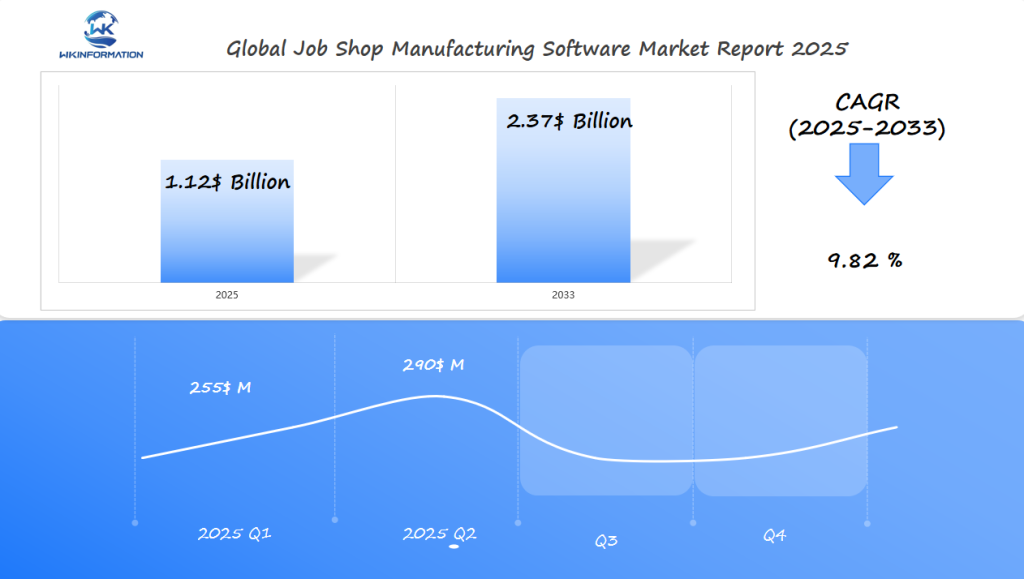

Job Shop Manufacturing Software Market Expected to Reach $1.12 Billion by 2025: Strategic Analysis of the U.S., Germany, and Japan

Explore the Job Shop Manufacturing Software Market trends, growth drivers, and competitive landscape. Get insights into market size, key players, and future opportunities.

- Last Updated:

Job Shop Manufacturing Software Market Q1 and Q2 of 2025 Forecast and Regional Focus

The Job Shop Manufacturing Software market is anticipated to reach $1.12 billion in 2025, growing at a CAGR of 9.82% through 2033. The market shows uneven growth in the first two quarters, with Q1 revenues estimated at $255 million and Q2 increasing to $290 million. This reflects rising demand for flexible, scalable software solutions to optimize production workflows.

Key Takeaways

- Job shop manufacturing software market expected to reach $1.12 billion by 2025

- Significant technological innovations driving market expansion

- Increasing demand for efficient production management solutions

- Digital transformation reshaping manufacturing operational strategies

- Small to medium-sized manufacturers leading software adoption trends

In-Depth Upstream and Downstream Industry Chain Analysis of Job Shop Manufacturing Software

Job shop manufacturing software is key to linking software development and manufacturing. It shows a complex network of parts that boost innovation and efficiency in custom making.

The making of job shop manufacturing software goes through many important steps:

- Getting needs from manufacturing folks

- Creating software that’s flexible and easy to change

- Adding smart algorithms

- Testing it to make sure it works with manufacturing

Key Components of Manufacturing Software Integration

Integrating manufacturing needs a smart approach to software making. It’s about building platforms that can easily link different production systems.

| Software Layer | Integration Function | Key Performance Indicators |

| Production Planning | Resource allocation | Efficiency optimization |

| Scheduling Module | Real-time workflow management | Reduced downtime |

| Quality Control | Automated inspection processes | Error reduction |

The upstream chain includes software architects, hardware engineers, and experts in making. They work together to create new solutions. The downstream part is about putting these technologies in different making places, making sure they can grow and change.

Strategic Technology Ecosystem

New technologies such as artificial intelligence and machine learning are transforming job shop software. These advancements enable smarter and more predictive production processes.

Market Trends Reflecting Demand for Customization and Operational Efficiency in Job Shops

The job shop manufacturing software market is changing fast. Manufacturers want solutions that offer customization and better efficiency. This is to tackle complex production challenges.

Here are some key trends driving this demand:

- Growing demand for cloud-based solutions that provide flexible, scalable infrastructure

- Rising emphasis on customization to address unique manufacturing workflows

- Integration of advanced technologies like AI and machine learning

- Enhanced mobile accessibility for real-time shop floor monitoring

Customization Driving Software Evolution

Modern job shops need software that can quickly adapt to new production needs. The trend towards customizable platforms helps manufacturers. They can tailor solutions to fit their specific workflow needs.

| Market Trend | Impact on Job Shops | Key Benefits |

| Cloud-Based Solutions | Reduced IT infrastructure costs | Scalability and remote access |

| AI Integration | Predictive maintenance | Improved scheduling accuracy |

| Mobile Accessibility | Real-time decision making | Enhanced operational visibility |

Manufacturers see the value in investing in adaptable, tech-advanced software. It’s key to staying competitive in a fast-changing production world.

Regulatory Restrictions Affecting Data Security and Industry Standards in Job Shop Software

The job shop manufacturing software world is getting more complex. This is due to strict rules and growing data security issues. Companies must deal with many standards and rules that guide their tech choices and how they work.

Manufacturers face many rules that affect their software choices and use. Important areas include:

- Protecting sensitive intellectual property

- Ensuring robust data security protocols

- Meeting industry-specific compliance mandates

- Implementing cybersecurity best practices

Critical Compliance Frameworks

Different manufacturing areas need their own rules. For example, aerospace and medical device makers have to follow stricter data protection rules than others.

| Industry Sector | Key Regulatory Requirements | Compliance Focus |

| Aerospace | AS9100 Standard | Quality Management |

| Medical Devices | FDA 21 CFR Part 820 | Quality System Regulation |

| General Manufacturing | GDPR Data Protection | Personal Data Security |

Software makers must keep up with new rules. They need to spend a lot on research, development, and security updates. This helps them meet standards and keep important manufacturing data safe.

Geopolitical Factors Influencing Market Expansion and Technology Transfer

Geopolitical factors play a crucial role in shaping the expansion of the job shop manufacturing software market and the transfer of related technologies across regions. These factors influence regulatory environments, cross-border collaborations, investment flows, and technology adoption rates.

Trade Policies and International Relations

Trade agreements, tariffs, and diplomatic relations between countries impact how easily software vendors can enter new markets or establish partnerships. Favorable trade policies encourage market expansion by reducing barriers, while geopolitical tensions may restrict technology transfer due to export controls or sanctions.

Regional Regulatory Frameworks

Different countries enforce varying regulations on data security, intellectual property protection, and industry compliance standards that affect job shop manufacturing software:

- North America emphasizes innovation-friendly policies with robust IP laws but strict data privacy regulations like GDPR for European operations.

- Europe, led by Germany’s advanced manufacturing sector, enforces stringent quality management standards (e.g., AS9100) and strong data protection rules.

- Asia-Pacific, including Japan, balances precision manufacturing requirements with emerging technology adoption supported by government initiatives.

These diverse regulatory landscapes require software providers to customize solutions to comply locally while maintaining global interoperability.

Technology Sovereignty and Data Localization

Some countries pursue technology sovereignty policies that encourage local development of manufacturing software or mandate data storage within national borders. This can limit foreign vendors’ market access or increase costs due to duplicated infrastructure, affecting global technology transfer dynamics.

Type Segmentation Detailing On-Premise and Cloud-Based Job Shop Manufacturing Software Solutions

Job shop manufacturing software has changed a lot. Now, businesses have many options to fit their needs. There are three main types: on-premise software, cloud-based solutions, and hybrid models.

Choosing the right software is a big decision for job shops today. Each type has its own benefits and challenges:

On-Premise Software Characteristics

- Complete control over data security

- Direct hardware management

- Customizable infrastructure

- Higher upfront investment

Benefits of Cloud-Based Solutions

- Scalable infrastructure

- Reduced IT maintenance costs

- Automatic software updates

- Accessible from multiple devices

Hybrid models offer a new way for job shops. They combine on-premise security with cloud convenience. This creates a strong tech setup.

Choosing the Right Deployment Strategy

Choosing the right software deployment strategy depends on several factors, including:

- Company size

- Industry regulations

- Budget constraints

- Existing technology setup

For small to medium-sized job shops, cost-effectiveness may lead them to opt for cloud-based solutions. On the other hand, larger companies might prefer hybrid or on-premise deployments to maintain control over their data.

Application Analysis Covering Production Planning, Scheduling, and Quality Control in Job Shops

Job shop manufacturing software is key for businesses wanting to improve their production. It makes complex manufacturing easier by combining important production management tasks.Application Analysis Covering Production Planning, Scheduling, and Quality Control in Job Shops

Job shop manufacturing software is key for businesses wanting to improve their production. It makes complex manufacturing easier by combining important production management tasks. When analyzing applications, it’s crucial to consider how each deployment strategy impacts production planning, scheduling, and quality control processes within job shops.

Today’s job shop manufacturing software offers many important features:

- Production planning optimization

- Dynamic resource allocation

- Real-time scheduling management

- Advanced quality control tracking

Strategic Production Planning Capabilities

Effective production planning requires intelligent software capable of managing multiple variables simultaneously. Job shop software assists manufacturers in organizing their production, optimizing resource utilization, and identifying issues proactively.

Scheduling and Resource Management

Scheduling is complex and needs advanced tools. Job shop software offers flexible scheduling that lets for quick changes. This ensures machines are used well and downtime is kept low.

| Software Capability | Key Benefits | Operational Impact |

| Production Planning | Workflow optimization | Reduced waste |

| Resource Allocation | Efficient material management | Cost reduction |

| Quality Control | Defect tracking | Improved product consistency |

Quality Control Integration

Quality control is a vital part of job shop manufacturing software. Automated tracking systems help manufacturers keep an eye on production standards. They can spot defects and meet strict quality rules.

Global Regional Overview Mapping Adoption and Market Growth of Job Shop Manufacturing Software

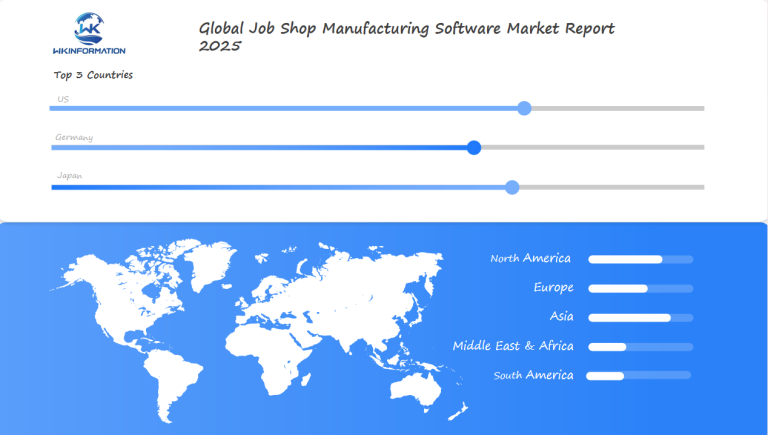

The job shop manufacturing software market is growing fast around the world. Each region has its own unique needs and technology levels. This diversity drives growth and new ideas in the market.

In North America, companies are quick to adopt new software. This is thanks to a strong tech base and a focus on digital change. The US is leading the way, with businesses eagerly embracing advanced job shop software.

Regional Market Dynamics

- North America: Highest software penetration rate at 35% market share

- Europe: Strong adoption driven by Industrie 4.0 initiatives

- Asia-Pacific: Rapidly expanding manufacturing sectors accelerating software integration

The Asia-Pacific region is experiencing rapid growth in its manufacturing industry, with countries such as China, Japan, and South Korea taking the lead. These nations require software solutions that can scale alongside their businesses.

Key Regional Adoption Factors

- Technological infrastructure maturity

- Manufacturing sector complexity

- Government digital transformation policies

- Investment in research and development

In Europe, especially in Germany and Switzerland, innovation is key. Their focus on precision and quality means they need top-notch software. This software helps them work more efficiently and improve their products.

U.S. Leadership in Job Shop Manufacturing Software Innovation and Adoption

The United States leads in job shop manufacturing software innovation. It drives technological changes that change the industrial world. The U.S. market is key for developing top solutions that make operations more efficient and productive for manufacturers.

- Robust research and development investments

- Strong collaboration between tech companies and manufacturing firms

- Supportive government initiatives promoting digital transformation

Technological Leadership and Adoption Rates

Job shop manufacturing software adoption in the U.S. has grown significantly. Small and medium-sized manufacturers see the value of advanced software solutions.

Industry Transformation Strategies

Manufacturing USA institutes have been key in speeding up software innovation. These platforms connect research and practical use, keeping U.S. job shops competitive worldwide.

Germany's Advanced Manufacturing Sector and Its Influence on Job Shop Software Development

German manufacturing leads in technology, changing job shop software development a lot. It’s a big player in Industrie 4.0, leading in digitalizing industries.

In Germany, the industrial IoT is a complex but advanced system. Manufacturers are making software that makes operations more efficient and connected.

Key Technological Drivers in German Manufacturing

- Advanced digital transformation strategies

- Comprehensive industrial IoT integration

- Robust software development frameworks

- Precision-driven manufacturing processes

Industrie 4.0 has changed how job shops develop software. German companies are making platforms for real-time data, predictive maintenance, and smooth production management.

| Technology Focus | Implementation Strategy | Expected Outcome |

| Industrial IoT | Networked Manufacturing Systems | Enhanced Production Efficiency |

| Industrie 4.0 | Smart Factory Automation | Reduced Operational Costs |

| Digital Twin Technology | Simulation and Optimization | Improved Product Development |

German manufacturers are setting global standards in job shop software development. They’re making manufacturing solutions that are smart and scalable.

Japan's Precision Manufacturing Industry and Its Unique Job Shop Software Requirements

Japanese manufacturing leads the world in innovation, setting high standards for precision and technology. The country’s software for manufacturing is a mix of advanced technology and a focus on always getting better.

Japan’s success in manufacturing comes from its special way of using technology. The software for job shops is made with the idea of continuous improvement in mind. It focuses on:

- Continuous process optimization

- Real-time performance tracking

- Seamless robotics integration

- Advanced quality management protocols

Robotics and Software Synergy

Robotics play a crucial role in Japanese manufacturing software. These systems assist manufacturers in:

- Automating complex production workflows

- Minimizing human error

- Enhancing precision in manufacturing

- Implementing adaptive learning algorithms

The emphasis on quality management goes beyond mere statistics. Japanese job shop software employs sophisticated algorithms to forecast and avert issues, enabling continuous improvement.

As manufacturing evolves worldwide, Japan’s strategy for job shop software continues to set the benchmark. It demonstrates that genuine innovation arises from a combined understanding of technology and human potential.

Future Development Focused on AI and IoT Integration in Job Shop Manufacturing Software

The manufacturing world is changing fast thanks to new tech. AI and IoT are making job shops more efficient and innovative.

Companies are using advanced digital tools to change how they make things. Predictive maintenance is a big win, helping avoid equipment breakdowns before they happen.

Key Technological Advancements

- Digital twins create virtual replicas of physical manufacturing systems

- Real-time analytics provide instant decision-making support

- Machine learning algorithms optimize production scheduling

- IoT sensors enable continuous performance monitoring

Digital twins help make manufacturing better by simulating processes. Intelligent systems can predict problems and suggest fixes, cutting downtime and boosting efficiency.

Transformative Impact of AI Technologies

AI is not just making things better; it’s changing how we make things. Predictive maintenance, for example, can cut equipment failures by 70%, making things more reliable.

Job shops that adopt these new tech will stay ahead in the manufacturing world.

Competitive Landscape Featuring Key Job Shop Manufacturing Software Vendors

Key players in the job shop manufacturing software market are focusing on cloud-based platforms, real-time production tracking, and AI-powered scheduling to improve operational efficiency and customization capabilities. They are expanding into emerging regions like Southeast Asia and Central Europe, where small and mid-sized manufacturers are increasingly adopting digital solutions to stay competitive in evolving industrial landscapes.

Key Players:

-

JobBOSS² (United States)

-

Shoptech E2 Shop System (United States)

-

ProShop ERP (United States)

-

MRPeasy (Estonia)

-

Total ETO (Canada)

-

ShopXpert (India)

-

Epicor Kinetic (United States)

-

Acumatica Cloud ERP (United States)

-

NetSuite ERP (United States)

-

CADDi Drawer (Japan)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Job Shop Manufacturing Software Market Report |

| Base Year | 2024 |

| Segment by Type |

· On-Premise · Cloud-Based |

| Segment by Application |

· Production Planning · Scheduling · Quality Control |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Job Shop Manufacturing Software Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Job Shop Manufacturing Software Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Job Shop Manufacturing SoftwareMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Job Shop Manufacturing SoftwarePlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Job Shop Manufacturing Software Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Job Shop Manufacturing Software Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Job Shop Manufacturing Software Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Job Shop Manufacturing SoftwareMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is job shop manufacturing software?

Job shop manufacturing software helps small to medium-sized factories manage their work. It handles planning, scheduling, and quality control. This software makes factories work better and more efficiently.

How does cloud-based job shop software differ from on-premise solutions?

Cloud-based software is more flexible and cheaper to maintain. It’s easy to access from anywhere. On the other hand, on-premise solutions give more control over data and are better for companies with special security needs.

What are the key benefits of job shop manufacturing software?

The main advantages are better planning, scheduling, and quality control. It also helps allocate resources well, monitor in real-time, cut costs, and boost efficiency.

How is AI transforming job shop manufacturing software?

AI is changing the game by predicting maintenance needs, improving scheduling, and offering deep analytics. It helps make decisions quickly and allocate resources smartly.

What regulatory considerations impact job shop manufacturing software?

Important rules include data privacy laws like GDPR and industry-specific rules. There are also cybersecurity standards to protect data and intellectual property.

Which regions are leading in job shop manufacturing software adoption?

North America, Europe (especially Germany), and the Asia-Pacific are leading. Each area has its own tech approaches and needs.

What factors are driving growth in the job shop manufacturing software market?

Growth comes from the need for better production management and tech advancements. The push for Industry 4.0, custom solutions, and digital transformation also play a role.

How important is mobile accessibility in modern job shop software?

Mobile access is key. It lets managers and workers check production, make decisions, and track progress from phones or tablets. This boosts flexibility and quick action.

What is the projected market size for job shop manufacturing software?

The market is expected to reach approximately $1.12 billion by 2025. This indicates significant growth and increased adoption across various manufacturing sectors.

How do job shop software solutions integrate with existing manufacturing equipment?

Modern software connects through Industrial IoT platforms. This allows easy data sharing, real-time monitoring, and better communication between systems and equipment. It makes production smoother and more efficient.