues to shape its trajectory, promising new avenues for growth and development. As this market evolves, staying informed about emerging trends will be key for anyone looking to capitalize on its potential.

Global Joint Cement Spacer Mold Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Joint Cement Spacer Mold Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Joint Cement Spacer MoldMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Joint Cement Spacer Moldplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Joint Cement Spacer Mold Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Joint Cement Spacer Mold Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Joint Cement Spacer Mold Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofJoint Cement Spacer MoldMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the significance of analyzing the upstream and downstream industry chain in the joint cement spacer mold market?

Analyzing the upstream and downstream industry chain is crucial for understanding the supply chain dynamics that affect market performance. It involves examining suppliers and manufacturers in the upstream chain, as well as distributors and end-users in the downstream chain, to identify how these relationships influence overall market trends.

What key trends are driving growth in the joint cement spacer mold market?

Key trends driving growth in the joint cement spacer mold market include increasing demand for joint replacement surgeries due to an aging population and rising prevalence of musculoskeletal disorders, advancements in materials like bioactive and antimicrobial spacer molds, and rising healthcare expenditure globally, especially in emerging economies.

What challenges do manufacturers face in the joint cement spacer mold market?

Manufacturers face several challenges including intense competition and pricing pressures, regulatory compliance issues that can hinder product approval and market entry, and economic factors such as fluctuations in raw material prices that impact production costs.

How do geopolitical factors influence the global joint cement spacer mold industry?

Geopolitical factors significantly influence the global joint cement spacer mold industry through global trade policies, particularly tariffs imposed on imported spacer molds from certain countries. These policies can affect pricing, availability, and competitive dynamics within the market.

What are the different types of joint cement spacer molds based on material composition?

Joint cement spacer molds can be segmented based on material types including Polyethylene (PE), Polypropylene (PP), PVC, PET, among others. Each material offers distinct properties that cater to various surgical applications and patient needs.

What is the future outlook for the joint cement spacer mold industry?

The future outlook for the joint cement spacer mold industry suggests continued growth driven by technological advancements, evolving consumer behaviors regarding joint surgeries, and potential developments in healthcare policies that may enhance access to these medical devices.