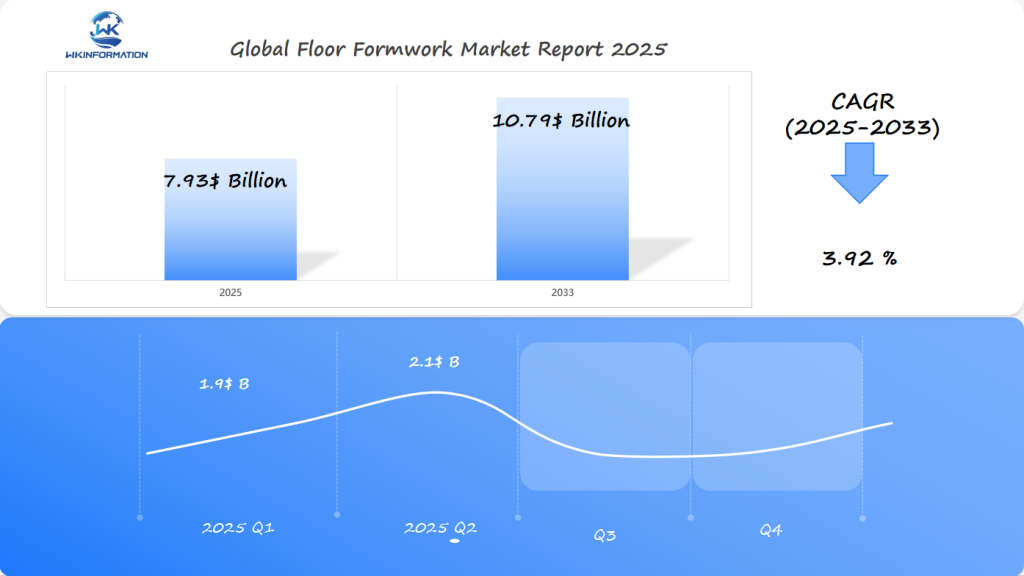

Floor Formwork Market Poised to Exceed $7.93 Billion by 2025, Led by US, Germany, and India

Explore the evolving floor formwork market through 2025, focusing on key regions – US, Germany, and India. This analysis examines Trump’s infrastructure plans, sustainable construction practices, and technological innovations shaping the industry’s future. Discover market trends, challenges, and growth opportunities in this comprehensive guide to formwork systems and infrastructure development.

- Last Updated:

Floor Formwork Market Forecast for Q1 and Q2 of 2025

The global Floor Formwork market is expected to reach USD 7.93 billion in 2025, growing at a CAGR of 3.92% from 2025 to 2033. The market will show steady growth, with significant contributions from the US, Germany, and India in the first half of 2025.

In Q1, the market size is anticipated to be around USD 1.9 billion, with the US leading due to the continued boom in the construction sector, especially in commercial real estate. Germany is expected to contribute strongly, given its well-established construction and engineering industries. India will also show significant growth, driven by rapid urbanization and increasing demand for residential and commercial developments. By Q2, the market is projected to grow to approximately USD 2.1 billion, as the demand for floor formwork solutions increases across all three regions. The US, Germany, and India are expected to remain the most critical markets to watch during the first half of 2025.

Decoding the Floor Formwork Market Upstream and Downstream Industry Chain

The floor formwork market operates through a complex supply chain with various stakeholders involved in different stages of production and distribution. Identifying these key players is crucial to understanding the market dynamics.

Key Players in the Supply Chain

- Raw Material Suppliers: These include producers of timber, steel, aluminum, and plastic, which are the primary materials used in formwork systems.

- Manufacturers: Companies like Doka GmbH, PERI SE, MEVA, and ULMA Group play a pivotal role by transforming raw materials into finished formwork products. Their innovation and production capacity significantly impact market supply.

- Distributors and Retailers: Responsible for ensuring that products reach construction companies globally. Their network strength can influence regional availability and pricing.

- Construction Firms: End-users of formwork systems, these firms dictate demand based on ongoing projects and future planning.

Impact of Downstream Activities on Market Growth

Downstream activities heavily influence the growth trajectory of the floor formwork market.

- Project Execution: Successful project execution by construction firms often requires efficient formwork solutions, increasing demand for advanced systems.

- Renovation and Maintenance: Growing trends in renovation projects drive continuous demand for adaptable formwork systems.

- Technological Integration: The adoption of technologies such as Building Information Modeling (BIM) enhances efficiency in downstream processes, fostering market expansion.

Understanding these dynamics offers valuable insights into how different stakeholders contribute to market growth and how downstream activities shape the industry’s future direction.

Revolutionary Trends Reshaping the Floor Formwork Industry

Recent years have seen significant advancements in modular floor formwork systems, which are changing traditional construction methods. These systems offer several advantages, including:

- Faster setup times

- Improved safety measures

Modular systems are designed to be easily assembled and disassembled, reducing labor costs and time on-site. They provide flexibility in design, allowing for a wide range of architectural possibilities while maintaining structural integrity.

Another important tool reshaping the floor formwork industry is Building Information Modeling (BIM). BIM improves project efficiency by providing a detailed digital representation of the building process. This technology enables better planning, coordination, and communication among stakeholders. By simulating various construction phases, BIM reduces errors and rework, ultimately saving time and resources.

In addition to BIM, other digital solutions are increasingly being adopted to streamline operations and reduce costs. Technologies such as drones for site inspection, 3D printing for creating precise moldings, and advanced software for project management are becoming integral in modern construction workflows. These solutions not only cut down operational expenses but also enhance precision and quality control.

The integration of these advanced technologies is driving a shift towards more efficient and sustainable construction practices. By minimizing waste and optimizing resource use, the industry is moving towards greener solutions that align with global sustainability goals.

Despite challenges such as high initial costs or the need for specialized training, these innovations are setting new standards in the floor formwork market, paving the way for future developments in construction technology.

Barriers to Growth What’s Holding Back the Floor Formwork Market?

The growth of the Floor Formwork Market faces several challenges that need addressing to unlock its full potential.

Economic Uncertainties

One significant obstacle is the economic uncertainties that affect investments in floor formwork projects. Fluctuations in global economies can lead to unpredictable funding for large-scale construction initiatives, causing delays or cancellations. This volatility makes it difficult for companies to plan and execute long-term strategies.

Regulatory Barriers

Regulatory barriers also pose a considerable challenge. Companies operating across different regions encounter diverse regulatory frameworks that can complicate compliance and increase operational costs. For instance, environmental regulations may require additional investments in sustainable materials or alternative construction methods, impacting profitability.

Competition from Alternative Methods

Competition from alternative construction methods further complicates market expansion efforts. As technology advances, new building techniques such as prefabricated structures and 3D printing gain traction. These alternatives can offer cost efficiencies and reduced construction times, making them attractive options over traditional formwork systems.

To navigate these challenges, industry players need to continually innovate and adapt to changing market conditions. Embracing digital solutions, enhancing regulatory compliance capabilities, and differentiating offerings will be crucial in overcoming these barriers and driving future growth in the Floor Formwork Market.

Floor Formwork Market Geopolitical Analysis Trade Wars and Policy Shifts

The floor formwork market faces significant challenges arising from geopolitical influences and shifting trade policies. These factors have profound implications on the cost and availability of materials essential for the manufacturing of formwork systems.

Impact of Trade Wars

- Ongoing trade wars, particularly between large economies, have led to increased tariffs on raw materials. This has directly impacted the cost structure for manufacturers in the floor formwork industry, leading to higher prices for steel, aluminum, and other critical components.

- Trade tensions also result in supply chain disruptions. Manufacturers may experience delays or shortages in acquiring necessary materials, complicating their ability to meet demand efficiently.

Government Policies and Construction Projects

- Government regulations significantly influence construction activities. Policies related to infrastructure development often dictate the pace and scale of projects that utilize floor formwork systems.

- In many regions, government incentives are provided for adopting sustainable construction practices. This encourages the use of innovative formwork solutions that align with environmental objectives, potentially reshaping market dynamics.

Understanding these geopolitical and policy shifts is crucial for stakeholders within the floor formwork market. By navigating these complexities effectively, companies can better position themselves to capitalize on emerging opportunities while mitigating risks associated with geopolitical uncertainties.

Segmentation by Type Exploring Innovations in Floor Formwork Solutions

The floor formwork market thrives on the diversity of materials, each with distinct characteristics and applications. Understanding these can empower you to make informed decisions tailored to specific project needs.

Timber Formwork

- Characteristics: Timber formwork is lauded for its flexibility and ease of handling. It is often utilized in projects where custom shapes are required, making it a popular choice for complex architectural designs.

- Applications: Commonly used in residential constructions due to its cost-effectiveness and adaptability. Recent innovations focus on enhancing durability and reducing moisture absorption, addressing some of its traditional drawbacks.

Steel Formwork

- Characteristics: Known for its strength and reusability, steel formwork offers precision and longevity. It is resistant to warping, making it ideal for repetitive use across multiple projects.

- Applications: Frequently employed in large-scale infrastructure projects where uniformity and accuracy are critical. Advances in design have led to lighter steel frames that do not compromise strength, facilitating easier transportation and installation.

Aluminum Formwork

- Characteristics: Aluminum formwork combines the lightweight nature of the material with high load-bearing capacity. Its corrosion resistance prolongs the lifespan of the formwork system.

- Applications: Predominantly used in high-rise buildings due to its quick assembly and disassembly capabilities. Recent developments include integrated modular systems that enhance speed without sacrificing quality or safety.

Each material has witnessed significant design innovations aimed at enhancing functionality, efficiency, and sustainability. These advances not only improve construction processes but also contribute to reducing costs and environmental impact—a reflection of the industry’s commitment to evolving needs while maintaining quality standards.

Segmentation by Application Where is Floor Formwork in High Demand?

The Floor Formwork Market sees strong demand across several key sectors, driven by the diverse applications of formwork systems in construction. Understanding these sectors provides insight into the market dynamics and potential areas for growth.

Key Sectors Driving Demand

1. Residential Construction

Increasing urbanization fuels the demand for residential buildings, necessitating efficient floor formwork solutions to accelerate project timelines and ensure structural integrity.

2. Commercial Buildings

The rise in global commercial development projects, including offices, retail spaces, and industrial facilities, propels the need for advanced formwork systems that can accommodate complex architectural designs.

3. Infrastructure Projects

Large-scale infrastructure developments such as bridges, tunnels, and highways require durable and adaptable formwork solutions. These projects often dictate trends in material innovation and design efficiency within the formwork industry.

Case Studies Highlighting Successful Applications

- Skyscraper Developments in Asia-Pacific: Skyscrapers in cities like Shanghai and Kuala Lumpur showcase innovative use of modular floor formwork systems. These systems enable faster assembly and disassembly, critical for high-rise construction.

- Public Infrastructure in Europe: Projects like the Crossrail initiative in London have demonstrated the effectiveness of floor formwork in managing large concrete pours while maintaining stringent safety standards.

- Residential Complexes in North America: In regions like California, where seismic activity is a concern, specialized aluminum formwork has been pivotal in constructing earthquake-resistant residential structures swiftly.

These examples illustrate how different applications leverage unique characteristics of floor formwork to meet specific project needs while driving market growth globally. Each sector’s unique demands contribute to continuous advancements and adaptations in floor formwork technologies.

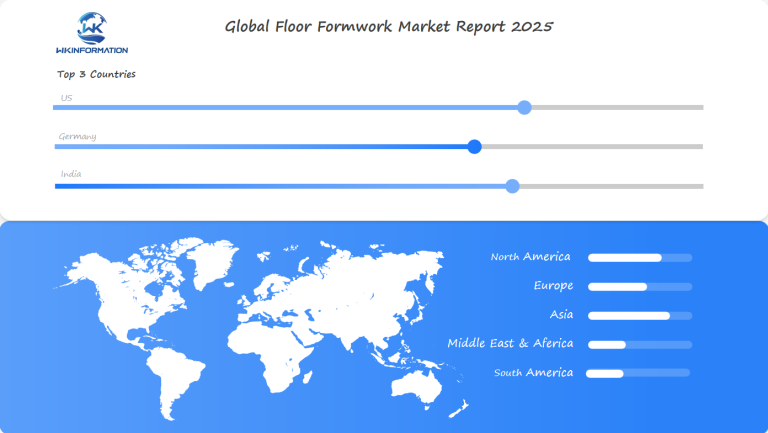

The Global Footprint of Floor Formwork Market Top Expanding Regions

Regional Analysis reveals significant expansion in the floor formwork market across key global markets, namely Asia-Pacific, North America, and Europe.

Asia-Pacific: A Powerhouse of Growth

- China and India lead the charge in the Asia-Pacific region, driven by rapid urbanization and extensive infrastructure projects. Government initiatives aimed at enhancing urban infrastructure have escalated demand for efficient construction solutions.

- In China, the government’s focus on smart city projects and modernization of existing infrastructure has created lucrative opportunities for floor formwork providers.

- India’s infrastructure boom is fueled by initiatives such as the Smart Cities Mission and Bharatmala project, underlining a robust market demand.

North America: Sustained Demand through Innovation

- The United States stands out with its dynamic construction sector. Increasing investments in residential and commercial buildings stimulate market growth.

- Technological advancements in formwork systems offer cost-effective solutions, aligning with the industry’s focus on sustainable building practices.

Europe: Balancing Tradition with Innovation

- In Europe, Germany emerges as a leading hub due to its strong emphasis on engineering excellence and quality standards. The region’s commitment to environmental sustainability aligns with the evolving demands of modern construction practices.

- Adoption of digital technologies like Building Information Modeling (BIM) enhances project efficiency, making it an attractive market for innovation-centric players.

Understanding these regional dynamics helps industry stakeholders tailor their strategies to capitalize on growth opportunities in these burgeoning markets.

US Floor Formwork Market Analysis Booming Construction and Market Growth

The United States is experiencing a robust construction sector, serving as a catalyst for the floor formwork market. Key drivers include:

1. Infrastructure Development

Federal and state-level investments in infrastructure projects such as bridges, highways, and public buildings contribute significantly to the demand for floor formwork systems.

2. Residential and Commercial Expansion

Urbanization trends and population growth spur the need for residential and commercial spaces, further fueling market growth.

3. Technological Advancements

Adoption of advanced technologies like Building Information Modeling (BIM) optimizes project planning and execution, enhancing efficiency in floor formwork applications.

Several factors underscore the market dynamics:

1. Government Initiatives

Policies promoting infrastructure rejuvenation under various federal programs stimulate demand for innovative formwork solutions.

2. Sustainability Focus

Increasing emphasis on environmentally friendly practices drives innovation in sustainable materials for floor formworks.

Industry leaders such as Doka GmbH and PERI SE capitalize on these opportunities by offering advanced products tailored to meet diverse project requirements. The competitive landscape is characterized by continuous innovation aimed at reducing costs and improving construction timelines. This environment not only supports existing players but also attracts new entrants seeking to leverage burgeoning opportunities within the US floor formwork market.

Germany Floor Formwork Market Analysis Leading Manufacturing Hub Insights

Germany is a key player in the global floor formwork market, leveraging its position as a top manufacturing center. The country’s construction industry benefits from advanced industrial capabilities and a skilled workforce, which aids in creating and utilizing new formwork solutions.

Key Factors Driving Growth:

- Strong Industrial Base: Germany’s robust industrial framework supports the production of high-quality formwork systems, ensuring efficient and reliable solutions for construction projects.

- Technological Advancements: German manufacturers are at the forefront of integrating digital technologies such as Building Information Modeling (BIM) and automation into formwork systems, enhancing project precision and reducing timeframes.

- Sustainability Initiatives: The emphasis on sustainable building practices is driving demand for eco-friendly formwork materials, aligning with Germany’s environmental goals.

Challenges:

Despite these strengths, challenges persist. The high cost of labor and stringent regulatory standards can impact profitability. However, these factors also incentivize innovation, pushing companies to develop cost-effective solutions that meet regulatory requirements. This is exemplified by the findings in the OECD Reviews of Innovation Policy, which highlight how such challenges can spur innovative practices.

Germany continues to lead by example in the floor formwork market through its commitment to innovation and sustainability. This dynamic environment fosters growth while addressing industry challenges head-on.

India Floor Formwork Market Analysis Infrastructure Boom Driving Demand

India’s construction industry is experiencing a surge, with infrastructure development at the forefront driving demand for floor formwork solutions. Rapid urbanization and government initiatives such as the Smart Cities Mission and Pradhan Mantri Awas Yojana have catalyzed growth in the sector.

Key factors fueling this demand include:

- Massive Infrastructure Projects: The Indian government’s focus on developing highways, bridges, and metro systems has significantly increased the need for efficient formwork systems. These projects require robust support structures, making formwork an essential component.

- Urban Housing Needs: With an increasing urban population, there’s a pressing demand for residential buildings. Modern formwork solutions are vital to meet tight deadlines and ensure quality construction.

- Emphasis on Sustainability: As sustainability becomes a priority, eco-friendly formwork materials such as reusable aluminum and plastic are gaining traction. This shift aligns with global trends towards greener construction practices.

The market is also seeing advancements in technology. Companies are adopting digital tools like BIM to streamline design and execution processes, enhancing project efficiency. Such innovations are expected to continue propelling the growth of India’s floor formwork market, making it a key player in the global arena.

The Future of Floor Formwork Market Emerging Technologies and Trends

The floor formwork market is about to undergo a significant change, thanks to new technological advancements and a growing emphasis on sustainability. These changes have the potential to reshape the industry and make construction processes more efficient.

Technological Advancements

New technologies like automated formwork systems are expected to bring about a major transformation in the industry. With automation being implemented in the assembly and disassembly of formwork, there will be a substantial decrease in labor costs and time required for these tasks, leading to improved overall efficiency of projects. Another area with great potential is robotics, where machines can take on repetitive jobs, ensuring accuracy while reducing human mistakes.

The combination of Building Information Modeling (BIM) and formwork systems presents a comprehensive solution that enhances design precision and resource management. BIM enables detailed visualization of projects prior to construction, allowing for better decision-making at every stage of the project.

Sustainability Trends

As environmental issues become more urgent, the floor formwork market is placing greater importance on sustainable practices. There is a growing trend towards using recyclable materials such as aluminum and plastic in formwork systems. These materials not only have a smaller impact on the environment but also offer durability and ease of handling.

Innovative methods like green concrete—which incorporates waste materials from industries—are being explored as complementary solutions for sustainable formwork. This shift towards eco-friendly practices aligns with global efforts to reduce carbon emissions in the construction industry.

These trends indicate a future where technology and sustainability come together to create a more efficient and environmentally conscious floor formwork market. As these innovations continue to evolve, they will play a vital role in overcoming existing challenges while opening up new avenues for growth.

Competitive Battle Who’s Leading the Floor Formwork Industry?

To understand the competitive landscape of the Floor Formwork Market, it’s important to know who the key players are and what strategies they are using. Leading companies such as Doka GmbH and PERI Group have a significant presence in this industry, holding large portions of the market.

- PERI Group – Germany

- Doka Group – Austria

- ULMA Construction – Spain

- BrandSafway – United States

- Layher – Germany

- Altrad Group – France

- RMD Kwikform – United Kingdom

- MEVA Formwork Systems – Germany

- WACO International – Germany

- NOE Formwork Systems – Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Floor Formwork Market Report |

| Base Year | 2024 |

| Segment by Type |

· Timber Formwork · Steel Formwork · Aluminum Formwork |

| Segment by Application |

· Residential Construction · Commercial Buildings · Infrastructure Projects |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The floor formwork market is expected to grow significantly, with an estimated value of around $7.93 billion by 2025. This growth is driven by strong demand in key areas such as the United States, Germany, and India, each contributing unique factors to the market dynamics.

Key Factors Driving Market Growth

- United States: The increasing number of construction projects and infrastructure advancements are crucial for market growth. The U.S.’s robust economic framework supports significant investments in construction technologies and innovations.

- Germany: Germany’s focus on precision engineering and quality enhances its leading position within the European sector of floor formwork solutions.

- India: Rapid urbanization and infrastructural developments highlight India’s growing demand for efficient and sustainable construction methods, driving the need for advanced formwork systems.

Technological Innovations Reshaping the Industry

Technological advancements such as modular systems, integration of Building Information Modeling (BIM), and digital solutions are transforming the industry landscape. Sustainability trends are also gaining traction, reflecting a global shift towards environmentally responsible construction practices.

Challenges Ahead

Despite the positive outlook, challenges remain including economic uncertainties and competition from alternative construction methods.

Leading Companies in the Industry

However, companies like Doka GmbH and PERI Group continue to lead with strategic innovations and competitive positioning.

The floor formwork industry is expected to evolve further, balancing growth opportunities with strategic adaptation to emerging trends and regional demands.

Global Floor Formwork Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Floor Formwork Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Floor Formwork Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Floor Formwork Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Floor Formwork Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Floor Formwork Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Floor Formwork Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Floor Formwork Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key players in the floor formwork market and their roles?

Key players in the floor formwork market include companies like Doka GmbH and PERI Group, who play significant roles in providing innovative solutions and materials. They are involved in various stages of the supply chain, from manufacturing to project implementation.

How do advanced technologies influence the floor formwork industry?

Recent innovations such as modular floor formwork systems and Building Information Modeling (BIM) are revolutionizing the industry. These technologies enhance project efficiency, reduce costs, and improve overall functionality in construction projects.

What barriers are currently affecting growth in the floor formwork market?

The floor formwork market faces several barriers including economic uncertainties that hinder investments, regulatory issues across different regions, and competition from alternative construction methods that challenge traditional practices.

How do geopolitical factors impact the floor formwork market?

Ongoing trade wars and government policies significantly affect material costs and availability for manufacturers. These geopolitical influences can create challenges for companies operating within the floor formwork sector, impacting their operational strategies.

Which sectors show high demand for floor formwork solutions?

High demand for floor formwork solutions is primarily driven by residential construction, commercial buildings, and infrastructure projects. Case studies highlight successful applications of these systems across various projects globally.

What is the future outlook for the floor formwork market?

The future of the floor formwork market looks promising with emerging technologies expected to shape its evolution. Sustainability trends are becoming increasingly important, driving innovation and influencing design practices within the industry.