Dunnage Packaging Market Set to Surpass $1.15 Billion by 2025: Protective Solutions in the U.S., Germany, and China

Explore the booming Dunnage Packaging Market trends, growth drivers, and key players. Get insights into protective packaging solutions shaping logistics and supply chain efficiency.

- Last Updated:

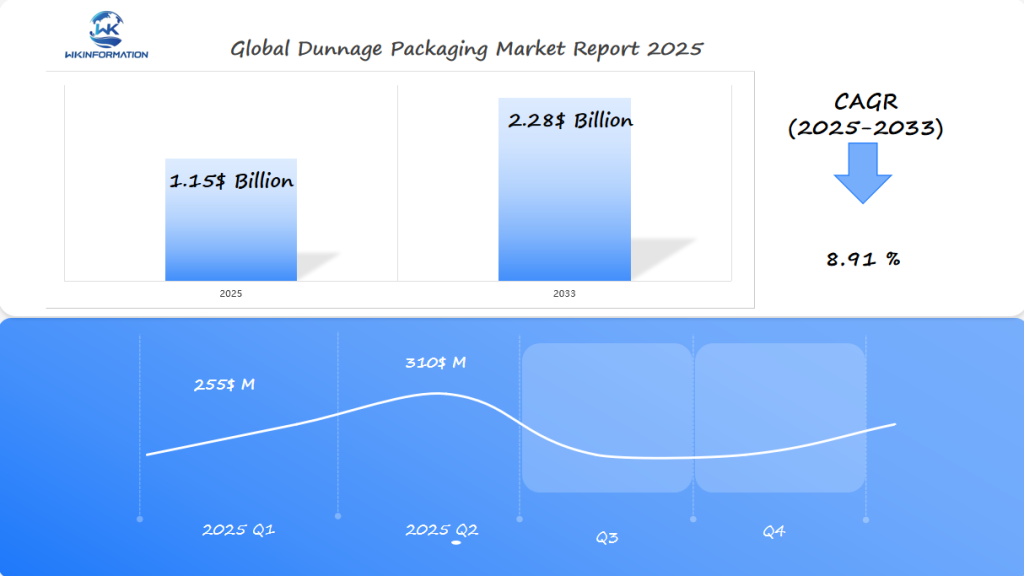

Dunnage Packaging Market Forecast for Q1 and Q2 2025

Dunnage Packaging is forecasted to reach $1.15 billion in 2025, maintaining an aggressive CAGR of 8.91% through 2033, reflecting strong market fundamentals. Q1 2025 market size is estimated at around $255 million, reflecting inventory adjustments and supply chain recalibration post-holiday season. The Q2 market is expected to expand to approximately $310 million, driven by surging e-commerce volumes, expanding global logistics networks, and increased emphasis on product protection during transit.

Key Takeaways

- Projected market value of $1.15 billion by 2025

- Increasing demand for advanced protective packaging solutions

- Growing focus on sustainable manufacturing practices

- Technological innovations driving market expansion

- Critical importance of industry chain analysis

Upstream and Downstream Industry Chain Analysis of the Dunnage Packaging Market

Upstream Industry Chain

- Raw Material Suppliers: The upstream sector includes suppliers of key raw materials such as recyclable plastics, biodegradable foams, and fabric textiles. Innovations in sustainable materials, like biodegradable foam and recyclable plastic alternatives with reduced carbon footprints, are critical drivers.

- Technology Providers: Companies providing smart packaging technologies, including IoT tracking systems, RFID tags, and sensor technologies, form a crucial part of the upstream chain. These innovations enable real-time product tracking and reduce damage risks.

- Manufacturing Equipment Suppliers: Providers of machinery and technology for producing lightweight, strong, and eco-friendly dunnage packaging materials support the manufacturing process.

Midstream Industry Chain

- Dunnage Packaging Manufacturers: These companies produce various types of dunnage packaging including corrugated plastic, foam, and fabric dunnage. They integrate sustainable materials and smart technology into their products to meet evolving market demands.

- R&D and Innovation Centers: Focus on developing new protective solutions that combine durability with environmental sustainability.

Downstream Industry Chain

- End-Use Industries:

- Automotive: Utilizes dunnage packaging primarily for component protection during shipping.

- Electronics: Requires advanced cushioning and smart packaging for sensitive goods.

- Industrial Goods: Needs robust protective packaging solutions for heavy and bulky products.

- Distributors and Logistics Providers: Play a vital role in handling and delivering dunnage packaging to various industries while ensuring compliance with environmental regulations.

- Retailers and E-commerce Platforms: Especially significant in regions like China where rapid e-commerce growth boosts demand for efficient protective packaging.

Market Influences Across the Chain

- Environmental Regulations: Impact raw material choices upstream and drive innovation in sustainable manufacturing practices midstream. They also influence downstream industry adoption rates.

- Geopolitical Factors: Affect global trade dynamics, raw material sourcing, manufacturing locations, and distribution channels.

- Technological Advancements: Drive integration of smart packaging across the chain from material development to end-user applications.

Trends in sustainable materials and smart packaging technologies

The dunnage packaging market is changing fast. It’s moving towards eco-friendly materials and smart packaging. This shift helps protect products and is better for the environment.

Here are the main trends in sustainable packaging:

- Recyclable plastic alternatives with reduced carbon footprint

- Biodegradable foam materials for cushioning

- Advanced reusable fabric packaging systems

- Integration of IoT tracking technologies

New smart packaging technologies are changing the game. They use RFID tags and sensors to track products in real-time. This cuts down on damage risks during transport.

Let’s look at some new sustainable dunnage materials:

| Material Type | Environmental Impact | Durability |

| Recycled Corrugated Plastics | Low Carbon Emissions | High |

| Biodegradable Foam | Minimal Waste | Medium |

| Organic Fabric Dunnage | Zero Synthetic Materials | Moderate |

Companies are spending a lot on research to make better packaging. They want to protect products and be kind to the planet. These new ideas are key to meeting the demand for green and smart packaging.

Market restrictions due to environmental regulations and cost factors

The dunnage packaging industry is facing big challenges. These come from new environmental rules and rising costs. Companies are under a lot of pressure to make sustainable packaging. They also have to deal with tough economic issues.

There are many challenges in the dunnage packaging world. These come from rules and money:

- Strict environmental regulations requiring reduced plastic usage

- Increased raw material procurement expenses

- Stringent waste management compliance standards

- Higher transportation and production costs

New rules are changing how companies package things. They need to use eco-friendly materials that are good for the planet. Recyclable and biodegradable packaging solutions are now key to staying in business.

Costs are also a big deal. Higher production and material costs are hard for small companies. Big companies with more money can handle these changes better.

Companies need to find new ways to solve these problems. They must find ways to be green and still make money. This means coming up with creative packaging that’s good for the planet and the wallet.

Geopolitical factors affecting global trade and manufacturing

The world of dunnage packaging manufacturing is changing fast because of complex global politics. Trade fights and changes in the economy make it hard for companies to keep their supply chains stable and reach new markets.

Important global trade issues in dunnage packaging include:

- Trade restrictions between big economic powers

- Regional economic partnerships

- Emerging market regulations

- Tariff implementations

Companies need to deal with complex diplomatic ties to stay competitive. Strategic adaptation becomes crucial as global politics keeps changing, asking for flexible ways to make things.

Big challenges in global trade for dunnage packaging manufacturing are:

- Shifting production places to avoid economic risks

- Creating new supply chain networks

- Using local manufacturing strategies

- Investing in new tech

International markets are closely linked, needing strong risk management plans. Companies must stay quick and ready for changes, keeping production smooth across different places.

Segmentation by Type: Corrugated Plastic, Foam, and Fabric Dunnage

The dunnage packaging market has three main types. Each offers special benefits for protecting products and making logistics smoother.

1. Corrugated Plastic Dunnage

Corrugated plastic dunnage is a go-to for many industries. It’s light but strong, protecting sensitive parts well.

2. Foam Dunnage

Foam dunnage is key for its shock-absorbing power. It’s a favorite for shielding delicate electronics and precise machinery on the move. Its density can be adjusted to fit different product needs.

3. Fabric Dunnage

Fabric dunnage is a new twist in protective packaging. It’s flexible, making it great for odd-shaped items. The auto and aerospace sectors love it for being light and fitting complex shapes.

| Dunnage Type | Primary Advantages | Key Applications |

| Corrugated Plastic | High durability, reusable | Electronics, automotive parts |

| Foam | Shock absorption, customizable | Precision machinery, fragile components |

| Fabric | Flexible, lightweight | Irregular shapes, aerospace components |

Each dunnage type plays a unique role in packaging. They tackle specific challenges in different industries with cutting-edge materials.

Segmentation by Application: Automotive, Electronics, and Industrial Goods

The dunnage packaging market shows big differences in three main areas: automotive, electronics, and industrial goods. Each field needs special protection methods to keep valuable items safe during transport and storage.

1. Automotive Dunnage

Automotive dunnage is a detailed way to protect complex parts. It needs strong packaging that can handle big shakes, changes in temperature, and rough handling. Foam inserts and sturdy plastic boxes help keep parts in place and moving little.

- Focus: Precision protection for engine components

- Key Requirements: Vibration resistance, precise positioning

- Typical Materials: Molded foam, reinforced plastics

2. Electronics Packaging

Electronics packaging faces special challenges with delicate tech gear. It uses materials that stop static and shock. This keeps the equipment safe during long trips around the world.

- Focus: Protection for electronic devices

- Key Requirements: Static protection, shock absorption

- Typical Materials: Anti-static foam, conductive materials

3. Industrial Goods Protection

Industrial goods need flexible packaging that can handle different shapes and weights. Containers made of corrugated plastic, wooden frames, and special supports protect big machinery, metal pieces, and complex items.

- Focus: Versatile protection for industrial products

- Key Requirements: Heavy-duty protection, adaptability

- Typical Materials: Corrugated plastics, wooden frames

Global Regional Analysis of the Dunnage Packaging Market

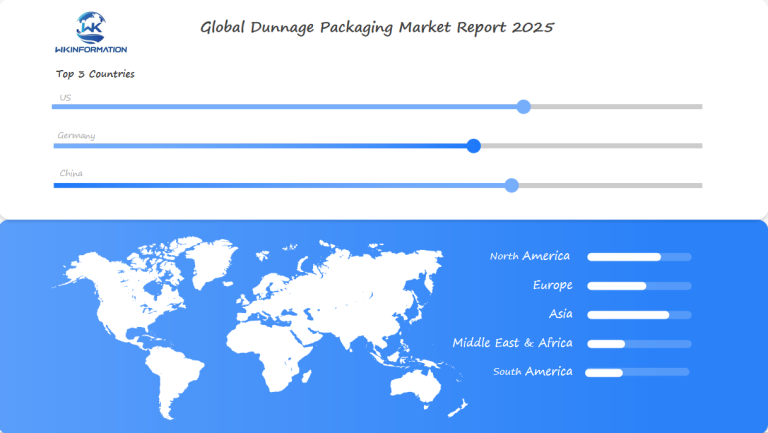

The global dunnage market shows big differences in each region. Each area has its own growth path and special features. Looking at market share by region, we see different patterns and chances for growth.

Regional analysis shows important market trends across continents:

- North America leads with advanced packaging technologies

- Asia-Pacific shows rapid manufacturing expansion

- European markets emphasize sustainable packaging solutions

Here are some detailed insights into how each region is doing:

- United States: Dominant market with substantial investment in protective packaging

- China: Fastest-growing segment driven by e-commerce and industrial growth

- Germany: Strong automotive sector influencing dunnage packaging innovations

Looking at market segments, we see important trends. The global dunnage market is strong because of its spread across different places. Each region adds its own special value to the market.

The U.S. market's advancements in reusable packaging solutions

The U.S. dunnage market has seen big changes in reusable packaging. American companies are leading the way in new packaging ideas. They’re making products that are good for the planet and keep things safe during transport.

Some big changes in the U.S. dunnage market include:

- Sustainable materials with extended lifecycle

- Lightweight yet durable packaging structures

- Modular design enabling multiple transportation cycles

- Advanced recyclable polymer technologies

Companies are putting a lot of money into research for intelligent packaging solutions. They want to make products that are better for the environment. The car and electronics industries are especially interested. They see the benefits for both their wallets and the planet.

These new packaging solutions are a big step forward for the U.S. dunnage market. By focusing on being green and efficient, American businesses are setting new standards worldwide.

Germany's focus on automotive component protection

Germany leads in protecting automotive components, setting high standards for engineering and packaging. The country’s car industry has developed top-notch dunnage solutions. These solutions focus on keeping products safe during transport and storage.

European packaging standards have been shaped by German methods. Big names like BMW, Mercedes-Benz, and Volkswagen work with packaging experts. Together, they create cutting-edge protective solutions. This teamwork leads to better ways to protect components.

- Advanced material selection for maximum protection

- Sustainable packaging design

- Precision engineering of dunnage solutions

The German method for dunnage combines function and care for the environment. New packaging designs cut down on waste while keeping components safe. Market trends show big growth in special packaging.

| Packaging Type | Protection Level | Sustainability Rating |

| Reusable Plastic Dunnage | High | Excellent |

| Custom Foam Inserts | Very High | Good |

| Recyclable Cardboard Containers | Moderate | Excellent |

German makers keep improving packaging, making it better for both the environment and component safety. Their dedication to quality keeps European standards ahead in the world of manufacturing.

China's rapid growth in e-commerce and manufacturing sectors

The Chinese dunnage market has grown fast, thanks to e-commerce and manufacturing growth. China has become a big player in packaging, using new tech and ideas.

What’s driving this growth?

- Rapid digital transformation in retail

- Increasing demand for protective packaging solutions

- Significant investments in manufacturing infrastructure

Online shopping has changed packaging needs a lot. The Chinese packaging industry now focuses on efficient, green, and safe packaging for online shopping.

The manufacturing sector’s growth has also helped the dunnage market. Chinese makers are creating advanced protective packaging for both local and global markets.

- E-commerce packaging volume increased by 35% in recent years

- Manufacturing sector investments continue to rise

- Technological innovation drives market competitiveness

China’s smart investments and tech skills make it a top player in dunnage packaging. This means more growth and new ideas in the future.

Future development outlook in the Dunnage Packaging market

The dunnage market forecast shows big changes in packaging. New technologies are changing how we protect items in many fields. New materials and designs are leading to big changes in the market.

Some key trends in dunnage packaging include:

- Advanced sustainable materials with less environmental harm

- Smart packaging with IoT sensors

- Lightweight but very protective designs

- AI for better packaging

New tech is opening up big chances for makers. 3D-printed dunnage solutions are a big step forward in custom protection. They allow for better protection of parts.

| Technology Category | Projected Market Impact | Estimated Growth Rate |

| Smart Packaging | High Customization | 12-15% annually |

| Sustainable Materials | Reduced Carbon Footprint | 8-10% annually |

| 3D-Printed Dunnage | Precision Manufacturing | 15-18% annually |

The packaging industry is set for big investments in research. Companies are focusing on solutions that are protective, green, and innovative. These moves will shape the future of dunnage packaging.

Competitor analysis highlighting key players and innovations

Key players in the dunnage packaging market are focusing on sustainable innovation and advanced protective solutions to meet the growing demand for efficient and eco-friendly packaging. They are expanding operations in regions such as Asia-Pacific and North America, where the rise of e-commerce and stringent environmental regulations are driving the need for recyclable and reusable packaging materials.

Key Players:

-

Pregis (United States)

-

Storopack (Germany)

-

Sealed Air Corporation (United States)

-

Ranpak (United States)

-

EAM-Mosca (United States / Germany)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Dunnage Packaging Market Report |

| Base Year | 2024 |

| Segment by Type |

· Corrugated Plastic · Foam · Fabric Dunnage |

| Segment by Application |

· Automotive · Electronics · Industrial Goods |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Dunnage Packaging Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Dunnage Packaging Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Dunnage Packaging Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Dunnage Packaging Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Dunnage Packaging Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Dunnage Packaging Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Dunnage Packaging Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Dunnage Packaging Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is dunnage packaging?

Dunnage packaging is a special way to protect goods during transport and storage. It stops products from getting damaged by keeping them still, absorbing shocks, and giving them support. It’s used in many industries.

What are the primary materials used in dunnage packaging?

The main materials used in dunnage packaging are:

- Corrugated plastic

- Foam

- Fabric

- Wood

Each material has its own benefits such as being lightweight, shock-absorbing, reusable, and providing a perfect fit for protection.

How does dunnage packaging benefit the automotive industry?

In the automotive industry, dunnage packaging plays a crucial role in ensuring safe shipping. It provides protection to various components such as engines and electronics, safeguarding them from potential damage during transportation and storage.

What are the emerging trends in dunnage packaging?

New trends include using green materials, smart packaging, and reusable solutions. Companies are using eco-friendly stuff, adding IoT sensors, and making packaging that can be used over and over again.

How do environmental regulations impact dunnage packaging?

Tighter green rules are making companies make packaging that can be recycled, biodegradable, and reused. This is pushing them to find new materials and designs that are good for the planet and still protect products.

What role does technology play in modern dunnage packaging?

Technology is transforming dunnage packaging through the use of smart tracking, RFID tags, and IoT sensors. These tools enable real-time monitoring of goods, enhance supply chain tracking, and provide valuable insights into the effectiveness of packaging.

Which industries primarily use dunnage packaging?

The main users of dunnage packaging are the:

- Automotive sector

- Electronics sector

- Industrial sector

- Aerospace sector

- E-commerce sector

Each of these industries requires specialized packaging that is tailored to meet the specific needs of their products during transportation and storage.

What are the key considerations when selecting dunnage packaging?

Important things to think about are the product’s weight, how fragile it is, the transport conditions, if it can be reused, the cost of materials, and its environmental impact. Companies need to find a balance between protection, efficiency, and being green.

How is the global dunnage packaging market expected to grow?

The market is expected to grow past $1.15 billion by 2025. This growth is due to more global trade, expanding manufacturing, and a bigger need for better protective packaging in many fields.

What innovations are emerging in dunnage packaging?

New ideas include:

- AI-designed packaging

- Advanced shock-absorbing materials

- Smart packaging that offers better protection and tracking