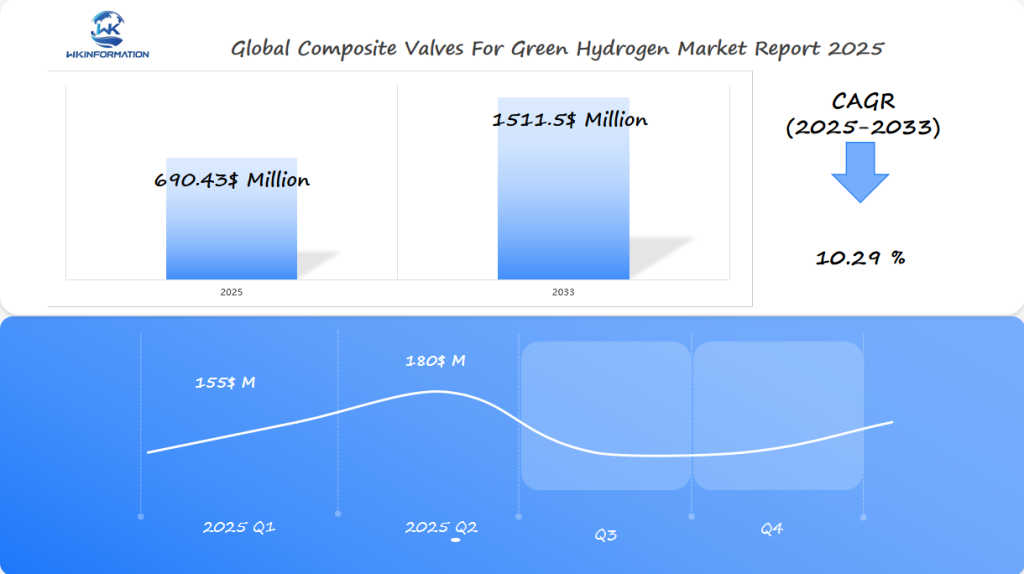

Composite Valves For Green Hydrogen Market Expected to Reach $690.43 Million Globally by 2025 with Leading Growth in Germany, the U.S., and Japan

Explore the Composite Valves For Green Hydrogen Market growth driven by renewable energy demands, technological innovations, and increasing hydrogen infrastructure development worldwide.

- Last Updated:

Composite Valves for Green Hydrogen Market Insights and Q1 and Q2 of 2025 Forecast

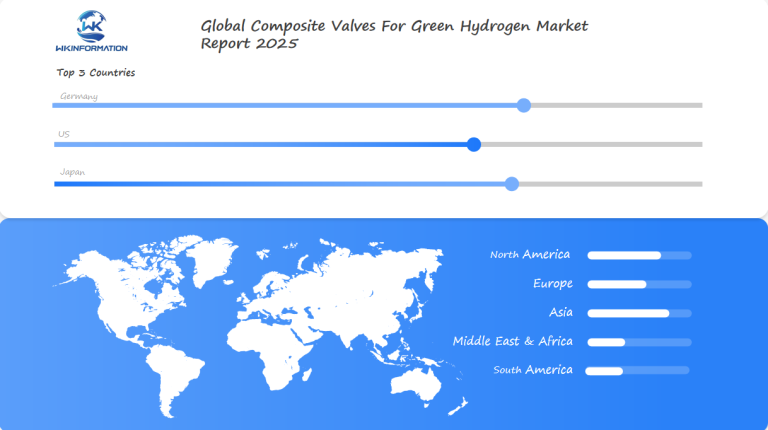

The Composite Valves for Green Hydrogen market is anticipated to hit $690.43 million in 2025, reflecting a strong CAGR of 10.29% through 2033. Q1 revenue is expected to reach approximately $155 million, increasing to around $180 million in Q2, fueled by the rapid deployment of green hydrogen infrastructure and growing demand for lightweight, corrosion-resistant valve systems. Germany, the U.S., and Japan are at the forefront of this market, backed by national hydrogen strategies, heavy R&D spending, and a mature base of composite materials engineering. These nations are crucial in driving valve technology suited for high-pressure, high-purity hydrogen applications that meet future energy transition goals.

Key Takeaways

- Composite valves are crucial for green hydrogen market development

- Market expected to reach $690.43 million by 2025

- Technological innovations driving sector growth

- Government policies supporting renewable energy transitions

- Specialized valve designs enabling safer hydrogen technologies

Understanding the Upstream and Downstream Industry Chain of Composite Valves for Green Hydrogen

The green hydrogen industry has a complex network of processes. These processes drive innovation in composite valve components. This network connects key manufacturing stages with advanced technologies, making a strong ecosystem for sustainable energy.

The upstream industry is key in making high-performance materials for composite valves. These materials need precise engineering and advanced science. They must meet the tough demands of hydrogen infrastructure.

Upstream Components and Materials

Important upstream components for composite valves include:

- Advanced polymer composites

- High-performance ceramic materials

- Corrosion-resistant metal alloys

- Specialized synthetic resins

Manufacturers aim to create lightweight yet durable composite valve components. These must resist hydrogen embrittlement and keep their shape under high pressure.

Downstream Applications and End-Users

The downstream industry has many uses for composite valves in green hydrogen systems. Key areas include:

- Hydrogen production facilities

- Energy storage infrastructure

- Transportation and distribution networks

- Fuel cell technologies

New markets are adopting composite valve technologies to boost efficiency and safety in hydrogen energy systems. The downstream industry keeps pushing for better, more reliable solutions for global sustainable energy challenges.

Market Trends and Innovations Shaping the Green Hydrogen Valve Sector

The green hydrogen industry is changing fast. This is thanks to new valve innovations and smart technologies. As the world moves towards cleaner energy, valve makers are creating advanced solutions for green hydrogen systems.

New trends in green hydrogen are changing how valves are made and work. The field is seeing big tech leaps. These advancements tackle big problems in moving and storing hydrogen.

Technological Advancements in Valve Design

Today’s valve technology is improving in several ways:

- Materials that don’t weaken from hydrogen exposure

- Improved seals to prevent leaks

- Lightweight and strong valves that resist corrosion

Integration of Smart Technologies and IoT

Smart valves are changing how we watch and fix things. New tech includes:

- Sensors that check how things are working in real time

- Algorithms that predict when things might need fixing

- Systems that let you check things from far away

Now, valve checks use Industrial Internet of Things (IIoT). This lets us see how valves are doing, any wear, and how well they’re working.

Regulatory and Market Restrictions Influencing Growth

The green hydrogen industry faces many regulatory challenges. These challenges affect the development and market growth of composite valves. Hydrogen safety rules are key in setting the rules for valve makers and users in different fields.

Ensuring safe and efficient hydrogen systems is crucial. Valve makers must follow strict environmental rules. These rules cover material choice, testing, and emissions control.

Safety Standards and Compliance Requirements

Important safety factors for hydrogen valve design include:

- Fugitive emissions testing protocols

- Material compatibility with hydrogen environments

- Pressure and temperature resistance specifications

- Leak detection and prevention mechanisms

Environmental Regulations Impacting Valve Design

Environmental standards push for new valve technology. Rules now ask for:

- Lower carbon footprint in making

- Better material durability

- More energy efficiency

- Greener production ways

| Regulatory Standard | Primary Focus | Industry Impact |

| NACE MR-0175 | Upstream Exploration | Corrosion Resistance |

| NACE MR-0103 | Refinery Environments | Material Selection |

| ISO 26262 | Safety Critical Systems | Risk Management |

The mix of hydrogen safety rules and advanced valve compliance is changing the green hydrogen future. It’s driving tech innovation and market growth.

Geopolitical Factors Driving the Composite Valve Market for Green Hydrogen

The global landscape of green hydrogen is rapidly evolving due to intricate political dynamics. Nations are implementing significant shifts in their energy strategies.

Green hydrogen policies play a crucial role in fostering innovation and creating employment opportunities. Governments are adopting a holistic approach, aiming to establish robust hydrogen infrastructures.

Global Energy Policies and Their Impact

Several key trends are defining the green hydrogen landscape:

- Ambitious carbon reduction targets

- Increased renewable energy investments

- Strategic national hydrogen roadmaps

The U.S. government is investing heavily in clean hydrogen technology to improve systems for producing green hydrogen.

International Collaborations and Trade Agreements

Valve trade deals are getting better as countries work on hydrogen chains. Partnerships across borders are opening up new tech and market chances.

Working together, countries are overcoming old hurdles in green hydrogen. These global efforts are key for standardizing tech and making energy networks more efficient.

New markets are showing a lot of promise for green hydrogen. Places like Asia-Pacific and Europe are leading in new valve tech.

Detailed Segmentation of Composite Valves by Type and Usage

The green hydrogen industry needs advanced composite valve technologies for safe and efficient work. Specialized valve designs are key in handling hydrogen’s unique challenges.

Composite valve types are made to meet hydrogen’s tough demands. They must handle extreme pressures, stop leaks, and work well in different places.

Primary Valve Categories in Hydrogen Systems

- Ball Valves: Provide exceptional shut-off capabilities

- Check Valves: Prevent reverse flow in hydrogen pipelines

- Needle Valves: Enable precise flow control

- Pressure Relief Valves: Ensure system safety under high-pressure conditions

Specialized Valve Designs for Critical Applications

Hydrogen valve applications need new engineering ideas. Makers create advanced composite valves with materials like stainless steel and high-performance polymers. This is to tackle hydrogen’s special molecular traits.

| Valve Type | Key Application | Material Composition |

| Cryogenic Ball Valve | Liquid Hydrogen Storage | Nickel Alloy |

| High-Pressure Globe Valve | Hydrogen Compression | Titanium Alloy |

| Flow Control Valve | Electrolysis Systems | Ceramic-Reinforced Composite |

The growth of composite valve tech keeps pushing innovation in green hydrogen. It helps build more efficient and reliable hydrogen systems around the world.

Applications Driving Demand in Green Hydrogen Composite Valves

The green hydrogen industry is growing fast. Composite valves are key in many areas. They help manage hydrogen safely and efficiently in important sectors.

New hydrogen production valves are changing clean energy. These valves work well with many hydrogen technologies. They make it easy to use different hydrogen systems together.

Hydrogen Production and Electrolysis

Electrolysis systems need special valves for hydrogen. These valves are important for:

- Managing hydrogen gas flow in water splitting

- Controlling pressure in electrolyzer stacks

- Protecting membranes in advanced units

Storage and Transportation Systems

Hydrogen storage valves handle high-pressure and cold hydrogen. New valve technologies help with:

- Storing compressed hydrogen

- Transporting liquid hydrogen

- Managing pressure safely

Fuel Cell Technologies

Fuel cell valves are used in many places. They help with:

- Controlling hydrogen flow in cars

- Generating power in industries

- Keeping systems running well

The green hydrogen world needs better valves all the time. This is because the needs of industries are getting more complex.

Global Regional Market Insights for Composite Valves in Green Hydrogen Industry

The global hydrogen valve market is growing fast. Different regions are playing big roles in this growth. This shows how important green hydrogen technologies are becoming around the world.

Recent studies show the global hydrogen valve market is changing a lot. Each region has its own special features that are driving new ideas and use.

North America and Europe: Leading Markets

North America and Europe are leading the way in the hydrogen valve market. They are moving fast because of:

- Strong government support for green hydrogen projects

- Leading-edge technology

- Big investments in renewable energy

Asia-Pacific: Rapid Growth and Emerging Opportunities

The Asia-Pacific region is showing great potential in hydrogen markets. Countries such as China, Japan, and South Korea are investing in hydrogen and becoming key players in the global hydrogen valve market.

Rest of the World: Developing Markets and Future Potential

Other parts of the world are also seeing the value of hydrogen technologies. They are starting to grow, with countries looking at green hydrogen as a clean energy option.

Germany's Leading Role in Composite Valves for Green Hydrogen

Germany is at the forefront of the global green hydrogen movement. With its technological expertise, the country is making significant progress in developing hydrogen infrastructure. Germany’s advanced valve manufacturing industry plays a crucial role in this endeavor, showcasing its engineering prowess and national commitment.

Germany’s strategy for green hydrogen revolves around establishing itself as a worldwide leader. The key components of this plan include:

- Strong government support for hydrogen technologies

- Extensive research and development networks

- State-of-the-art engineering capabilities

- Dedication to sustainable industrial transformation

Government Initiatives and Industry Collaborations

Germany’s national hydrogen strategy supports tech growth. The government has launched programs to boost hydrogen infrastructure in Germany. These efforts help companies like GSR Ventiltechnik GmbH and ADAMS Armaturen GmbH create new valve solutions.

Key Players and Technological Advancements

Leading German valve manufacturers are at the forefront of composite valve technology. Companies like Hartmann Valves GmbH and others are producing valves capable of withstanding demanding hydrogen environments. This demonstrates Germany’s exceptional engineering capabilities in the field of green hydrogen.

The U.S. Market: Growth Drivers and Opportunities in Composite Valves

The US hydrogen valve market is growing fast. This growth comes from national plans and new tech. American makers are leading in green hydrogen, opening doors for jobs and new tech.

The US is investing a lot in hydrogen tech. Several things are pushing the composite valve sector forward:

- Federal support for clean energy

- More money for hydrogen infrastructure

- New tech in making valves

Federal and State-Level Hydrogen Initiatives

US hydrogen plans are helping valve makers a lot. The Department of Energy has big plans to help hydrogen grow. This includes cars, factories, and power plants.

Domestic Manufacturing and Supply Chain Development

Top US valve makers are making special parts for hydrogen. Emerson Electric Co., Crane Company, and PARKER HANNIFIN CORP are key. They help grow US making skills.

| Manufacturer | Hydrogen Valve Specialization | Market Impact |

| Emerson Electric Co. | High-pressure hydrogen valves | National infrastructure projects |

| Crane Company | Cryogenic hydrogen applications | Advanced industrial solutions |

| PARKER HANNIFIN CORP | Precision control valves | Transportation and energy sectors |

The Made in USA idea is very important now. Makers are working hard on new tech. They aim to meet high safety and quality standards.

Japan's Role and Market Outlook in Green Hydrogen Composite Valves

The Japanese hydrogen market is leading the way in green energy. It’s a key player in creating new hydrogen technologies. Japan is making big steps towards sustainable energy with its investments and support.

Japan’s hydrogen strategy is driving tech progress in the hydrogen valve industry. The goal to cut carbon emissions is fueling research in composite valves.

National Hydrogen Strategy and Industry Support

Key efforts in Japan include:

- Government funding for hydrogen infrastructure

- Tax breaks for hydrogen tech research

- Partnerships between companies and research groups

KITZ Corporation is a top name in hydrogen exports. It shows Japan’s skill in making valves.

Technological Innovations and Export Potential

Japanese companies are at the forefront of advanced composite valve technology. Their expertise in producing high-quality materials positions them as leaders in hydrogen exports.

| Technology Area | Innovation Level | Global Competitiveness |

| Valve Materials | High | Excellent |

| Manufacturing Precision | Very High | Superior |

| Export Potential | Significant | Growing |

Japan’s valve industry is investing in research and development, aiming to reshape the global green hydrogen landscape. This initiative is expected to drive innovation and promote sustainable energy practices worldwide.

Future Development and Innovation Prospects in Composite Valve Technology

The world of valve technology is changing fast. New discoveries in materials science and digital tech are leading the way. Engineers are exploring new designs, especially for green hydrogen use.

New materials are changing how valves are made. They offer better strength and can handle tough conditions. This means valves can work under higher pressures and in harsher environments.

Cutting-Edge Manufacturing Techniques

New ways of making valves are bringing big changes. These include:

- Additive manufacturing for complex shapes

- Nano-engineering for better materials

- 3D printing of valve parts

- Advanced heat treatments

AI in Valve Systems: A Technological Leap

Artificial intelligence is making valves smarter. Intelligent valve systems can tell when they need maintenance and work better. They use data in real-time to improve efficiency and safety.

AI brings many benefits, such as:

- Algorithms for predicting maintenance

- Monitoring performance in real-time

- Automated reports for diagnostics

- Systems that adapt and improve

The future of composite valve technology looks bright. It promises better precision, reliability, and smart performance in many industries.

Competitive Landscape Highlighting Major Industry Players

Key players in the composite valves market for green hydrogen applications are prioritizing the development of advanced materials and designs to ensure safety and efficiency in hydrogen systems. Given hydrogen’s small molecular size and high diffusivity, these valves are engineered to withstand high pressures and prevent leaks, addressing challenges such as hydrogen embrittlement through the use of specialized alloys and composite materials.

Key Players:

-

Emerson Electric (United States)

-

Swagelok (United States)

-

Parker Hannifin (United States)

-

IMI Precision Engineering (United Kingdom)

-

Velan Inc. (Canada)

-

Crane Co. (United States)

-

Cameron (Schlumberger) (United States)

-

Dwyer Instruments (United States)

-

Samson AG (Germany)

-

Festo (Germany)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Composite Valves For Green Hydrogen Market Report |

| Base Year | 2024 |

| Segment by Type |

· Cryogenic Ball Valve · High-Pressure Globe Valve · Flow Control Valve |

| Segment by Application |

· Hydrogen Production and Electrolysis · Storage and Transportation Systems · Fuel Cell Technologies |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Composite Valves For Green Hydrogen Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Composite Valves For Green Hydrogen Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Composite Valves For Green Hydrogen Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Composite Valves For Green Hydrogen Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Composite Valves For Green Hydrogen Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Composite Valves For Green Hydrogen Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Composite Valves For Green Hydrogen Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Composite Valves For Green Hydrogen Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are composite valves in the green hydrogen market?

Composite valves are specialized valve components designed for green hydrogen applications. They are constructed using advanced materials that offer improved safety and efficiency compared to traditional valves.

These innovative materials have the ability to withstand hydrogen-related damage, ensuring the longevity of the valves even in harsh operating environments.

Why are composite valves critical for green hydrogen technologies?

Composite valves are essential for green hydrogen technologies because they perform exceptionally well in challenging hydrogen environments. Unlike metal valves, composite valves offer enhanced safety and durability, making them a superior choice for effectively managing hydrogen.

What industries are using composite valves for green hydrogen?

Many sectors use them, such as:

- Hydrogen production

- Renewable energy

- Transportation

- Fuel cells

- Energy storage

They are necessary for precise hydrogen handling in industrial processes.

How do composite valves contribute to green hydrogen safety?

Composite valves contribute to green hydrogen safety through the use of advanced seals and smart systems. These features play a crucial role in preventing leaks and monitoring performance, thereby ensuring safe operation in hydrogen applications.

Which regions are at the forefront of composite valve development for green hydrogen?

Germany, the U.S., Japan, and Asia-Pacific countries are leading the way. They are investing in research and infrastructure, which in turn drives innovation in composite valves.

What technological innovations are emerging in composite valve design?

New materials and IoT sensors are being used. Additive manufacturing and nano-components also improve performance. These advancements make valves better and last longer.

How do regulatory standards impact composite valve manufacturing?

Standards set safety and emissions rules. They guide material choice and design. This ensures valves are safe and reliable for hydrogen use.

What are the main challenges in developing composite valves for green hydrogen?

The primary challenges in developing composite valves for green hydrogen include:

- Managing hydrogen damage

- Finding strong materials

- Making them affordable

- Meeting safety regulations

How do composite valves support the global transition to clean energy?

Composite valves play a crucial role in supporting the global transition to clean energy in several ways:

- Enhancing safety and efficiency of hydrogen infrastructure: Composite valves help make hydrogen infrastructure safer and more efficient, ensuring reliable transportation and storage of hydrogen.

- Supporting renewable energy and reducing carbon emissions: By improving the efficiency of hydrogen systems, composite valves contribute to the overall effectiveness of renewable energy sources and help reduce carbon emissions.

- Facilitating the growth of green hydrogen as a clean energy source: Composite valves enable the widespread adoption of green hydrogen, which is produced using renewable energy, making it a viable and sustainable clean energy solution.

What is the projected market growth for composite valves in green hydrogen?

The market is expected to grow significantly, potentially reaching $690.43 million by 2025. This growth can be attributed to increased support, technological advancements, and investment in hydrogen.