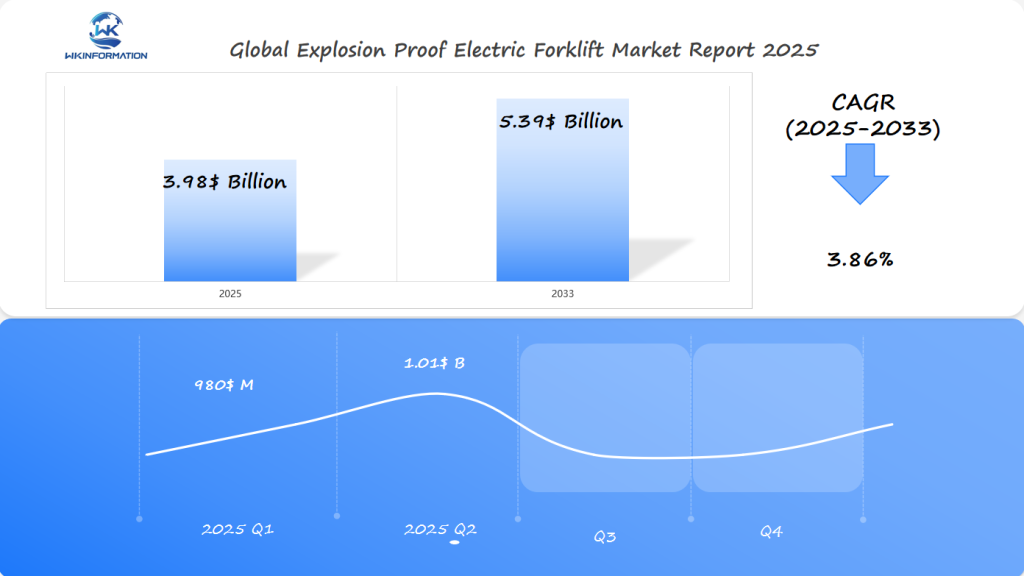

2025 Explosion Proof Electric Forklift Market Boom: Exceeding $3.98 Billion with Enhanced Safety Solutions in US, Germany, and China

Discover the booming explosion proof electric forklift market set to exceed $3.98 Billion by 2025, driven by enhanced safety solutions in US, Germany & China.Learn about advanced safety solutions, market trends, and key developments across the US, Germany, and China in high-risk industrial sectors.

- Last Updated:

Explosion Proof Electric Forklift Market Q1 and Q2 2025 Predictions

The Explosion Proof Electric Forklift market size in 2025 is expected to reach USD 3.98 billion, with a CAGR of 3.86% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately USD 980 million, driven by the growing demand for safe material handling solutions in industries such as mining, chemical, and petrochemical sectors, where explosive environments require specialized equipment.

The US, Germany, and China are expected to lead the market, with increased adoption of explosion proof electric forklifts to comply with safety regulations. By Q2 2025, the market is expected to reach around USD 1.01 billion as the trend toward automation and sustainable energy solutions in industrial operations continues to rise.

Analyzing the Upstream and Downstream Dynamics of the Explosion Proof Electric Forklift Market

To fully grasp the supply chain behind explosion proof electric forklifts, it’s essential to look at the different parts involved and the major manufacturers who are crucial in production. Leading companies such as Toyota, Mitsubishi, and Hyster-Yale are at the forefront of this industry. They are primarily focused on incorporating cutting-edge safety features into their designs to comply with international regulations.

Key Players in Production

These manufacturers have strict manufacturing processes in place that prioritize adherence to safety certifications. Additionally, they utilize innovative technologies to improve the reliability of their products.

- Toyota: Known for its commitment to quality and efficiency, Toyota integrates advanced safety systems into its electric forklifts.

- Mitsubishi: With a focus on sustainability, Mitsubishi incorporates eco-friendly technologies in its forklift production while ensuring compliance with safety standards.

- Hyster-Yale: This company specializes in heavy-duty electric forklifts designed for demanding environments, meeting rigorous safety requirements.

The Importance of Distribution Channels

Another crucial aspect of the market dynamics is the role played by distribution channels. Explosion proof electric forklifts are specialized vehicles that require a well-organized logistics framework for safe and efficient delivery to high-risk industries such as oil, gas, and mining.

Components of the Distribution Network

The distribution network typically consists of:

- Direct sales through manufacturer representatives.

- Collaborations with specialized industrial equipment suppliers.

- Aftermarket services offering maintenance and parts replacement.

Logistics strategies often involve sophisticated tracking systems for managing inventory, ensuring timely delivery while upholding strict safety protocols during transportation. This approach is vital for meeting the urgent needs of industries where operational safety is critical.

The Connection Between Manufacturing and Distribution

The relationship between manufacturing excellence and strategic distribution demonstrates how explosion proof electric forklifts effectively reach end-users. This ensures that these essential assets operate safely within hazardous environments worldwide.

Key Trends Shaping the Explosion Proof Electric Forklift Industry

Exploration into key industry trends reveals significant developments in safety features and technological advancements.

Advanced Safety Features

Manufacturers are introducing advanced safety elements such as explosion proof lighting systems and intrinsically safe solutions designed for hazardous areas. These innovations enhance operational safety by reducing ignition risks in environments with flammable gases or combustible dust.

Technological Advancements

Technological advancements play a pivotal role in improving the efficiency and performance of explosion proof electric forklifts. New battery technologies are being developed that not only extend operational hours but also minimize hazards associated with battery recharging in explosive atmospheres. Enhanced motor designs contribute to better energy consumption, ensuring that these forklifts perform optimally while adhering to safety standards.

Regulatory Compliance

An essential aspect of market growth is strict regulatory compliance with international standards like IECEx. Compliance ensures equipment used in explosive atmospheres meets rigorous safety criteria, providing assurance of reliability and safety to industries operating under high-risk conditions. This compliance is crucial for manufacturers aiming to maintain competitive advantage and trust within the market.

As these trends continue to evolve, they shape the future landscape of explosion proof electric forklifts, driving innovation and setting new benchmarks for safety and performance across global markets.

Overcoming Challenges in Explosion Proof Electric Forklift Development

The development of explosion proof electric forklifts presents unique design challenges for manufacturers. Crafting a vehicle capable of operating safely in volatile environments requires meticulous attention to components that could potentially ignite explosive materials. Manufacturers must consider factors such as the integration of explosion proof lighting systems and intrinsically safe electrical circuits, ensuring each element is robust enough to withstand hazardous conditions.

Obtaining safety approvals for these specialized forklifts involves rigorous testing and certification processes. Compliance with international standards like IECEx is mandatory, necessitating thorough evaluations to verify that every aspect of the forklift meets stringent safety requirements. This often includes stress testing under extreme conditions to ensure reliability and effectiveness in preventing ignition sources.

Despite advancements in technology and design, market barriers persist that may hinder the widespread adoption of explosion proof forklifts. High production costs associated with the specialized components and certification processes can lead to elevated prices, making these forklifts less accessible for smaller operations. Additionally, the necessity for ongoing maintenance and regulatory compliance presents long-term financial commitments that some companies might find challenging to sustain.

Navigating these complexities requires innovative solutions and strategic planning from manufacturers aiming to expand their presence in the Explosion Proof Electric Forklift Market.

Geopolitical Impact on Explosion Proof Electric Forklifts in Hazardous Locations

Understanding the geopolitical landscape is crucial for navigating the explosion proof electric forklift market. Regulations surrounding explosive atmospheres differ significantly across regions, often shaped by each country’s unique political and industrial context.

For instance, regions like the European Union enforce stringent safety regulations through frameworks such as the ATEX directive, influencing manufacturers’ design and compliance strategies. In contrast, other areas might have more relaxed standards, affecting market entry strategies. Such variations in regulatory environments can be further understood by examining comprehensive studies like this one from the Bureau of Safety and Environmental Enforcement which provides valuable insights into safety regulations in hazardous locations.

The Role of Political Stability

Political stability plays a pivotal role in shaping investment opportunities in industrial safety equipment across global markets. In politically stable regions, there is typically a consistent regulatory environment that encourages investment in safety technologies, including explosion proof forklifts. This stability attracts international manufacturers seeking reliable markets to expand their operations and promote safer industrial practices.

The Impact of Political Instability

On the other hand, political instability can deter investments due to unpredictable regulatory changes and potential disruptions in supply chains. Companies must remain agile and informed about geopolitical developments to capitalize on emerging opportunities while mitigating risks associated with volatile political climates.

By understanding these geopolitical factors, stakeholders can better navigate the complexities of global markets for explosion proof electric forklifts, aligning their strategies with regional regulatory requirements and political conditions to ensure successful market penetration.

Market Segmentation: Types of Explosion Proof Electric Forklifts and Their Applications

Explosion proof electric forklifts are categorized into distinct classes based on their design and safety features.

1. Class I Forklifts

These forklifts are specifically designed for environments where flammable gases or vapors may be present. These vehicles are crucial in sectors like oil and gas, where the risk of explosion is heightened due to volatile substances.

2. Class II Forklifts

These forklifts focus on areas prone to combustible dust, such as mining operations and certain manufacturing processes. These environments demand robust safety mechanisms to prevent ignition.

Applications of Explosion Proof Electric Forklifts

1. Oil and Gas Industry

In the oil and gas industry, explosion proof forklifts play a vital role in handling materials safely within refineries and storage facilities.

2. Mining Sector

The mining sector relies heavily on these specialized vehicles to transport equipment and raw materials without risking explosions from dust particles.

3. Manufacturing Facilities

Manufacturing facilities that produce or utilize chemicals also benefit from using these vehicles by maintaining operational safety.

Benefits of Explosion Proof Electric Forklifts

These forklifts not only enhance safety but also improve efficiency by allowing operations to continue smoothly under stringent conditions.

As industries expand and safety regulations tighten, the demand for these types of forklifts continues to rise, reflecting their indispensable role across various high-risk sectors. This diversification in applications highlights the adaptability and necessity of explosion proof technologies in modern industrial settings.

The Role of Explosion Proof Electric Forklifts in Dangerous Industrial Environments

In hazardous environments, maintaining operational safety is crucial. Explosion proof electric forklifts play a vital role in these situations. They are specifically designed to reduce the risk of ignition caused by flammable gases, vapors, and combustible dusts. By following strict safety standards like IECEx, these specialized vehicles create a controlled working environment, protecting both workers and equipment.

Why Are Explosion Proof Electric Forklifts Important?

The significance of explosion proof electric forklifts goes beyond just meeting regulations. They are an essential part of effective risk management strategies in high-risk industries such as oil & gas, mining, and chemical manufacturing. These forklifts are equipped with advanced safety features—such as explosion proof lighting systems and intrinsically safe components—that actively prevent potential ignition sources.

Here are two key reasons why explosion proof electric forklifts are important:

- Operational Efficiency: Explosion proof electric forklifts improve efficiency by allowing smooth operations in areas where conventional vehicles would be highly dangerous.

- Safety Assurance: By minimizing the chances of accidents related to explosive environments, they contribute to a safer workplace.

Investing in explosion proof forklifts is a proactive approach to managing risks that not only meets legal requirements but also supports the overall objective of maintaining uninterrupted and secure industrial operations.

Regional Insights: Explosion Proof Electric Forklift Market Growth Globally

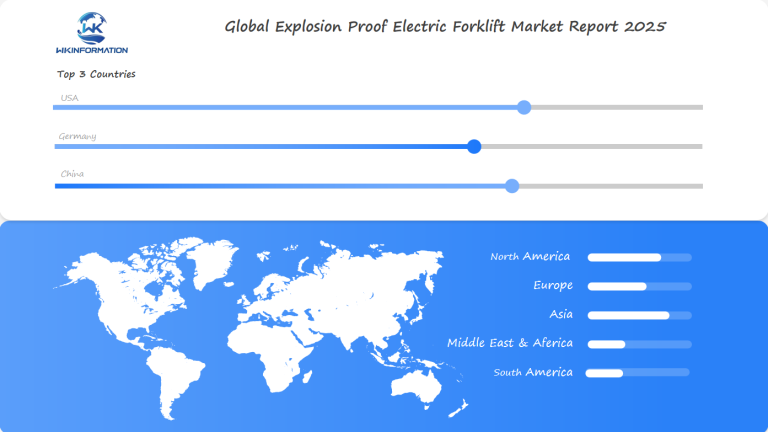

The explosion proof electric forklift market is experiencing significant growth, driven by regional factors that highlight the unique contributions of the US, Germany, and China. Each of these regions has its own specific factors that are pushing their markets forward.

United States

- The US market benefits from a strict regulatory environment that prioritizes workplace safety standards.

- Industries such as oil, gas, and manufacturing are increasingly adopting explosion proof forklifts to comply with these regulations.

- The emphasis on safety solutions aligns with a nationwide trend towards enhancing operational security in hazardous environments.

Germany

- Germany’s demand surge is closely tied to its strong oil and gas sector.

- The focus on industrial safety and compliance with international standards supports the adoption of explosion proof technologies.

- Manufacturing innovations within Germany also contribute to the growth of this market segment.

China

- China’s role as a manufacturing powerhouse cannot be understated.

- Production capacity and technological advancements position China as a leader in supplying explosion proof forklifts globally.

- The integration of cutting-edge technologies ensures that Chinese manufacturers meet both domestic and international safety requirements.

This regional analysis highlights the various factors influencing growth trends in key markets, emphasizing the interaction between regulatory frameworks, industrial demands, and technological advancements.

The US’s Market for Explosion Proof Electric Forklifts in Industrial Safety

The US explosion proof electric forklift market is experiencing significant expansion, driven by key factors that underscore the importance of industrial safety regulations. The implementation of stringent regulatory frameworks plays a pivotal role in shaping this growth trajectory. These frameworks are designed to promote workplace safety standards, particularly in industries where explosive atmospheres are a concern.

Key factors contributing to the rapid expansion of the US market include:

- Regulatory Compliance: Stringent regulations such as those enforced by the Occupational Safety and Health Administration (OSHA) mandate the use of explosion proof equipment in hazardous environments. Compliance with these regulations ensures that companies prioritize safety in their operations.

- Technological Innovations: As manufacturers strive to meet regulatory demands, there has been a surge in technological advancements. Innovations like explosion proof lighting systems and intrinsically safe designs enhance the safety and efficiency of electric forklifts, making them more attractive to industries operating under strict safety guidelines.

- Rising Awareness: There is an increasing awareness among businesses about the risks associated with flammable gases, vapors, and combustible dusts. This awareness drives demand for advanced safety solutions, prompting companies to invest in explosion proof forklifts to mitigate potential hazards.

- Economic Incentives: Government incentives for adopting safer industrial practices further stimulate market growth. By offering tax breaks or subsidies for compliance with safety standards, policymakers encourage companies to upgrade their equipment to meet modern safety requirements.

In sum, these driving forces collectively foster an environment conducive to growth within the US explosion proof electric forklift market. As regulations continue to evolve, manufacturers and businesses alike are motivated to innovate and comply with stringent standards, ensuring operational safety across various high-risk sectors.

China’s Contribution to Explosion Proof Forklift Manufacturing

China is a leader in the global market for explosion proof electric forklifts. Chinese manufacturers have used their large industrial base and technological expertise to gain a strong position in this industry. The country’s production capacity is unmatched, allowing them to quickly ramp up production to meet the increasing global demand for explosion proof solutions.

Several factors contribute to China’s dominance:

1. Robust Production Capabilities

China has a large number of manufacturing plants equipped with advanced technology. This allows Chinese manufacturers to efficiently produce high-quality forklifts in large quantities. As a result, they can deliver products on time to both domestic and international markets, earning a reputation as a reliable supplier.

2. Technological Advancements

Chinese manufacturers constantly invest in research and development to improve their products. This has led to significant advancements in areas such as battery technologies, lighting systems, and safety designs. These innovations are now standard features in Chinese-produced forklifts, enhancing both safety and operational efficiency.

3. Cost-Effective Manufacturing

By optimizing their production processes and sourcing materials locally, Chinese manufacturers can offer competitive pricing without sacrificing quality. This cost-effectiveness makes them appealing partners for industries worldwide that are looking for dependable yet affordable explosion proof solutions.

The combination of large production capacity and advanced technology puts China at the forefront of this specialized market. As the demand for safer industrial equipment continues to grow, China is well-positioned to serve both existing customers and new markets seeking reliable explosion proof electric forklifts.

Germany’s Demand for Explosion Proof Electric Forklifts in Oil and Gas Industries

Germany’s thriving oil and gas sector serves as a major catalyst for the increasing demand for explosion proof electric forklifts. This demand is driven by several key factors that make these specialized vehicles essential for safe operations in high-risk industries.

1. Stringent Safety Regulations

The German market operates under rigorous safety standards that necessitate the use of explosion proof equipment in hazardous environments. The strict adherence to these regulations ensures that the oil and gas industry prioritizes operational safety, leading to a higher demand for forklifts designed to function safely around flammable gases and vapors.

2. Innovation in Energy Efficiency

As Germany continues to lead in sustainability initiatives, there is a growing emphasis on energy-efficient solutions within industrial sectors. Explosion proof electric forklifts align with this trend by offering reduced emissions and enhanced energy efficiency, making them an attractive option for companies looking to minimize their environmental impact while maintaining safety standards.

3. Technological Advancements

The integration of advanced technologies, such as intrinsically safe components and improved battery systems, enhances the performance of these forklifts. These innovations not only boost operational efficiency but also reduce potential ignition risks during battery recharging, making them highly suitable for volatile environments typical of the oil and gas sector.

4. Economic Stability and Industrial Growth

Germany’s stable economy supports substantial investment in industrial safety equipment. This financial backing enables continuous upgrades and adoption of state-of-the-art forklifts, ensuring they meet evolving safety requirements while supporting the growth of the oil and gas industry.

These factors collectively contribute to the robust demand for explosion proof electric forklifts within Germany’s oil and gas sector, highlighting the importance of tailored solutions that ensure both safety and efficiency.

Innovations in Explosion Proof Electric Forklifts for Enhanced Safety

Innovation trends are propelling the explosion proof electric forklift industry towards unprecedented heights, with recent advancements in safety features setting new benchmarks. Key players in this domain are integrating cutting-edge technologies to bolster both design aesthetics and functional capabilities.

Advanced Battery Technologies

One of the most significant innovations is the development of advanced battery technologies. These batteries not only extend operational longevity but also enhance safety by minimizing risks associated with recharging in explosive environments. Lithium-ion batteries, known for their efficiency and reduced emissions, are becoming a standard choice due to their reliability and durability under hazardous conditions.

Intrinsically Safe Components

Leading manufacturers are investing heavily in intrinsically safe components. These components are designed to prevent sparks or heat generation, reducing the risk of ignition in volatile atmospheres. This focus on safety is crucial for industries dealing with flammable gases or combustible dust.

Smart Sensor Integration

Smart sensor technology is another trend shaping the future of explosion proof forklifts. Sensors monitor environmental conditions in real-time, providing operators with critical data to make informed decisions. This technology enhances situational awareness and ensures timely interventions to prevent mishaps.

Ergonomic and Aesthetic Enhancements

Design aesthetics and ergonomics have seen considerable improvements as well. Manufacturers are crafting vehicles that not only meet stringent safety standards but also offer enhanced comfort and usability for operators. Streamlined designs that facilitate better maneuverability within confined spaces are increasingly in demand.

Future Technologies

Looking ahead, future technologies like AI-driven diagnostics and predictive maintenance systems could revolutionize how explosion proof forklifts operate. These systems promise to proactively identify potential issues before they escalate, ensuring uninterrupted operations and heightened safety.

The integration of these innovations demonstrates a clear commitment to advancing both safety and efficiency, setting the stage for a thriving future in hazardous industrial environments. This progression signifies an exciting era for stakeholders eager to capitalize on enhanced safety solutions within the sector.

Key Competitors in the Explosion Proof Electric Forklift Market

The explosion proof electric forklift market is shaped by several major players who dominate the competitive landscape. These manufacturers hold significant market shares, leveraging their expertise and innovation to cater to high-risk industries.

-

Shenyang Goldlion Machinery Co., Ltd. – China

-

Hangcha Group Co., Ltd. – China

-

Anhui Heli Co., Ltd. – China

-

Jungheinrich – Germany

-

Mitsubishi Logisnext – Japan

-

Doosan Industrial Vehicle Co., Ltd. – South Korea

-

Baoli Machinery Co., Ltd. – China

-

Crown Equipment Corporation – United States

-

Toyota Material Handling – Japan

-

KION Group – Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Explosion Proof Electric Forklift Market Report |

| Base Year | 2024 |

| Segment by Type | · Tons · More Than 2 Tons |

| Segment by Application | · Petroleum And Chemical Industry · Pharmaceutical Industry · Textile Industry · Logistics Industry · Others |

| Geographies Covered | · North America(United States,Canada)

· Europe(Germany,France,UK,Italy,Russia) · Asia-Pacific(China,Japan,South Korea,Taiwan) · Southeast Asia(India) · Latin America(Mexico,Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast,company share,competitive landscape,growth factors and trends |

The Explosion Proof Electric Forklift Market is expected to grow and reach over $5.39 billion by 2033. This growth is driven by the demand for better safety solutions in dangerous environments, especially in industries like oil & gas, mining, and manufacturing. Countries like the US, Germany, and China are leading the way with strict regulations and technological advancements. As businesses focus on safety and sustainability, explosion proof electric forklifts are becoming crucial for secure and efficient operations in high-risk areas.

Global Explosion Proof Electric Forklift Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Explosion Proof Electric Forklift Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Explosion Proof Electric ForkliftMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Explosion Proof Electric Forkliftplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Explosion Proof Electric Forklift Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Explosion Proof Electric Forklift Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Explosion Proof Electric Forklift Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofExplosion Proof Electric Forklift Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the explosion proof electric forklift market by 2025?

The explosion proof electric forklift market is projected to exceed $3.98 billion by 2025, driven by enhanced safety solutions in hazardous environments.

How do explosion proof electric forklifts enhance operational safety?

Explosion proof electric forklifts contribute to operational safety by being specifically designed to operate in hazardous environments, reducing the risk of accidents and ensuring compliance with safety regulations.

What are the key trends currently shaping the explosion proof electric forklift industry?

Key trends include the introduction of advanced safety features, technological innovations for improved efficiency, and compliance with international standards like IECEx for safety assurance.

What challenges do manufacturers face in developing explosion proof electric forklifts?

Manufacturers encounter design complexities, rigorous certification processes, and market barriers that may hinder the widespread adoption of explosion proof forklifts.

How does geopolitical stability affect the explosion proof electric forklift market?

Geopolitical stability influences regulations surrounding explosive atmospheres and affects investment opportunities in industrial safety equipment globally, impacting market dynamics.

What types of industries utilize explosion proof electric forklifts?

Explosion proof electric forklifts are utilized across various sectors including oil & gas, mining, and manufacturing, where they play a crucial role in maintaining operational safety in hazardous environments.