Fire Assay Crucible Market to Hit $251.4 Million by 2025: Mining and Metallurgy Growth in the U.S., South Africa, and Canada

In this article, we will explore how technological advancements are improving assay precision through innovations like automated systems and high-temperature electric furnaces. These developments promise improved efficiency in mining operations. We will also discuss initiatives promoting material sustainability, which foster an environmentally friendly approach to fire assaying.

- Last Updated:

Fire Assay Crucible Market Outlook for Q1 and Q2 2025

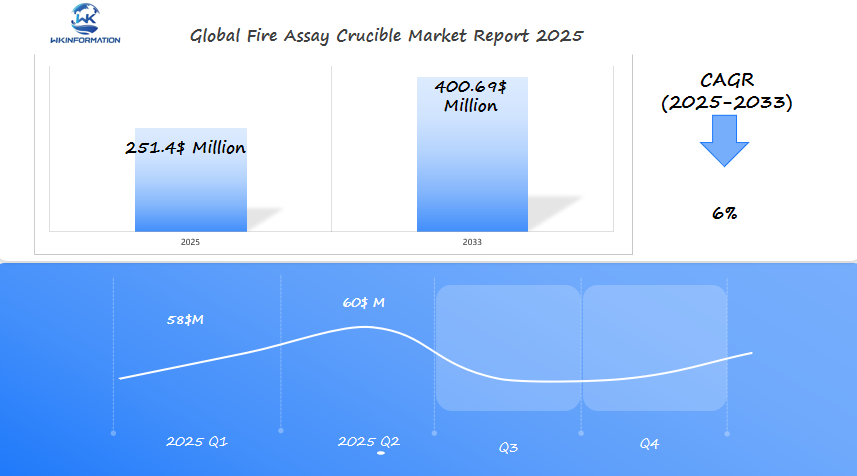

The Fire Assay Crucible market is projected to reach $251.4 million in 2025, with a CAGR of 6% from 2025 to 2033. In Q1 2025, the market is expected to be valued at $58 million, driven by the increasing use of fire assay crucibles in mining and metal testing industries in the U.S., South Africa, and Canada. These crucibles are essential for the precise analysis of precious metals, such as gold and silver, through the fire assay process.

By Q2 2025, the market is expected to reach $60 million, with the U.S. leading in demand due to its mining sector’s growth, South Africa focusing on its mining exploration activities, and Canada continuing to be a major player in gold mining. The expanding mining and metallurgy sectors will continue to fuel demand for high-quality fire assay crucibles.

Key Takeaways

- The global fire assay crucible market is projected to reach $251.4 million by 2025.

- The growth is driven by advancements in mining and metallurgy in countries like the U.S., South Africa, and Canada.

- The increasing demand for precious metal testing is a key factor contributing to market expansion.

- The expanding mining industry is also driving the growth of the crucible market.

- The demand for high-quality crucibles used in fire assay processes is growing.

Fire Assay Crucible Upstream and Downstream Industry Chain Analysis

Understanding the industry chain of fire assay crucibles requires a comprehensive analysis of its upstream and downstream components.

Upstream Component

The upstream segment involves suppliers of raw materials such as zirconium, silicon carbide, and other refractory materials used in the production of fire assay crucibles. These materials are crucial for the durability and heat resistance of the crucibles.

Understanding the Industry Chain

The industry chain of fire assay crucibles is complex, involving various stakeholders from raw material suppliers to end-users in the mining and metallurgy industries. The upstream segment is critical as it determines the quality and availability of raw materials. Suppliers of high-quality raw materials play a vital role in ensuring that the crucibles manufactured are durable and can withstand high temperatures.

The downstream segment, on the other hand, involves the mining and metallurgy industries that use these crucibles for precious metal testing and extraction. The demand from these industries drives the production and innovation in fire assay crucibles. As the mining industry continues to evolve, the demand for high-quality crucibles is expected to increase.

Key Players in the Supply Chain

Key players in the supply chain of fire assay crucibles include raw material suppliers, crucible manufacturers, and distributors. Raw material suppliers such as those providing zirconium and silicon carbide are essential for the production of high-quality crucibles. Crucible manufacturers must innovate and improve their products to meet the evolving needs of the mining industry.

As stated by an industry expert, “The quality of the crucible is directly related to the quality of the raw materials used.” This emphasizes the importance of upstream suppliers in the industry chain. Furthermore, distributors play a crucial role in ensuring that the crucibles reach the end-users efficiently.

The integration of advanced materials and manufacturing techniques is expected to drive innovation in the fire assay crucible industry.

Overall, understanding the industry chain of fire assay crucibles is crucial for identifying trends and challenges in the market. By analyzing the upstream and downstream components, stakeholders can better navigate the complexities of the supply chain and make informed decisions.

Increasing use in gold, silver, and precious metal testing

The use of Fire Assay Crucibles is on the rise in the precious metal testing industry, driven by the need for accurate measurements. As the demand for gold, silver, and other precious metals continues to grow, the importance of precise testing methods becomes increasingly crucial.

Fire Assay Crucibles play a vital role in the testing process, allowing for the precise measurement of precious metal content in ores and other materials. The increasing demand for these metals, driven by investment and jewelry demand, is fueling the need for reliable testing methods.

Applications in Precious Metal Testing

Fire Assay Crucibles are used in various applications, including gold, silver, and other precious metal testing. The crucibles are designed to withstand high temperatures, ensuring accurate and reliable results.

The use of Fire Assay Crucibles in precious metal testing offers several benefits, including:

- High accuracy: Fire Assay Crucibles allow for precise measurements, ensuring accurate results.

- Reliability: The crucibles are designed to withstand high temperatures, reducing the risk of damage or contamination.

- Efficiency: Fire Assay Crucibles enable fast and efficient testing, streamlining the testing process.

| Application Benefits Gold testing | High accuracy, reliability, and efficiency |

| Silver testing | Precise measurements, reduced risk of contamination |

| Other precious metal testing | Accurate results, efficient testing process |

The growing demand for precious metals is driving the adoption of Fire Assay Crucibles in various testing applications. As the industry continues to evolve, the importance of accurate and reliable testing methods will remain a top priority.

Challenges in material durability, heat resistance, and supply chain logistics

The production and distribution of fire assay crucibles face several challenges, including issues with materials and logistics. Manufacturers need to create crucibles that can endure very high temperatures and have a longer lifespan, minimizing the need for frequent replacements.

Material Challenges

One of the significant challenges in the Fire Assay Crucible Market is improving material longevity and heat resistance. The crucibles used in fire assay processes, such as this , are exposed to extreme temperatures, which can cause them to degrade over time. To address this, manufacturers are working to develop advanced materials that can withstand these conditions, thereby improving the overall quality and reliability of the crucibles.

Recent advancements in material science have led to the development of new materials with enhanced properties. For instance, some manufacturers are now using high-quality ceramic materials that offer superior heat resistance and durability. The use of such materials not only improves the performance of the crucibles but also reduces the need for frequent replacements, thereby saving time and costs.

Supply Chain Issues

Another challenge facing the Fire Assay Crucible Market is related to supply chain logistics. The availability of raw materials and the production capacity of manufacturers can impact the supply of crucibles. Disruptions in the supply chain can lead to delays and increased costs, affecting the overall efficiency of the industry.

To mitigate these issues, manufacturers are adopting strategies to strengthen their supply chains. This includes diversifying their supplier base, investing in inventory management systems, and developing contingency plans to address potential disruptions. By doing so, they can ensure a more stable supply of raw materials and finished crucibles, ultimately benefiting the end-users.

| Challenge | Description | Impact |

| Material Longevity | Degradation of crucible material over time | Increased replacement costs and downtime |

| Heat Resistance | Inability to withstand extreme temperatures | Reduced crucible performance and accuracy |

| Supply Chain Logistics | Disruptions in raw material supply and production | Delays and increased costs |

Understanding the Global Mining Industry: The Impact of Geopolitics

Geopolitical factors are essential in shaping the global mining industry. Various elements, such as regional trends, regulatory shifts, and geopolitical occurrences, influence this sector.

Regional Mining Trends

Different regions have distinct mining trends, driven by factors such as geological characteristics, investment climate, and local regulations. For instance, the United States has seen significant growth in mining activities due to favorable regulations and abundant mineral resources.

In contrast, other regions face challenges related to political instability, environmental concerns, or infrastructure limitations. Understanding these regional trends is essential for companies operating in the global mining industry.

Mining Regulations

Mining regulations vary significantly across different countries and regions. Some countries have stringent environmental regulations, while others may have more lenient laws.

Companies operating in the global mining industry must comply with local regulations, which can impact their operations and profitability. Regulatory changes can also affect the industry’s overall trends and outlook.

- Regional regulations influence mining activities

- Companies must adapt to changing regulatory environments

- Regulatory changes can impact industry trends and outlook

The global mining industry is subject to a complex array of geopolitical influences and regulatory frameworks. Understanding these dynamics is crucial for companies operating in this industry, as they navigate the challenges and opportunities presented by regional trends and regulatory changes.

Segmentation by material composition, size, and heat resistance

The fire assay crucible market can be segmented based on various factors including material composition, size, and heat resistance. This segmentation is crucial for understanding the diverse needs of the mining and metallurgy industries.

Material Composition Variations

Different materials used in the manufacture of fire assay crucibles offer varying levels of durability and heat resistance. For instance, crucibles made from certain ceramic materials are known for their high heat resistance, making them suitable for applications involving extremely high temperatures.

The choice of material also affects the crucible’s resistance to chemical corrosion, which is a critical factor in the extraction and analysis of precious metals. Manufacturers often provide crucibles made from a range of materials to cater to different customer needs.

Size and Heat Resistance Factors

The size of a fire assay crucible is another important factor, as it determines the quantity of material that can be processed in a single assay. Larger crucibles can handle more material, making them suitable for high-volume applications.

Heat resistance is closely related to the material composition of the crucible. Crucibles with high heat resistance can withstand the extreme temperatures required for fire assaying, ensuring that the material being analyzed is not contaminated or altered during the process.

- Crucibles are available in various sizes to meet different application needs.

- The material composition affects the crucible’s durability and resistance to chemical corrosion.

- High heat resistance is critical for applications involving extreme temperatures.

Applications in precious metal extraction, chemical testing, and refining

Fire Assay Crucibles are versatile tools used in various industries, including chemical testing and precious metal extraction. These crucibles are built to endure extreme heat, making them perfect for a wide range of industrial uses.

Precious Metal Extraction

In the realm of precious metal extraction, Fire Assay Crucibles are indispensable. These specialized crucibles are used to melt and separate metals from ores. The process involves heating the ore to high temperatures, allowing the metal to be extracted and purified. The crucibles must be able to withstand extreme temperatures and corrosive environments.

Applications of Fire Assay Crucibles

The applications of Fire Assay Crucibles in precious metal extraction, chemical testing, and refining highlight their importance in various industrial processes. Their ability to withstand high temperatures and corrosive environments makes them a vital component in these applications.

1. Precious Metal Extraction

In precious metal extraction, Fire Assay Crucibles are used to melt and separate metals from ores.

2. Chemical Testing

In chemical testing, these crucibles are used to analyze the composition of materials.

3. Refining

In refining, they play a crucial role in purifying metals to high levels of purity.

The high-temperature resistance and durability of Fire Assay Crucibles make them an essential tool in these processes.

Regional growth patterns and demand in mining-heavy regions

Regional growth patterns play a crucial role in determining the demand for Fire Assay Crucibles in the mining industry. The demand for these crucibles is not uniform across the globe; instead, it is heavily influenced by the mining activities in specific regions.

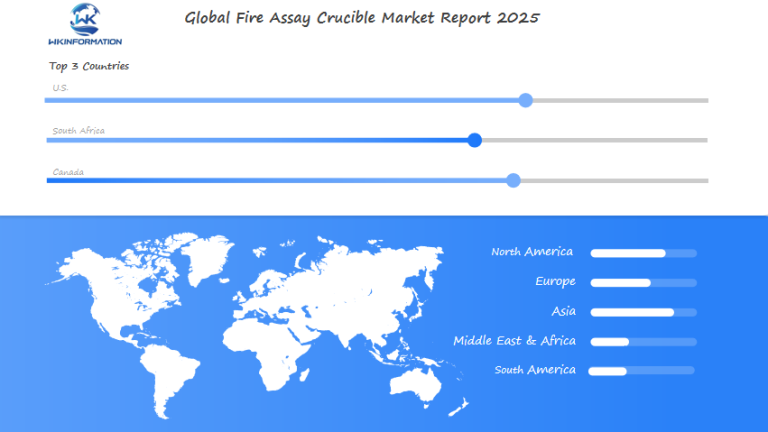

The U.S., South Africa, and Canada are among the countries with significant mining activities, leading to a high demand for Fire Assay Crucibles. Mining-heavy regions drive the demand for these crucibles due to their critical role in the extraction and analysis of precious metals.

Regional Demand Analysis

The regional demand analysis reveals that the demand for Fire Assay Crucibles is closely tied to the mining industry’s growth patterns. In regions with increased mining activities, the demand for these crucibles tends to be higher.

A detailed analysis of regional demand patterns is essential for manufacturers and suppliers looking to expand their market presence. By understanding the growth patterns in mining-heavy regions, businesses can better tailor their strategies to meet the demand for Fire Assay Crucibles.

| Region | Mining Activities | Demand for Fire Assay Crucibles |

| U.S. | Significant gold and precious metal mining | High demand |

| South Africa | Major gold and platinum mining industry | High demand |

| Canada | Significant mineral exploration and mining | Moderate to high demand |

The table above illustrates the demand for Fire Assay Crucibles in different regions. The U.S. and South Africa have a high demand due to their significant mining activities, while Canada’s demand is moderate to high.

Understanding these regional growth patterns and demand trends is crucial for businesses operating in the Fire Assay Crucible market. By analyzing these patterns, companies can identify opportunities for growth and develop targeted strategies to meet the demand in mining-heavy regions.

U.S. Demand for Fire Assay Equipment in Gold and Precious Metals Processing

Fire assay equipment, including crucibles, is essential for the U.S. mining industry, especially in the processing of gold and precious metals. The United States has a large number of mining operations in different states, which creates a significant need for fire assay equipment.

The U.S. mining industry is well-established, with many operations extracting gold, silver, and other precious metals. The demand for fire assay equipment comes from the requirement for precise and effective processing of these metals. Fire assay crucibles are used to melt and analyze the metal content, ensuring that the extracted metals meet the necessary standards.

U.S. Mining Industry Overview

The U.S. mining industry is a significant contributor to the country’s economy, with many mining operations located in states such as Nevada, California, and Alaska. The industry is driven by the demand for precious metals, including gold, silver, and platinum. The use of fire assay equipment, including crucibles, is essential in the processing of these metals.

The image represents the U.S. mining industry, highlighting the importance of fire assay equipment in gold and precious metals processing.

The demand for fire assay equipment in the U.S. is also driven by the need for accurate and reliable results. Fire assay crucibles are designed to withstand high temperatures, ensuring that the metal content is accurately analyzed. The use of high-quality crucibles is essential in maintaining the integrity of the assay results.

South Africa’s growing mining industry driving crucible requirements

South Africa’s rich mineral resources have positioned the country as a significant player in the global mining industry, driving the need for crucibles. The country’s mining industry is a major contributor to its economy, with a long history of gold and precious metal extraction.

The South African mining sector is characterized by its rich mineral deposits, including gold, platinum, and other precious metals. As the industry continues to grow, the demand for high-quality fire assay crucibles is expected to increase.

South African Mining Sector

The growth of the mining industry in South Africa is driven by the country’s rich mineral resources and favorable mining policies. The industry is expected to continue growing, driven by increasing demand for precious metals and minerals.

- The country’s gold mining industry is one of the largest in the world, with many mines operating in the Witwatersrand Basin.

- South Africa is also a significant producer of platinum and other precious metals, with many mines operating in the Bushveld Complex.

- The mining industry is a major contributor to South Africa’s economy, providing employment and generating revenue.

As the mining industry growth continues, the demand for high-quality crucibles will increase, driving the need for manufacturers to improve their products and services.

Canada’s role in mineral exploration and assay laboratory growth

Canada has become a major player in the global mineral exploration industry, leading to the growth of assay laboratories. The country’s abundant mineral resources and favorable mining policies have attracted significant investment, resulting in increased exploration activities.

As a result, there has been a corresponding rise in the demand for high-quality assay crucibles. Assay laboratories in Canada are essential for analyzing mineral samples, determining their composition, and identifying potential mining opportunities.

Canadian Mineral Exploration

The Canadian mineral exploration industry is known for its wide range of geographical areas, from the Canadian Shield to the Cordilleran region. This variety offers both opportunities and challenges for miners and explorers.

Key areas include the provinces of Quebec, Ontario, and British Columbia, which are known for their abundant mineral deposits. The growth in these areas is supported by advancements in exploration technologies and a growing emphasis on sustainable mining practices.

Assay Laboratory Growth

The expansion of assay laboratories in Canada is closely connected to the growth of the mineral exploration sector. As exploration activities increase, so does the demand for dependable and precise assay results.

This has resulted in investments in laboratory infrastructure and technology, improving the abilities of Canadian assay laboratories to efficiently process and analyze mineral samples.

The rising need for assay crucibles is a direct result of this growth, as these crucibles are crucial for the accurate analysis of mineral samples.

Innovations in Crucible Material Technology and Durability

Innovations in material science are transforming the fire assay crucible industry, with a focus on durability and heat resistance. The development of new materials and manufacturing processes is essential for enhancing the performance of crucibles used in the mining and metallurgy sectors.

The advancements in crucible material technology are primarily aimed at improving the heat resistance and lifespan of crucibles. Manufacturers are allocating resources towards research and development efforts to produce materials capable of enduring high temperatures and corrosive conditions.

Advances in Material Technology

Recent breakthroughs in material science have led to the development of advanced ceramic materials and composites that offer superior durability and heat resistance. These materials are being used to manufacture crucibles that can perform consistently under high-temperature conditions.

The use of advanced materials also contributes to durability improvements in crucibles, reducing the need for frequent replacements and minimizing downtime in industrial processes.

Some of the key benefits of these advancements include:

- Increased heat resistance

- Improved material longevity

- Enhanced durability

- Better performance in corrosive environments

As the demand for high-quality crucibles continues to grow, manufacturers are expected to further innovate and improve their products, driving growth in the fire assay crucible market.

Key competitors in the fire assay crucible market

- Morgan — Windsor, UK

- CS CERAMIC — Zhuhai, China

- ATLANTIC Schmelztiegel Christoph — Aue, Germany

- Decent — Shanghai, China

- Western Refractories — Casper, USA

- Sepor — Los Angeles, USA

- Liling Xing Tai Long — Liling, China

- Jintuo Group — Qingdao, China

- Qingdao Yosion — Qingdao, China

- Qingdao Kingpro — Qingdao, China

Overall

| Report Metric | Details |

| Report Name | Global Fire Assay Crucible Market Report |

| Base Year | 2024 |

| Segment by Type | · Below 100ml

· 100ml-500ml · Above 500ml |

| Segment by Application | · Precious Metal Analysis

· Mineral Analysis · Fire Analysis · Gold Analysis · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Fire Assay Crucible Market is expected to grow significantly, driven by the expanding mining and metallurgy industries. As the demand for precious metal testing continues to rise, advancements in material technology are playing a crucial role in shaping the market’s future.

Emerging Trends and Opportunities

The market for fire assay crucibles is expected to grow significantly due to the increasing use of these crucibles in testing gold, silver, and other precious metals. Key regions driving this growth are the U.S., South Africa, and Canada, which have significant mining activities and require high-quality assay equipment.

As the market evolves, companies that innovate and adapt to changing conditions are likely to succeed. The development of more durable and heat-resistant crucibles is expected to drive growth, with major competitors in the market investing heavily in research and development.

The outlook for the Fire Assay Crucible Market is positive, with significant opportunities for growth and development. As the mining and metallurgy industries continue to expand, the demand for high-quality fire assay crucibles is expected to rise, driving market growth and innovation.

Global Fire Assay Crucible Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Fire Assay Crucible Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Fire Assay CrucibleMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Fire Assay Crucibleplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Fire Assay Crucible Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Fire Assay Crucible Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Fire Assay Crucible Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofFire Assay CrucibleMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Fire Assay Crucible Market by 2025?

The Fire Assay Crucible Market is expected to reach $251.4 million by 2025.

What are the key factors driving the growth of the Fire Assay Crucible Market?

The growth of the Fire Assay Crucible Market is driven by:

- Advancements in mining and metallurgy, particularly in countries like the U.S., South Africa, and Canada.

- Increasing demand for precious metal testing.

What are some of the challenges faced by the Fire Assay Crucible Market?

The Fire Assay Crucible Market faces challenges related to material longevity, heat resistance, and supply chain logistics, including the need for improved materials and manufacturing processes.

How is the Fire Assay Crucible Market segmented?

The Fire Assay Crucible Market can be segmented based on material composition, size, and heat resistance, with different materials and sizes suitable for different applications.

What are the key applications of Fire Assay Crucibles?

Fire Assay Crucibles are used in various applications, including precious metal testing, extraction, chemical testing, and refining, playing a critical role in the mining and metallurgy industries.

Which regions are driving the demand for Fire Assay Crucibles?

The demand for Fire Assay Crucibles is driven by mining-heavy regions, including the U.S., South Africa, and Canada, where significant mining activities are taking place.

What is the outlook for the Fire Assay Crucible Market?

The outlook for the Fire Assay Crucible Market is positive, with significant opportunities for growth and development driven by the expanding mining and metallurgy industries.

What innovations are taking place in the Fire Assay Crucible Market?

The Fire Assay Crucible Market is witnessing innovations in material technology aimed at improving durability and performance, including the development of new materials and manufacturing processes.