2025 Coiled Tubing Market Boom: Surging to $3.37 Billion with Unstoppable Growth in USA, Russia, and Saudi Arabia

Explore the dynamic coiled tubing market’s projected growth to $3.37 billion by 2025, driven by technological innovations and expanding applications in oil and gas operations. Discover key market players, regional insights focusing on USA, Russia, and Saudi Arabia, and emerging trends shaping this critical industry sector.

- Last Updated:

Coiled Tubing Market: Q1 and Q2 2025 Predictions

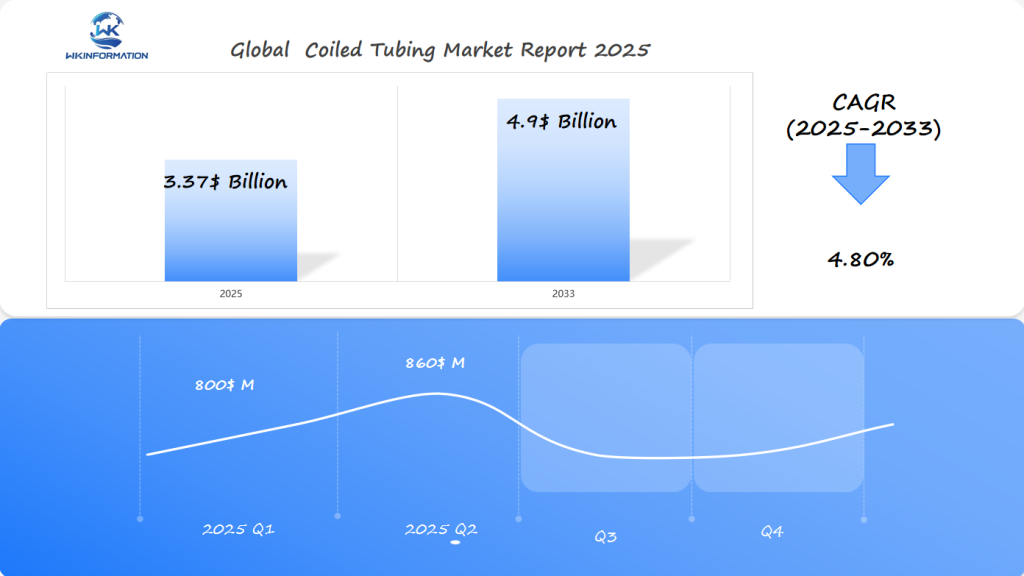

The Coiled Tubing market, valued at USD 3.37 billion in 2025, is projected to grow at a CAGR of 4.80% from 2025 to 2033, driven by efficiency demands in oil and gas operations.

In Q1 2025, the market is expected to generate around USD 800 million, supported by increased oil exploration activities in key regions such as the U.S., China, and Saudi Arabia. By Q2 2025, the market is predicted to grow to about USD 860 million, driven by the rise in production activities and advancements in well intervention technologies.

Understanding the Upstream and Downstream Dynamics in the Coiled Tubing Market

The coiled tubing market operates within two primary sectors of the oil and gas industry: upstream activities and downstream services.

Upstream Activities

In upstream operations, coiled tubing plays a crucial role in exploration and production phases. It aids in:

- Well drilling

- Efficient extraction of resources

- Overall productivity enhancement through real-time monitoring and intervention

Downstream Services

Conversely, downstream services focus on refining and processing operations. Here, coiled tubing is instrumental in maintenance tasks such as:

- Cleaning pipelines

- Descaling pipelines

- Ensuring optimal flow efficiency

Its adaptability allows for swift deployment without the need for extensive rigging or equipment dismantling.

Coiled tubing’s unique lifecycle—spanning from initial drilling to routine maintenance—contributes significantly to improving operational efficiencies in both sectors. This dual-role capability not only reduces downtime but also lowers operational costs, directly impacting market growth positively.

The continuous integration of advanced technology with coiled tubing processes further amplifies its role across these dynamics. With the oil and gas industry’s persistent demand for enhanced efficiency and cost-effectiveness, the relevance of coiled tubing remains indispensable, fostering substantial growth projections into 2025.

Emerging Trends Shaping the Coiled Tubing Industry

The coiled tubing industry is undergoing significant transformation, driven by several emerging trends. Technological innovations are at the forefront, enhancing the efficiency and capabilities of coiled tubing services. With real-time monitoring, operators can now optimize operations instantly, reducing downtime and increasing productivity.

One major trend is the move towards integrated service offerings. Companies are bundling coiled tubing with other services to provide comprehensive solutions. This approach not only streamlines operations but also offers cost efficiencies, making it more attractive to clients focused on maximizing return on investment.

A shift towards sustainability is also shaping the industry. There’s a growing emphasis on minimizing environmental impact through cleaner technologies and practices. The adoption of greener methods aligns with global sustainability goals and caters to an increasingly eco-conscious market.

These trends reflect a broader evolution in the industry as it adapts to changing demands and technologies. Embracing these changes ensures that companies remain competitive while meeting the evolving needs of their clients in this dynamic sector.

Overcoming Challenges in Coiled Tubing Technology and Supply Chains

In the rapidly evolving Coiled Tubing Market, several challenges demand attention. Key issues include:

1. Technological Barriers

The industry faces hurdles in integrating advanced technologies, essential for enhancing operational efficiency. Many service providers encounter difficulties in adapting to new tech due to high costs and a steep learning curve.

2. Supply Chain Issues

Disruptions in supply chains can lead to delays and increased costs. These disruptions are often caused by geopolitical instability, fluctuating raw material prices, and logistical bottlenecks.

3. Operational Challenges

Maintaining seamless operations in diverse environments presents its own set of challenges. Factors such as harsh weather conditions and varying regulatory requirements further complicate operational workflows.

Addressing these challenges involves strategic solutions:

- Companies are investing in research and development to overcome technological barriers, focusing on developing cost-effective solutions that integrate seamlessly with existing systems.

- To mitigate supply chain issues, firms are diversifying their supplier base and adopting real-time tracking systems to enhance transparency and responsiveness.

- Operationally, leveraging predictive maintenance technologies helps in preemptively addressing equipment failures, reducing downtime, and optimizing resource allocation.

These proactive measures are instrumental in stabilizing the coiled tubing market’s growth trajectory amidst these challenges.

Geopolitical Impact on Coiled Tubing Market Development and Adoption

Geopolitical factors play a crucial role in shaping the dynamics of the coiled tubing market. As global oil prices fluctuate, they directly influence the demand for coiled tubing services. For instance, higher oil prices can lead to increased investments in exploration and production activities, driving the adoption of advanced coiled tubing technologies. Conversely, when prices plummet, companies may cut back on such expenditures, impacting market growth.

Regional Stability and Investment Decisions

Regional stability significantly affects investment decisions within the coiled tubing sector. Countries with stable political climates tend to attract more foreign investments in their oil and gas industries. This stability encourages technological advancements and infrastructure development necessary for efficient operations. In contrast, regions experiencing political unrest or conflict may see delays or reductions in investments as companies seek to mitigate risks.

International Relations and Market Adoption Rates

International relations also impact market adoption rates. Trade agreements and diplomatic ties can facilitate easier access to technology and resources needed for coiled tubing operations. On the other hand, sanctions or trade barriers might hinder market expansion by restricting access to essential equipment or technologies.

Understanding these geopolitical influences is vital for stakeholders aiming to navigate the complex landscape of the global coiled tubing market effectively.

Market Segmentation: Types of Coiled Tubing and Their Key Applications

Types of Coiled Tubing

Coiled tubing comes in various types, each catering to specific industry needs. The most common types are:

- Standard Coiled Tubing: Utilized for routine maintenance and light drilling operations. Its versatility makes it ideal for a range of applications.

- High Strength Coiled Tubing: Engineered for challenging environments where durability is paramount. This type often features enhanced tensile strength, suitable for deeper wells and high-pressure zones.

- Corrosion Resistant Coiled Tubing: Designed to withstand harsh chemical environments, frequently used in offshore operations or wells with high sulfur content.

Key Application Areas

The application areas for coiled tubing are diverse, reflecting its crucial role in the oil and gas industry:

- Drilling Operations: Coiled tubing is employed in underbalanced drilling, enabling continuous circulation of fluids while drilling, which reduces risks and enhances efficiency.

- Well Completion Strategies: It plays a significant part in well completions by facilitating the installation of downhole equipment without the need for additional rigging.

- Maintenance Practices: Regular maintenance tasks such as cleaning, scale removal, and acidizing benefit from the flexibility and efficiency of coiled tubing.

Each type of coiled tubing offers unique benefits that address specific operational challenges, thereby playing a vital role in enhancing productivity across various segments of the oil and gas sector.

Coiled Tubing in Oil & Gas Exploration, Well Completion, and Maintenance

Coiled tubing plays a crucial role in the oil and gas industry, especially in exploration, well completion, and maintenance activities. Its flexibility and efficiency make it a valuable tool for improving the productivity of oil and gas wells.

Exploration

- Efficient Drilling: Coiled tubing is widely used for drilling operations due to its ability to drill without rotating the pipe, enhancing safety and reducing time.

- Underbalanced Drilling: This technique benefits from coiled tubing as it allows for continuous circulation of drilling fluids, minimizing formation damage and improving reservoir contact.

Well Completion

- Precision Operations: Coiled tubing facilitates precise placement of tools and materials within the wellbore, essential for tasks such as gravel packing and setting plugs.

- Multistage Fracturing: In horizontal wells, coiled tubing enables efficient multistage fracturing, optimizing resource extraction.

Maintenance

- Cost-effective Cleaning: Regular cleaning of wellbores using coiled tubing helps maintain optimal production rates by removing obstructions like scale or sand.

- Remedial Interventions: The technology allows for swift intervention in wells needing repairs or enhancements, reducing downtime and extending the life of the well.

By integrating advanced technologies such as real-time monitoring systems, coiled tubing operations are becoming increasingly sophisticated, driving further efficiencies in these critical areas. This integration not only streamlines processes but also supports environmental sustainability goals within the industry.

Regional Insights: Coiled Tubing Market Growth by Region

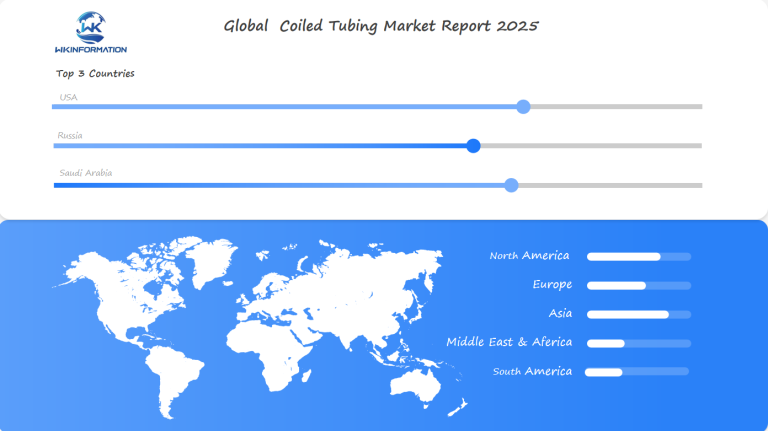

The coiled tubing market is witnessing significant growth across key regions, notably the USA, Russia, and Saudi Arabia. Each of these regions presents unique drivers and growth rates, contributing to the dynamic landscape of the industry.

1. USA

As a global leader in coiled tubing services, the USA continues to witness strong growth fueled by ongoing exploration and production activities. The increasing adoption of advanced well intervention techniques, automation, and environmentally friendly technologies is enhancing operational efficiency. Additionally, sustained investments in shale gas and tight oil extraction further contribute to market expansion.

2. Russia

With its vast oil reserves and strategic importance in the global energy landscape, Russia remains a key player in the coiled tubing market. The country’s focus on optimizing extraction processes, improving recovery rates, and meeting both domestic and international energy demands is driving growth. Investments in modernized well maintenance techniques and enhanced oil recovery solutions are further strengthening the market.

3. Saudi Arabia

As one of the world’s largest oil producers, Saudi Arabia continues to invest heavily in oilfield technologies, including coiled tubing services. The country’s commitment to increasing production efficiency, maintaining well integrity, and adopting innovative extraction methods is shaping the market’s trajectory. Ongoing initiatives to expand oil production capacity and develop advanced drilling solutions are reinforcing long-term growth prospects.

These geographical trends underscore the varied yet interconnected nature of coiled tubing market dynamics globally, each region contributing uniquely to the industry’s evolution.

The USA’s Leading Role in Coiled Tubing Technology and Adoption

The United States continues to be at the forefront of the coiled tubing industry, driven by a combination of innovation, investment, and a commitment to efficiency. The country’s leadership is shaped by various factors that not only fuel domestic growth but also influence global industry trends.

1. Technological Advancements

Cutting-edge innovations are a defining feature of the USA’s coiled tubing sector. Companies are constantly refining techniques to enhance operational performance, improve well intervention processes, and maximize resource extraction. Real-time data analytics, automation, and the integration of artificial intelligence in well servicing are reshaping industry standards. The development of high-strength, lightweight materials is further optimizing equipment durability and efficiency.

2. Robust Investment Landscape

Continuous investments in exploration, drilling, and production activities strengthen the USA’s position as a leader in coiled tubing applications. Companies are channeling resources into research and development, infrastructure expansion, and workforce training to meet growing industry demands. Strategic partnerships and collaborations among energy firms, technology providers, and research institutions further accelerate advancements, ensuring long-term growth and competitiveness.

3. Commitment to Sustainability and Efficiency

With environmental concerns becoming increasingly significant, the USA’s coiled tubing market is adapting by incorporating eco-friendly practices. Efforts to reduce emissions, optimize energy consumption, and implement greener extraction techniques are shaping the industry’s future. Regulatory policies and corporate sustainability initiatives are driving the development of cleaner, more efficient technologies that align with both economic and environmental objectives.

These factors collectively position the USA as a powerhouse in the coiled tubing industry. The dynamic and forward-thinking nature of the market fosters continuous evolution, setting benchmarks for technological adoption and operational excellence worldwide.

Russia’s Demand for Coiled Tubing in Its Oil & Gas Sector

Russia remains a dominant force in the global oil and gas industry, leveraging its vast reserves to drive demand for coiled tubing services. The country’s expansive oil fields necessitate advanced extraction techniques, making coiled tubing an essential tool for enhancing efficiency, optimizing well performance, and maintaining production levels.

1. Strong Market Potential

Russia’s oil industry continues to evolve, with increasing reliance on coiled tubing technologies to support ongoing extraction efforts. The country’s vast reserves present significant opportunities for market expansion, as energy companies seek to maximize output while maintaining cost-effectiveness. The strategic utilization of these resources fuels the steady growth of coiled tubing applications.

2. Rising Demand for Well Intervention and Completion

The operational demands of Russia’s oil fields require continuous improvements in well servicing, intervention, and completion processes. Coiled tubing plays a crucial role in minimizing downtime, enhancing oil recovery rates, and ensuring prolonged well productivity. The increasing need for efficient extraction methods further reinforces the demand for advanced coiled tubing solutions.

3. Commitment to Technological Advancements

Russia’s focus on modernizing its oil extraction processes is evident in its investments in cutting-edge technologies. Innovations in coiled tubing materials, real-time data monitoring, and automated intervention systems are shaping the industry’s future. These technological advancements not only improve operational efficiency but also solidify Russia’s competitive position in the global energy market.

As Russia continues to optimize its natural resources and enhance oilfield performance, coiled tubing services will remain integral to the country’s long-term energy strategy. The combination of resource abundance, technological progress, and strategic investments ensures sustained growth and innovation in the sector.

Saudi Arabia’s Strategic Role in Coiled Tubing Market Expansion

Saudi Arabia’s strategic investments are a key driver of growth in the coiled tubing market, reinforcing its position as a global leader in oil extraction technologies. With a strong focus on advancing well intervention methods and optimizing production efficiency, the country continues to expand its coiled tubing services to meet increasing energy demands.

Key Factors Driving Market Growth

1. Commitment to Technological Innovation

Saudi Arabia is heavily investing in state-of-the-art extraction technologies to enhance operational efficiency, reduce downtime, and improve oil recovery rates. The integration of advanced automation, real-time monitoring systems, and high-performance materials in coiled tubing applications is transforming the sector, making operations more precise and sustainable.

2. Strong Growth Trajectory

The country’s proactive approach to modernizing its oil production infrastructure is fueling market expansion. With increasing demand for efficient well intervention and maintenance services, coiled tubing remains a critical component in maximizing output from both mature and newly developed oil fields. These efforts contribute to long-term growth and industry stability.

3. Attraction of Global Partnerships

Saudi Arabia’s large-scale investment initiatives and commitment to innovation are drawing international collaborations, fostering knowledge exchange, and accelerating technological advancements in coiled tubing applications. By creating a highly competitive and forward-thinking market environment, the country is strengthening its influence in the global energy sector.

Through continuous advancements and strategic investments, Saudi Arabia is shaping the future of coiled tubing services, ensuring sustained industry growth and reinforcing its role as a central hub for oilfield innovation.

Future Innovations in Coiled Tubing and Its Applications in the Industry

The future of coiled tubing is set to be transformed by several anticipated innovations that promise to enhance its applications within the industry. These future technologies are geared towards improving operational efficiency, safety, and environmental sustainability.

1. Real-Time Data Monitoring

Innovations in sensor technology are enabling real-time data monitoring, allowing operators to make informed decisions quickly. This advancement enhances the precision of operations and reduces downtime.

2. Advanced Materials

The development of new materials with higher strength-to-weight ratios is expected to improve the durability and flexibility of coiled tubing. Such materials can withstand harsher environments, expanding the potential for deeper and more complex well interventions.

3. Automation and Robotics

The integration of automation into coiled tubing operations is anticipated to reduce human error and increase safety. Robotic systems could perform tasks such as pipe handling and maintenance, minimizing risks associated with manual operations.

4. Environmentally Friendly Solutions

As the industry shifts towards sustainability, innovations focused on reducing environmental impact are gaining traction. Biodegradable fluids and energy-efficient processes are becoming integral parts of coiled tubing services.

These innovations not only broaden the scope of coiled tubing applications but also pave the way for enhanced oil recovery techniques, well intervention strategies, and other specialized uses. As technology continues to evolve, the coiled tubing industry looks toward a future where these cutting-edge solutions redefine service efficiency and effectiveness.

Major Competitors in the Coiled Tubing Market

The coiled tubing market has several key players known for their advanced technologies and strategic investments. These companies are competing to capture emerging opportunities and meet the growing demand in the industry.

-

Halliburton – United States

-

Schlumberger Limited – United States

-

Baker Hughes Company – United States

-

Weatherford International PLC – Ireland

-

NexTier Oilfield Solutions – United States

-

Calfrac Well Services Ltd. – Canada

-

STEP Energy Services – Canada

-

Key Energy Services, LLC – United States

-

Trican Well Service Ltd. – Canada

-

Altus Intervention – Norway

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Coiled Tubing Market Report |

| Base Year | 2024 |

| Segment by Type | · Well Intervention

· Drilling Service · Perforating · Fracturing · Milling Services |

| Segment by Application | · Wellbore Cleanouts

· Hydraulic Fracturing · Cementing · Pipeline Cleanout · Fishing Operations |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The coiled tubing market is experiencing significant growth, driven by the strong demand for efficient oil and gas extraction solutions. It is expected to reach $4.9 billion by 2033, thanks to important advancements and regional expansions.

Key drivers include:

- Technological Innovation: Enhanced operational efficiency through real-time monitoring and integrated service offerings is transforming the industry landscape.

- Regional Growth Leaders:

- USA: Leads with substantial investments, underpinned by technological advancements and sustainability efforts.

- Saudi Arabia: Rapid expansion fueled by strategic investments in extraction technologies.

- Russia: Leveraging its vast oil reserves for notable market growth.

Major industry players such as Schlumberger Limited, Baker Hughes Company, and Halliburton Company are continually advancing tools and technologies to sustain competitiveness. Their proactive strategies highlight a commitment to innovation and market adaptation.

As geopolitical dynamics and sustainability concerns shape future trends, the industry’s adaptability will determine long-term success. This evolving landscape promises exciting opportunities for stakeholders, heralding a new era of growth and innovation in the coiled tubing market.

Global Coiled Tubing Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Coiled Tubing Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Coiled TubingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Coiled Tubingplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Coiled Tubing Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Coiled Tubing Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Coiled Tubing Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCoiled Tubing Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the global coiled tubing market by 2025?

The global coiled tubing market is projected to reach $3.37 billion by 2025, driven by increasing demand from key regions such as the USA, Russia, and Saudi Arabia.

How do upstream and downstream processes impact the coiled tubing market?

Upstream activities involve exploration and production, while downstream services include refining and distribution. Coiled tubing enhances operational efficiency in both sectors, significantly impacting overall market growth.

What emerging trends are currently shaping the coiled tubing industry?

Current trends include technological innovations like real-time monitoring and integrated service offerings, which enhance operational efficiency and promote sustainability in coiled tubing operations.

What challenges does the coiled tubing industry face?

The industry faces technological barriers, supply chain issues, and operational challenges. Solutions are being implemented to address these challenges effectively.

How do geopolitical factors influence the coiled tubing market?

Geopolitical situations can significantly affect market dynamics, including how global oil prices impact demand for coiled tubing services. Regional stability also plays a crucial role in investment levels.

What are the key applications of different types of coiled tubing in the market?

Different types of coiled tubing are used across various sectors for applications such as drilling, well completion strategies, and maintenance practices in oil exploration.