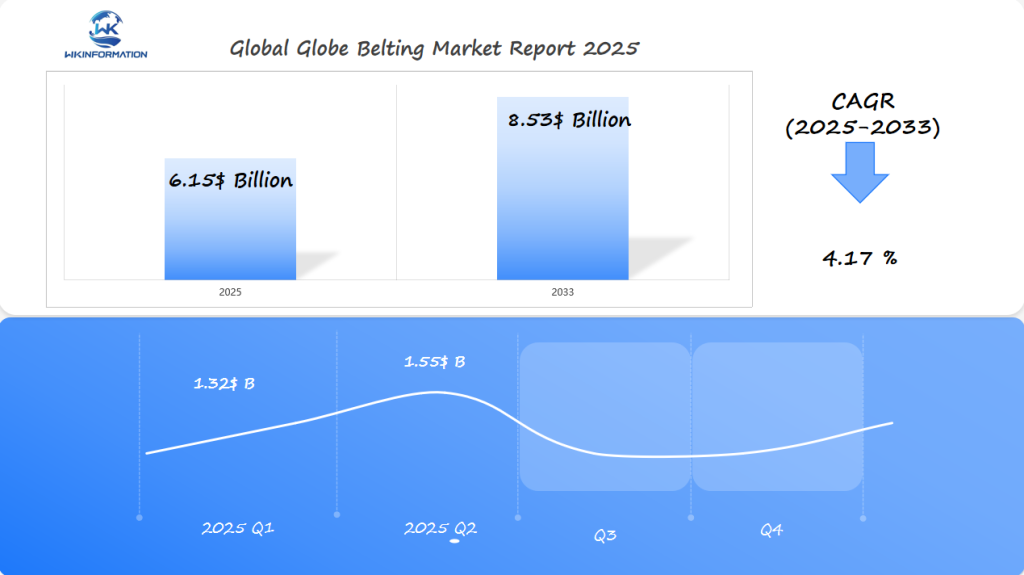

Globe Belting Market to Hit $6.15 Billion Globally by 2025: Mining and Conveyor Automation Fuel Demand in the U.S., India, and Indonesia

The Globe Belting Market shows robust growth driven by mining sector expansion and increased automation in material handling. Industry leaders focus on durability and energy efficiency.

- Last Updated:

Globe Belting Market Performance in Q1 and Q2 of 2025

The Globe Belting market is on track to achieve $6.15 billion in 2025, growing at a CAGR of 4.17% from 2025 to 2033. Q1 revenues are estimated at around $1.32 billion, with Q2 increasing to approximately $1.55 billion, reflecting a recovery in mining, heavy-duty manufacturing, and logistics sectors after seasonal slowdowns. The rebound in Q2 is also influenced by resumed infrastructure activity and cross-border commodity movement.

Key Takeaways

- Market projected to reach $6.15 billion by 2025

- Mining and logistics sectors driving significant demand

- Technological automation accelerating market expansion

- Increasing focus on advanced material handling solutions

- Conveyor belt technologies evolving rapidly

Globe Belting market upstream and downstream industry chain analysis

The global belting market is a complex web of raw materials, manufacturers, and end-users. They are all connected through detailed supply chain networks. These connections drive innovation and efficiency in many industrial sectors.

Key components of the supply chain include:

- Raw material suppliers specializing in rubber, synthetic fibers, and advanced composites

- Manufacturing facilities producing specialized conveyor belt systems

- Distribution networks connecting manufacturers with industrial end-users

Manufacturers face tough challenges in the supply chain. Important factors affecting the market include:

- Fluctuating raw materials pricing

- Technological advancements in belt engineering

- Evolving industrial requirements

Supply Chain Segment Key Characteristics Market Impact Raw Material Suppliers Rubber, synthetic polymers, steel cables Directly influences production costs Belt Manufacturers Specialized conveyor belt production Drives technological innovation End-Users Mining, logistics, manufacturing sectors Determines market demand

The supply chain’s complexity requires constant adjustments. Strategic partnerships between raw material providers, manufacturers, and end-users help create strong networks. These networks can tackle new industrial challenges.

Durable belting solutions gain traction amid smart material handling trends

The industrial world is changing fast with new material handling tech. Durable belts are leading this change, making things more efficient and effective. Companies are creating smart conveyor systems with the latest tech to improve how things work.

Smart conveyors are changing how we handle materials:

- Integration of real-time monitoring sensors

- Advanced wear-resistant belt materials

- Lightweight and modular belt designs

- Predictive maintenance capabilities

Today’s durable belts can handle tough industrial settings. They use top-notch materials to cut down on downtime and save on maintenance. Technological innovations are making conveyor systems smarter and more responsive.

Fields like mining, logistics, and manufacturing are quickly adopting these smart technologies. They’re using belts that last longer, carry more, and track better. This makes their operations smoother and more efficient.

These new tech advancements are boosting performance and making material handling more sustainable and affordable worldwide.

Limitations include high replacement cycles and operational downtime

The globe belting market faces big maintenance challenges. These challenges affect how well things work. Replacing industrial belts often means a lot of downtime for production.

Key limitations in belt management include:

- Extended downtime during belt replacement

- High costs associated with frequent maintenance

- Productivity losses from unexpected equipment failures

When belts need to be replaced often, it hurts how well things run. Industrial belts are complex. They need special skills and exact technical help.

| Maintenance Factor | Impact on Operations | Estimated Downtime |

| Standard Belt Replacement | Moderate Disruption | 6-12 hours |

| Complex Belt System | Significant Disruption | 24-48 hours |

| Emergency Repair | Critical Production Halt | 48-72 hours |

New ways to fix things before they break are being made. New sensors and systems watch belts in real time. They catch problems early, cutting down on unplanned stops.

Smart maintenance is changing how we handle belts. It turns problems into chances for better performance.

Changes in Mining Exports and Safety Regulations

The global mining industry is changing fast. This is due to complex politics and new safety rules. Recent changes in trade have also changed how mining companies buy equipment and work.

Factors Affecting Mining Trade

Important factors in the mining industry’s trade include:

- More focus on keeping workers safe

- Tighter safety rules worldwide

- New tech to reduce risks

- Politics affecting mining

Countries are setting stricter safety standards. This affects belt making and moving systems. Keeping up with these rules is key for mining companies to stay ahead globally.

The Link Between Politics and Mining Success

New trends show a link between stable politics and mining success. Safe countries get more investment, leading to a mix of tech and rules.

Global trade and safety rules keep changing the mining world. Mining companies must now think differently about choosing equipment, managing risks, and working efficiently.

Globe Belting market segmentation by type: cotton belting, rubber belting, synthetic belting, PVC belting

The global belting market offers a wide range of belt types. Each is made for different industrial needs. It’s key to know the material to pick the right belt for the job.

There are four main types of belts:

- Cotton Belting: Made from natural fibers, it’s traditional.

- Rubber Belting: Flexible and strong, it’s great for tough jobs.

- Synthetic Belting: Uses advanced materials for special tasks.

- PVC Belting: A plastic option that’s easy on the wallet.

Each belt has its own strengths. Cotton belts are light, rubber belts handle friction well. Synthetic belts are precise, and PVC belts are budget-friendly.

Choosing the right belt depends on a few things:

- How well it handles heat

- Its strength

- The environment it’s in

- The needs of the industry

The belting market keeps growing. Makers are working hard to create better belts for tough jobs.

Globe Belting market segmentation by application: mining, logistics, manufacturing, food processing

The global belting market covers key areas like mining, logistics, manufacturing, and food processing. It uses advanced belt customization to meet each industry’s needs. This way, manufacturers create conveyor systems that fit the unique demands of different work environments.

Important sectors that use advanced belting technologies include:

- Mining: Robust belts designed for heavy-duty material transportation

- Logistics: Precision-engineered systems for efficient supply chain management

- Manufacturing: High-performance belts supporting complex production processes

- Food Processing: Hygienic and sanitization-compliant conveyor solutions

Each industry has its own belt needs. Mining operations demand extreme durability and wear resistance. Food processing focuses on sanitation and safety. Manufacturing needs belts that handle constant movement and precise alignment.

Belt customization is a key innovation. Manufacturers create special materials and designs for each industry. This ensures belts work best in different settings.

By focusing on belt design, companies can improve efficiency and reduce downtime. They meet the complex needs of various industries worldwide.

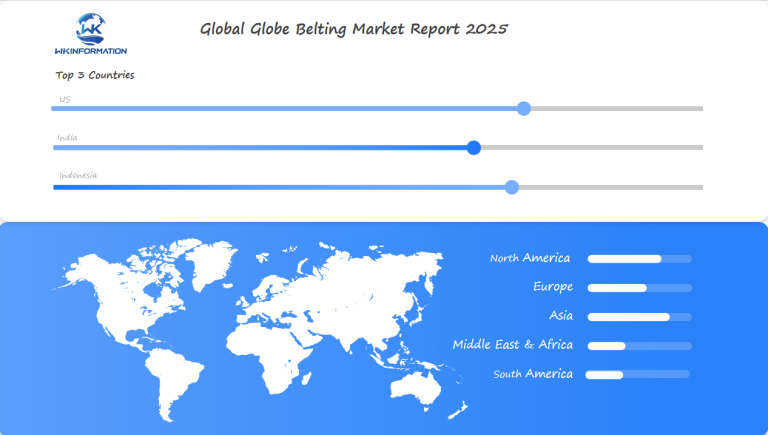

Global Globe Belting Market Regional Landscape

The global globe belting market is full of different regions with their own growth paths. Comprehensive market research shows big differences in how these regions grow.

Leading Regions in the Conveyor Belt Market

1. Asia-Pacific: The Leader

Asia-Pacific is leading the conveyor belt market. It’s growing fast because of quick industrial growth and new infrastructure. Countries like China, India, and Japan are seeing big increases in market share.

2. North America: Steady Growth

North America is growing steadily in the conveyor belt market.

3. Western Europe: Quick Innovation

Western Europe is innovating quickly in the conveyor belt industry.

4. Emerging Markets in Southeast Asia: New Opportunities

Emerging markets in Southeast Asia offer new chances for growth in the global belting market.

Understanding Regional Differences

Each region has its own special traits because of local industrial needs. Technological advancements and regulatory environments shape the market in different ways.

Strategies for Global Success

To succeed globally, companies need to:

- Invest wisely

- Tailor their strategies to each region

Sectors like mining, logistics, and manufacturing are key drivers of growth in the global belting market.

U.S. Globe Belting Market: Automated Logistics and Industrial Processing

The U.S. market trends in globe belting are changing fast. This is thanks to new industrial technology and automation. Companies are quickly adapting to the needs of today’s logistics and manufacturing.

Some important changes in the U.S. globe belting market are:

- More smart conveyor systems are being used

- IoT-enabled tracking technologies are being integrated

- Advanced materials are making belts last longer and work better

Automation is changing how we process materials. New belt technologies are making material handling more efficient. Precision-engineered belting solutions are key for companies wanting to improve their operations.

U.S. makers are putting a lot of money into research. They’re working on belting systems that can handle tough conditions and still perform well. They’re looking to make belts that are both strong and light, to save on upkeep and boost output.

The market is moving towards belting solutions made just for certain industries. This push for custom solutions is driving innovation. It’s opening up new chances for tech-focused makers in the U.S. globe belting field.

India Globe Belting market: large-scale mining and construction

The Indian market for globe belting is seeing big changes. This is thanks to more infrastructure and a strong mining sector. Experts say India could become a big name in conveyor belt tech worldwide.

Key areas of growth include:

- Rapid infrastructure project implementations

- Increased mechanization in mining operations

- Growing industrial automation requirements

- Strategic investments in material handling solutions

The mining sector is a big driver for globe belting demand in India. New belting tech is key for better mineral extraction and transport.

| Sector | Growth Potential | Key Drivers |

| Mining | High | Technological upgradation |

| Construction | Medium-High | Infrastructure investments |

| Manufacturing | Medium | Automation trends |

Global makers are seeing India’s potential. They’re making belting solutions for different needs. Innovative material technologies will help the market grow even more.

Technology and government support for making things in India are helping the globe belting market grow.

Indonesia Globe Belting market: growing demand from coal and rubber industries

The Indonesian market is at a key point in the global conveyor belting world. It’s driven by strong coal mining and rubber plantations. Indonesia is growing its industrial base with better belting solutions.

Demand from Coal Mining

Coal mining is a big reason for the need for conveyor belts in Indonesia. The coal mining industry needs belts that can handle tough conditions. Experts in the rubber market see the special challenges Indonesia’s complex industry brings.

- Coal mining sector generates substantial belting requirements

- Rubber plantations contribute to specialized conveyor belt manufacturing

- Increasing industrial automation drives belt technology innovation

Contribution from Rubber Plantations

Rubber plantations are key for Indonesia’s belting needs. The country’s big rubber production helps make top-notch conveyor systems. Manufacturers are making belts that last long and handle heat well.

Future Outlook

With coal mining and rubber together, Indonesia is a key place for new belting tech. Trends show more money going into smart ways to move materials. This will help many industries work better.

Future focus on heat-resistant and recyclable belting materials

The global belting industry is changing fast. It’s moving towards better materials and being more eco-friendly. Companies are working on new conveyor belt technologies. These aim to solve big problems like heat resistance and environmental impact.

Material innovation is changing the belting world:

- High-performance synthetic materials with exceptional heat resistance

- Recyclable belting solutions reducing industrial waste

- Composite materials enhancing durability and operational efficiency

Sustainability is a big reason for these changes. Scientists are finding new ways to make heat-resistant belting materials. They want to reduce harm to the environment while keeping performance high in tough industrial settings.

New trends show big investments in:

- Advanced polymer technologies

- Circular economy manufacturing processes

- Energy-efficient production methods

The future of belting materials is about smart solutions. These need to be strong, last long, and good for the planet. Companies are working hard to make products that meet tough standards for both industry and the environment.

Competitive insights across global and regional belt manufacturers

Key players in the globe belting market are focusing on developing high-durability materials and specialized belt designs to serve industries like mining, logistics, and food processing. They are expanding into regions such as Asia-Pacific and Africa, where industrialization and infrastructure projects are accelerating demand for efficient material handling solutions. Strategic alliances with equipment manufacturers and investments in smart monitoring technologies are helping these companies enhance operational efficiency and grow their global market share.

Key Players:

-

Global Belting Technologies (USA)

-

Tiantie Industrial (China)

-

Continental AG (Germany)

-

Bridgestone Corporation (Japan)

-

Fenner Dunlop (UK / USA – depending on division)

-

Sempertrans (Austria)

-

Goodyear Rubber Products (USA)

-

Habasit AG (Switzerland)

-

Mitsuboshi Belting Ltd. (Japan)

-

Bando Chemical Industries (Japan)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Globe Belting Market Report |

| Base Year | 2024 |

| Segment by Type |

· Cotton Belting · Rubber Belting · Synthetic Belting · PVC Belting |

| Segment by Application |

· Mining · Logistics · Manufacturing · Food Processing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Globe Belting Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Globe Belting Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Globe Belting Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Globe Belting Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Globe Belting Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Globe Belting Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Globe Belting Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Globe Belting Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Globe Belting market?

The market is growing fast because of more automation in handling materials. The mining sector is also expanding. Plus, new technologies in conveyor systems are making things more efficient and better.

How are manufacturers addressing durability challenges in belting solutions?

Companies are using smart technology and new materials to make belts last longer. This helps them perform better in harsh environments and reduces downtime.

What are the key material types in the Globe Belting market?

The main materials are cotton, rubber, synthetic, and PVC belts. Each has its own strengths and is used in different fields like mining, logistics, and food processing.

How do geopolitical factors impact the Globe Belting market?

Changes in mining exports, new safety rules, and industrial growth affect belt demand and design. These changes vary by region.

What challenges does the Globe Belting industry currently face?

The major challenges include long replacement times, downtime, fluctuations in the cost of raw materials, and stringent safety and performance standards.

Which regions are showing the most promising growth in the Globe Belting market?

India and Indonesia are growing fast. India is driven by big projects in infrastructure and mining. Indonesia’s coal and rubber industries are also strong.

What are the emerging trends in belting materials?

The focus is on materials that can handle heat and are recyclable. This meets the need for sustainable and high-performance belts in tough conditions.

How is technology influencing conveyor belt design?

Technology is making conveyor belts smarter and more efficient. It helps with predictive maintenance and reduces downtime, which improves overall performance.

What makes the U.S. Globe Belting market unique?

The U.S. market is advanced, with a focus on automation and high-tech in logistics and processing. It also values innovative belts to stay competitive globally.

How do different industries impact Globe Belting requirements?

Each industry has its own needs. Mining wants belts that last, food processing needs clean belts, manufacturing wants precision, and logistics wants belts that work efficiently.