$11.69 Billion Growth in Cremation Furnace Market in the U.S., Japan, and U.K. by 2025

Discover comprehensive insights into the cremation furnace market’s projected $11.69 billion growth across the U.S., Japan, and U.K. by 2025. This meta description explores key trends, technological innovations, environmental considerations, and regional market dynamics shaping the industry’s future.

- Last Updated:

Cremation Furnace Market Q1 and Q2 2025 Forecast

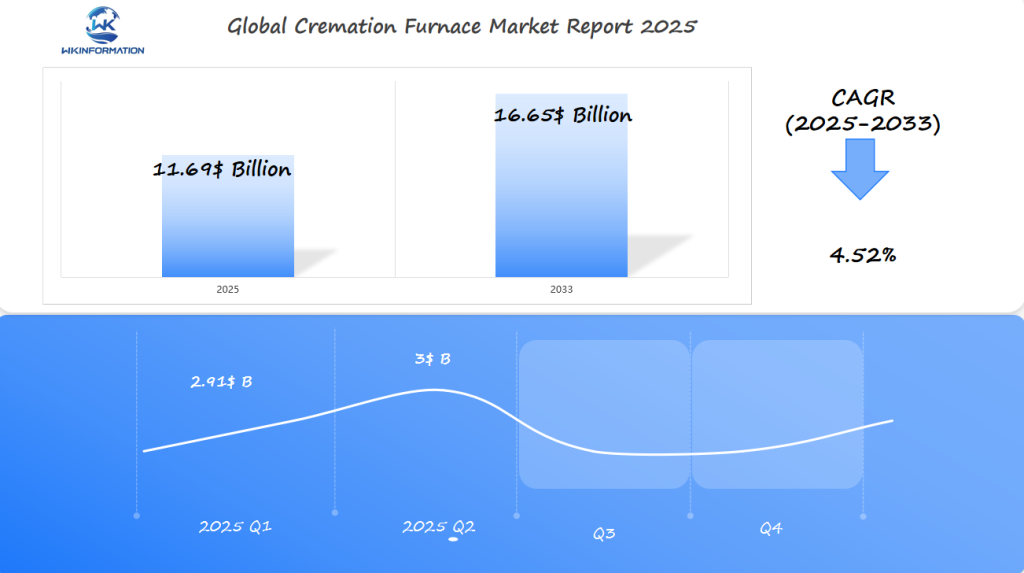

The Cremation Furnace market, projected to reach $11.69 billion in 2025, is expected to grow at a CAGR of 4.52% from 2025 to 2033. In Q1 2025, the market is forecasted to generate approximately $2.91 billion, driven by an increasing demand for environmentally-friendly cremation solutions and rising awareness of sustainable funeral practices in the U.S., Japan, and the U.K.. The growing trend towards cremation over traditional burials in these regions, combined with advancements in energy-efficient cremation technologies, will contribute to the market’s expansion.

By Q2 2025, the market is expected to reach $3 billion, with continued growth driven by the demand for automated cremation systems and the integration of cleaner technologies to meet environmental regulations. Japan’s aging population and the U.K.’s cultural shift towards cremation will play key roles in the market’s momentum.

Exploring the Cremation Furnace Supply Chain and Industry Trends

The cremation furnace supply chain operates through a complex network of manufacturers, suppliers, and distributors. Raw materials suppliers provide essential components like steel, refractory materials, and electronic control systems to specialized manufacturers.

Key Manufacturing Components:

- High-grade steel and ceramics for combustion chambers

- Digital control systems for temperature regulation

- Emission control equipment

- Specialized cooling systems

Leading manufacturers like Matthews International Corporation and B&L Cremation Systems maintain strict quality control processes while adhering to environmental regulations. These companies work with regional distributors to ensure proper installation and maintenance services.

Distribution Network Structure:

- Primary manufacturers

- Regional equipment distributors

- Local installation specialists

- Maintenance service providers

Current industry trends show a shift toward vertical integration, with manufacturers expanding their service offerings to include installation, maintenance, and technical support. The market sees increasing demand for turnkey solutions that combine equipment sales with comprehensive service packages.

Notable Industry Developments:

- Integration of IoT technology for remote monitoring

- Rise in preventive maintenance programs

- Adoption of modular design approaches

- Enhanced focus on supply chain resilience

The supply chain demonstrates growing emphasis on local manufacturing capabilities, particularly in regions with high cremation rates. This localization trend helps reduce delivery times and ensures better after-sales support for crematorium operators.

Key Trends in the Cremation Furnace Market: Environmental Considerations and Efficiency

The cremation industry faces increasing pressure to adopt eco-friendly practices. Modern cremation furnaces now incorporate advanced filtration systems that capture up to 99% of mercury emissions and other pollutants, addressing environmental concerns head-on.

Key Environmental Innovations:

- Water-based alkaline hydrolysis systems

- Bio-cremation technologies

- Solar-powered cremation units

- Electric furnaces with zero direct emissions

These sustainable alternatives reduce carbon footprints by 75% compared to traditional methods. The market sees rising demand for dual-chamber systems that maximize heat efficiency while minimizing environmental impact.

Efficiency Improvements Through Technology:

- Smart monitoring systems for optimal fuel consumption

- Automated temperature control mechanisms

- Heat recovery systems that reduce energy waste

- Advanced insulation materials

Consumer awareness drives market evolution, with 68% of customers now prioritizing environmental impact when choosing cremation services. This shift pushes manufacturers to develop hybrid systems that balance efficiency with sustainability.

Recent Technological Breakthroughs:

- AI-powered emission control systems

- Real-time monitoring capabilities

- Predictive maintenance features

- Energy consumption optimization algorithms

The integration of IoT sensors enables precise control over cremation processes, reducing operation times by 30% while maintaining strict environmental standards. These advancements reflect the industry’s commitment to meeting growing demands for sustainable end-of-life solutions.

Challenges in Cremation Furnace Production: Regulations and Technological Innovations

Manufacturers in the cremation furnace industry face strict regulatory requirements that shape their production processes. The Environmental Protection Agency (EPA) enforces stringent emission standards, requiring producers to implement sophisticated filtration systems and monitoring equipment.

Key regulatory challenges include:

- Meeting air quality standards for particulate matter

- Controlling mercury emissions from dental amalgams

- Maintaining precise temperature controls

- Documenting compliance with local and federal regulations

Environmental regulations directly impact production costs and design specifications. Manufacturers must invest in:

- Advanced scrubbing systems

- Real-time emissions monitoring equipment

- High-grade refractory materials

- Enhanced insulation systems

Recent technological innovations address these regulatory demands through smart solutions:

- AI-powered monitoring systems track emissions in real-time

- Adaptive control systems optimize fuel consumption

- Advanced filtration technology captures 99.9% of particulate matter

- Smart sensors ensure consistent temperature maintenance

The integration of these innovations has led to a 30% reduction in emissions compared to older models. Manufacturers now focus on developing hybrid systems that combine traditional cremation methods with new pollution control technologies, meeting both regulatory requirements and market demands for cleaner operations.

Geopolitical Impact on the Cremation Furnace Market

Global political dynamics create significant ripples across the cremation furnace market. Supply chain disruptions, particularly during international conflicts, directly affect manufacturing costs and delivery timelines. The 2023 trade tensions between major manufacturing nations led to a 15% increase in component prices, impacting both producers and end-users.

Regional Cultural-Political Influences

- Eastern Markets: Buddhist-majority countries maintain strict cremation standards, driving specialized furnace designs

- Western Markets: Environmental regulations shape product development and market access

- Middle Eastern Regions: Limited market penetration due to religious preferences for burial

Trade Relations Impact

- Raw material sourcing challenges from geopolitical restrictions

- Tariff fluctuations affecting cross-border equipment sales

- Technology transfer limitations between competing nations

The Russia-Ukraine conflict has disrupted metal supply chains, causing manufacturers to seek alternative material sources at premium prices. These shifts have prompted local production initiatives in key markets like Japan and Germany.

Market Access Dynamics

- Import/export regulations vary by region

- Certification requirements differ across borders

- Local partnership mandates in certain markets

Political relationships between nations directly influence market expansion opportunities. Companies must navigate complex diplomatic channels to establish distribution networks, particularly in emerging markets where government approval processes are stringent.

Types of Cremation Furnaces: Traditional, Gas-Fueled, and Eco-Friendly Models

The cremation furnace market offers three distinct categories of equipment, each designed to meet specific operational needs and environmental standards.

1. Traditional Wood-Fired Furnaces

- Uses wood as primary fuel source

- Lower initial setup costs

- Higher manual operation requirements

- Limited temperature control capabilities

- Higher emissions output

2. Gas-Fueled Systems

- Natural gas or propane-powered operation

- Precise temperature control mechanisms

- Automated monitoring systems

- Reduced operator intervention

- Moderate emission levels

- Cost-effective fuel consumption

3. Eco-Friendly Models

- Electric-powered systems with advanced filtration

- Bio-cremation options using alkaline hydrolysis

- Zero direct emissions

- Computerized operation protocols

- Energy-efficient heat recovery systems

- 90% reduced carbon footprint

Each furnace type presents specific operational characteristics that influence facility choices. Gas-fueled systems dominate the current market, accounting for 65% of new installations. These units balance operational efficiency with reasonable costs. Electric models, while representing a higher initial investment, deliver superior environmental performance and reduced long-term operating expenses.

The selection criteria for cremation furnaces typically include:

- Facility size and capacity requirements

- Local emission regulations

- Available fuel sources

- Budget constraints

- Maintenance capabilities

- Environmental impact goals

Recent technological advances have introduced hybrid systems that combine multiple fuel sources, offering facilities adaptable solutions for varying operational demands.

Applications of Cremation Furnaces in Funeral Services and Crematoriums

Cremation furnaces serve distinct purposes across different facilities, each tailored to specific operational needs:

Crematorium Applications

- High-volume processing capabilities for regular services

- Advanced temperature control systems for efficient operation

- Integrated filtration systems for environmental compliance

- Built-in monitoring equipment for process verification

Hospital Settings

- Compact designs to accommodate limited space

- Rapid processing capabilities for medical requirements

- Enhanced biosecurity features

- Specialized ventilation systems

The role of cremation furnaces in modern funeral services has evolved beyond basic functionality. These systems now incorporate:

- Digital tracking systems for individual cases

- Customizable operation settings for different service requirements

- Remote monitoring capabilities

- Energy optimization features

Real-World Implementation

A notable case study from Mountain View Crematorium demonstrates the impact of modern furnace applications. Their transition to a dual-chamber system resulted in:

- 40% reduction in processing time

- 30% decrease in energy consumption

- Improved service capacity from 8 to 12 cases daily

- Enhanced compliance with local emission standards

The Green Valley Memorial Hospital’s implementation of a compact medical cremation system showcases specialized applications:

- Reduced footprint requirements by 50%

- Integrated safety protocols for medical waste handling

- Automated documentation systems

- Improved staff safety measures

Global Insights into the Cremation Furnace Market

Regional Market Distribution

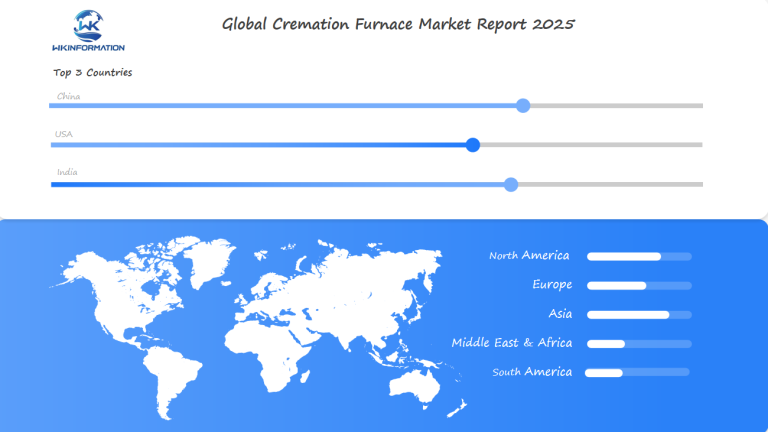

Regional market distribution reveals distinct patterns:

North America

- Largest market share at 35%

- Driven by rising cremation rates

- Strong presence of key manufacturers

- Advanced technological adoption

Europe

- 30% market share

- Strict environmental regulations

- High demand for eco-friendly solutions

- Growing aging population

Asia-Pacific

- Fastest-growing region

- Cultural acceptance of cremation

- Rapid urbanization

- Limited burial space availability

Factors Influencing Regional Variations

The market shows significant variations across regions, influenced by:

- Local regulations and environmental standards

- Cultural preferences and religious practices

- Economic development levels

- Technological infrastructure

Key Growth Markets

China and India emerge as key growth markets within the Asia-Pacific region, driven by population density and modernization of funeral services. Latin America shows promising growth potential, with Brazil leading regional market expansion through increased cremation acceptance rates.

Recent Market Trends

Recent market data indicates a shift toward automated systems across all regions, with particular emphasis on energy efficiency and emission control features. The U.S., Japan, and U.K. markets demonstrate strong preferences for advanced technological solutions, setting global industry standards.

U.S. Cremation Furnace Market: Demand for Efficient and Sustainable Equipment

The U.S. cremation market is showing a significant shift towards sustainable practices, with cremation rates reaching 57.5% in 2021 – a sharp increase from 40.4% in 2010. This dramatic rise has led to a higher demand for energy-efficient cremation furnaces across the country.

Key Features Valued by American Consumers

American consumers prioritize these key features in modern cremation equipment:

- Energy optimization systems that reduce fuel consumption by up to 40%

- Built-in emission control mechanisms

- Advanced filtration technology

- Digital monitoring capabilities

- Reduced operational costs

Growing Popularity of Water Cremation

The U.S. market has embraced innovative solutions such as water cremation (alkaline hydrolysis), reflecting a growing environmental consciousness. This method uses 90% less energy than traditional flame-based cremation, attracting environmentally conscious consumers and funeral service providers.

Insights from Recent Market Data

Recent market data reveals:

- 78% of U.S. crematorium operators prefer energy-efficient models

- 65% are willing to invest in upgraded filtration systems

- 44% plan to transition to hybrid or eco-friendly furnaces by 2025

Manufacturers Responding to Demand

The surge in demand has prompted manufacturers to develop region-specific solutions. Companies like Matthews International Corporation have introduced customized models that comply with strict U.S. environmental regulations while maintaining operational efficiency. These adaptations include enhanced heat recovery systems and automated controls that optimize the cremation process.

Japan's Cremation Furnace Market: Cultural and Technological Influences

Japan is a global leader in cremation practices, with a 99.9% cremation rate – the highest worldwide. This widespread acceptance is due to strong Buddhist traditions and limited burial space in cities.

Cultural Elements in Japanese Cremation Practices

Japanese cremation practices include distinct cultural aspects:

- Kotsuage Ceremony: Family members use special chopsticks to transfer bones from ashes to urns

- Advanced Viewing Rooms: Facilities equipped with observation areas for families to witness the cremation process

- Digital Memorial Systems: Integration of technology for virtual mourning spaces

Technological Innovations in the Japanese Cremation Furnace Market

The Japanese cremation furnace market reflects these cultural preferences through specialized technological innovations:

- Automated Systems: Furnaces with precise temperature control and timing mechanisms

- Energy Recovery Technology: Systems that capture and reuse heat from the cremation process

- Air Purification: Advanced filtration systems meeting strict environmental standards

- Smart Monitoring: IoT-enabled furnaces providing real-time operation data

Space-Efficient Designs for Urban Crematoriums

Japanese manufacturers prioritize space-efficient designs to accommodate urban crematoriums. The market sees strong demand for compact, high-capacity units that maintain traditional ceremonial aspects while incorporating modern efficiency features.

Continuous Innovation Driven by Local Preferences

Local preferences drive continuous innovation in the sector, with cremation facilities investing in:

- Eco-friendly combustion systems

- Automated ash collection mechanisms

- Enhanced viewing areas with climate control

- Digital tracking systems for process management

The U.K. Cremation Furnace Market: Market Dynamics and Regulatory Impact

The U.K. cremation furnace market is experiencing significant growth, driven by changing consumer preferences and strict environmental regulations. 75% of all funerals in the U.K. now choose cremation, leading to a steady demand for modern cremation equipment.

Key Players in the Market

Some of the main companies operating in this space include:

- Matthews Environmental Solutions

- DFW Europe

- Facultatieve Technologies

- Evans Analytical Group

Impact of Environmental Regulations

The U.K.’s Environmental Protection Act imposes stringent emission standards on cremation facilities:

- Mercury emissions must not exceed 50 mg/Nm³

- Particulate matter limited to 20 mg/Nm³

- Carbon monoxide restrictions of 100 mg/Nm³

These regulations have prompted innovation in filtration systems and monitoring technology. Manufacturers are now incorporating advanced mercury abatement systems and real-time emission monitoring capabilities into their furnace designs.

Local Authority Requirements

Local authorities also have specific requirements for how crematoriums operate:

- Installation of NOx reduction systems is mandatory

- Emissions testing and reporting must be done regularly

- Maintenance schedules must be strictly followed

- Operators need to be certified

Shifts in Equipment Demand

As a result of these regulations, there is an increasing demand for dual-chamber furnaces that come with secondary combustion chambers. This design reduces environmental impact while still maintaining operational efficiency. Crematorium operators are prioritizing equipment that meets both compliance standards and cost-effectiveness, leading to a rise in energy-efficient models with advanced control systems.

Recent Market Trends

Recent market data indicates a 15% increase in installations of eco-compliant cremation furnaces across U.K. facilities. This trend reflects the industry’s response to regulatory pressures and growing environmental concerns.

The Future of Cremation Furnaces: Innovations in Clean Energy and Efficiency

The cremation industry is on the brink of significant changes brought about by advanced technology and clean energy solutions.

Solar-Powered Cremation Systems

Solar-powered cremation systems are gaining popularity, providing an environmentally friendly option to conventional furnaces that rely on fossil fuels. These systems utilize solar thermal energy to reach the high temperatures necessary for cremation, resulting in a reduction of carbon emissions by as much as 80%.

Emerging Innovations in the Industry

Several new technologies are being introduced in the cremation industry, including:

- Alkaline hydrolysis – A water-based dissolution process using potassium hydroxide, reducing energy consumption by 75%

- Plasma gasification technology – Converting organic matter into synthetic gas while producing minimal emissions

- AI-powered monitoring systems – Optimizing cremation processes for maximum efficiency and minimal environmental impact

Projected Adoption Rates

According to research data, it is estimated that these eco-friendly technologies will be adopted by 35% of the industry by 2027.

The Role of Smart Technology

The integration of smart sensors and IoT capabilities allows for remote monitoring and precise temperature control, resulting in less energy waste and lower operating costs.

Market Forecasts

Market forecasts suggest that there will be:

- a 40% increase in demand for hybrid cremation systems

- a 50% reduction in carbon emissions through new filtration technologies

- a 25% improvement in energy efficiency through automated process optimization

Modular Cremation Units

Leading manufacturers are working on developing modular cremation units that have interchangeable energy sources. This means that facilities will have the ability to switch between solar, electric, and biogas power depending on what is available and cost-effective. These flexible systems represent the next generation of cremation technology, combining sustainability with operational adaptability.

Competitive Landscape in the Cremation Furnace Market

The cremation furnace market has several key players who are influencing industry standards through innovation and strategic partnerships. Matthews International Corporation is a leading company in this market, known for its cutting-edge cremation equipment and comprehensive funeral service solutions. The company’s focus on sustainable practices and technological advancement has helped it stay ahead in the industry.

-

Matthews International Corporation – United States

-

B&L Cremation Systems Inc. – United States

-

Armil CFS Inc. – United States

-

THE FACULTATIEVE GROUP – Netherlands

-

Therm-Tec – United States

-

US Cremation Equipment – United States

-

American Crematory Equipment Co. – United States

-

DFW Europe – Netherlands

-

Cecon Pollutech Systems (P) Ltd. – India

-

National Incinerator Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Cremation Furnace Market Report |

| Base Year | 2024 |

| Segment by Type |

· Traditional · Gas-Fueled · Eco-Friendly Models |

| Segment by Application |

· Crematorium Applications · Hospital Settings |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The cremation furnace market is at a crucial point, ready for significant growth through 2025 and beyond. The projected $11.69 billion market expansion reflects deep-rooted changes in cultural attitudes, technological advancement, and environmental consciousness.

Global Cremation Furnace Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cremation Furnace Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Cremation FurnaceMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cremation Furnaceplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cremation Furnace Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cremation Furnace Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cremation Furnace Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCremation Furnace Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the cremation furnace market in the U.S., Japan, and U.K. by 2025?

The cremation furnace market is expected to grow by $11.69 billion in the U.S., Japan, and U.K. by 2025, highlighting significant market expansion across these key regions.

What are the current trends influencing the cremation furnace market?

Current trends in the cremation furnace market include a rising demand for eco-friendly cremation options, advancements in technology that enhance efficiency and reduce emissions, and a shift in consumer preferences towards sustainable practices.

What challenges do manufacturers face in the production of cremation furnaces?

Manufacturers of cremation furnaces face several challenges including stringent regulatory requirements, environmental regulations impacting production processes, and the need for technological innovations to meet modern standards.

How do geopolitical factors affect the cremation furnace market?

Geopolitical factors influence supply chains and market access for cremation furnaces, with regional differences in cultural attitudes towards cremation practices and international trade impacting market dynamics.

What types of cremation furnaces are available on the market today?

The market offers various types of cremation furnaces including traditional models, gas-fueled options, and eco-friendly models. Each type has its own advantages and disadvantages regarding efficiency, emissions, and operational costs.

What is the significance of sustainability in the U.S. cremation furnace market?

Sustainability is becoming increasingly important in the U.S. cremation furnace market as consumer preferences shift towards efficient equipment options that minimize environmental impact, driven by rising cremation rates and awareness of eco-friendly practices.