Gypsum Plasterboard Market Expected to Exceed $2.65 Billion Globally by 2025: Significant Growth in China, Germany, and the U.S.

The gypsum plasterboard market is projected to surpass $2.65 billion globally by 2025, driven by rising construction activities worldwide. Key growth markets include China, Germany, and the U.S., fueled by urbanization, infrastructure development, and a focus on energy-efficient building materials. Regulatory compliance, environmental policies, and safety standards shape market dynamics.

- Last Updated:

Gypsum Plasterboard Market Q1 and Q2 of 2025 Forecast and Regional Insights

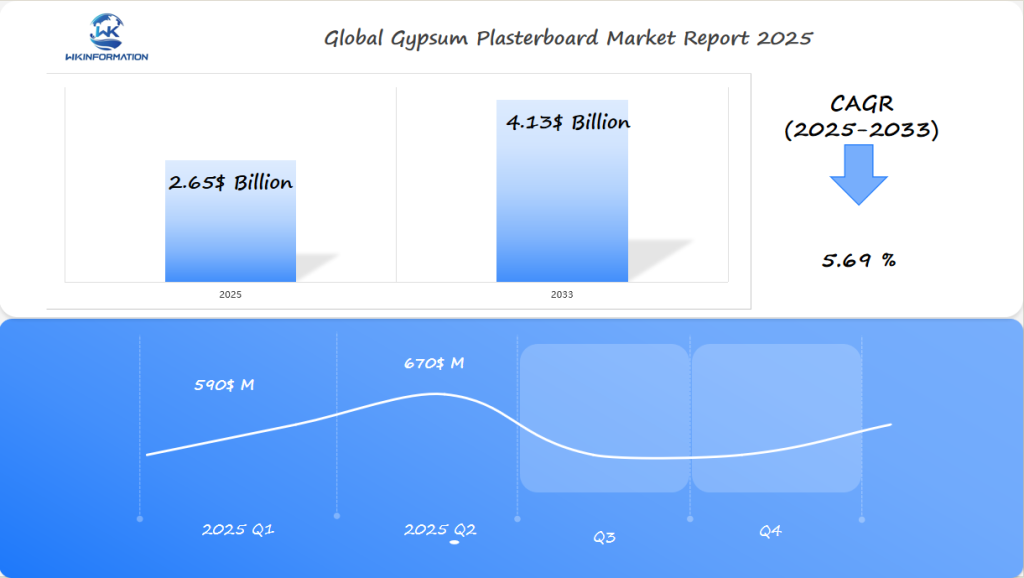

The Gypsum Plasterboard market is projected to hit $2.65 billion in 2025, expanding at a CAGR of 5.69% through 2033. The market in early 2025 is forecasted to be uneven, with Q1 estimated at $590 million and increasing to $670 million in Q2. This reflects fluctuations linked to construction seasonality and infrastructure development projects.

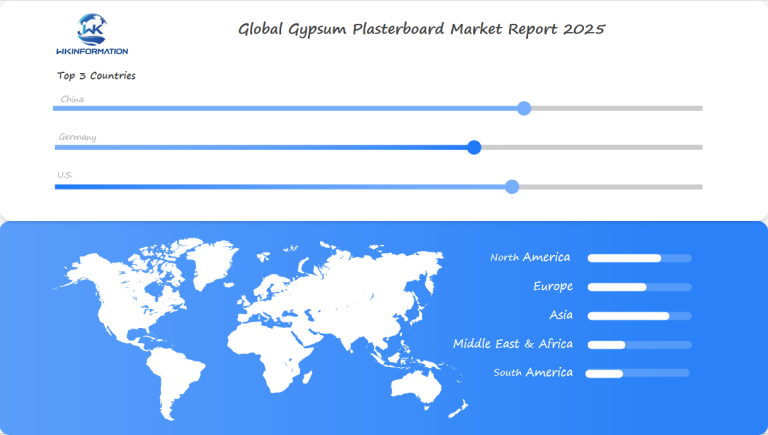

China dominates the market with large-scale urbanization and government-backed construction initiatives. Germany drives demand through stringent building codes emphasizing sustainability and energy efficiency. The U.S. market benefits from renovation activities and commercial construction growth. These regions are crucial for monitoring regulatory impacts, raw material supply, and technological innovations in building materials.

Analysis of Upstream and Downstream Industry Chain for Gypsum Plasterboard

Upstream Raw Materials

Upstream raw materials form the foundation of the gypsum plasterboard industry. The process begins with gypsum mining, where natural gypsum ore is extracted, crushed, and then calcined to produce stucco—the primary input for plasterboard manufacturing. Synthetic gypsum, a byproduct from flue-gas desulfurization in power plants, is increasingly used as an alternative to minimize environmental impact and ensure consistent quality.

Manufacturing Processes

Manufacturing processes involve blending calcined gypsum with additives such as starch, foaming agents, and fiberglass. This mixture is sandwiched between sheets of heavy paper or fiberglass mats before being cut, dried, and finished. Automation and continuous production lines have streamlined these steps, improving efficiency and reducing wastage across the supply chain gypsum board sector.

Distribution Channels

Distribution channels include wholesalers, building material retailers, direct sales to contractors, and specialized distributors servicing large institutional or infrastructural projects. End-user industries span residential construction, commercial buildings, industrial facilities, and institutional spaces such as schools and hospitals.

Suppliers and Contractors

Suppliers and contractors play a vital role in connecting upstream production with downstream applications. Raw material suppliers ensure steady input flow; manufacturers rely on logistics partners for timely delivery; contractors select appropriate boards based on project requirements. Collaboration across these nodes is essential for delivering high-quality products on schedule while meeting evolving demands for sustainability and performance.

Current Trends Driving Gypsum Plasterboard Market Expansion

Significant increases in construction spending are fueling gypsum plasterboard demand worldwide. Both residential and commercial sectors are expanding at an unprecedented pace, particularly as governments and private investors prioritize new infrastructure and urban renewal projects. Large-scale housing schemes in Asia Pacific nations and a surge in office and retail space construction across North America and Europe are central to this growth.

Growing Demand for Energy-Efficient Building Materials

A growing focus on energy-efficient building materials is reshaping project specifications. Developers, architects, and contractors increasingly select gypsum plasterboard for its lightweight nature, thermal insulation properties, and compatibility with green building certifications such as LEED or BREEAM. Products like moisture-resistant and fire-rated boards address sustainability mandates while enhancing occupant safety—two qualities now expected by both regulators and end users.

Urbanization Trends Driving Market Expansion

Rapid urbanization trends, especially in China, India, Indonesia, and Southeast Asian economies, drive substantial market expansion. Urban migration patterns create demand for high-density housing, schools, healthcare facilities, and commercial spaces—all of which rely on gypsum plasterboard systems for cost-effective interior construction. Government initiatives aimed at “smart city” development continue to push urban boundaries outward, sustaining long-term demand for advanced building solutions.

These dynamics set the stage for evolving regulatory landscapes impacting material choices and industry practices.

Market Restrictions and Regulatory Factors Affecting Gypsum Plasterboard

Building regulations and environmental standards are crucial in shaping the Gypsum Plasterboard Market. Following regional rules often decides whether a product is accepted and can enter the market.

1. Regulatory Compliance by Region

Different regions have specific safety codes and technical standards that gypsum board products must adhere to:

- In North America, strict safety codes are enforced for gypsum board, particularly regarding fire resistance and seismic performance.

- The European Union emphasizes harmonized technical standards under the Construction Product Regulation (CPR), requiring CE marking and adherence to EN 520 for plasterboards.

- In Asia Pacific, countries such as China and India are strengthening building regulations related to material quality, recyclability, and emissions.

2. Environmental Policies Influencing Material Choices

Sustainability is a key factor in procurement decisions as governments implement green building codes and environmental certifications like LEED and BREEAM. Manufacturers are facing pressure to:

- Reduce carbon footprints

- Increase recycled content

- Adopt cleaner production processes

In response to these changing requirements, the Gypsum Plasterboard Market is introducing eco-friendly products.

3. Safety Standards for Fire Resistance and Indoor Air Quality

National safety codes often mandate that gypsum boards meet minimum fire ratings, especially for applications in schools, hospitals, and high-rise buildings. Additionally, boards must comply with indoor air quality benchmarks by limiting volatile organic compound (VOC) emissions. Certifications such as GREENGUARD or Blue Angel validate these properties, providing assurance to contractors and end-users.

For every manufacturer aiming to maintain market access in both established and emerging economies, paying attention to regulatory compliance is crucial.

Geopolitical Influences on the Gypsum Plasterboard Industry

1. International Trade Relations

International trade relations play a crucial role in the gypsum plasterboard market. Trade policies and agreements between countries significantly affect the import and export of raw materials such as gypsum. For instance, favorable trade agreements can lower costs and increase availability, while restrictive policies can cause supply shortages and elevate prices.

2. Tariffs

Tariffs imposed on gypsum and related products impact pricing and supply chain stability. Tariffs can lead to increased production costs for manufacturers who rely on imported gypsum, which may result in higher prices for end-users. For example, the U.S.-China trade tensions have led to fluctuations in gypsum board prices due to imposed tariffs on raw materials.

3. Geopolitical Tensions

Geopolitical tensions can disrupt market dynamics, especially in regions with significant construction activities. Conflicts or political instability can hinder the mining and processing of gypsum, leading to supply chain disruptions. This instability can affect both the availability and cost of gypsum plasterboards globally.

Understanding these geopolitical influences is vital for stakeholders in the gypsum plasterboard industry to navigate challenges and capitalize on opportunities within an ever-changing global landscape.

Comprehensive Type Segmentation in Gypsum Plasterboard Market

Dominance of Wallboards in Interior Applications

Wallboards are the most common type of gypsum plasterboard, mainly because they are widely used for interior walls and partitions. Their flexibility and easy installation make them a popular choice for both homes and businesses. The lightweight nature of wallboards makes them easy to handle and reduces labor costs, which is why they dominate the market.

Growth Prospects of Pre-Decorated Boards

Pre-decorated boards are becoming more popular because they require less maintenance and are easy to install. These boards come with finishes already applied, so there is no need for additional decorative work after installation. This is especially beneficial in commercial settings where time efficiency and lower labor costs are important. As a result, the demand for pre-decorated boards is expected to increase significantly.

Comparison with Specialized Boards

Specialized gypsum boards such as fire-resistant and moisture-resistant variants cater to specific needs within the construction industry:

- Fire-resistant boards are essential for enhancing safety standards, particularly in high-risk areas like commercial kitchens or industrial facilities.

- Moisture-resistant boards are crucial in environments prone to humidity, such as bathrooms and basements, preventing mold growth and structural damage.

Each type offers unique benefits tailored to different applications, ensuring that the comprehensive range of gypsum plasterboards meets diverse construction requirements effectively.

Application Segmentation and Usage Trends in Gypsum Plasterboard

The Gypsum Plasterboard Market is defined by varied applications across key construction sectors, each with distinct usage patterns and growth drivers.

Residential Buildings

Residential buildings remain the dominant consumers of gypsum boards. Homeowners and developers favor plasterboard for its ease of installation, cost-effectiveness, and performance in interior wall and ceiling systems. Renovation projects and new housing starts continually reinforce this demand, especially in urbanizing regions where fast-track construction is a priority.

Commercial Construction

Commercial construction uses gypsum plasterboard extensively in office complexes, retail centers, hotels, and mixed-use developments. The ability to create flexible interior layouts, combined with acoustic insulation properties, makes gypsum board the preferred choice for partition walls and ceilings in high-traffic environments.

Industrial Applications

Industrial applications of gypsum board are gaining ground as manufacturers seek lightweight alternatives for partitions and plant offices within factories. These boards also find utility in storage facilities and logistics hubs where rapid deployment is essential.

Pre-Engineered Metal Buildings (PEMBs)

Pre-engineered metal buildings (PEMBs) represent an emerging segment. As industrial parks and modular construction methods proliferate, gypsum plasterboard is increasingly specified for non-load-bearing partitions due to its adaptability and compatibility with steel framing systems.

Institutional Sectors

Institutional sectors—schools, healthcare facilities, government buildings—are adopting specialized gypsum boards with enhanced fire resistance or moisture protection to meet stringent regulatory requirements.

Global Regional Analysis of Gypsum Plasterboard Market Development

A detailed regional market analysis reveals significant differences in growth patterns and market drivers for gypsum plasterboard worldwide.

1. Asia Pacific: Leading the Way

Asia Pacific leads global expansion, fueled by robust construction activity in China, India, and Southeast Asia. Rapid urbanization, infrastructure investments, and a growing middle class are accelerating demand. China dominates the region, with large-scale residential and commercial projects requiring vast quantities of gypsum board. Local government incentives and an emphasis on modernizing building standards further amplify this trend.

2. North America: Steady Growth

North America maintains strong momentum, driven by ongoing residential development and the need for reconstruction after natural disasters. The U.S. continues to invest in energy-efficient buildings—gypsum boards play a central role in meeting these performance targets. The prevalence of drywall construction methods sustains high consumption levels across both new builds and renovations.

3. Europe: Gradual Recovery

Europe is witnessing steady recovery in the housing sector, particularly in Germany, France, and the UK. Sustainability mandates and stringent building codes are steering demand toward eco-friendly gypsum board products. The focus on retrofitting older structures with modern materials adds an additional layer of opportunity.

Key drivers differ between developing and developed regions. Developing markets prioritize affordability and rapid deployment for large-scale projects, while developed regions emphasize sustainability, quality standards, and regulatory compliance. This divergence shapes product preferences and creates distinct growth trajectories within the global gypsum plasterboard industry.

China’s Gypsum Plasterboard Market: Demand and Innovation

China continues to lead the world in gypsum plasterboard consumption, mainly due to unprecedented urbanization and large-scale infrastructure projects. The increasing number of residential high-rises, commercial complexes, and government-supported affordable housing initiatives is driving demand to new heights. Urbanization in China has created new urban centers and expanded existing cities at a scale unmatched by other regions, leading to a constant need for efficient building materials like gypsum plasterboard.

Key factors behind China market growth:

- Rapid Urbanization:

- Over 60% of China’s population now lives in urban areas. The construction of new apartments, shopping malls, hospitals, and schools has put pressure on supply chains. Local governments are also implementing ambitious urban development plans, which increases the demand for materials that can be installed quickly.

- Innovation by Chinese Manufacturers:

- Leading companies such as Beijing New Building Material (BNBM) have invested heavily in research and development. They have also adopted automated manufacturing processes to ensure precise board thickness, improve fire resistance, and maintain consistent product quality. Additionally, these manufacturers are integrating recycled materials like flue gas desulfurization (FGD) gypsum into their production processes to reduce environmental impact and meet sustainability goals set by the government.

Innovation in both production technology and sustainability practices positions China as a leader in the global gypsum plasterboard market. This ongoing evolution ensures that domestic suppliers remain competitive while supporting rapid urban transformation.

Overview of Germany’s Gypsum Plasterboard Market

Germany stands out in the European gypsum market, largely due to a strong recovery in its housing sector after the recession. The revival of residential construction has increased the demand for gypsum plasterboard, as developers look for efficient solutions for interior walls and ceilings. Construction activity is not limited to new buildings—renovation projects and energy efficiency upgrades also contribute significantly to the consumption of plasterboards.

Key Trends in Germany’s Gypsum Plasterboard Market

Here are some key trends shaping the gypsum plasterboard market in Germany:

- Focus on sustainability initiatives: Compliance with strict EU regulations has led to widespread use of environmentally friendly materials. Gypsum plasterboard producers are investing in low-emission manufacturing processes and increasing recycled content in their products.

- Preference for certified building materials: Builders and architects prioritize products that contribute to green building certifications such as DGNB or LEED. This aligns with both government mandates and consumer demand for sustainable living environments.

- Innovation in product offerings: German manufacturers are focusing on innovation by developing fire-resistant, moisture-resistant, and sound-insulating boards that meet the changing needs of modern construction.

Future Prospects for Germany’s Gypsum Plasterboard Market

The ongoing shift towards sustainable construction practices is expected to drive steady growth in Germany’s gypsum plasterboard market. As both public and private sectors increase investment in energy-efficient buildings, the demand for gypsum boards is likely to remain strong, supporting broader European sustainability goals.

U.S. Gypsum Plasterboard Market Trends and Future Growth

Key Drivers of Gypsum Plasterboard Demand

The demand for gypsum plasterboard in the U.S. is primarily driven by the following factors:

- U.S. Construction Expansion: The growth of the construction industry in the United States, including large-scale infrastructure projects, population growth, and urban development, is a key driver of gypsum plasterboard demand.

- Natural Disaster Rebuilding: Reconstruction efforts following natural disasters such as hurricanes, wildfires, and tornadoes are another significant factor contributing to the demand for gypsum plasterboard.

- Energy Efficiency Demand: Increasing focus on energy efficiency in buildings, driven by developers and building owners seeking reduced operational costs and compliance with regulations like LEED certification, is also boosting the demand for gypsum boards.

Role of Gypsum Plasterboard in Construction

Gypsum plasterboard plays a crucial role in meeting the needs of various construction projects:

- Interior Solutions: Gypsum boards provide rapid and flexible interior solutions that are required in both new construction and renovation projects.

- Non-Load-Bearing Partitions: The material’s adaptability to non-load-bearing partitions makes it a popular choice for residential, commercial, and institutional projects.

- Quick Installation: Contractors rely on gypsum plasterboard for its quick installation, which is essential for timely reconstruction after natural disasters.

- Fire-Resistant Properties: The fire-resistant characteristics of gypsum boards help communities recover swiftly while adhering to strict building codes.

Emerging Trends in the Gypsum Plasterboard Market

Several trends are emerging in the gypsum plasterboard market that are likely to shape its future growth:

- Widespread Code Adoption: Local jurisdictions are increasingly mandating energy-efficient construction practices through building codes, which may boost the demand for gypsum boards as part of compliant designs.

- Product Innovation: Manufacturers are introducing innovative products with features such as enhanced moisture resistance, mold inhibition, or recycled content to attract environmentally conscious builders.

These trends highlight the strategic significance of gypsum plasterboard in promoting resilient and sustainable construction practices across the United States.

Forecasting Future Market Development and Technological Advances

The global gypsum plasterboard market is expected to see substantial growth, with a projected compound annual growth rate (CAGR) of 5.69% from 2025 to 2033. This impressive growth trajectory indicates that the market valuation will rise from USD 2.65 billion in 2025 to approximately USD 4.13 billion by 2033.

Technological innovation in gypsum plasterboard production is playing a crucial role in this expansion. Emerging technologies are significantly improving product performance, enhancing durability, and making installation more efficient. Some notable advancements include:

- Smart Gypsum Boards: Integrating sensors and smart materials to monitor building health and environmental conditions.

- Lightweight Boards: Reducing material usage without compromising strength, leading to easier handling and lower transportation costs.

- Enhanced Fire Resistance: Developing boards with superior fire resistance properties for increased safety in residential and commercial buildings.

Sustainability trends are also shaping the future of the gypsum plasterboard market. There’s a growing emphasis on eco-friendly products that minimize environmental impact. Innovations such as recycled gypsum content and low-emission manufacturing processes align with global sustainability goals and regulatory requirements.

These technological advancements are expected to drive demand across various sectors, ensuring robust market growth well into the next decade.

Competitive Landscape and Key Market Players in Gypsum Plasterboard

The Gypsum Plasterboard Market is influenced by major industry leaders, strategic expansions, and frequent mergers & acquisitions. Companies in this market compete based on their ability to innovate, operate globally, and adapt to changing building standards.

Key Players:

-

Saint-Gobain – France

-

USG Corporation (a subsidiary of Knauf) – United States

-

National Gypsum Company – United States

-

Georgia-Pacific – United States

-

LafargeHolcim – Switzerland

-

Knauf Gips KG – Germany

-

Continental Building Products – United States

-

Etex Group – Belgium

-

CertainTeed – United States

-

Siniat – Belgium

Industry Mergers & Acquisitions:

Recent activity highlights consolidation trends among key players gypsum plasterboard. Notable transactions include USG Corporation’s acquisition by Knauf, strengthening its North American presence, and Saint-Gobain’s purchase of U.S.-based Continental Building Products. These moves enhance distribution capabilities, foster innovation pipelines, and reinforce competitive advantage across new regions.

The competitive landscape remains dynamic as companies pursue technological leadership while responding to shifts in regional demand profiles.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Gypsum Plasterboard Market Report |

| Base Year | 2024 |

| Segment by Type |

· Fire-resistant Boards · Moisture-resistant Boards · Others |

| Segment by Application |

· Residential Buildings · Commercial Construction · Industrial Applications · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The gypsum plasterboard market is poised for strong growth, driven by increased residential and commercial construction, especially in emerging Asia Pacific countries like China, India, and Indonesia, alongside expansion in the U.S. construction sector fueled by demand for energy-efficient solutions and disaster rebuilding. Recovery in the housing sector across North America and Europe, with Germany’s focus on sustainable materials, further supports this trend. Wallboards dominate the product segment due to their widespread use in interior walls and partitions, while pre-decorated boards gain popularity for their ease of installation and low maintenance, particularly in commercial applications. Key sectors include residential buildings, pre-engineered metal buildings, and industrial, commercial, and institutional facilities. Technological advancements and sustainability initiatives continue to enhance market prospects, with active mergers and acquisitions driving product and regional expansion in a competitive landscape.

Global Gypsum Plasterboard Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Gypsum Plasterboard Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Gypsum Plasterboard Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Gypsum Plasterboard Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Gypsum Plasterboard Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Gypsum Plasterboard Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Gypsum Plasterboard Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Gypsum PlasterboardMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the importance of gypsum plasterboard in construction?

Gypsum plasterboard is essential for both residential and commercial buildings due to its fire resistance, sound insulation, and thermal efficiency features, creating safe and comfortable indoor environments.

Which key regional markets are driving the growth of the gypsum plasterboard industry?

China, Germany, and the United States are leading the growth of the global gypsum plasterboard market, each driven by different factors such as rapid urbanization, housing sector recovery, and construction sector expansion.

What are the current trends driving the expansion of the gypsum plasterboard market?

Significant increases in construction spending globally, growing demand for energy-efficient building materials, and urbanization trends are key factors fueling the growth of the gypsum plasterboard market.

How are market restrictions and regulatory factors affecting gypsum plasterboard?

Building regulations and environmental standards impact product acceptance and market entry. Regulatory compliance varies by region, focusing on safety codes, environmental policies, and safety standards for fire resistance and indoor air quality.

What are some emerging trends in the gypsum plasterboard market?

Emerging trends include widespread adoption of energy-efficient construction practices, product innovation like moisture-resistant boards, and a growing emphasis on sustainability through eco-friendly products.

What is the forecast for future market development and technological advances in the gypsum plasterboard industry?

The global gypsum plasterboard market is projected to grow significantly with technological advancements such as smart gypsum boards, lightweight boards, enhanced fire resistance properties. The focus on sustainability is expected to drive demand across various sectors.

Who are some key players in the competitive landscape of the gypsum plasterboard market?

Major industry players engage in strategic expansions, mergers & acquisitions to innovate and adapt to changing building standards, influencing competition dynamics within the industry.