Home Appliances Glass Market Forecasted to Hit $8.26 Billion by 2025: Transparent Growth in China, Italy, and the U.S.

Explore the Home Appliances Glass market with insights on key drivers of growth, challenges, industry chain dynamics, and global market segmentation. Discover the impact of smart home trends, geopolitical influences, and future technologies shaping the industry. Gain valuable information on energy-efficient glass technologies driving market demand and the role of key players like China, Italy, and the U.S. in this evolving market landscape.

- Last Updated:

Home Appliances Glass Market in Q1 and Q2 of 2025

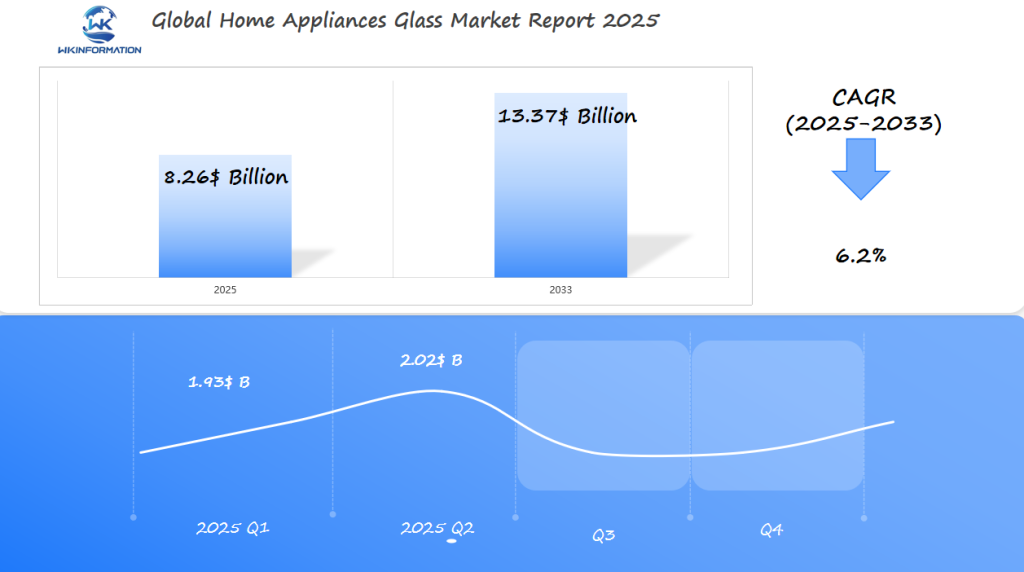

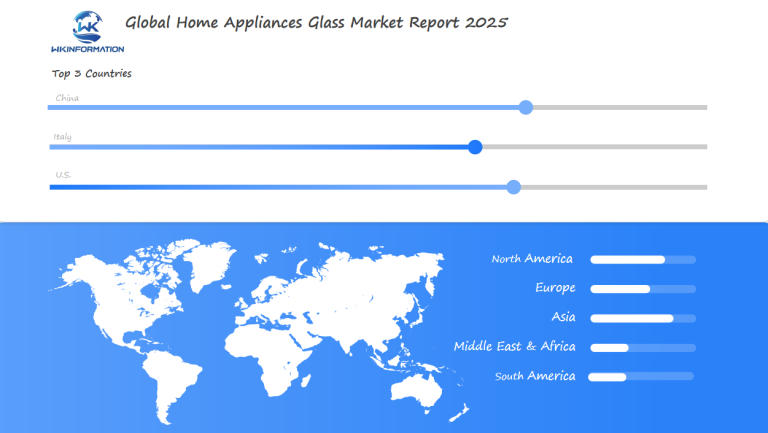

The Home Appliances Glass market is on track to reach $8.26 billion in 2025, registering a CAGR of 6.2% from 2025 to 2033. Q1 market size is forecasted at $1.93 billion, climbing to $2.02 billion by Q2. China dominates production thanks to its extensive appliance manufacturing ecosystem and mature supply chains. Italy is investing in high-end, design-centric appliance glass for luxury home products, capitalizing on consumer demand for aesthetics and energy efficiency. In the U.S., smart home integration is boosting the need for durable, heat-resistant glass in ovens, refrigerators, and washers. New advancements in tempered and coated glass, including anti-fingerprint and low-E technologies, are contributing to innovation in both form and function.

Key Takeaways

- The global market is expected to reach $8.26 billion by 2025.

- Increasing demand for smart home appliances drives growth.

- Energy-efficient glass technologies are in high demand.

- China, Italy, and the U.S. are key players in the industry.

- The market is witnessing significant growth due to technological advancements.

Home Appliances Glass market upstream and downstream industry chain outlook

The industry chain of the Home Appliances Glass market includes raw material suppliers, manufacturers, and appliance makers. This intricate network is essential for understanding the market’s dynamics and predicting its future growth.

Understanding the Industry Chain

The Home Appliances Glass market’s industry chain can be broken down into upstream, midstream, and downstream segments.

1. Upstream Segment

The upstream segment involves raw material suppliers who provide essential materials like silica sand, soda ash, and limestone for glass manufacturing.

2. Midstream Segment

The midstream segment is dominated by glass manufacturers who produce various types of glass, including tempered, laminated, and patterned glass, used in home appliances. Companies in this segment employ advanced manufacturing technologies to meet the increasing demand for high-quality glass.

3. Downstream Segment

The downstream segment comprises appliance makers who integrate the glass products into their appliances, such as ovens, refrigerators, and microwaves. The demand from this segment drives the growth of the Home Appliances Glass market.

Key players in the industry chain are focusing on innovations and efficiency improvements. For instance, advancements in glass manufacturing technologies have enabled the production of thinner, stronger, and more energy-efficient glass.

- Raw material suppliers are exploring sustainable sourcing options.

- Glass manufacturers are investing in research and development to improve product quality.

- Appliance makers are integrating smart technologies into their products, driving the demand for specialized glass.

Understanding these dynamics is essential for stakeholders to navigate the market effectively and capitalize on emerging opportunities.

Smart home trends fueling demand in the Home Appliances Glass market

As smart home technology advances, the demand for specialized glass in home appliances is on the rise. The integration of smart features into home appliances is enhancing user experience and driving the need for advanced glass materials that can support these technologies.

The Rise of Smart Home Appliances

The home appliances industry is undergoing a significant transformation with the advent of smart home technology. Smart home appliances are becoming increasingly popular, offering consumers convenience, energy efficiency, and innovative features. These appliances require specialized glass that can withstand various stresses while maintaining aesthetic appeal.

The Role of Glass Technology

Glass technology is playing a crucial role in this transformation. Manufacturers are developing glass materials that are not only durable and resistant to thermal stress but also capable of integrating smart features. For instance, glass used in smart ovens and microwaves must be able to withstand high temperatures while providing a clear display of cooking settings.

Impact on Demand for Specialized Glass

The increasing demand for smart home appliances is directly impacting the demand for specialized glass. The need for glass that can support smart features, such as touch controls and displays, is driving innovation in glass technology. This includes the development of:

- Tempered glass with enhanced strength and durability

- Laminated glass for improved safety and security

- Coated glass for energy efficiency and aesthetic appeal

Future Growth and Expectations

As the home appliances industry continues to evolve, the demand for advanced glass materials is expected to grow. Manufacturers are investing in research and development to create glass that not only meets the functional requirements of smart appliances but also enhances their aesthetic appeal.

The trend towards smart homes is expected to continue, driving further innovation in glass technology. As consumers become more accustomed to smart home devices, their expectations for appliance performance, energy efficiency, and design will continue to shape the market.

Restrictions: breakage risk, weight, energy standards, and coating tech

The Home Appliances Glass industry faces challenges such as breakage and energy efficiency issues. As the market continues to grow, manufacturers must tackle these problems to ensure glass is widely used in home appliances.

Breakage risk

The risk of breakage is a major concern because it can pose safety risks and increase maintenance costs for consumers. To address this, manufacturers are creating tempered glass and other sturdy glass types that can handle everyday wear and tear.

Challenges Facing the Home Appliances Glass Market

Weight Considerations

Weight considerations are a significant challenge in the Home Appliances Glass market. Glass is generally heavier than other materials, which can impact the overall design and functionality of appliances. To address this, manufacturers are exploring lightweight glass technologies that can reduce the weight of appliances without compromising their durability.

Stringent Energy Standards

Stringent energy standards are also driving innovation in the Home Appliances Glass market. Manufacturers must develop glass that not only meets energy efficiency requirements but also provides optimal performance. This has led to the development of advanced coating technologies that can enhance the energy efficiency of appliances.

The following table highlights some of the key challenges facing the Home Appliances Glass market and potential solutions:

| Challenge Potential Solution Breakage Risk | Tempered Glass, Durable Coatings |

| Weight Considerations | Lightweight Glass Technologies |

| Energy Standards | Advanced Coating Technologies |

As the Home Appliances Glass market continues to evolve, addressing these challenges will be crucial to its success. By developing innovative glass technologies and manufacturing processes, manufacturers can overcome these challenges and capitalize on the growing demand for glass in home appliances.

Geopolitical Influence on Glass Material Supply and Appliance Manufacturing

Geopolitics significantly affects the availability and price of glass materials used in home appliances. Factors such as trade policies, regional conflicts, and global economic changes directly influence the Home Appliances Glass market.

Global Supply Chain Dynamics

The global supply chain for glass materials is complex, involving multiple parties across different countries. Trade policies and tariffs imposed by governments can either make it easier or harder for goods to move, affecting the overall cost and availability of glass materials.

Regional conflicts and geopolitical tensions can disrupt supply chains, leading to fluctuations in market prices. For example, conflicts in areas rich in raw materials needed for glass production can cause shortages and increased costs.

The dynamics of the global supply chain also influence the manufacturing of appliances. Appliance manufacturers heavily depend on a steady supply of glass materials to keep production levels up. Any disruption in the supply chain can lead to production delays and increased costs, ultimately impacting the end consumer.

- Trade policies affecting import/export of glass materials

- Regional conflicts disrupting supply chains

- Global economic shifts influencing demand and supply

Understanding these geopolitical factors is crucial for stakeholders in the Home Appliances Glass market. By analyzing these dynamics, manufacturers and suppliers can better navigate the complexities of the global supply chain and make informed decisions to reduce risks and take advantage of opportunities.

Home Appliances Glass market segmentation by type: tempered, laminated, patterned

The market for Home Appliances Glass is segmented based on the type of glass used, which includes tempered, laminated, and patterned glass. Each type has its unique characteristics and applications in home appliances.

- Tempered Glass: Also known as toughened glass, tempered glass is processed to enhance its strength and durability. It is widely used in home appliances such as ovens and cooktops due to its ability to withstand high temperatures and thermal stress.

- Laminated Glass: Laminated glass consists of two or more layers of glass bonded together with an interlayer. This type of glass offers increased safety and security, making it suitable for applications like refrigerators and washing machines where impact resistance is important.

- Patterned Glass: Patterned glass features decorative designs or textures that provide privacy while allowing light to pass through. It is commonly used in microwave ovens and other appliances where aesthetics play a role in design.

Types of Glass Used in Home Appliances

1. Laminated Glass

Laminated glass consists of multiple layers of glass bonded together with an interlayer. This type of glass is valued for its safety features, as it holds together when broken, reducing the risk of injury. Laminated glass is often used in applications where safety is a concern.

2. Patterned Glass

Patterned glass, also known as figured glass, has a decorative pattern or texture. It is used in home appliances to provide a unique aesthetic appeal while maintaining functionality. The demand for patterned glass is driven by consumer preferences for stylish and modern appliances.

The market share of each glass type varies based on factors such as safety regulations, consumer preferences, and technological advancements. Understanding the characteristics and applications of each glass type is crucial for manufacturers to meet the evolving demands of the home appliances market.

Home Appliances Glass Market Segmentation by Application: Ovens, Refrigerators, Microwaves, Induction Cooktops

plays a crucial role in the home appliances industry, with applications ranging from ovens to induction cooktops. The versatility of glass makes it an ideal material for various home appliances, driven by consumer preferences for durability, aesthetics, and functionality. For instance, the use of glass in ovens not only enhances the design but also provides durability. Similarly, glass is increasingly being used in refrigerators and microwaves, offering a sleek aesthetic while ensuring functionality. Finally, the application of glass in induction cooktops is a testament to its versatility and adaptability in modern home appliances.

Applications of Home Appliances Glass

The Home Appliances Glass market is divided into several main categories based on its use: ovens, refrigerators, microwaves, and induction cooktops. Each of these categories has its own specific needs and trends that affect the demand for glass.

Ovens

In ovens, glass is used for doors and sometimes for shelves. The demand here is driven by the need for heat resistance and visibility. Consumers prefer glass that can withstand high temperatures without compromising on clarity or durability.

Refrigerators

Refrigerators use glass for shelves and sometimes for doors, especially in high-end models. The trend towards smart refrigerators and customizable interiors is boosting the demand for specialized glass that can support these features.

Microwaves

Microwaves also utilize glass for their doors, requiring it to be both heat-resistant and transparent. The growing popularity of microwaves in urban households is contributing to the increased demand for microwave-specific glass.

Induction Cooktops

Induction cooktops represent another significant application, where glass is used for the cooking surface. The trend towards sleek, modern kitchen designs is driving the demand for durable, high-quality glass that can withstand the rigors of cooking.

The market trends in each of these segments are influenced by factors such as technological advancements, consumer preferences, and design trends. Understanding these trends is crucial for manufacturers to tailor their products to meet the specific requirements of each appliance segment.

Global Home Appliances Glass Market Regional Evaluation

Regional dynamics play a crucial role in shaping the Home Appliances Glass market, with distinct patterns emerging in Asia, Europe, and North America. The market’s growth and trends are significantly influenced by local demand, manufacturing capabilities, and regulatory environments.

Key Regional Insights

Asia

The Home Appliances Glass market in Asia is driven by the presence of major manufacturing hubs, particularly in China. The region’s growing demand for home appliances, coupled with its competitive manufacturing landscape, contributes to its dominant market position.

Europe

InEurope, the market is characterized by a strong emphasis on energy efficiency and sustainability. The region’s stringent regulations regarding energy consumption and environmental impact drive the demand for high-quality, eco-friendly glass for home appliances.

North America

North America represents another significant market, with the United States being a major contributor. The region’s market is influenced by consumer preferences for smart home appliances and the integration of advanced technologies.

Key Drivers of Growth

- Increasing demand for smart home appliances in North America and Europe.

- Growing manufacturing capabilities in Asia, particularly in China.

- Rising emphasis on energy efficiency and sustainability in Europe.

The regional analysis of the Home Appliances Glass market highlights the diverse trends and growth prospects across different regions. Understanding these regional dynamics is crucial for stakeholders to identify emerging opportunities and navigate the complex global market landscape.

China's Home Appliances Glass Market: Massive Production and Low-Cost Advantage

China plays a crucial role in the global home appliances glass market due to its extensive manufacturing infrastructure. The country’s ability to produce large quantities of high-quality glass at competitive prices has greatly impacted the global supply chain.

Factors Behind China’s Dominance

China’s leading position in the home appliances glass industry can be attributed to its:

- Large-scale production capabilities

- Economical manufacturing processes

The country’s glass manufacturing industry has made significant investments in advanced technology, allowing for the production of various types of glass, such as tempered, laminated, and patterned glass, which are utilized in different home appliances.

China’s Dominance in the Market

The appliance glass market in China is driven by the country’s extensive manufacturing base and the presence of numerous suppliers. This has created a competitive environment that benefits both local and international manufacturers.

Low-Cost Advantage

A key factor contributing to China’s success in the global market is its low-cost advantage. The country’s well-developed infrastructure, skilled workforce, and favorable business environment enable manufacturers to keep production costs low, making Chinese glass products highly competitive in the international market.

Regional Market Analysis

From a regional market analysis perspective, China’s influence on the global home appliances glass market is significant. The country’s large production capacity not only meets domestic demand but also caters to international markets, making it a crucial player in the global supply chain.

China’s massive production capabilities and low-cost advantage have cemented its position as a leader in the global home appliances glass market. As the demand for home appliances continues to grow, China’s role in the global market is expected to remain significant.

Italy's Home Appliances Glass Market: Premium Aesthetics and Design Integration

Italy’s Home Appliances Glass industry is shaping the future of appliance design with a strong focus on style and functionality. Italian manufacturers are known for their premium designs and innovative use of glass technology in home appliances.

Italy’s Design Philosophy

Italian design is highly regarded for its emphasis on aesthetics without compromising functionality. The Home Appliances Glass market in Italy reflects this philosophy, with manufacturers incorporating advanced glass technologies to create sleek, modern appliances that are both visually appealing and highly functional.

Key Features of Italian Home Appliances Glass

- Premium Materials: Use of high-quality glass that ensures durability and aesthetic appeal.

- Innovative Designs: Integration of cutting-edge design principles to create modern and sleek appliances.

- Advanced Technologies: Incorporation of advanced glass technologies such as tempering and coating to enhance performance and safety.

Italian Home Appliances Glass Design

The Italian Home Appliances Glass industry is also characterized by its ability to balance form and function. Manufacturers are continually pushing the boundaries of what is possible with glass in home appliances, from creating complex shapes to integrating glass with other materials.

Market Impact

The influence of Italian design and manufacturing in the Home Appliances Glass market is significant. Italian companies are leaders in producing high-end appliances that set standards for the industry globally.

| Feature | Description | Benefit |

| Tempered Glass | Heat-treated glass for enhanced strength | Increased durability and safety |

| Laminated Glass | Multiple layers of glass for improved security | Enhanced safety and reduced noise |

| Coated Glass | Special coatings for energy efficiency and aesthetics | Improved energy efficiency and design flexibility |

Italy’s contribution to the Home Appliances Glass market is not just about aesthetics; it’s also about driving innovation and setting new standards for the industry. As the demand for smart and energy-efficient appliances continues to grow, Italian manufacturers are well-positioned to lead the way.

U.S. Home Appliances Glass Market: Energy Compliance and Smart Appliance Use

The U.S. market for Home Appliances Glass is rapidly evolving with a strong focus on innovation and environmental regulations. The demand for energy-efficient appliances is increasing, driven by consumer awareness and government regulations aimed at reducing energy consumption.

Energy Efficiency and Smart Appliances in the U.S.

The U.S. Department of Energy has implemented strict energy efficiency standards for home appliances, which has led to an increased demand for specialized glass that can help appliances meet these standards. For example, low-e (low emissivity) glass is being used in refrigerators and ovens to reduce heat transfer and improve energy efficiency.

Smart appliances are another significant trend influencing the Home Appliances Glass market in the U.S. These appliances, which can be controlled and monitored remotely through smartphone apps, require specialized glass that can support touch-screen functionality and durability.

The market is also seeing a shift towards sustainable and eco-friendly materials, with manufacturers exploring the use of recyclable glass and minimizing waste in their production processes.

Key Drivers and Trends

- Increasing demand for energy-efficient appliances

- Growing adoption of smart home technologies

- Strict government regulations on energy consumption

- Advancements in glass technology, such as low-e coatings and tempered glass

As the U.S. Home Appliances Glass market continues to change, manufacturers will need to stay ahead by investing in research and development, and adopting innovative technologies that meet the evolving needs of consumers and regulatory requirements.

Future of Home Appliances Glass: nanocoatings and recyclable tech

The Home Appliances Glass industry is about to undergo a technological revolution, thanks to advancements in nanocoatings and recyclable glass. With consumers increasingly seeking sustainable and energy-efficient home appliances, manufacturers are embracing innovative glass technologies to meet these demands.

Emerging Technologies in Home Appliances Glass

Nanocoatings are one of the key emerging technologies in the Home Appliances Glass market. These coatings can provide enhanced durability, ease of cleaning, and even energy efficiency by reducing the need for frequent cleaning or improving the thermal insulation properties of glass.

Benefits and Applications of Nanocoatings

- Improved durability and resistance to scratches and corrosion

- Easy-to-clean surfaces, reducing maintenance needs

- Potential for energy efficiency improvements

Another significant trend is the development of recyclable glass technologies. As environmental concerns continue to grow, manufacturers are under increasing pressure to reduce waste and improve the recyclability of their products.

A Path to Sustainability: Recyclable Tech

| Technology | Benefits | Potential Impact |

| Nanocoatings | Durability, Easy Cleaning, Energy Efficiency | Reduced Maintenance, Lower Energy Consumption |

| Recyclable Glass | Environmentally Friendly, Reduced Waste | Sustainable Manufacturing, Lower Environmental Impact |

As these technologies continue to evolve, we can expect to see significant advancements in the Home Appliances Glass market. The integration of nanocoatings and recyclable tech will not only enhance the performance and sustainability of home appliances but also drive market growth and consumer satisfaction.

The future of Home Appliances Glass is bright, with emerging technologies set to play a crucial role in shaping the industry. As manufacturers continue to innovate and adopt these technologies, consumers can look forward to more efficient, sustainable, and high-performance home appliances.

Competitive insight into global Home Appliances Glass players

The global Home Appliances Glass market is expected to reach $8.26 billion by 2025, with key players such as China, Italy, and the U.S. driving significant growth. The industry chain includes raw material suppliers, glass manufacturers, and appliance makers, each playing a crucial role in the market’s dynamics. Smart home trends are fueling demand for specialized glass in appliances, with nanocoatings and recyclable tech shaping the future of the industry.

Key Players:

- SCHOTT AG – Germany

- Guardian Industries Holdings – United States

- Nippon Electric Glass Co., Ltd. – Japan

- Saint-Gobain S.A. – France

- AGC Inc. – Japan

- Corning Incorporated – United States

- Pilkington Group Limited – United Kingdom

- Xinyi Glass Holdings Limited – China

- Fuyao Glass Industry Group Co., Ltd. – China

- Sisecam Flat Glass – Turkey

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Home Appliances Glass Market Report |

| Base Year | 2024 |

| Segment by Type | ·Tempered Glass

·Laminated Glass ·Patterned Glass |

| Segment by Application | ·Ovens

·Refrigerators ·Microwaves ·Induction Cooktops |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Home Appliances Glass Market is about to experience significant growth, driven by the increasing use of smart home technologies and the rising demand for energy-efficient appliances.

As discussed earlier, trends such as the rise of smart homes, advancements in glass technology, and the increasing importance of energy efficiency are expected to shape the future of the Home Appliances Glass Market. The market forecast indicates a significant increase in demand, with the global market projected to reach $8.26 billion by 2025.

For stakeholders, understanding glass market trends and the changing landscape of the Home Appliances Glass Market is essential. This knowledge will help them navigate the challenges and opportunities in this industry. As manufacturers continue to innovate and embrace new technologies, we can expect to see major changes in the market. These transformations will be driven by the need for sustainability and energy efficiency.

Global Home Appliances Glass Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Home Appliances Glass Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Home Appliances Glass Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Home Appliances Glass Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Home Appliances Glass Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Home Appliances Glass Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Home Appliances Glass Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Home Appliances Glass Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Home Appliances Glass market?

The growth is attributed to the rising demand for smart home appliances and energy-efficient glass technologies.

What are the main challenges facing the Home Appliances Glass market?

The market faces challenges such as:

- The risk of breakage

- Weight considerations

- Stringent energy standards

- The need for advanced coating technologies

How is the Home Appliances Glass market segmented by type?

The market is divided into three types of glass: tempered, laminated, and patterned. Each type has its own distinct features and uses.

What are the key applications of Home Appliances Glass?

Home Appliances Glass is used in:

- Ovens

- Refrigerators

- Microwaves

- Induction cooktops

The demand for Home Appliances Glass is driven by consumer preferences, appliance design, and technological advancements.

How does geopolitics influence the Home Appliances Glass market?

Geopolitics play a crucial role in the supply chain of glass materials and appliance manufacturing, with trade policies, tariffs, and regional conflicts impacting availability and cost.

Why are nanocoatings and recyclable tech important for the future of Home Appliances Glass?

New technologies such as nanocoatings and recyclable glass are expected to play a significant role in shaping the future of the market. They will influence trends, cater to changing consumer demands, and promote environmental sustainability.

How does China’s production capacity affect the global Home Appliances Glass market?

China’s large production capabilities and cost-effective manufacturing advantage have a significant impact on the global supply chain and market dynamics.

What role does Italy play in the Home Appliances Glass market?

Italy is known for its high-end appliance designs and styles. It adds value to the market through:

- Incorporating design elements

- Using advanced glass technologies

- Implementing creative methods