2025 Conductivity Controller Market: Seizing $1.32 Billion Global Opportunities, Optimizing Processes in China, USA, Germany

A comprehensive analysis of the conductivity controller market’s explosive growth through 2025, focusing on China, USA, and Germany’s market dominance. Explore technological innovations, industry applications, and key growth drivers shaping this dynamic sector’s future.

- Last Updated:

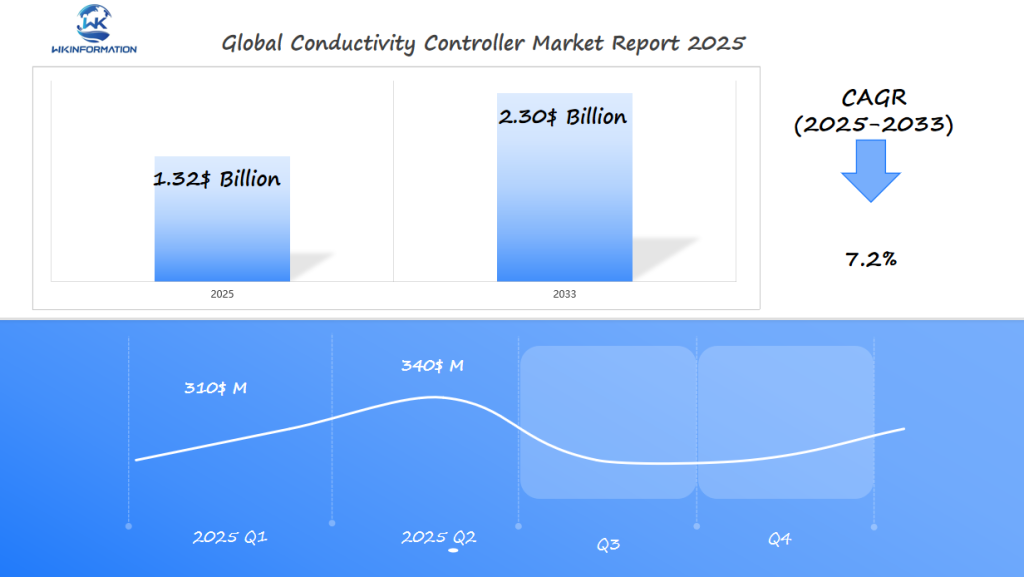

Conductivity Controller Market Forecast for Q1 and Q2 2025

The conductivity controller market is projected to reach $1.32 billion in 2025, growing at a compound annual growth rate (CAGR) of 7.2% from 2025 to 2033. In Q1 2025, the market value is anticipated to be around $310 million, driven by high demand in industries such as water treatment, pharmaceuticals, and chemical processing. The growth in Q2 2025 is expected to accelerate slightly, reaching approximately $340 million, as key markets like the United States, Germany, and China continue to expand their industrial sectors and emphasize the need for accurate monitoring and control of conductivity levels. The U.S. remains the largest market due to its advanced infrastructure and regulatory standards, while China and Germany see strong demand from growing manufacturing and industrial activities. For a comprehensive analysis of the market dynamics and an in-depth forecast, we encourage you to read the Wkinformation Research sample and full report.

Upstream and Downstream Industry Chain Analysis: The Conductivity Controller Supply Chain Explained

Understanding the supply chain of conductivity controllers is crucial for grasping their market dynamics. This supply chain can be divided into two main segments: upstream and downstream processes.

Upstream Processes

The upstream segment involves the initial stages of production. Key players here include:

- Component Manufacturers: These companies produce essential parts such as sensors and circuit boards.

- Raw Material Suppliers: They provide materials like metals and semiconductors necessary for manufacturing.

These elements are critical as they form the building blocks of conductivity controllers, impacting both cost-effectiveness and technological capabilities.

Downstream Processes

In the downstream segment, focus shifts to distribution and usage:

- Distributors: They play a pivotal role in making conductivity controllers accessible to various industries by managing logistics and inventory.

- End-users: Industries such as water treatment, pharmaceuticals, and electronics rely on these devices for precise monitoring and control of electrical conductivity.

Each component of this supply chain works synergistically to ensure that conductivity controllers meet market demands efficiently. Understanding these roles helps highlight the importance of strategic partnerships and innovation in maintaining a competitive edge.

Trend Analysis: Innovations and Trends in Conductivity Controller Technology

The conductivity controller market is undergoing a significant transformation, primarily driven by technological advancements that are setting new benchmarks for efficiency and precision. A major catalyst for this shift is the integration of Artificial Intelligence (AI). AI enhances the operational capabilities of conductivity controllers, enabling them to process data more effectively and provide real-time insights. This integration leads to improved decision-making processes in industrial environments.

In addition to AI, the market is witnessing a surge in advanced sensor technologies which are paving the way for innovation. These sensors offer improved accuracy and reliability, essential for applications requiring precise monitoring of electrical conductivity. The development of sensor technologies ensures that conductivity controllers can adapt to different industrial needs, providing customized solutions that tackle specific challenges.

Key Innovations in Conductivity Controller Technology

Some of the key innovations in this field include:

- AI-driven analytics: This feature enables predictive maintenance and optimizes performance.

- Smart sensors: These sensors offer heightened sensitivity and adaptability for various environmental conditions.

- Wireless connectivity: This capability allows for seamless integration into existing automation systems.

These technological trends not only enhance the functionality of conductivity controllers but also promote their adoption in industries such as water treatment, pharmaceuticals, and manufacturing. As industries continue to search for advanced solutions, these innovations are expected to play a significant role in shaping the future direction of the conductivity controller market.

Restriction Analysis: Challenges Facing the Conductivity Controller Industry

The conductivity controller market faces several challenges that may hinder its growth. Some of the key obstacles include:

- High R&D costs: Developing advanced technologies involves significant expenses, particularly when incorporating cutting-edge innovations such as AI and smart sensors into conductivity controllers.

- Fluctuating raw material prices: Volatile prices of raw materials lead to increased manufacturing costs, impacting profit margins and pricing strategies. Effective supply chain management is essential to maintain cost-effectiveness without compromising quality.

- Regulatory challenges: Stringent regulations regarding product safety and compliance add complexity for manufacturers. Understanding and following these regulations requires extensive knowledge of industry standards, which can be resource-intensive.

“Balancing regulatory requirements with innovation is crucial for staying competitive in the market.”

These challenges not only affect current players but also discourage new companies from entering the conductivity controller market. To overcome these obstacles, businesses need to develop strategic plans, find innovative solutions, and prioritize sustainable practices that align with changing consumer demands and regulatory frameworks.

Geopolitical Analysis: The Impact of Global Politics on Conductivity Controller Production and Trade

Global politics plays a crucial role in shaping the production capabilities and trade policies of conductivity controllers. Geopolitical tensions between major economic powers can lead to shifts in trade dynamics, impacting supply chains and market accessibility.

1. Trade Policies

Tariffs and trade agreements significantly influence the flow of goods across borders. For instance, ongoing trade negotiations between the USA and China can alter import-export duties, affecting pricing strategies and competitive positioning for manufacturers in these regions.

2. Production Capabilities

Political instability or sanctions can disrupt manufacturing activities, limiting access to essential raw materials or advanced technologies. Such disruptions necessitate diversifying supply chains to mitigate risks associated with geopolitical uncertainties.

3. Regional Market Dynamics

In Europe, Brexit has introduced new regulatory challenges and border controls, impacting the seamless movement of goods within the region. Companies must navigate these complexities to maintain operational efficiency.

4. Strategic Alliances

Forming strategic alliances with local partners can be a viable strategy to circumvent geopolitical barriers while tapping into regional expertise and distribution networks.

Understanding these geopolitical factors is crucial for stakeholders aiming to optimize their operations and leverage emerging opportunities within the conductivity controller market.

Segmentation Type Market Analysis: Conductivity Controller Market Segmentation by Type and Application

Understanding market segmentation is crucial in evaluating conductivity controllers. This segment can be classified primarily by type and application.

Types of Conductivity Controllers

- Traditional but reliable, these controllers are widely used due to their simplicity and cost-effectiveness.

- They are favored in industries where intricate digital features are unnecessary, such as basic water treatment facilities.

- These controllers offer advanced features like real-time monitoring and data logging capabilities.

- Enhanced accuracy and integration with automation systems make them ideal for high-tech applications in pharmaceuticals and electronics.

Applications of Conductivity Controllers

- Water Treatment: Ensures compliance with environmental standards by maintaining optimal levels of conductivity.

- Chemical Industry: Critical for controlling the concentration of solutions, ensuring product consistency.

- Food & Beverage: Helps maintain quality control during processing stages.

This segmentation highlights the diverse functionalities and growing versatility of conductivity controllers across industrial landscapes. Understanding these distinctions supports informed decision-making regarding investment and implementation strategies within various domains.

Application Market Analysis: The Role of Conductivity Controllers in Water Treatment

In the water treatment industry, conductivity controllers play a crucial role in maintaining and ensuring optimal water quality. These devices provide accurate monitoring and control of electrolyte levels, allowing for precise regulation of water chemical properties. This precision is vital for various applications, including municipal water supplies, wastewater treatment, and industrial processes.

Key Functions of Conductivity Controllers in Water Treatment:

1. Monitoring Electrolyte Levels

Conductivity controllers measure the electrical conductivity of water, which indicates its ionic composition. By monitoring these levels, operators can maintain the necessary balance of salts and minerals.

2. Controlling Chemical Dosage

These controllers help manage the addition of chemicals to the water system. They ensure that disinfectants and pH adjusters are dosed correctly, preventing overuse or underuse which could impact water safety.

3. Ensuring Compliance

With stringent regulations governing water quality standards, conductivity controllers help facilities meet legal requirements. Regular data logging and reporting from these devices support compliance with health and safety guidelines.

As industries increasingly adopt automation technologies, the demand for reliable conductivity controllers in the water treatment sector continues to rise. The integration of advanced sensors and AI further enhances their ability to deliver accurate data, supporting efficient operation and maintenance practices.

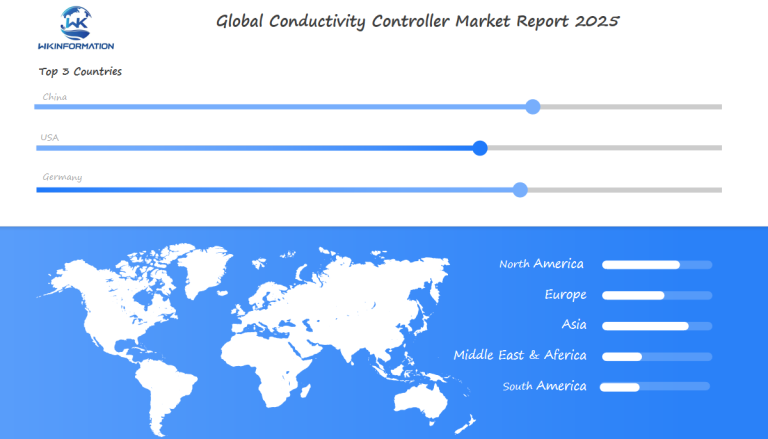

Global Conductivity Controller Market Region Analysis: Regional Market Trends Beyond Top 3 Countries

The global market for conductivity controllers is witnessing diverse trends beyond the dominant arenas of China, the USA, and Germany. As industries worldwide gravitate towards enhanced operational efficiency and sustainability, other regions are emerging as pivotal players.

1. Asia-Pacific (excluding China)

Countries such as India and Japan are experiencing significant growth. The burgeoning industrial sectors in these nations are investing heavily in automation technologies, driving demand for advanced conductivity controllers. Japan’s focus on precision manufacturing and India’s expanding infrastructure projects contribute to this dynamic market shift.

2. Europe (outside Germany)

Nations like France and Italy are emphasizing eco-friendly production processes. This trend aligns with the increasing adoption of conductivity controllers designed to optimize energy usage and ensure compliance with stringent environmental regulations.

3. Latin America

Emerging economies in this region are increasingly adopting industrial automation to boost productivity. Brazil and Mexico, in particular, show potential as they modernize their manufacturing landscapes, creating opportunities for conductivity controller suppliers.

4. Middle East & Africa

While still developing in terms of industrial automation, there is a noticeable push towards modernization. The growing water treatment sector across these areas is catalyzing demand for reliable conductivity control solutions.

These regions collectively contribute to an evolving global landscape where tailored technology integration continues to drive market expansion.

China Conductivity Controller Market Analysis: Chinese Market Growth, Electronics Industry Expansion, Investment Trends

China has a strong hold on the conductivity controller sector, and there are several key reasons behind this. The country’s large electronics industry has been instrumental in driving market growth. With significant investments in manufacturing capabilities, China is leading the way in technological advancements and aligning its strategies with global demands.

Key Factors Driving Growth:

1. Electronics Industry Expansion

- China’s electronics sector has seen rapid growth, with increased production and demand for conductivity controllers essential for maintaining quality and precision in electronic devices.

- The integration of advanced sensor technologies within the industry underlines the need for precise electrical conductivity monitoring.

2. Automotive Industry Influence

- The automotive sector’s expansion contributes significantly to market growth. Conductivity controllers are vital in electric vehicles (EVs) for battery management and ensuring optimal performance.

- As China continues to invest heavily in EV infrastructure and technology, the demand for high-performance conductivity controllers rises correspondingly.

3. Investment Trends

- Robust investment trends highlight China’s commitment to sustaining its leadership position in the global market. Government initiatives and incentives for research and development amplify these efforts.

- Companies are channeling resources into innovative solutions that integrate AI and automation technologies to enhance product offerings.

This analysis highlights China’s strategic position in the conductivity controller market, focusing on growth factors that align with both national development goals and international market demands.

USA Conductivity Controller Market Analysis: Innovation Focus USA R&D Investment Trends

The United States is a key player in the Conductivity Controller Market, driven by its strong focus on innovation and significant R&D investment trends. One of the main contributors to this landscape is the medical device sector, where conductivity controllers are crucial for ensuring precision and reliability in equipment used across various healthcare applications.

1. Innovation Focus

American companies are leading the way in developing cutting-edge technologies, integrating AI and advanced sensors into conductivity controllers. This innovation not only improves product performance but also aligns with the broader trend of increased automation in industrial processes.

2. R&D Investment

The U.S. market is characterized by substantial investments in research and development. Such investments fuel advancements that cater to specific industry needs, including medical, consumer electronics, and environmental monitoring sectors.

3. Key Sectors Driving Demand

Medical Devices: Conductivity controllers are crucial for maintaining the accuracy and safety of medical equipment.

Consumer Electronics: With an increasing demand for smart devices, precise conductivity control becomes vital.

Environmental Monitoring: Ensuring water quality through effective monitoring systems is a growing priority.

The combination of innovation and strategic investments positions the U.S. as a leader in the global conductivity controller market, paving the way for future technological breakthroughs.

Germany Conductivity Controller Market Analysis: Engineering Excellence and Quality Standards Impact

Germany is known for its exceptional engineering skills in the conductivity controller market, producing top-notch products. The country’s reputation for precise engineering and innovation is deeply rooted in its manufacturing processes, resulting in conductivity controllers that are known for their accuracy and dependability.

Engineering Prowess

German manufacturers use advanced technology to create innovative conductivity controllers. By incorporating complex components and materials, these devices are able to meet the demanding needs of various industries. This emphasis on superior engineering allows for the production of controllers that function optimally in different environments, making them more appealing to global markets.

Quality Standards

Strict quality standards are crucial in shaping the market dynamics in Germany. These standards guarantee that conductivity controllers not only perform well but also comply with safety and durability regulations. German companies maintain high-quality control measures to deliver products that excel in terms of lifespan and efficiency.

Market Impact

The effect of these quality standards goes beyond product development; it also influences consumer confidence and brand loyalty. Industries that heavily rely on accurate conductivity measurements, such as pharmaceuticals and chemical processing, prefer controllers made in Germany because of their unmatched precision and reliability.

Germany’s commitment to quality and innovation continues to fuel growth in the conductivity controller market, solidifying its position as a leader in this industry.

Future Development Analysis: The Future of Conductivity Controllers in Process Industries

Automation Technologies Future Trends

The landscape for conductivity controllers is set to transform significantly by 2025, driven by advancements in automation technologies and emerging future trends. As industries lean towards enhanced automation, the role of conductivity controllers is becoming more pivotal in ensuring operational efficiency.

Key Predictions:

- Integration with AI: Conductivity controllers are expected to increasingly integrate with artificial intelligence, enabling predictive maintenance and real-time data analysis. This will enhance decision-making processes and optimize resource allocation.

- Advanced Sensor Technologies: The incorporation of advanced sensors will bolster the precision and reliability of conductivity measurements, vital for sectors such as pharmaceuticals and food processing, where accuracy is paramount.

- Collaborative Robotics: The rise of collaborative robotics (cobots) within industrial settings will necessitate the use of sophisticated conductivity controllers that can seamlessly interact with robotic systems to maintain consistent production quality.

- Sustainability Focus: As industries adopt sustainable practices, there is a growing trend toward eco-friendly materials and energy-efficient manufacturing processes. Conductivity controllers designed to support these initiatives will become increasingly valuable.

These developments suggest a future where conductivity controllers not only improve operational efficiency but also contribute to broader industry goals such as sustainability and innovation. As technology continues to evolve, these tools will play an integral role in shaping the process industries of tomorrow.

Competitor Analysis: Major Players in the Conductivity Controller Market

- OHAUS CORPORATION

- Koehler Instrument Company

- ifm efector inc.

- Chemetrics Incorporated

- Hach Company

- Foerster Instruments Inc.

- Myron L Company

- Walchem

- Thermo Scientific

- HORIBA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Conductivity Controller Market Report |

| Base Year | 2024 |

| Segment by Type |

· Drive Coil · Corrosion-resistant Material Electrode |

| Segment by Application |

· Water Quality Monitoring · Boiler · Swimming Pool · Research and Teaching · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Understanding the regional factors at play is vital as China, the USA, and Germany spearhead the growth of the conductivity controller market. The progress and plans of these countries serve as standards for others to follow. There are future prospects with new developments in automation technologies that will require fresh methods to improve efficiency by 2025. The industry is on the brink of change, driven by technological advancements and strategic investments, offering a vibrant scene full of opportunities for those willing to adjust and create in their quest for greatness in this changing market.

Global Conductivity Controller Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Conductivity Controller Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Conductivity ControllerMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Conductivity Controllerplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Conductivity Controller Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Conductivity Controller Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Conductivity Controller Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofConductivity ControllerMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the significance of the upstream and downstream processes in the conductivity controller supply chain?

The supply chain for conductivity controllers consists of upstream manufacturing processes, where key players focus on production and raw material sourcing, and downstream operations, which involve distribution and end-users. Understanding these processes is crucial for identifying market dynamics and ensuring product efficiency.

How are technological advancements influencing the conductivity controller market?

Technological innovations such as AI integration and advanced sensor technologies are significantly shaping the conductivity controller market. These advancements enhance performance, accuracy, and efficiency in various applications, particularly in water treatment.

What challenges does the conductivity controller industry currently face?

The conductivity controller industry faces several challenges that hinder market growth, including high research and development costs, fluctuating raw material prices, and a complex regulatory landscape affecting product safety and compliance.

How do global politics affect the production and trade of conductivity controllers?

Global trade policies and geopolitical tensions can significantly influence production capabilities and trade dynamics within the conductivity controller market. These factors can lead to shifts in supply chains and impact pricing strategies across regions.

What are the main types of conductivity controllers in the market?

The conductivity controller market can be segmented by type into analog and digital controllers. Each type serves specific applications with varying functionalities, catering to diverse industry needs.

What role do conductivity controllers play in water treatment processes?

Conductivity controllers are vital in the water treatment industry as they ensure water quality by monitoring and regulating electrical conductivity levels. This helps maintain optimal conditions for various applications, from industrial processes to drinking water safety.