2025 Electric Spindles Market: Exploring $1.67 Billion Global Innovations, Powering Manufacturing in China, Germany, and Switzerland

Discover how China’s manufacturing prowess, Germany’s technological innovation, and Switzerland’s precision engineering are reshaping the 2025 Electric Spindles Market. Explore key market trends, regional dominance, and strategic factors driving industry growth in this comprehensive analysis of the global electric spindles landscape.

- Last Updated:

Electric Spindles Market Forecast and Key Trends

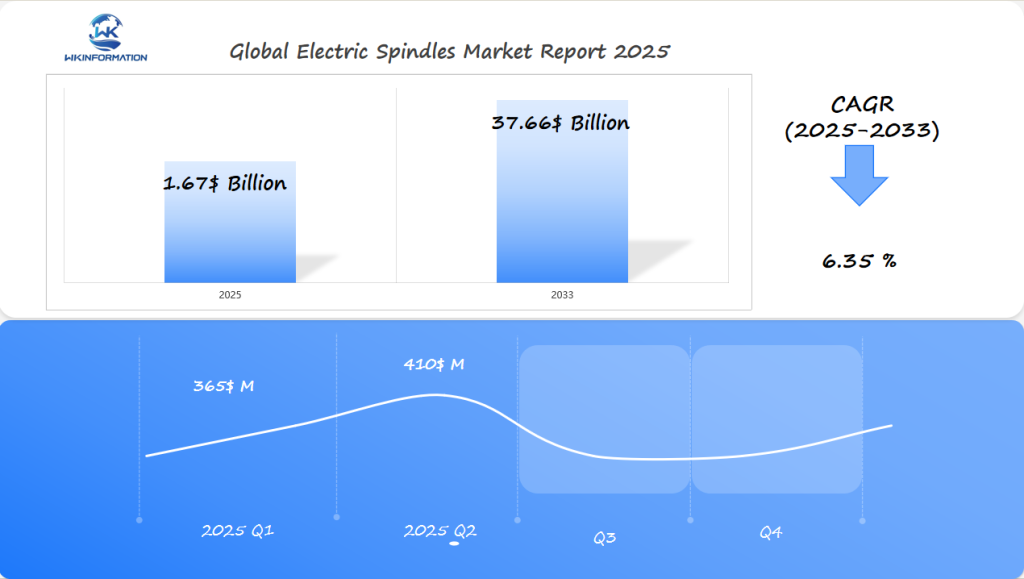

The Electric Spindles market is projected to reach a valuation of USD 1.67 billion in 2025, with a CAGR of 6.35% expected between 2025 and 2033. Based on industry trends and growth momentum, the market is estimated to generate approximately USD 365 million in Q1 of 2025 and USD 410 million in Q2 of 2025, reflecting the increasing adoption of high-speed machining and automation technologies.

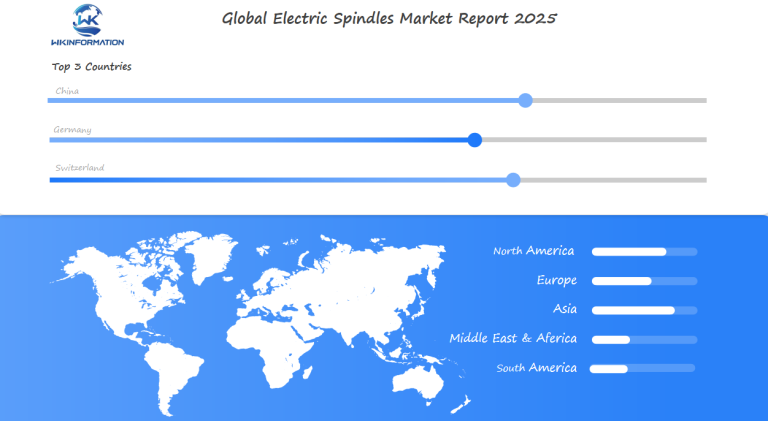

Among the key regions, China, Germany, and Switzerland stand out as the most critical markets for analysis due to their strong presence in precision manufacturing, advanced machinery production, and continuous technological innovations. These countries are expected to drive market expansion, presenting substantial opportunities for industry stakeholders.

Upstream and Downstream Industry Chain Analysis

Understanding the supply chain for electric spindles is essential to grasp the dynamics of this robust market. The industry chain can be broadly categorized into upstream and downstream components.

Upstream Components

- Raw Materials: High-quality steel, ceramic, and composite materials form the backbone of electric spindle production.

- Component Suppliers: Bearings, cooling systems, and sensors are crucial parts supplied by specialized manufacturers.

- Technology Providers: Companies offering software solutions for design and performance optimization play a vital role.

Roles of Suppliers

- Material Suppliers: Ensure the provision of durable materials that meet industry standards.

- Component Manufacturers: Deliver precision parts necessary for spindle functionality.

Downstream Components

- Manufacturing: Involves assembling raw materials and components into fully integrated spindle systems.

- Distribution Channels: Comprise wholesalers, retailers, and online platforms facilitating product reach to end-users.

- End Users: Industries such as automotive, aerospace, and electronics utilize electric spindles for various applications.

Roles of Manufacturers

- Assembling Firms: Combine upstream components into functional units ready for deployment.

- Quality Assurance Teams: Maintain stringent checks to ensure performance reliability in diverse applications.

This intricate supply chain underscores the collaboration between different entities to meet growing demands efficiently.

Trend Analysis: Emerging Trends in Electric Spindles Technology

The electric spindles market is witnessing significant technological advancements, driven by the need for increased efficiency and precision in manufacturing. Key innovations are reshaping the landscape:

1. Self-Monitoring Systems

Modern electric spindles now integrate smart technologies, enabling real-time monitoring and diagnostics. This self-monitoring capability helps in predictive maintenance, reducing downtime and prolonging spindle life.

2. High-Speed Capabilities

Technological advancements have enabled electric spindles to reach higher rotational speeds, which directly enhances production rates and precision in machining tasks.

3. Energy Efficiency

New designs focus on minimizing energy consumption without compromising performance, aligning with sustainability goals across industries.

The advent of Industry 4.0 has further influenced electric spindle technology. The integration of IoT and automation into spindle systems supports seamless communication between machines, enhancing process automation and control. These smart technologies allow manufacturers to optimize workflows and improve operational efficiency.

Additionally, automation plays a crucial role, with electric spindles being pivotal in automated manufacturing processes. Their ability to deliver consistent high-speed performance makes them indispensable in sectors requiring precision machining, such as aerospace and automotive industries. This trend towards enhanced automation and connectivity is expected to drive continued innovation within the electric spindles market.

Restriction Analysis: Challenges in the Electric Spindles Market

The Electric Spindles Market faces several market challenges that impact its growth potential.

1. High Initial Investment Costs

For small enterprises, the substantial upfront investment needed to adopt electric spindle technology presents a significant barrier. The cost factors include not only the purchase of advanced spindles but also the necessary upgrades to existing machinery and infrastructure. This financial burden can deter smaller companies from entering or expanding within this market space.

2. Compatibility Issues

Another critical challenge is the issue of compatibility with existing machinery. Not all current equipment is designed to integrate seamlessly with electric spindles, leading to potential disruptions during installation and operation. This lack of compatibility can slow down the adoption rate as businesses may hesitate to overhaul their equipment or invest in additional modifications.

These investment barriers and technical hurdles highlight the need for strategic planning and innovation among industry players to facilitate smoother integration processes. By addressing these obstacles, manufacturers can better position themselves in a competitive landscape that demands both agility and foresight.

Geopolitical Analysis: How Global Politics Influence Electric Spindles Production and Trade

International relations and trade policies play a crucial role in shaping the production and trade dynamics of electric spindles. Geopolitical influences often dictate the flow of raw materials, technological collaboration, and market access, which are crucial for the electric spindles industry.

Key Geopolitical Factors Affecting Electric Spindles Industry

- Trade Policies: Tariffs and trade agreements significantly impact the cost structure and competitiveness of electric spindle manufacturers. For instance, fluctuating tariffs on steel and other essential components can alter production costs, affecting pricing strategies and profit margins.

- Political Alliances: Diplomatic relations between countries influence partnerships in research and development. Countries with strong bilateral ties may collaborate on technological advancements, leading to enhanced product offerings and market expansion.

- Regulatory Environment: Compliance with international standards is mandatory for global trade. Changes in regulations across different regions can affect production processes, requiring manufacturers to adapt swiftly to maintain market presence.

- Supply Chain Disruptions: Political instability or sanctions can disrupt supply chains, impacting the availability of critical components needed for electric spindle production. Manufacturers must navigate these challenges to ensure uninterrupted operations.

Understanding these geopolitical factors is essential for stakeholders looking to thrive in the increasingly interconnected global market of electric spindles.

Segmentation Type Market Analysis: Electric Spindles Market Segmentation by Type and Application

Understanding market segmentation for electric spindles is crucial for identifying opportunities and challenges within the industry. The market is segmented primarily by type and application, each serving distinct needs in various industries.

Types of Electric Spindles:

- Built-in Spindles

- These spindles are integrated into the machine tool, offering a compact design that enhances stability and precision. Commonly used in high-speed CNC machining, they reduce vibration and improve accuracy, making them ideal for tasks requiring fine detail.

- Motorized Spindles

- Featuring an independent motor, motorized spindles provide flexibility and power across diverse applications. Suitable for heavy-duty operations such as high-speed milling and grinding, their versatility makes them a popular choice among manufacturers.

Application Areas:

- Internal Grinding: Electric spindles play a pivotal role in internal grinding processes where precision and speed are paramount. The ability to maintain high RPMs ensures efficient material removal while maintaining surface integrity.

- CNC Milling: In CNC milling, both built-in and motorized spindles enable precise control over cutting tools. Their role in facilitating complex geometries and high-volume production cannot be overstated, particularly in industries such as automotive and aerospace manufacturing.

This segmentation underscores the adaptability of electric spindles to meet specific industrial demands, highlighting their importance in modern manufacturing environments.

Application Market Analysis: The Role of Electric Spindles in Industrial Automation

Electric spindles are essential in industrial automation, especially in industries like automotive and aerospace. They play a crucial role in improving manufacturing processes, making CNC machines more accurate and efficient.

How Electric Spindles Impact Industrial Automation

- Enhanced Automation: In industries where precision and speed are critical, electric spindles make operations smoother by reducing setup times and improving consistency. They are integrated into automated systems, allowing for the production of high-quality components with less manual work.

- Precision Machining: Electric spindles are known for their ability to deliver precise performance required for tasks like internal grinding and CNC milling. This capability is vital for creating parts that meet strict industry standards, particularly in aerospace, where even small errors can cause significant problems.

The Growing Demand for Electric Spindles

The Electric Spindles Market is benefiting from these advantages, with manufacturers increasingly choosing electric spindles instead of traditional options. This shift not only improves production efficiency but also aligns with the rising need for environmentally friendly solutions.

As industrial automation continues to progress, the dependence on high-performance electric spindles is expected to grow. This will lead to further innovations in this ever-changing field.

Global Electric Spindles Market Region Analysis: Regional Market Trends

The global electric spindles market shows different trends in various regions, with each area playing a unique role in the industry’s growth. One region that is particularly important is the Asia Pacific, where the market is experiencing strong growth. This increase is mainly driven by significant domestic investments in advanced manufacturing technologies.

1. Asia Pacific Dominance

The region’s rapid industrialization and commitment to embracing cutting-edge technology enhance its position as a leader in the electric spindles market. Countries like China and India are at the forefront, leveraging their vast manufacturing sectors to drive demand for high-performance electric spindles.

2. Investment in Technology

Governments and private enterprises across Asia Pacific are channeling resources into upgrading manufacturing infrastructures. This investment supports the integration of electric spindles into various industrial applications, such as CNC machining and high-speed cutting.

3. Growing Industrial Base

With an expanding industrial base, Asia Pacific nations are prioritizing automation and precision engineering, further increasing the adoption of electric spindle systems.

The focus on innovation and efficiency in this region sets the stage for continued growth, positioning Asia Pacific as a crucial player in shaping the future of the electric spindles market.

China Electric Spindles Market Analysis

The China market analysis shows that this region is a major player in the electric spindles market. The growing industrialization efforts are driving China’s demand for electric spindles. The country’s goal of becoming a global manufacturing leader is supported by significant investments in advanced manufacturing technologies, which are fueling growth in this industry.

Key Demand Drivers

The main factors driving the demand for electric spindles in China are:

- Substantial Investments: China has been investing heavily in developing and acquiring cutting-edge manufacturing technologies. This investment is crucial for local manufacturers to improve quality and production efficiency.

- Rapid Industrialization: As one of the fastest industrializing countries in the world, China needs advanced equipment like electric spindles to maintain high standards in manufacturing precision and speed.

- Technological Advancements: Continuous technological improvements are a key feature of China’s industrial strategy, leading to the adoption of more efficient and powerful electric spindle systems.

The emphasis on improving manufacturing capabilities aligns with China’s strategic objectives to meet domestic demands and compete globally. This dynamic environment ensures that China’s electric spindles market remains an essential part of the global supply chain, showcasing its influence and potential for future growth.

Germany Electric Spindles Market Analysis

Germany is a technological leader in electric spindle production, known for its innovation and quality. With its excellent engineering skills, Germany has an advantage in the Electric Spindles Market due to its advanced manufacturing abilities and strong research and development (R&D) efforts.

Factors Contributing to Germany’s Position

Several factors contribute to Germany’s influential position:

- Cutting-Edge Technology: German manufacturers prioritize integrating advanced technologies like Industry 4.0 into their spindle systems, enhancing precision and efficiency.

- Strong Industrial Base: With a well-established industrial sector, Germany serves as a hub for high-quality spindle production, catering to both domestic and international markets.

- Global Influence: The country’s emphasis on quality standards influences global market dynamics. Companies worldwide look to German innovations as benchmarks for performance and reliability.

- Collaborative Ecosystem: Germany fosters collaboration between academic institutions, research organizations, and industrial players, driving continuous advancement in spindle technology.

The German electric spindles market not only supplies high-performance products but also shapes global trends through technological leadership. This focus on innovation ensures that German manufacturers remain competitive players on the international stage, contributing significantly to advancements within the industry.

Switzerland Electric Spindles Market Analysis

Switzerland stands out in the electric spindles market for its commitment to precision engineering. Known for maintaining strict quality standards, Swiss manufacturers prioritize careful design and craftsmanship, especially in electric spindle systems. This dedication to excellence ensures that Swiss-produced spindles meet the high demands of accuracy and reliability required in modern manufacturing.

Key Factors Driving Switzerland’s Electric Spindles Market

- Precision Engineering: Swiss companies use advanced engineering techniques to create electric spindles with unmatched precision. This focus guarantees superior performance and durability, making Switzerland a major player in providing top-quality spindle solutions.

- Quality Standards: The country’s rigorous quality assurance processes are a defining feature of its manufacturing industry. These standards ensure that every electric spindle produced is consistently high-quality, making them highly desirable in industries where precision is critical.

- Innovation and Expertise: Swiss manufacturers continuously invest in research and development, fostering innovation in the industry. Their knowledge not only improves product quality but also leads to advancements in spindle technology.

Swiss electric spindles are essential for applications that require tight tolerances and reliability, further solidifying Switzerland’s position as a leader in the global market for high-precision machinery components.

Future Development Analysis: The Future of Electric Spindles in High-Speed Machining

Electric spindles are expected to play a crucial role in the evolution of high-speed machining applications. This technology continues to evolve, driven by the demand for increased precision and speed in manufacturing processes.

Key Predictions for Future Trends:

- Advanced Materials: The use of advanced materials like carbon fiber and ceramics in spindle construction promises higher rotational speeds and improved thermal stability.

- Smart Technologies Integration: Incorporating IoT devices and sensors into electric spindles allows real-time monitoring and predictive maintenance, enhancing performance reliability.

- Miniaturization: As industries push for more compact solutions, the trend towards miniaturizing electric spindles without compromising power or efficiency is expected to grow.

- Energy Efficiency: Future developments will likely focus on reducing energy consumption while maintaining high output, aligning with global sustainability goals.

The trajectory of high-speed machining is set to redefine manufacturing capabilities. As electric spindle technologies advance, industries can anticipate improvements in production efficiency and quality. The integration of cutting-edge innovations positions these spindles as critical components in the next-generation manufacturing landscape.

Competitor Analysis: Major Players in the Electric Spindles Market

- Siemens AG

- Fischer Precise

- Westwind Air Bearings

- Kessler Group

- Guangzhou Haozhi Industrial Co. Ltd.

- GMN Paul Müller Industrie GmbH & Co. KG

- NSK Ltd.

- JTEKT Corporation

- Schaeffler Technologies AG & Co. KG

- Timken Company

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Electric Spindles Market Report |

| Base Year | 2024 |

| Segment by Type |

· Rolling Motor Spindles · Air Bearing Motor Spindles · Liquid Journal Motor Spindles · Others |

| Segment by Application |

· Printed Circuit Board · Consumer Electronics · Machinery Manufacturing · Automotive and Aerospace · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The electric spindles market is at a crucial point, ready for strong growth driven by key industries like automotive and aerospace. This upward trend is powered by advancements in automation and the integration of Industry 4.0 technologies, focusing on precision and efficiency in manufacturing processes.

Key Drivers

- Automation and Precision: Electric spindles are essential for modern automated systems that require high-speed and precise machining capabilities.

- Innovations: Continuous technological improvements make these components vital in CNC machinery.

- Sustainability: Energy-efficient designs align with global sustainability goals, attracting environmentally conscious manufacturers.

Challenges remain, particularly the high initial investment and compatibility issues with existing systems, which can hinder adoption among smaller businesses. However, despite these obstacles, the demand for electric spindles is expected to grow as industries move towards more advanced manufacturing techniques.

Geopolitical factors and regional dynamics highlight the significance of strategic positioning within this market. China’s rapid industrialization efforts, Germany’s technological leadership, and Switzerland’s commitment to precision engineering all play crucial roles in shaping global production and trade dynamics.

For stakeholders looking to seize opportunities in the changing electric spindles market, it’s essential to stay updated on emerging trends, potential challenges, and competitive strategies.

Global Electric Spindles Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Electric Spindles Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Electric SpindlesMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Electric Spindlesplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Electric Spindles Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Electric Spindles Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Electric Spindles Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofElectric SpindlesMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the supply chain for electric spindles?

The supply chain for electric spindles involves key components such as suppliers, manufacturers, and distributors. Suppliers provide raw materials, while manufacturers focus on the production and assembly of electric spindles. Distributors then handle the logistics and delivery of finished products to end-users in various industries.

How are technological advancements influencing electric spindle technology?

Technological advancements are significantly shaping electric spindle technology through automation and the integration of smart technologies. The impact of Industry 4.0 is particularly notable, as it enhances manufacturing processes and allows electric spindles to adapt by improving performance and efficiency.

What challenges does the electric spindles market face?

The electric spindles market faces several challenges, including high initial investment costs that deter small enterprises from adopting this technology. Additionally, compatibility issues with existing machinery can hinder market growth, making it difficult for businesses to integrate new systems.

How do geopolitical factors affect the production and trade of electric spindles?

Geopolitical influences play a crucial role in shaping the production and trade dynamics of electric spindles. International relations and trade policies can impact supply chains, pricing, and market access for manufacturers operating in different regions.

What are the main types of electric spindles in the market?

Electric spindles can be segmented into two main types: built-in spindles and motorized spindles. Each type serves different application areas, such as internal grinding or CNC milling, catering to diverse industrial needs.

What is the significance of electric spindles in industrial automation?

Electric spindles are vital in enhancing industrial automation processes across sectors like automotive and aerospace. They provide precision machining capabilities that improve productivity, accuracy, and overall efficiency in manufacturing operations.