2025 Compression Molding Machine Market: Capturing $13.33 Billion Global Potential, Revolutionizing Plastics Production in China, Germany & India

Explore the booming compression molding machine market through 2025, featuring China’s manufacturing dominance, Germany’s technological innovation, and India’s rapid industrial growth. Discover key trends, applications, and regional insights shaping this dynamic industry’s future.

- Last Updated:

Compression Molding Machine Market Forecast for 2025

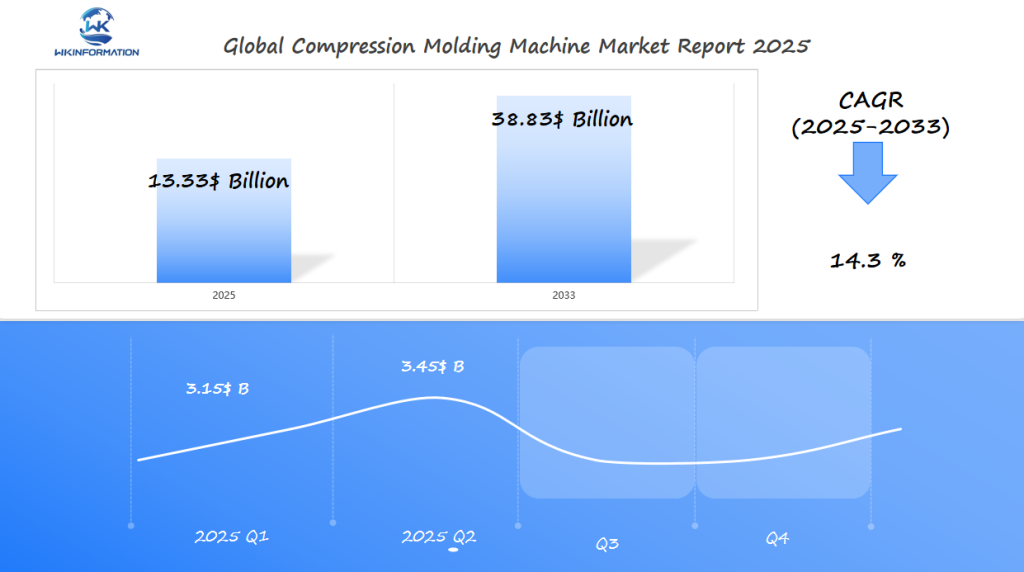

The global compression molding machine market is projected to reach $13.33 billion USD in 2025, with an anticipated CAGR of 14.3% from 2025 to 2033. Based on this growth, we can expect the market to perform strongly in the first half of 2025, with Q1 and Q2 seeing significant traction. Specifically, the Q1 2025 market share is estimated to be around $3.15 billion USD, followed by Q2, where a slight increase is expected, reaching approximately $3.45 billion USD. This increase in demand can be attributed to industries in China, Germany, and India, which are currently driving much of the growth in both production capabilities and technological advancements in the compression molding sector.

The rise in demand is particularly evident in the automotive and packaging industries, where advanced compression molding machines are essential for high-precision, high-volume manufacturing processes. Companies in these regions are investing heavily in automation to improve efficiency and reduce production costs. As a result, these markets are expected to continue their leadership in the compression molding machine sector throughout 2025 and beyond.For a detailed analysis of market trends, competitive landscape, and future growth projections, we recommend reviewing the Wkinformation Research sample and full report.

Upstream and Downstream Industry Chain Analysis: Understanding the Compression Molding Machine Supply Chain

The compression molding machine market is crucial for various industries, including automotive and aerospace. It provides a way to create large, sturdy parts with intricate shapes, making it vital for manufacturing composite materials. This market is expected to experience significant growth by 2025 due to technological advancements and increased demand.

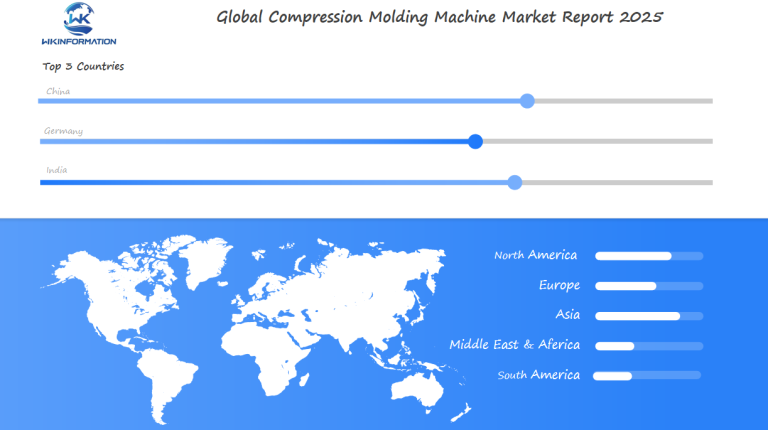

Key Regions Influencing the Market

Several key areas are playing a significant role in shaping the future of this market:

- China: Leading the way with its high production capacity and export volume. Since 2024, Chinese exports of compression molds have seen a notable recovery, targeting countries like Thailand and Russia.

- Germany: Known for its quality and innovation in manufacturing. The country prioritizes technological advancement to stay competitive, producing machinery that meets strict international standards.

- India: Experiencing rapid growth driven by its expanding manufacturing sector and increasing demand for plastics. The strong chemical manufacturing base in India further strengthens its global position.

These regions are working together to propel the compression molding machine market forward, each bringing unique strengths—production power from China, technological excellence from Germany, and emerging industrial capabilities from India.

Trend Analysis: Innovations and Trends in Compression Molding Machine Technology

Understanding the supply chain dynamics of the compression molding machine industry involves examining the upstream and downstream processes. In manufacturing, upstream refers to the initial stages involving raw material acquisition and production inputs, while downstream focuses on processing, distribution, and the final product’s delivery to end-users.

Upstream Dynamics

Key players in the upstream segment include:

- Raw material suppliers

- Component manufacturers

These entities provide essential inputs such as thermosetting plastics, which are integral to creating high-performance compression molds.

Downstream Dynamics

On the other side of the spectrum, the downstream components involve:

- Distributors

- Retailers

These parties are responsible for getting finished products into the hands of industries like automotive and aerospace.

The interplay between these stages significantly impacts market growth. Efficient supply chain management ensures a steady flow of materials, reduces production costs, and enhances product quality. Companies that master this dynamic often see a competitive edge through improved efficiency and scalability.

Supply chain analysis reveals how fluctuations in raw material availability or logistical challenges can ripple through the entire production process, influencing pricing, delivery times, and ultimately, market expansion capabilities. As such, innovation within this framework is critical for sustaining growth in the compression molding machine sector.

Restriction Analysis: Challenges Facing the Compression Molding Machine Industry

Recent technological advancements are reshaping the landscape of the compression molding machine industry. Automation and digitization play pivotal roles, enabling machines to deliver higher precision and efficiency. The integration of IoT and AI technologies allows for real-time monitoring and predictive maintenance, reducing downtime and enhancing production capabilities.

Emerging trends highlight a shift towards more sustainable practices. The development of bioplastics as an alternative to traditional thermosetting resins presents new opportunities for eco-friendly production. Machines are increasingly designed to accommodate these materials, reflecting a broader trend towards sustainability in manufacturing processes.

Another significant trend is the focus on energy efficiency. Innovations in machine design aim to reduce energy consumption without compromising performance. This is particularly crucial as industries seek to lower operational costs while adhering to environmental regulations.

Challenges remain, particularly regarding resource availability and regulatory compliance. However, the industry’s commitment to continuous innovation suggests a promising trajectory towards overcoming these obstacles. As technology progresses, the compression molding machine market is set to witness transformative changes that will define its future growth and development well into 2025.

Geopolitical Analysis: The Impact of Global Politics on Compression Molding Machine Production and Trade

The Compression Molding Machine Market faces significant challenges stemming from geopolitical dynamics. Resource scarcity is a pressing issue, with raw materials sometimes becoming difficult to source due to political tensions or trade restrictions. For instance, fluctuating tariffs and embargoes can disrupt the steady flow of necessary components, impacting production timelines and costs.

Additionally, regulatory issues present hurdles for manufacturers. Different countries maintain varying safety standards and environmental regulations, requiring companies to adapt their products accordingly. This not only complicates manufacturing processes but also increases compliance costs.

To navigate these challenges, industry players can adopt several strategies:

- Diversification of Supply Chains: By sourcing raw materials from multiple regions, companies can reduce dependency on any single country and mitigate risks related to political instability.

- Investment in R&D: Developing alternative materials or technologies that comply with a broader range of regulations can help companies maintain competitiveness across different markets.

- Strategic Partnerships: Collaborating with local firms in key regions can provide valuable insights into navigating regulatory landscapes and accessing essential resources more efficiently.

Such proactive approaches are essential for maintaining stability and growth within the ever-evolving geopolitical landscape.

Segmentation Type Market Analysis: Compression Molding Machine Market Segmentation by Type and Application

Geopolitical factors play a crucial role in shaping trade dynamics and manufacturing capabilities in the compression molding machine market. Political scenarios across the globe influence how and where these machines are manufactured and traded. For instance, tariffs and trade agreements can significantly impact the flow of goods between countries, affecting both production costs and market accessibility.

Consider the US-China trade relations, a notable case study illustrating geopolitical tensions affecting the compression molding machine market. The imposition of tariffs by the United States on Chinese goods led to increased costs for manufacturers relying on Chinese parts, disrupting supply chains. This scenario prompted many companies to reassess their sourcing strategies, often looking towards alternative markets like Vietnam or Thailand for components.

Key Considerations

- Trade Flows: Political decisions can alter trade routes, making it essential for businesses to stay informed about international policies.

- Manufacturing Capabilities: Shifts in geopolitical climates may necessitate changes in production locations to maintain competitive advantages.

Understanding these dynamics is critical for stakeholders aiming to navigate the complex landscape of global manufacturing. With geopolitical factors constantly evolving, staying adaptable is key to maintaining resilience in this volatile market sector.

Application Market Analysis: The Role of Compression Molding Machines in Composite Manufacturing

Compression molding machines are essential in making composite materials. They can create complex shapes accurately, which is crucial for many industries.

Types of Compression Molding Machines

- Hydraulic Compression Molding Machines

- These are commonly used for their accuracy and control over pressure and temperature, making them perfect for producing car parts and large aerospace components.

- Mechanical Compression Molding Machines

- Known for their speed and efficiency, these machines are often used in situations where quick production cycles are important, like in consumer electronics.

- Pneumatic Compression Molding Machines

- These machines offer flexibility and are used in cases where lower pressures are needed, suitable for small production runs or specialized parts.

Applications Across Industries

- Automotive Industry: Used to make lightweight yet strong parts like bumpers, dashboards, and engine covers.

- Aerospace Sector: Important for creating high-strength components that must endure harsh conditions, such as wing parts and structural elements.

- Electronics: Employed to manufacture casings that require precise measurements and intricate designs.

Each type of compression molding machine has its own benefits designed for specific industry requirements. This drives innovation and efficiency in the processes of making composites.

Global Compression Molding Machine Market Region Analysis: Regional Market Dynamics

Compression molding plays a crucial role in the production of composites, known for its ability to create intricate shapes with high precision. This level of accuracy is essential in industries such as automotive and aerospace, where the complexity of components and their performance are critical.

Why Compression Molding?

1. Complex Shapes

The compression molding process allows the creation of intricate designs that are often unachievable through other methods. This advantage makes it a preferred choice for manufacturers aiming to meet specific design criteria without compromising on quality.

2. High Dimensional Accuracy

Accuracy in dimensions ensures that the parts fit perfectly into their designated applications, reducing waste and improving the overall efficiency of production processes.

Countries like China, Germany, and India are leading the way in reaping these benefits. China’s dominance is evident in its large production capacity and export volume. Germany’s technological expertise enhances the quality of machinery, while India’s rapidly growing industrial sector drives demand.

The global market for compression molding machines thrives on these regional advantages, highlighting the crucial role of this technology in advancing composite manufacturing. By embracing innovative methods, manufacturers can continue to leverage these benefits, fostering growth and creativity in their respective markets.

China Compression Molding Machine Market Analysis

China plays a crucial role in the compression molding machine market, showing impressive growth and influence. Its dominance is highlighted by a significant increase in both the consumption and production of compression type molds. This growth is in line with the overall trends seen in the Asia-Pacific region, where technological advancements and rising demand from end-user industries are driving market dynamics.

Regional Analysis: Asia-Pacific vs Europe vs North America

1. Asia-Pacific

The rise in industrial activities and the region’s focus on manufacturing excellence position Asia-Pacific as a frontrunner in market growth. China’s initiatives to enhance production capabilities and export volumes highlight its strategic role within this landscape.

2. Europe

Known for its technological expertise, Europe, particularly Germany, maintains a competitive edge through innovation in compression molding technologies. The emphasis on quality and engineering precision further solidifies its standing.

3. North America

A significant market driven by demand from sectors like automotive and aerospace. The focus here is on integrating cutting-edge technologies to meet evolving industry standards.

The interaction between these regions shows different growth potentials shaped by their strengths in technology, demand, and industrial expansion. China’s leadership in production scale and export activities significantly impacts the global trajectory of the compression molding machine market.

Germany Compression Molding Machine Market Analysis

Germany is known for its technological expertise and commitment to quality in the compression molding machine industry. The country is a leader in innovation, constantly pushing the limits of manufacturing and engineering excellence. German manufacturers are famous for their top-notch machinery that meets and often exceeds industry standards. This focus on precision and reliability ensures that German machines remain competitive worldwide.

Challenges from China

Despite Germany’s technological advancements, China’s dominance in the market poses a significant challenge. China’s ability to produce compression molding machines on a large scale gives it a major advantage in terms of cost-effectiveness. The high volume of production allows China to offer competitive pricing, making it an appealing supplier for many global markets. China’s strategic emphasis on exporting strength is clear, with major destinations including Thailand, Russia, and Vietnam.

Strategies of German Manufacturers

German manufacturers respond to this challenge by prioritizing continuous innovation and strict quality control measures. This approach helps maintain their reputation for producing long-lasting and efficient machinery. As the demand for top-quality compression molding machines increases, Germany’s focus on innovation could make it the preferred choice for industries where performance and durability are crucial.

The ongoing rivalry between Germany’s technological superiority and China’s extensive manufacturing capabilities creates a competitive landscape in the global market.

India Compression Molding Machine Market Analysis

India is becoming a strong competitor in the compression molding machine market, thanks to its rapidly growing manufacturing sector. The country’s significant growth is driven by a high demand for plastics in various industries, making India an important player globally.

Key Factors Driving India’s Growth

- Expanding Manufacturing Sector: India’s manufacturing landscape is rapidly expanding, with numerous industries leveraging compression molding technology to enhance production efficiency and product quality.

- Strong Chemical Manufacturing Base: The presence of a well-established chemical industry underpins India’s capacity to produce high-quality molding machines, offering a competitive edge in the market.

The Influence of German Technology

Germany’s expertise in technology plays a crucial role in India’s growth potential. German manufacturers have consistently stayed ahead through continuous innovation and strict quality control measures. This commitment to excellence sets a benchmark for Indian manufacturers aiming to improve their global standing.

- Technological Edge: Leveraging advancements in technology, German companies have refined their production processes, ensuring high standards that Indian manufacturers can aspire to replicate.

- Quality Control: Stringent measures adopted by German firms ensure that every machine meets rigorous industry requirements, serving as an exemplar for quality assurance in India’s growing market.

Opportunities for Growth

India’s potential is ripe for exploration, with ample opportunities for local and international players looking to invest in this dynamic market.

Future Development Analysis: The Future of Compression Molding Machines in Advanced Materials

India’s rapid growth potential in the compression molding machine market is drawing significant attention from global manufacturers. The country’s appeal as a manufacturing hub stems from several key factors:

1. Skilled Workforce

India boasts a large pool of technically skilled professionals, making it an ideal location for setting up facilities to produce advanced compression molding machinery. This availability of talent supports innovation and boosts productivity, essential components for competing in the global market.

2. Cost-Effective Operations

Lower labor costs coupled with government incentives for manufacturing make India an economically attractive destination for investment in this sector.

While India presents numerous opportunities, challenges also exist:

1. Infrastructure Bottlenecks

Despite government efforts, inadequate infrastructure remains a hurdle for many industries. Poor transportation networks and inconsistent power supply can impede efficient production and distribution processes.

2. Regulatory Landscape

Navigating India’s regulatory environment can be complex. Manufacturers must adapt to local compliance requirements, which can vary significantly across regions.

These factors collectively shape India’s landscape for future development in compression molding technology. As the country continues to address these challenges, it positions itself as a formidable player in the production of advanced materials through compression molding technology.

Competitor Analysis: Key Players in the Compression Molding Machine Market

- PAN STONE

- Wabash MPI

- ARBURG

- Sacmi

- Tung Yu Hydraulic Machinery Co., LTD.

- Sumitomo (SHI) Demag, Freeman Schwabe

- Milacron

- Beckwood Press

- REP International

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Compression Molding Machine Market Report |

| Base Year | 2024 |

| Segment by Type | ·2-Layer Mold Compression Molding Machine

·3-Layer Mold Compression Molding Machine ·Other |

| Segment by Application |

· Pharmaceutical · Chemical · Other |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Compression Molding Machine Market is a dynamic and rapidly evolving sector with regional strengths and significant global potential. Understanding the key players dominating this space is crucial for strategizing entry or expansion plans.

Key Regional Players

- China: Leading in production and export volume, China’s market strength lies in its ability to scale manufacturing processes efficiently. However, maintaining quality standards amidst rapid growth can be challenging.

- Germany: Renowned for technological advancements, Germany excels with high-quality machinery that meets strict industry standards. The focus on continuous innovation and stringent quality control measures offers a competitive edge but may result in higher production costs.

- India: Experiencing explosive growth driven by industrial expansion and a robust chemical manufacturing base. The availability of a skilled workforce supports this trajectory, though infrastructure bottlenecks present challenges.

Factors to Consider

In evaluating these regions, companies should consider:

- Strengths:

- China: Cost-efficient production

- Germany: Technological superiority

- India: Rapid market growth

- Weaknesses:

- China: Quality control concerns

- Germany: Higher operational costs

- India: Infrastructure limitations

Identifying these factors helps businesses navigate the competitive landscape effectively, making informed decisions tailored to each region’s unique advantages and challenges.

Global Compression Molding Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Compression Molding Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Compression Molding MachineMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Compression Molding Machineplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Compression Molding Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Compression Molding Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Compression Molding Machine Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCompression Molding MachineMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the significance of the compression molding machine market in various industries?

The compression molding machine market plays a crucial role in multiple industries such as automotive, aerospace, and consumer goods, as it enables the efficient production of complex shapes with high dimensional accuracy. As demand for advanced materials and manufacturing capabilities grows, the significance of this market continues to increase.

Which regions are currently driving growth in the compression molding machine market?

Key regions driving growth in the compression molding machine market include China, Germany, and India. These countries are experiencing significant advancements in technology and increasing demand from end-user industries, contributing to their leadership in the global market.

What challenges does the compression molding machine industry face?

The compression molding machine industry faces several challenges including resource scarcity, regulatory issues, and technological limitations. Companies must develop strategies to overcome these obstacles to sustain growth and innovation within the sector.

How do geopolitical factors influence the compression molding machine supply chain?

Geopolitical factors significantly impact trade flows and manufacturing capabilities within the compression molding machine sector. Issues like US-China trade relations can create uncertainties that affect production costs and market access for manufacturers globally.

What types of compression molding machines are available and what are their applications?

There are various types of compression molding machines designed for different applications across industries such as automotive and aerospace. Each type is engineered to meet specific production needs and efficiency requirements, highlighting their versatility in manufacturing processes.

What innovations are expected to shape the future of compression molding machines?

Future developments in compression molding machines may focus on sustainability through innovations like bioplastics instead of traditional resins. Additionally, advancements aimed at improving efficiency and production capabilities will be key trends to watch as the industry evolves.