2025 Epoxy Resin Solid Insulated Ring Main Units Market Unlocking $1.8 Billion Opportunities in US, China, and Germany

- Last Updated:

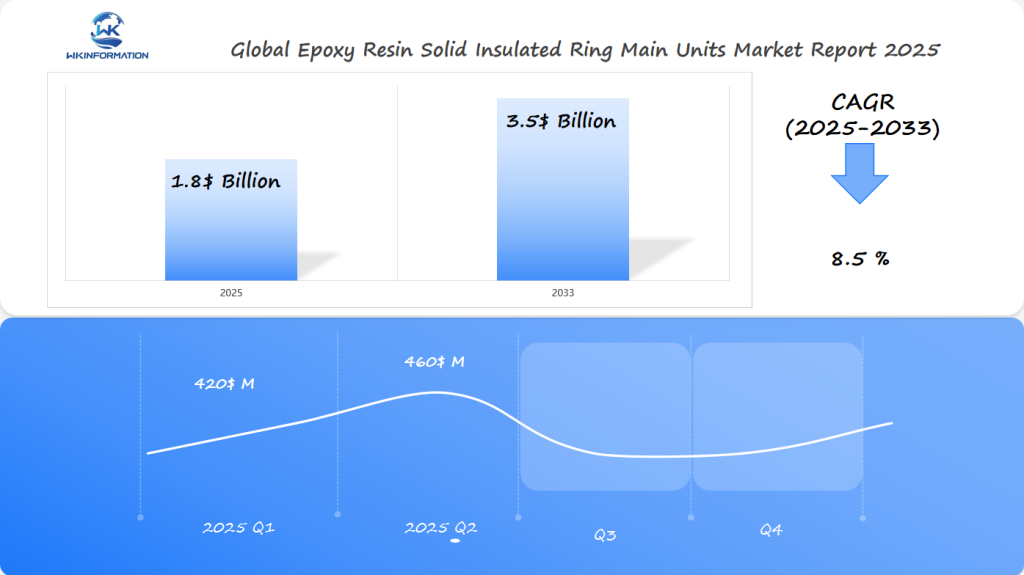

Epoxy Resin Solid Insulated Ring Main Units Market Forecast for Q1 and Q2 2025

The global Epoxy Resin Solid Insulated Ring Main Units (RMU) market was valued at USD 1.8 billion in 2025, with a CAGR of 8.5% projected from 2025 to 2033. The estimated market size in Q1 2025 is around USD 420 million, growing to approximately USD 460 million by Q2 2025.

The US, China, and Germany are at the forefront of market growth, primarily due to the rising demand for reliable and efficient power distribution solutions. The US is witnessing increasing investments in smart grid technologies and renewable energy infrastructure, leading to higher adoption of solid insulated RMUs. China, as a global leader in electrical infrastructure development, is rapidly expanding its urban and industrial power networks, creating strong demand for advanced insulation technologies. Germany, with its commitment to sustainable energy and grid modernization, is actively investing in eco-friendly and high-performance electrical equipment.

The market is benefiting from increasing awareness of environmentally friendly and compact switchgear solutions, replacing traditional SF6-insulated units. Additionally, advancements in high-voltage insulation materials and modular designs are expected to accelerate the adoption of epoxy resin solid insulated RMUs across power utilities and industrial applications.

Epoxy Resin Solid Insulated Ring Main Units Market Upstream and Downstream Industry Chain Analysis

To fully understand the dynamics of the epoxy resin solid insulated ring main units (RMUs) market, it’s crucial to analyze its supply chain. This industry chain consists of upstream suppliers, who provide the necessary raw materials for manufacturing epoxy resins, and downstream consumers, who utilize these RMUs across various sectors.

Upstream Suppliers: Key Players in Epoxy Resin Production

The production of epoxy resins relies on specific raw materials such as bisphenol A and epichlorohydrin. These materials are sourced from upstream suppliers to create the epoxy resin used in RMUs. Notable manufacturers in this segment include:

- The Dow Chemical Company

- Covestro AG

- DuPont de Nemours Inc.

These companies are instrumental in producing high-quality epoxy resin, which is essential for RMUs. They employ advanced technologies to improve product durability and performance.

Downstream Consumers: Industries Benefiting from Epoxy Resin RMUs

The RMUs made with epoxy resin find applications in various sectors. The primary users of these units include:

- Utilities: Ensuring stable electricity distribution.

- Industrial applications: Supporting operations in manufacturing plants.

- Urban infrastructure: Facilitating reliable power systems in metropolitan areas.

Understanding this intricate network of suppliers, manufacturers, and end-users underscores the significance of epoxy resin RMUs in maintaining efficient power distribution systems worldwide.

Emerging Trends Driving the Epoxy Resin Solid Insulated Ring Main Units Market in 2025

Increasing Demand for Renewable Energy Solutions

The surge in global focus on renewable energy sources is catalyzing demand for advanced power distribution systems. Epoxy resin solid insulated ring main units (RMUs) are playing a pivotal role in supporting renewable projects by providing robust and reliable electrical insulation.

Adoption of Smart Grid Technologies

Smart grid technologies are reshaping the landscape of electrical infrastructure, necessitating RMUs that can integrate seamlessly into these advanced systems. The adoption of smart grids is driving innovation within the RMU market, requiring units that offer enhanced monitoring, control capabilities, and efficient energy management.

Innovations Enhancing Functionality and Reliability of RMUs

Continuous innovations are enhancing the functionality and reliability of epoxy resin RMUs. Advancements such as improved insulation materials and smarter design features are increasing their efficiency, making them indispensable in modern electrical networks. This trend underscores the importance of ongoing research and development within the sector to meet evolving industry needs.

Regulatory Challenges and Market Restrictions Impacting the Industry

Navigating the regulatory landscape is crucial for stakeholders in the Epoxy Resin Solid Insulated Ring Main Units (RMUs) market. Regulations governing environmental standards, safety protocols, and energy efficiency are prominent. These regulations ensure that RMUs comply with industry standards, promoting safer and more sustainable power distribution systems.

Manufacturers face significant compliance challenges, including adhering to stringent environmental laws that dictate permissible emission levels during production processes. Ensuring compliance with these regulations often requires substantial investment in technology and processes, impacting operational costs.

Market restrictions can hinder growth by imposing limitations on production capacities or restricting certain substances used in manufacturing. These restrictions may arise from regional trade policies or international agreements aimed at reducing carbon footprints. For instance, sourcing raw materials like epoxy resins may become challenging due to trade barriers, affecting supply chains.

Understanding these dynamics is essential for manufacturers aiming to thrive in a highly regulated environment while meeting evolving market demands.

Geopolitical Factors Reshaping the Epoxy Resin Solid Insulated Ring Main Units Market

Geopolitical factors significantly impact the Epoxy Resin Solid Insulated Ring Main Units (RMUs) market. Here are some key ways in which these factors influence the industry:

1. Geopolitical Tensions

Geopolitical tensions can disrupt RMU supply chains, influencing both availability and pricing. For instance, conflicts or diplomatic issues between major manufacturing regions can lead to delays and increased costs.

2. International Trade Policies

International trade policies also play a crucial role. Tariffs and trade agreements directly affect the epoxy resin market, which is essential for RMU production. Changes in these policies can either facilitate smoother transactions or introduce new challenges for manufacturers and suppliers.

3. Regional Influences

Regional influences contribute to demand and supply dynamics. In regions like the US, China, and Germany, varying regulatory standards and economic conditions create unique market environments. These factors alter how RMUs are produced and distributed, affecting the overall growth potential within each area.

Understanding these dynamics is essential for stakeholders looking to capitalize on emerging opportunities in the industry.

Market Segmentation of Epoxy Resin Solid Insulated Ring Main Units by Type and Key Sectors

The epoxy resin solid insulated RMUs market is segmented into various types, tailored to meet diverse application needs. These include:

- Indoor RMUs: Primarily used in urban infrastructure projects where space constraints are a concern.

- Outdoor RMUs: Designed to withstand harsh environmental conditions, making them ideal for rural and industrial settings.

Key sectors leveraging these RMUs encompass:

- Utilities: Essential for efficient power distribution in substations and urban grids.

- Industrial Applications: Critical for maintaining reliable power supply in manufacturing plants and heavy industries.

Segment performance analysis reveals that the utilities sector displays robust growth due to ongoing infrastructure upgrades. Industrial applications, on the other hand, are driven by the increasing demand for uninterrupted power supplies. Both sectors underscore the diversity and adaptability of epoxy resin solid insulated RMUs, highlighting their vital role in modern power distribution systems.

Application Scope and Demand Growth of Epoxy Resin Solid Insulated Ring Main Units

Epoxy Resin Solid Insulated Ring Main Units (RMUs) are becoming increasingly vital across various sectors due to their versatility and efficiency. Urban infrastructure stands out as a primary application area, where RMUs support reliable power distribution in densely populated regions. Their compact design and high reliability make them ideal for integration into urban grids, enhancing the overall resilience of city power networks.

Factors Driving Demand Growth

Demand growth for these RMUs is driven by several factors:

- Renewable Energy Integration: As renewable energy sources proliferate, RMUs facilitate seamless integration into existing grids, ensuring efficient power flow.

- Smart Grid Technologies: The shift towards smart grids requires advanced RMUs capable of handling dynamic loads while providing real-time data for grid management.

- Industrial Expansion: Manufacturing hubs and industrial zones benefit from the enhanced safety and reduced maintenance costs offered by epoxy resin-insulated RMUs.

These trends underscore the expanding application scope and robust demand growth in the Epoxy Resin Solid Insulated Ring Main Units market.

Global Epoxy Resin Solid Insulated Ring Main Units Market Regional Analysis and Forecast

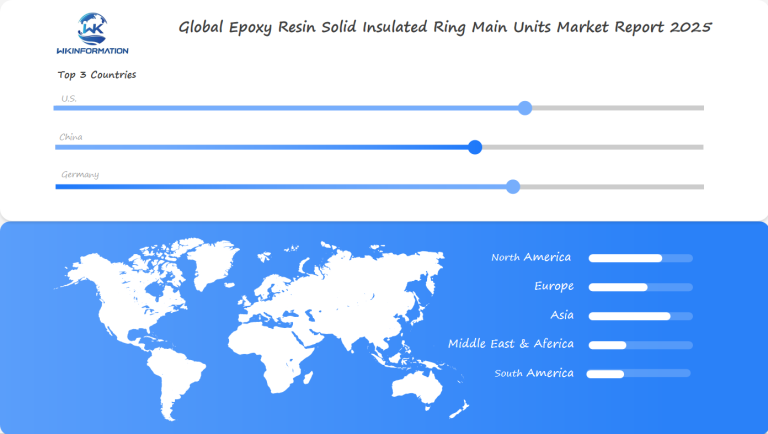

The global analysis of epoxy resin solid insulated ring main units reveals significant opportunities within regional markets such as the US, China, and Germany. Each region has its own factors driving market growth:

1. United States

The US is a key market due to its focus on upgrading old electrical systems. The demand for epoxy resin solid insulated ring main units (RMUs) is expected to rise significantly with the implementation of smart grid technologies and the shift towards renewable energy sources.

2. China

China, being a major player in global manufacturing, presents opportunities for RMU adoption. The country’s ongoing investments in urban development and industrial expansion, along with its commitment to reducing carbon emissions, align with the increased use of efficient power distribution systems.

3. Germany

Germany’s dedication to sustainability drives the growth of RMUs in the country. The transition towards renewable energy solutions, supported by a strong regulatory framework, encourages innovation and adoption of advanced power distribution technologies.

Forecasting until 2029 indicates that these regions will collectively propel the market towards greater heights, with anticipated advancements in technology enhancing efficiency and reliability.

US Epoxy Resin Solid Insulated Ring Main Units Market Performance and Competitor Insights

The US epoxy resin solid insulated ring main units (RMUs) market is witnessing steady growth due to the increasing demand for reliable and efficient electrical distribution systems. These units are crucial in medium-voltage applications and are particularly valued for their enhanced safety features, compact design, and environmentally friendly properties. The market is supported by the ongoing expansion of renewable energy infrastructure, smart grid initiatives, and the need for energy-efficient solutions.

Market Performance

The US market for epoxy resin solid insulated RMUs is driven by the upgrading of electrical grids, the adoption of sustainable energy practices, and growing demand for safer, more durable electrical components. The need for grid modernization, especially in urban areas and remote locations, fuels the adoption of these units as part of smart grid systems and energy-efficient infrastructures.

China Epoxy Resin Solid Insulated Ring Main Units Market Growth Potential and Expansion Strategies

The China epoxy resin RMUs market has witnessed steady growth over the past few years, driven by urbanization, the need for modernized electrical infrastructure, and a shift towards renewable energy sources. Key factors contributing to market expansion include:

-

Government Initiatives: China’s commitment to reducing carbon emissions and enhancing power grid efficiency has propelled investments in high-performance insulating technologies.

-

Increasing Demand for Sustainable Infrastructure: The push for sustainable infrastructure projects has increased the demand for epoxy resin RMUs, known for their durability and lower environmental impact.

-

Technological Advancements: Advances in epoxy resin formulations and insulation technologies have resulted in enhanced performance, making these RMUs more attractive for use in diverse sectors.

Key Drivers of Market Growth

-

Urbanization and Smart Cities: As China’s urbanization rate continues to rise, there is a growing need for reliable power distribution systems, particularly in new and expanding urban areas. Epoxy resin RMUs are gaining popularity due to their compact design, which is ideal for space-constrained environments like urban infrastructure.

-

Renewable Energy Integration: With China focusing on renewable energy sources such as solar and wind, the need for flexible, robust power distribution systems like RMUs to connect renewable generation with the grid is on the rise.

-

Energy Efficiency Regulations: The push for energy-efficient solutions in China’s industrial and commercial sectors is driving the demand for advanced electrical components, including epoxy resin RMUs, which are energy-efficient and long-lasting.

Germany Epoxy Resin Solid Insulated Ring Main Units Market Trends and Market Demand

The Germany Epoxy Resin Solid Insulated Ring Main Units (RMUs) Market is experiencing growth driven by several key trends:

-

Sustainability Focus: Germany’s commitment to environmental sustainability and energy efficiency supports the adoption of epoxy resin RMUs, which are eco-friendly and provide long-term reliability with minimal environmental impact.

-

Energy Transition: As part of its “Energiewende” initiative, Germany is investing heavily in renewable energy. Epoxy resin RMUs are essential in integrating renewable sources into the grid, offering a reliable solution for modern power distribution.

-

Smart Grid Development: The shift toward smart grids is driving the demand for compact, efficient, and digitally compatible RMUs. Epoxy resin units support the digitalization of power networks, ensuring enhanced operational control and efficiency.

-

Infrastructure Modernization: With urbanization and industrial expansion, the need for reliable, space-saving electrical infrastructure is increasing, positioning epoxy resin RMUs as a preferred choice for modern power distribution systems.

Future Innovations and Technological Advancements in Epoxy Resin Solid Insulated Ring Main Units

The rapid evolution of technology presents numerous opportunities to enhance the efficiency and reliability of Epoxy Resin Solid Insulated Ring Main Units (RMUs). Emerging technologies are paving the way for significant improvements:

1. Smart Sensors and IoT Integration

These advancements enable real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency.

2. Advanced Materials

Innovations in materials science are leading to the development of epoxy resins with superior insulation properties, increased thermal stability, and improved environmental resistance.

3. Automation and Robotics in Manufacturing

The integration of automation technologies is streamlining production processes, ensuring higher precision and consistency in RMU manufacturing.

Future innovations are anticipated to focus on:

- Nanotechnology Applications: Enhancing the mechanical properties and lifespan of RMUs by incorporating nanomaterials into epoxy resins.

- Sustainable Manufacturing Practices: Emphasizing eco-friendly production processes that reduce environmental impact without compromising product quality.

These technological advancements promise not only to optimize current RMU capabilities but also to unlock new possibilities in power distribution systems.

Competitive Landscape and Leading Players in the Market

The competitive landscape of the Epoxy Resin Solid Insulated Ring Main Units Market is predominantly shaped by industry giants. These organizations play pivotal roles in driving innovation and setting industry standards.

- ABB – Switzerland

- Eaton – Ireland

- General Electric – United States

- Schneider Electric – France

- Siemens – Germany

- Entec Electric & Electronic – South Korea

- Larsen & Toubro – India

- Hangzhou Hexing Electrical – China

- Chint Electrics – China

- Daqo Group – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Epoxy Resin Solid Insulated Ring Main Units Market Report |

| Base Year | 2024 |

| Segment by Type |

· Indoor RMUs · Outdoor RMU |

| Segment by Application |

· Utilities · Industrial Applications |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Epoxy Resin Solid Insulated Ring Main Units market demonstrates significant potential for growth and transformation in the coming years. The industry’s expansion is driven by technological advancements, increasing demand for sustainable power distribution solutions, and evolving global energy needs. Key market drivers include the growing adoption of renewable energy systems, smart grid technologies, and innovative functionalities that enhance operational efficiency.

Regional opportunities, particularly in major markets like the United States, China, and Germany, present substantial growth potential for industry stakeholders. The integration of advanced technologies, coupled with a strong focus on sustainability and efficiency, continues to shape the market landscape.

As the industry evolves, manufacturers and suppliers must remain adaptable to changing regulatory requirements, geopolitical influences, and market demands. Success in this dynamic market requires a strategic approach that balances innovation, sustainability, and operational excellence.

For stakeholders looking to capitalize on market opportunities, staying informed about industry trends, technological developments, and regulatory changes will be crucial for maintaining competitive advantage and achieving sustainable growth in the epoxy resin RMU sector.

Global Epoxy Resin Solid Insulated Ring Main Units Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Epoxy Resin Solid Insulated Ring Main Units Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Epoxy Resin Solid Insulated Ring Main Units Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Epoxy Resin Solid Insulated Ring Main Units players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Epoxy Resin Solid Insulated Ring Main Units Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Epoxy Resin Solid Insulated Ring Main Units Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Epoxy Resin Solid Insulated Ring Main Units Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Epoxy Resin Solid Insulated Ring Main Units Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are Epoxy Resin Solid Insulated Ring Main Units (RMUs) and why are they important?

Epoxy Resin Solid Insulated Ring Main Units (RMUs) are critical components in power distribution systems, providing reliable and efficient electrical distribution. They enhance safety and reduce maintenance needs, making them essential for utilities and industrial applications.

What is the projected growth rate of the Epoxy Resin Solid Insulated Ring Main Units market?

The Epoxy Resin Solid Insulated Ring Main Units market is expected to witness significant growth, with projections indicating a robust increase in market value driven by rising demand for renewable energy solutions and smart grid technologies.

Who are the key suppliers and end-users in the epoxy resin RMUs supply chain?

Key suppliers include major manufacturers such as The Dow Chemical Company and Covestro AG, while end-users span various sectors including utilities, industrial applications, and urban infrastructure that rely on RMUs for efficient power distribution.

What emerging trends are influencing the Epoxy Resin Solid Insulated Ring Main Units market by 2025?

Emerging trends driving the market include an increased focus on renewable energy solutions, the adoption of smart grid technologies, and innovations that enhance the functionality and reliability of RMUs.

What regulatory challenges do manufacturers face in the Epoxy Resin Solid Insulated Ring Main Units market?

Manufacturers in the epoxy resin RMUs market must navigate a complex regulatory landscape that includes compliance challenges and potential restrictions which can impact their production processes and overall market growth.

How do geopolitical factors affect the Epoxy Resin Solid Insulated Ring Main Units market?

Geopolitical factors such as international trade tensions and regional influences can significantly reshape supply chains for RMUs. Trade policies also play a crucial role in determining the dynamics of demand and supply within the epoxy resin market.