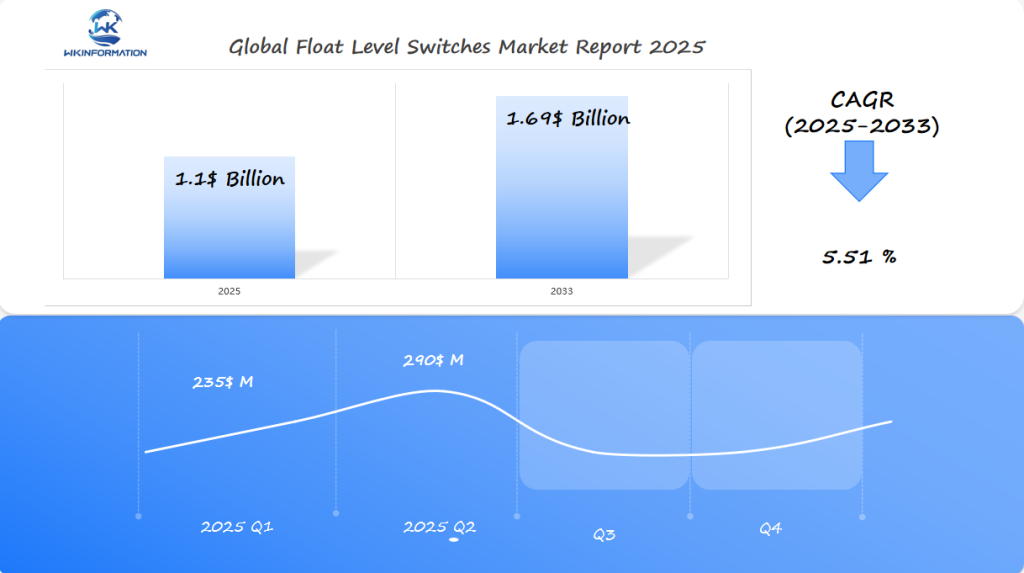

Float Level Switches Market Forecasted at $1.1 Billion by 2025: Process Automation Spurs Growth in the U.S., Saudi Arabia, and Malaysia

The Float Level Switches Market expands with rising demand in process automation, water treatment, and industrial applications. Discover key trends driving market growth through 2025.

- Last Updated:

Float Level Switches Market Performance in Q1 and Q2 of 2025

The global Float Level Switches market is anticipated to hit $1.1 billion by 2025, advancing at a CAGR of 5.51% through 2033. Market activity in Q1 is estimated at $235 million, while Q2 is expected to improve to $290 million, with stronger demand from the water treatment, oil & gas, and food processing industries. The second quarter often brings increased fluid management needs due to infrastructure rollouts and seasonal maintenance cycles.

Key Takeaways

- Float level switches market projected to reach $1.1 billion by 2025

- Process automation driving significant market expansion

- Critical applications across multiple industrial sectors

- Technological innovations improving switch performance

- Increasing demand for precise liquid level monitoring

Float Level Switches Market Upstream and Downstream Industry Chain Analysis

The float level switches market is a complex web of suppliers, makers, and users. Knowing the industry chain helps us see how value is made and how the market works.

Upstream Suppliers and Raw Materials

Upstream suppliers are key in making float level switches. They use:

- High-grade stainless steel

- Precision-engineered plastics

- Magnetic and electrical parts

- Corrosion-resistant alloys

Manufacturing Process and Quality Control

Manufacturers use advanced engineering to turn raw materials into smart float level switches. Precision manufacturing ensures they work well in many industries.

Downstream Industries and Distribution Channels

Downstream industries help the float level switches market grow. The main users are:

- Oil and gas processing

- Water treatment facilities

- Chemical manufacturing plants

- Food and beverage production

Distribution channels include direct sales to industries and partnerships with control component providers.

Automation in fluid management and oil storage drives market trends

The industrial world is changing fast, thanks to new ways of managing fluids. Float level switches are key in these changes. They help control processes better than ever before.

IIoT is making old ways of monitoring look outdated. Now, smart float level switches can collect and analyze data in real-time. They offer:

- Continuous liquid level monitoring

- Predictive maintenance strategies

- Remote operational tracking

- Enhanced safety protocols

Industrial Transformation through Smart Sensing

Oil storage facilities are seeing big benefits from these new technologies. Precision sensors with IIoT can give instant updates on tank levels and more. This means less downtime and better use of resources.

Fluid management automation is a big step forward in controlling industrial processes. With advanced float level switch technologies, companies can work more efficiently and safely.

Challenges: Calibration Drift, Float Compatibility, and Harsh Environment Wear

Float level switches face significant challenges that impact their performance and reliability. Calibration drift is a major issue for those who require precise fluid level measurements.

Challenges in Accurate Measurement

One major technical challenge is calibration drift. This means that over time, measurements become less accurate. Float level switches are used in many industrial settings where they can be affected by various factors.

These factors include:

- changes in temperature

- chemical reactions

- mechanical stress

All of these can negatively impact how well the sensor works.

Material and Design Innovations

Manufacturers are developing new solutions to handle harsh environments. Specialized float materials and new sensor designs help maintain high performance. With precision engineering, floats now operate more effectively in challenging industrial conditions.

Strategic Technological Responses

Engineers are using smart calibration methods to reduce drift. This makes measurements more reliable over time. Some strategies include:

- Advanced sensor self-diagnostic capabilities

- Improved material science for float construction

- Enhanced environmental protection mechanisms

By addressing calibration drift, float compatibility, and harsh environment issues, manufacturers are enhancing float level switch technology.

Geopolitical Role in Petrochemical Policy and Industrial Safety Mandates

The float level switches market is closely linked to global politics. This is especially true for petrochemical policy and industrial safety rules. International trade deals and changing global ties greatly influence market plans and new tech.

Global politics are changing the industrial world. They are pushing companies to rethink safety and tech development. Important factors include:

- More strict rules in different parts of the world

- Tighter safety rules in growing markets

- Complicated trade talks that affect tech sharing

Regional Policy Influences on Market Dynamics

Each region has its own way of handling petrochemical policy. The U.S. pushes for tech innovation, while the Middle East focuses on updating infrastructure. Europe puts a big emphasis on green practices and following environmental rules.

It’s key for float level switch makers to keep up with safety rules and tech needs. They need to:

- Meet strict safety standards

- Have better monitoring tools

- Make products that last in tough conditions

Strategic Market Positioning

Global companies are changing their plans to fit with new global trends. Being proactive in adapting to new rules is a big advantage in the float level switches market.

Float Level Switches market segmentation by type

The float level switches market offers a wide range of technologies. These are designed to meet various needs in industries. There are three main types of float switches, each for different uses and challenges.

Different industries use different float switch types for accurate liquid level detection. The three main types are:

- Vertical float switches: Ideal for tall, narrow containers with vertical mounting requirements

- Horizontal float switches: Best suited for wide storage tanks and horizontal measurement applications

- Multi-point float switches: Designed for complex monitoring systems requiring multiple measurement points

Vertical Float Switches: Precision in Vertical Spaces

Vertical float switches are great for monitoring liquid levels in narrow vessels. They have a compact design that fits well in tight spaces. This makes them ideal for water treatment, chemical processing, and industrial storage.

Horizontal Float Switches: Expansive Monitoring Capabilities

Horizontal float switches are perfect for monitoring liquid levels in wide storage areas. They are versatile and can handle large tanks, reservoirs, and industrial containers.

Multi-Point Float Switches: Advanced Monitoring Solutions

Multi-point float switches are leading the way in liquid level detection technology. They have the capability to monitor levels at various locations, providing exceptional accuracy for intricate industrial operations.

Float Level Switches market segmentation by application: oil tanks, water treatment, food & beverage, chemical plants

The float level switches market covers key industrial areas. It ensures precision and safety in various sectors. Companies are making special products for oil tanks, water treatment, food and beverage, and chemical plants.

Different fields need unique float level switch technologies. This is to manage liquid levels well. Each area has its own design needs for the best performance and reliability.

Key Application Segments

- Oil Tanks: Important for checking storage levels and avoiding overflow in oil storage

- Water Treatment: Key for managing water levels and controlling pumps

- Food and Beverage: Crucial for clean liquid level checks in food processing

- Chemical Plants: Needed for accurate liquid measurement in complex settings

Industrial Requirements

Float level switches in chemical plants must handle harsh environments. Food and beverage industries need strict cleanliness standards. Oil tanks require sensors that work well in extreme conditions.

Market Dynamics

The global market for float level switches is growing. Industries want better liquid monitoring tools. Water treatment and chemical plants are big areas for new sensor tech.

Global Overview of the Float Level Switches Market

The global market for float level switches is complex and always changing. It shows how different areas help the industry grow and get better. This helps us understand the market better.

- North America leads with advanced industrial automation technologies

- Asia-Pacific shows rapid expansion in manufacturing sectors

- Middle East exhibits strong petrochemical industry integration

- European markets focus on precision engineering applications

Market Segmentation by Geographic Potential

The competitive landscape of float level switches shows unique traits in each region. Each area has its own tech preferences and ways of using these switches. This affects how the market works globally.

Investments in research and development are key to the global float level switches market. Companies are working hard to meet the needs of each region. They focus on the tech and industry needs of each area.

U.S. Float Level Switches Market: Industrial Automation and Water Systems

The U.S. market for float level switches is crucial in industrial automation and water systems. New technology and strict regulations are driving growth in this sector.

- More float level switches are being integrated with SCADA systems.

- Advanced wireless monitoring for water systems is becoming widespread.

- There’s an emphasis on improved accuracy in industrial automation.

Regulatory Landscape and Technology Innovations

The EPA and ANSI/ISA standards are shaping float level switch technology. Manufacturers are developing more advanced sensors to fulfill demanding industrial requirements.

Water Systems and Industrial Applications

Water systems are a big area for growth in float level switches in the U.S. Cities and big companies are using new tech to work better and cut risks.

As industrial automation tech keeps getting better, float level switches will keep being vital in U.S. making and managing big projects.

Saudi Arabia Float Level Switches market: oilfield operations and petrochemicals

The Saudi Arabia market is a key place for advanced industrial measurement tech, especially in oilfields and petrochemicals. The country’s focus on tech innovation is changing how float level switches are used in important areas.

Saudi Vision 2030 has made float level switch tech more popular in many industries. This push for modern and efficient ways has opened up big chances for precise measurement solutions.

Market Dynamics and Technology Integration

- Increasing investment in industrial automation

- Growing demand for advanced sensor technologies

- Enhanced focus on environmental monitoring systems

Petrochemical plants are changing fast with new tech. Oilfield operations use float level switches a lot for:

- Managing liquid levels better

- Making operations safer

- Monitoring in real-time

Technology Adoption Landscape

Global manufacturers are viewing Saudi Arabia as a crucial market for float level switch technology. The country’s goal to implement more advanced industrial technology domestically presents a significant opportunity for companies globally.

Malaysia Float Level Switches Market: Process Industries and Export Manufacturing

Malaysia leads in industrial innovation in Southeast Asia. Its process industries are growing fast, thanks to float level switch technologies. The country’s role in global manufacturing has made its industry strong, offering chances for advanced sensors and export.

The market for float level switches in Malaysia is growing fast. This is especially true in key sectors that need exact fluid management. These sectors include:

- Electronics and semiconductor manufacturing

- Petrochemical processing

- Water treatment facilities

- Food and beverage production

Strategic Manufacturing Ecosystem

Malaysia is becoming a key player in process industries. The government’s National Policy on Industry 4.0 has boosted tech adoption. This policy helps local makers create advanced float level switch solutions for both local and global markets.

Exporting float level switches is a big money-maker for Malaysian tech firms. They use top-notch engineering and low costs to grow their reach in industrial automation worldwide.

Technological Innovation Landscape

Malaysian engineers are creating next-generation float level switches. These advanced switches are designed to meet demanding industrial requirements, with a focus on:

- Durability: Built to last longer in challenging environments

- Precision: Capable of measuring fluid levels with greater accuracy

- Compatibility: Seamlessly integrating with smart systems for enhanced automation

This development showcases Malaysia’s expertise in the field of industrial sensor technology.

Future innovation in magnetostrictive and non-contact sensors

The world of level measurement technology is changing fast. Magnetostrictive sensors and non-contact sensors are leading the way. They bring new levels of precision and reliability to fluid level monitoring.

Magnetostrictive sensors are a big step up in measurement tech. They use magnetic properties for top-notch accuracy in various industries. Their benefits include:

- Extremely high precision measurement

- Enhanced durability in harsh environments

- Minimal maintenance requirements

- Wide range of temperature and pressure tolerances

Emerging Technological Breakthroughs

Non-contact sensors are changing the game in level measurement. They don’t touch the media they measure. This brings big advantages for complex industrial processes.

| Sensor Type | Accuracy | Application Range |

| Magnetostrictive Sensors | ±0.1% | Chemical, Oil & Gas |

| Non-Contact Sensors | ±0.5% | Water Treatment, Food Processing |

Future advancements in these sensors will likely focus on better signal processing and lower power use. They will also improve wireless communication. Researchers aim to link them with Internet of Things (IoT) systems for smarter, more responsive systems.

Competitive field of industrial control component providers

Key players in the float level switches market are focusing on enhancing durability and chemical resistance to serve critical applications in water treatment, oil & gas, and chemical processing industries. They are expanding into emerging markets such as Southeast Asia and the Middle East, where investments in industrial infrastructure and utilities are increasing. Strategic collaborations with automation system integrators and the development of smart sensing technologies are enabling these companies to offer more reliable solutions and strengthen their market footprint.

Key Players:

-

VEGA Grieshaber KG (Germany)

-

Gems Sensors & Controls (USA)

-

Magnetrol International (USA)

-

Honeywell (USA)

-

Siemens (Germany)

-

ABB (Switzerland)

-

Endress+Hauser (Switzerland)

-

Krohne Group (Germany)

-

Emerson Electric (USA)

-

Dwyer Instruments (USA)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Float Level Switches Market Report |

| Base Year | 2024 |

| Segment by Type |

· Vertical Float Switches · Horizontal Float Switches · Multi-Point Float Switches |

|

Segment by Application |

· Oil Tanks · Water Treatment · Food & Beverage · Chemical Plants |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Float Level Switches Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Float Level Switches Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Float Level Switches Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Float Level Switches Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Float Level Switches Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Float Level Switches Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Float Level Switches Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Float Level Switches Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for Float Level Switches by 2025?

The market for Float Level Switches is expected to hit $1.1 billion by 2025. This growth is mainly due to the rising need for automation in various industries.

Which industries primarily use Float Level Switches?

Float Level Switches are primarily used in industries such as:

- Oil and gas

- Water treatment

- Chemical processing

They also play a crucial role in:

- Food and beverage systems

- Renewable energy systems

How Float Level Switches are adapting to modern industrial technologies

Float Level Switches are now integrated with Industrial Internet of Things (IIoT) platforms. This integration allows for real-time monitoring and data analytics. It also supports smart monitoring and predictive maintenance.

What are the main challenges in Float Level Switch technology?

Challenges include calibration drift and issues with float compatibility. They also face durability problems in harsh environments. To overcome these, manufacturers are using advanced calibration, new materials, and better designs.

How many types of Float Level Switches exist?

There are mainly three types: vertical, horizontal, and multi-point float switches. Each is designed for different needs and applications.

Are Float Level Switches being used in emerging technologies?

Yes, they are being used in new areas like smart cities, renewable energy, and advanced automation.

How do geopolitical factors impact the Float Level Switches market?

International trade, safety laws, and petrochemical policies affect the market. They influence supply chains and the development of Float Level Switch technology.

Which regions are experiencing the highest growth in Float Level Switches?

North America, Europe, Asia-Pacific, and the Middle East & Africa are at the forefront of growth. Each region has its own speed and preferences for technology.

How are Float Level Switches evolving with technological innovations?

The technology is advancing with new sensing technologies and wireless monitoring. It’s also becoming more compatible with modern control systems.

What future innovations are expected in Float Level Switch technology?

Future advancements will focus on better accuracy and reliability. There will also be more IoT-enabled solutions and designs for complex environments.