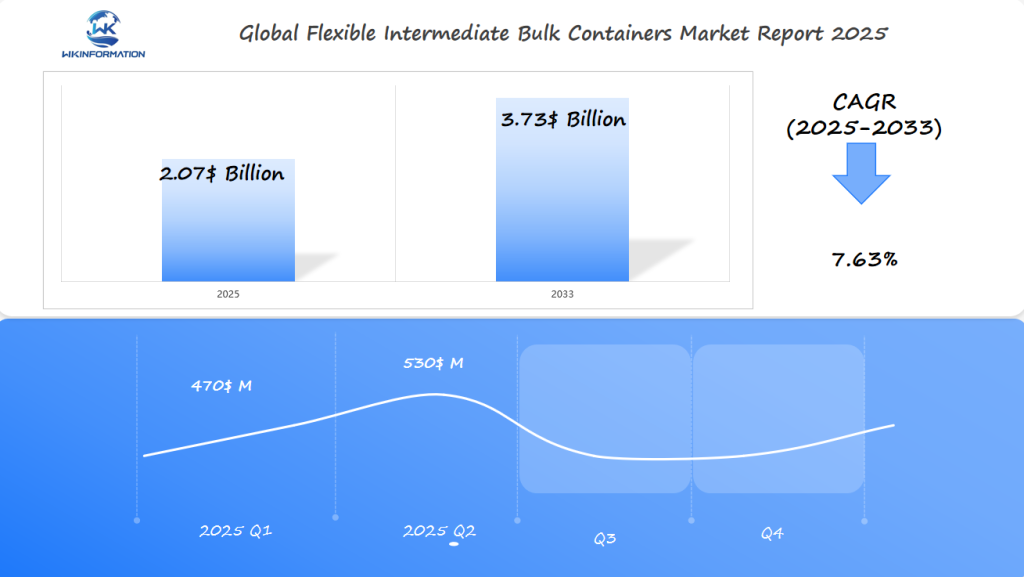

Flexible Intermediate Bulk Containers Market Expected to Reach $2.07 Billion by 2025: Bulk Material Handling in the U.S., India, and Brazil

Explore the growing Flexible Intermediate Bulk Containers Market, expected to reach $2.07 Billion by 2025.

- Last Updated:

Flexible Intermediate Bulk Containers Market Forecast for Q1 and Q2 2025

The Flexible Intermediate Bulk Containers (FIBC) market is projected to reach $2.07 billion in 2025, driven by a CAGR of 7.63% over the forecast period to 2033. Market size for Q1 2025 is estimated at approximately $470 million, reflecting a measured start influenced by fluctuating raw material costs and supply chain adaptations. By Q2, the market is expected to grow significantly to around $530 million, supported by rising demand across agriculture, chemical, and construction sectors.

The U.S., India, and Brazil are identified as pivotal markets, with expanding industrial activities and evolving packaging regulations fueling adoption. These countries remain critical focal points for assessing early 2025 growth patterns and strategic investment opportunities in bulk packaging solutions.

Upstream and Downstream Industry Chain Analysis of the Flexible Intermediate Bulk Containers Market

A comprehensive analysis of the FIBC market requires a deep dive into its supply chain dynamics. The FIBC market is influenced by various factors across the supply chain, including raw material suppliers, manufacturers, and end-users.

The upstream segment of the industry chain includes suppliers of raw materials such as polypropylene and polyethylene. These materials are crucial for the production of FIBCs, and their prices can significantly impact the overall cost of FIBC manufacturing.

Understanding the supply chain dynamics

The supply chain dynamics of the FIBC market are complex, involving multiple stakeholders. The downstream segment comprises industries that use FIBCs, such as chemicals, food products, and construction materials. Understanding the demands and requirements of these industries is vital for FIBC manufacturers to tailor their products accordingly.

Effective supply chain management in the FIBC market involves:

- Coordinating with raw material suppliers

- Optimizing production processes

- Ensuring timely delivery to end-users

This not only helps in reducing costs but also in improving customer satisfaction.

Key aspects of the FIBC supply chain

To gain a comprehensive understanding of the FIBC supply chain, it is essential to analyze the following key aspects:

- Raw material sourcing and procurement

- Production and manufacturing processes

- Logistics and distribution

- End-user industries and their specific requirements

By analyzing these aspects of the supply chain, stakeholders can identify opportunities for growth and improvement in the FIBC market.

Trends in cost-effective and efficient bulk packaging solutions

The trend towards cost-effective bulk packaging is transforming the Flexible Intermediate Bulk Containers (FIBC) market. As industries continue to demand more efficient and cost-effective packaging solutions, manufacturers are responding with innovative designs and manufacturing processes.

Innovations in FIBC design and manufacturing

FIBC manufacturers are focusing on design innovations that enhance the functionality and efficiency of bulk packaging. This includes the development of FIBCs with improved durability, better material handling, and more efficient filling and discharge systems.

The use of advanced materials and manufacturing technologies is enabling the production of high-quality FIBCs that meet the specific needs of various industries, from chemicals to food products.

Impact of technological advancements on FIBC production

Technological advancements are playing a crucial role in the evolution of FIBC production. Advances in material science and manufacturing processes are allowing for the creation of FIBCs that are not only more durable but also more efficient in terms of material usage and transportation costs.

Some of the key technological advancements include:

- The use of advanced polymers and fabrics that offer improved strength and durability.

- Innovative manufacturing processes that enable the production of customized FIBCs with specific features such as anti-static properties or enhanced UV resistance.

- The integration of smart technologies into FIBCs for real-time tracking and monitoring.

These innovations are expected to drive the growth of the FIBC market by providing end-users with more efficient, cost-effective, and reliable bulk packaging solutions.

Market restrictions due to environmental concerns and material regulations

With rising environmental concerns, the FIBC market is experiencing a shift towards more sustainable practices and materials. The use of non-biodegradable materials in FIBC production has been a significant environmental concern, prompting regulatory bodies to impose stricter regulations.

Impact of environmental regulations on FIBC production

The FIBC industry is facing increasing pressure to comply with environmental regulations, which are expected to slow down market growth. Manufacturers are moving towards eco-friendly materials and production methods to reduce the environmental impact of FIBCs.

Key environmental concerns include:

- The use of non-biodegradable materials

- Inadequate disposal methods for used FIBCs

- Potential for pollution during production and transportation

To tackle these issues, regulatory bodies are introducing stricter guidelines for FIBC production, such as using recyclable materials and implementing more efficient disposal methods. This change is driving innovation in the industry, with manufacturers looking into new materials and designs that have a smaller environmental footprint.

The shift towards sustainable practices is not just about following regulations but also about gaining a competitive edge. Companies that actively embrace eco-friendly practices are likely to enjoy a better brand image and stronger customer loyalty.

Geopolitical factors influencing global trade and agricultural exports

Understanding the relationship between geopolitical factors and global trade is essential for comprehending the ups and downs of agricultural exports and FIBC demand. When geopolitical tensions arise, trade policies may change, which can impact the flow of goods, including agricultural products, across borders.

The impact of trade policies on FIBC demand

Trade policies, such as tariffs and quotas, have a significant effect on the demand for FIBCs. For example, if tariffs on agricultural products increase, it may result in a decrease in exports. Consequently, this decline in exports would lead to a reduced need for FIBCs used in the agricultural sector.

Impact of trade policies on FIBC demand

The demand for FIBCs is closely tied to the global trade dynamics, particularly in the agricultural sector. Changes in trade policies can either boost or hinder the demand for FIBCs.

- Tariffs and quotas can reduce agricultural exports, leading to decreased demand for FIBCs.

- Trade agreements can facilitate the export of agricultural products, increasing the demand for FIBCs.

- Political stability in key agricultural-producing countries can ensure a steady supply of FIBCs.

The table below illustrates the potential impact of geopolitical factors on FIBC demand in different regions.

| Region | Geopolitical Factor | Impact on FIBC Demand |

| North America | Trade agreements | Increased demand |

| Europe | Tariffs on imports | Decreased demand |

| Asia | Political stability | Steady demand |

Understanding these dynamics is essential for FIBC manufacturers to anticipate and respond to changes in demand. By monitoring geopolitical developments and their impact on global trade, manufacturers can adjust their production and distribution strategies accordingly.

Segmentation by Type: Type A, B, C, and D FIBCs

Understanding the different types of FIBCs is crucial for determining their applications across various industries. The Flexible Intermediate Bulk Containers market is segmented into Type A, B, C, and D FIBCs, each designed to meet specific industrial needs.

Type A FIBCs are standard containers made from woven polypropylene fabric. They are suitable for packaging dry, free-flowing powders and granules. Type A FIBCs are commonly used in industries such as food products and construction materials, where the product does not require special electrostatic discharge properties.

Characteristics and applications of different FIBC types

Type B FIBCs

Type B FIBCs are also made from woven polypropylene but are designed to be used where there is a risk of ignition. They are not intended for use in hazardous areas but offer a level of safety due to their construction. Type B FIBCs are often used in the chemical industry for products that are not highly sensitive to static electricity.

Type C FIBCs

Type C FIBCs are designed with conductive threads woven into the fabric, providing a safe discharge path for static electricity. This makes Type C FIBCs ideal for use in hazardous environments where the risk of explosion is high, such as in certain chemical processing operations.

Type D FIBCs

Type D FIBCs, also known as static dissipative FIBCs, are made with a special fabric that allows static electricity to be dissipated without the need for grounding. Type D FIBCs are used in applications where the product is sensitive to static electricity, and there’s a need to prevent static discharge.

The choice of FIBC type depends on the specific requirements of the product being packaged, including considerations for static electricity, product safety, and regulatory compliance. By understanding the characteristics and applications of Type A, B, C, and D FIBCs, businesses can select the most appropriate container for their needs, ensuring safe and efficient transportation and storage of their products.

Segmentation by Application: Chemicals, Food Products, Pharmaceuticals, and Construction Materials

FIBCs are used in various industries such as chemicals, food products, pharmaceuticals, and construction materials. Each industry has its own specific needs. To effectively serve these industries, it is important to have a thorough understanding of their requirements and the regulations that apply to them.

Industry-Specific Requirements for FIBCs

Different industries have specific requirements when it comes to Flexible Intermediate Bulk Containers (FIBCs). Here are some of the key industries and their respective FIBC requirements:

1. Chemicals Industry

The chemicals industry requires FIBCs that can handle corrosive materials and safely transport hazardous substances. These FIBCs must also have safety features like static-dissipative materials to prevent any ignition sources.

Chemical Industry Requirements:

- Resistance to corrosive substances

- Static-dissipative properties

- Compliance with hazardous materials regulations

2. Food Products Industry

On the other hand, the food products industry demands FIBCs that meet strict food-grade standards. This ensures that the packaging material does not contaminate the food being stored or transported. Additionally, these FIBCs should be cleanable and designed to prevent the growth of bacteria and other microorganisms.

Food Products Industry Requirements:

- Food-grade material compliance

- Cleanability and sanitation

- Prevention of microbial growth

3. Pharmaceuticals Industry

The pharmaceuticals sector has its own set of requirements for FIBCs. These containers must maintain the integrity and efficacy of pharmaceutical products, protecting them from contamination during transportation and storage. Compliance with pharmaceutical regulations is also crucial in this industry.

Pharmaceuticals Industry Requirements:

- Protection against contamination

- Maintenance of product integrity

- Compliance with pharmaceutical regulations

4. Construction Materials Industry

Finally, the construction materials industry relies on FIBCs for efficient transportation of bulk materials such as sand, gravel, and cement. These containers need to be durable enough to withstand harsh conditions on construction sites while ensuring strength in handling heavy loads.

Construction Materials Industry Requirements:

- Durability and strength

- Resistance to weather conditions

- Efficiency in bulk material handling

FIBC applications

| Industry | FIBC Requirements | Key Features |

| Chemicals | Resistance to corrosive substances, static-dissipative properties | Safety features, compliance with hazardous materials regulations |

| Food Products | Food-grade material, cleanability | Prevention of microbial growth, sanitation |

| Pharmaceuticals | Protection against contamination, maintenance of product integrity | Compliance with pharmaceutical regulations, product safety |

| Construction Materials | Durability, resistancetoweatherconditions | Efficiencyinbulkmaterialhandling,strength |

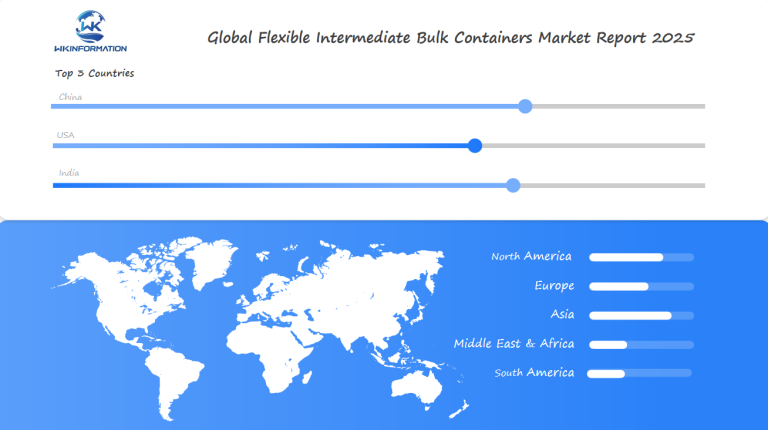

Global Regional Analysis of the Flexible Intermediate Bulk Containers Market

The FIBC market is influenced by various regional factors, including industrial growth, trade policies, and regulatory environments. Understanding these regional dynamics is crucial for stakeholders to identify opportunities and challenges.

Regional market trends and growth prospects

The global FIBC market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World. Each region exhibits unique market trends driven by local industrial activities, economic conditions, and regulatory frameworks.

North America

The region is characterized by a high demand for FIBCs, driven by the chemical and agricultural industries. The presence of key manufacturers and a well-developed logistics infrastructure further contribute to market growth.

Europe

Europe’s FIBC market is influenced by stringent environmental regulations and a strong focus on sustainable packaging solutions. The region’s industrial sector, particularly in Germany and the UK, drives the demand for high-quality FIBCs.

Asia-Pacific

This region is expected to witness significant growth due to rapid industrialization, expanding agricultural sectors, and increasing trade activities. Countries like China and India are major contributors to the region’s FIBC demand.

| Region | Key Drivers | Growth Prospects |

| North America | Chemical and agricultural industries, logistics infrastructure | Steady growth driven by industrial demand |

| Europe | Environmental regulations, industrial sector | Moderate growth with a focus on sustainability |

| Asia-Pacific | Industrialization, agricultural expansion, trade activities | High growth potential driven by regional development |

The Rest of the World, including regions like Latin America and the Middle East, also presents opportunities for FIBC manufacturers due to growing industrial and agricultural activities.

Regional market analysis is essential for understanding the global FIBC market’s complexities. By examining regional trends and growth prospects, stakeholders can make informed decisions to capitalize on emerging opportunities.

The U.S. market's advancements in industrial packaging solutions

The U.S. industrial packaging landscape is evolving rapidly with advancements in Flexible Intermediate Bulk Containers (FIBCs). The demand for FIBCs is increasing across various industries, including chemicals, food products, and construction materials, driven by the need for efficient and cost-effective packaging solutions.

The U.S. FIBC market is benefiting from technological innovations that enhance the design and manufacturing of FIBCs. These advancements include improved material durability, better sealing mechanisms, and more efficient filling and discharge systems.

Impact of Technological Innovations

Technological innovations are significantly impacting the U.S. FIBC market. Some of the key advancements include:

- Enhanced Material Quality: New materials and manufacturing processes are improving the durability and performance of FIBCs.

- Advanced Design Features: Innovations in design are making FIBCs more user-friendly and efficient.

- Increased Safety Features: Technological advancements are incorporating more safety features into FIBCs, reducing the risk of accidents and spills.

The following table highlights some of the key technological innovations and their benefits in the U.S. FIBC market:

| Technological Innovation Benefits Improved Material Durability | Enhanced strength and resistance to damage |

| Better Sealing Mechanisms | Reduced risk of spills and leaks |

| Efficient Filling and Discharge Systems | Increased productivity and reduced labor costs |

These technological innovations are expected to drive the growth of the U.S. FIBC market in the coming years. As industries continue to demand more efficient and cost-effective packaging solutions, the market is likely to witness significant advancements.

India's growing agricultural exports and packaging needs

India’s growing agricultural exports are presenting new opportunities for the packaging industry, particularly for FIBC manufacturers. The agricultural sector is a significant contributor to India’s economy, and the increasing demand for Indian agricultural products globally is driving the need for efficient packaging solutions.

FIBC manufacturers in India

The government’s initiatives to boost agricultural exports have led to a surge in the demand for Flexible Intermediate Bulk Containers (FIBCs). These high-capacity bags, often referred to as FIBCs, are widely used in the agricultural sector for packaging and transporting goods such as grains, fertilizers, and other commodities. They offer an ideal solution due to their durability, cost-effectiveness, and ability to hold large quantities of products.

As the demand for Indian agricultural products continues to rise globally, the need for efficient and reliable packaging solutions like FIBCs will only increase. This presents a lucrative opportunity for FIBC manufacturers in India to expand their operations and cater to this growing market.

Opportunities for FIBC Manufacturers

The growing demand for FIBCs in India’s agricultural sector presents significant opportunities for manufacturers. To capitalize on this trend, FIBC manufacturers must focus on producing high-quality, durable, and cost-effective packaging solutions that meet the specific needs of the agricultural industry.

Some of the key opportunities for FIBC manufacturers in India include:

- Developing FIBCs that are tailored to the specific needs of the agricultural sector, such as containers for handling grains and other commodities.

- Investing in research and development to improve the quality and durability of FIBCs.

- Expanding production capacity to meet the growing demand from the agricultural sector.

By focusing on these areas, FIBC manufacturers in India can not only meet the growing demand for packaging solutions but also contribute to the country’s agricultural export growth.

Brazil's Growing Need for Bulk Packaging in Commodity Exports

Brazil’s commodity export sector is thriving, leading to a rising demand for dependable and affordable bulk packaging solutions. As one of the top exporters of commodities like soybeans, iron ore, and coffee, Brazil’s need for Flexible Intermediate Bulk Containers (FIBCs) is on the upswing. This increase is fueled by the requirement for effective packaging capable of accommodating substantial quantities of products.

Impact of Commodity Exports on Brazil’s FIBC Market

The growth in commodity exports has a direct and significant impact on Brazil’s FIBC market. As exports increase, so does the demand for packaging solutions that are both efficient and cost-effective. FIBCs have become a preferred choice for many industries due to their durability, flexibility, and the ability to be customized according to specific needs.

Demand Drivers for FIBCs in Brazil

The demand for FIBCs in Brazil is not only driven by the volume of commodity exports but also by the type of commodities being exported. For instance, the export of agricultural products like soybeans and coffee requires FIBCs that are designed to handle bulk quantities without damage.

| Commodity | Export Volume (2022) | FIBC Demand (2022) | Projected Demand (2025) |

| Soybeans | 100 million tons | 500,000 units | 700,000 units |

| Iron Ore | 200 million tons | 300,000 units | 500,000 units |

| Coffee | 50 million tons | 200,000 units | 300,000 units |

Market Growth Potential

The increasing demand for FIBCs in Brazil’s commodity export sector is expected to drive market growth. Manufacturers are focusing on producing high-quality FIBCs that meet international standards. This trend is likely to continue as Brazil’s commodity exports are projected to grow.

Future development outlook in the Flexible Intermediate Bulk Containers market

The Flexible Intermediate Bulk Containers (FIBC) market is expected to grow significantly, driven by emerging trends and increasing demand for efficient packaging solutions. As industries continue to evolve, the need for cost-effective and reliable packaging options is becoming more pronounced.

Emerging Trends Shaping the FIBC Market

Several emerging trends are expected to shape the future of the FIBC market.

Innovations in FIBC Design and Manufacturing

Innovations in FIBC design and manufacturing are leading to more efficient and sustainable packaging solutions. The use of advanced materials and technologies is enhancing the durability and versatility of FIBCs, making them suitable for a wider range of applications.

Increased Focus on Sustainability

Increased focus on sustainability is another key trend driving the market’s growth. With growing environmental concerns, industries are shifting towards more eco-friendly packaging options. FIBCs, being reusable and recyclable, are becoming a preferred choice for many businesses.

Rising Demand Across Industries

The demand for FIBCs is expected to rise across various industries, including chemicals, food products, pharmaceuticals, and construction materials. Each of these industries has specific requirements for packaging, and FIBCs are being tailored to meet these needs.

| Industry | FIBC Requirements | Growth Prospects |

| Chemicals | High durability, resistance to chemicals | High demand for safe and reliable packaging |

| Food Products | Food-grade materials, ease of cleaning | Growing need for hygienic and efficient packaging |

| Pharmaceuticals | Compliance with regulatory standards, tamper-evident | Increasing demand for secure and compliant packaging |

The future development outlook for the FIBC market is promising, with emerging trends and growth prospects indicating a positive trajectory. As the market continues to evolve, it is expected that innovations in design, manufacturing, and materials will play a crucial role in shaping its future.

Competitor analysis highlighting key players and innovations

The Flexible Intermediate Bulk Containers market is highly competitive, with several key players vying for dominance. A detailed competitor analysis shows that companies such as Greif, Inc. and Mondi Group are leading the way, propelling market expansion through innovative approaches.

Here are some of the major companies operating in this market:

- Berry Global – United States

- Greif – United States

- Mondi Group – United Kingdom

- Huhtamaki – Finland

- UPM Raflatac – Finland

- Smurfit Kappa – Ireland

- Amcor – Switzerland

- Sealed Air – United States

- Sonoco – United States

- Glenroy Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Flexible Intermediate Bulk Containers Report |

| Base Year | 2024 |

| Segment by Type |

· Type A · Type B · Type C · Type D |

| Segment by Application |

· Chemicals · Food Products · Pharmaceuticals · Construction Materials |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Flexible Intermediate Bulk Containers Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Flexible Intermediate Bulk Containers Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Women’s ActivewearMarket Segmentation Overview

Chapter 2: Competitive Landscape

- GlobalFlexible Intermediate Bulk Containers players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Flexible Intermediate Bulk Containers Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Flexible Intermediate Bulk Containers Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Flexible Intermediate Bulk Containers Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWomen’s ActivewearMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the expected growth rate of the Flexible Intermediate Bulk Containers market?

The Flexible Intermediate Bulk Containers market is expected to reach $2.07 billion by 2025, driven by the rising need for bulk material handling.

What are the key factors influencing the FIBC market?

The FIBC market is influenced by various factors, including raw material suppliers, manufacturers, and end-users, as well as environmental concerns and material regulations.

What are the different types of FIBCs available in the market?

FIBCs are categorized into different types, including Type A, B, C, and D, each with its characteristics and applications.

Which industries use FIBCs?

FIBCs are used in various industries, including:

- Chemicals

- Food products

- Pharmaceuticals

- Construction materials

Each industry has its own specific requirements and regulations.

How do trade policies and tariffs impact the demand for FIBCs?

Changes in trade policies and tariffs can impact the demand for FIBCs, particularly in the agricultural sector, making it essential for manufacturers to monitor these factors.

What is driving the growth of the FIBC market in India?

India’s growing agricultural exports are creating opportunities for FIBC manufacturers, driven by government initiatives and increasing demand from global markets.

What is the outlook for the FIBC market in Brazil?

Brazil’s demand for bulk packaging solutions, including FIBCs, is increasing due to the growing commodity exports, driving the growth of the Brazilian FIBC market.

Who are the key players in the FIBC market?

The FIBC market is highly competitive, with key players such as Greif, Inc., and Mondi Group, adopting various strategies, including innovations in FIBC design and manufacturing.

What are the emerging trends in the FIBC market?

The FIBC market is experiencing several emerging trends, such as:

- The increasing demand for efficient and cost-effective packaging solutions

- Technological innovations in the industry

- Growing industrialization across various sectors