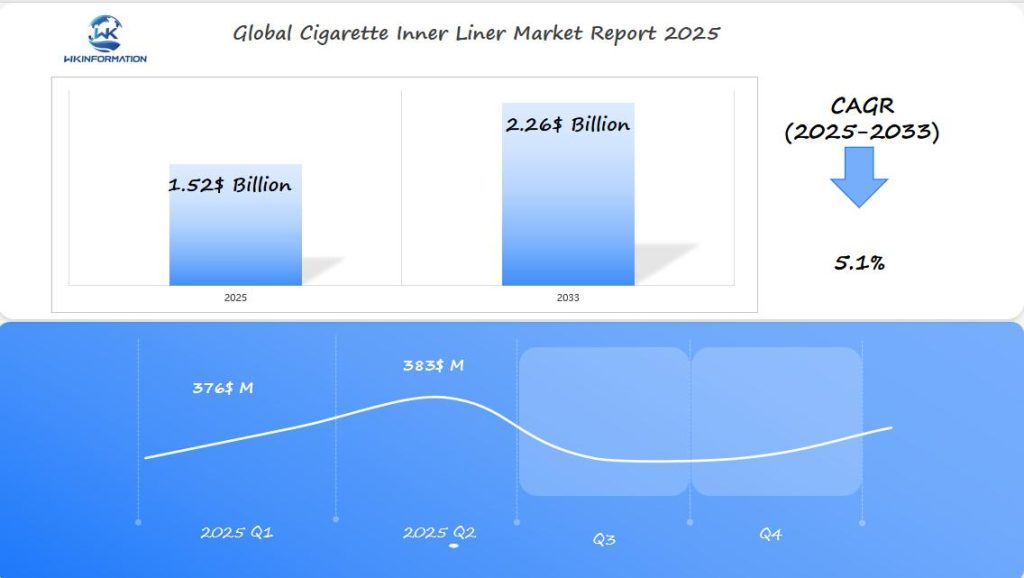

Cigarette Inner Liner Market Projected to Exceed $1.52 Billion by 2025: Key Markets in the U.S., China, and Germany

The Cigarette Inner Liner Market is projected to exceed $1.52 billion by 2025. The market is driven by increasing demand for high-quality smoking products and advancements in liner materials, which enhance cigarette quality and consumer experience.

- Last Updated:

Cigarette Inner Liner Market in Q1 and Q2 of 2025

The Cigarette Inner Liner market is forecast to reach $1.52 billion by the end of 2025, supported by a CAGR of 5.1% over the forecast period.

Q1 2025 estimates place the market at around $376 million, with Q2 expected to grow modestly to $383 million. In the U.S., despite overall smoking decline, premium brands and specialty products continue to sustain demand for quality packaging. China remains the dominant global producer and consumer of cigarettes, maintaining steady inner liner consumption. Germany focuses on regulation-compliant, eco-friendly liner materials as part of broader sustainability efforts in packaging.

Analysis of the Upstream and Downstream Industry Chain in the Cigarette Inner Liner Market

Understanding the upstream industry is crucial for analyzing the Cigarette Inner Liner market. The upstream industry, which involves the production of raw materials and components necessary for Cigarette Inner Liner manufacturing, significantly impacts the overall quality and cost of the final product.

Upstream Industry Analysis

The upstream industry for Cigarette Inner Liners includes suppliers of raw materials such as paper, aluminum foil, and various adhesives. The quality and availability of these materials are critical factors that influence the production process.

Raw Materials Used in Cigarette Inner Liner Production

The primary raw materials used in the production of Cigarette Inner Liners are paper, aluminum foil, and adhesives. The selection of these materials is based on their quality, durability, and compliance with regulatory standards.

| Raw Material | Description | Importance in Cigarette Inner Liner Production |

| Paper | Provides structural integrity and printability | Essential for the liner’s base structure |

| Aluminum Foil | Offers barrier properties against moisture and air | Critical for preserving cigarette freshness |

| Adhesives | Ensures the liner is securely attached to the cigarette | Vital for maintaining the liner’s position during packaging |

The sourcing of high-quality raw materials poses a challenge for manufacturers due to factors such as fluctuating commodity prices and stringent regulatory requirements. Ensuring a stable supply chain is essential for maintaining production consistency.

Trends Driving the Cigarette Inner Liner Market in 2025

As we approach 2025, several key trends are expected to influence the Cigarette Inner Liner Market. The market is experiencing a significant shift due to changing consumer preferences, regulatory requirements, and innovations in packaging materials.

Emerging Trends in Cigarette Packaging

The cigarette packaging industry is evolving rapidly, driven by the need for sustainable and eco-friendly packaging solutions. One of the emerging trends is the use of biodegradable materials for inner liners, which is expected to gain traction in the coming years.

Packaging innovations are not only limited to materials but also extend to design and functionality. For instance, inner liners with enhanced barrier properties are being developed to preserve the freshness of cigarettes.

The table below highlights some of the key trends and their expected impact on the Cigarette Inner Liner Market:

| Trend | Description | Expected Impact |

| Eco-friendly packaging | Use of biodegradable materials | High demand for sustainable inner liners |

| Advanced materials | Innovations in barrier properties | Improved preservation of cigarette freshness |

| Regulatory compliance | Adherence to packaging regulations | Increased adoption of compliant inner liners |

These emerging trends are expected to drive the growth of the Cigarette Inner Liner Market in 2025, with a focus on market trends and cigarette packaging innovations.

Challenges in the Cigarette Inner Liner Manufacturing Process

Ensuring the quality and regulatory compliance of cigarette inner liners poses significant challenges for manufacturers. The production process involves various stages, from material selection to final packaging, each with its own set of challenges.

Quality Control and Regulatory Compliance

Quality control is a critical aspect of cigarette inner liner manufacturing. Manufacturers must adhere to stringent quality standards to ensure that their products meet the required specifications.

This involves implementing robust quality control measures at every stage of the production process. Advanced technologies, such as automated inspection systems, can help in detecting defects and ensuring consistency in product quality.

The regulatory landscape for cigarette inner liners is complex and varies by region. Manufacturers must comply with regulations related to material safety, packaging, and environmental impact.

Regulatory compliance is not only a legal requirement but also essential for maintaining a company’s reputation and avoiding costly fines.

To overcome these challenges, manufacturers can adopt several strategies. These include investing in advanced quality control technologies and implementing sustainable practices to reduce environmental impact.

- Implementing robust quality control measures

- Investing in advanced technologies for defect detection

- Ensuring compliance with regional regulations

- Adopting sustainable manufacturing practices

Geopolitical Factors Affecting Cigarette Inner Liner Production and Trade

Geopolitical factors are important in determining how cigarette inner liners are produced and traded around the world. The complex interactions between countries, trade agreements, and regulations have a significant impact on the global supply chain of this essential part of cigarette production.

Key Geopolitical Factors Influencing the Market

The market for cigarette inner liners is influenced by several geopolitical factors:

- Trade policies: Government decisions regarding imports and exports can directly affect the availability and cost of materials used in production.

- Regulations: Laws and rules governing manufacturing processes or environmental standards can impact production capabilities and costs.

These factors can either promote or restrict the movement of goods across borders, ultimately shaping the dynamics of the industry. For example, tariffs imposed on imported materials may increase production costs for manufacturers relying on those inputs. On the other hand, trade agreements between countries have the potential to create new opportunities by opening up markets and reducing barriers to entry.

Impact of Trade Policies on Cigarette Inner Liner Market

Trade policies have a direct impact on the global demand for cigarette inner liners. Protectionist measures, such as tariffs and quotas, can limit market access and affect the profitability of manufacturers. Conversely, free trade agreements can boost the market by reducing barriers and increasing competition.

The ongoing shifts in global trade dynamics, including the rise of protectionism and the renegotiation of trade agreements, have created uncertainty in the market. Manufacturers and suppliers must navigate these changes carefully to maintain their competitive edge.

The impact of trade policies on the cigarette inner liner market is multifaceted. Not only do they affect the cost and availability of raw materials, but they also influence the competitiveness of manufacturers in the global market. As the global trade landscape continues to evolve, understanding these dynamics will be crucial for stakeholders in the tobacco products industry.

Geopolitical considerations, particularly trade policies, play a significant role in shaping the cigarette inner liner market. Manufacturers and suppliers must stay informed about geopolitical developments to adapt their strategies and remain competitive in a rapidly changing global environment.

Type Segmentation: Non-Toxic vs. Standard Cigarette Inner Liner Materials

The type of material used for cigarette inner liners plays a crucial role in determining the overall quality and safety of the packaging.

Cigarette inner liners are primarily made from two types of materials: non-toxic and standard. The distinction between these materials is significant, as it affects not only the consumer’s health but also the environmental impact of the packaging.

Comparison of Non-Toxic and Standard

materials are gaining popularity due to their reduced environmental footprint and health benefits. These materials are designed to minimize the release of harmful chemicals during the production and disposal processes.

In contrast, standard materials have been widely used in the industry for their cost-effectiveness and established supply chains. However, they may contain substances that are harmful to human health and the environment.

A comparison of the two reveals that non-toxic materials offer several advantages, including:

- Reduced health risks associated with toxic chemicals

- Lower environmental impact due to biodegradable components

- Increasing consumer preference for eco-friendly products

On the other hand, standard materials have their own set of benefits, such as:

- Lower production costs

- Established manufacturing processes

- Widespread availability

The market demand for non-toxic materials is on the rise, driven by consumer awareness and regulatory pressures. As a result, manufacturers are shifting towards the development and use of non-toxic inner liner materials.

Applications of Cigarette Inner Liner in Cigarette Manufacturing

Inner liners play a vital role in maintaining the freshness and quality of cigarettes. The primary function of a cigarette inner liner is to prevent moisture from entering the cigarette and to maintain its flavor and aroma.

The inner liner is a crucial component in the cigarette manufacturing process, as it directly affects the overall quality of the final product. Cigarette manufacturing involves several precise steps, and the inner liner is one of the key elements that ensure the cigarettes remain fresh and of high quality.

Role of Inner Liners in Cigarette Packaging

Inner liners are not just limited to maintaining freshness; they also play a significant role in packaging materials. The type of inner liner used can impact the overall packaging process and the perception of the product by the consumer.

The tobacco industry has seen a significant shift towards using high-quality inner liners that not only preserve the cigarette’s quality but also comply with regulatory standards.

Some of the key applications of inner liners in cigarette manufacturing include:

- Maintaining the freshness and flavor of cigarettes

- Preventing moisture from entering the cigarette

- Enhancing the overall packaging of the product

- Complying with regulatory standards in the tobacco industry

The importance of inner liners in cigarette manufacturing cannot be overstated. As the demand for high-quality cigarettes continues to grow, manufacturers are focusing on improving the quality of their inner liners to meet consumer expectations.

For instance, a high-quality inner liner can significantly maintain the freshness and flavor of cigarettes while also preventing moisture from entering. This dual functionality not only enhances the overall packaging but also ensures compliance with regulatory standards, thereby reflecting positively on the brand’s image.

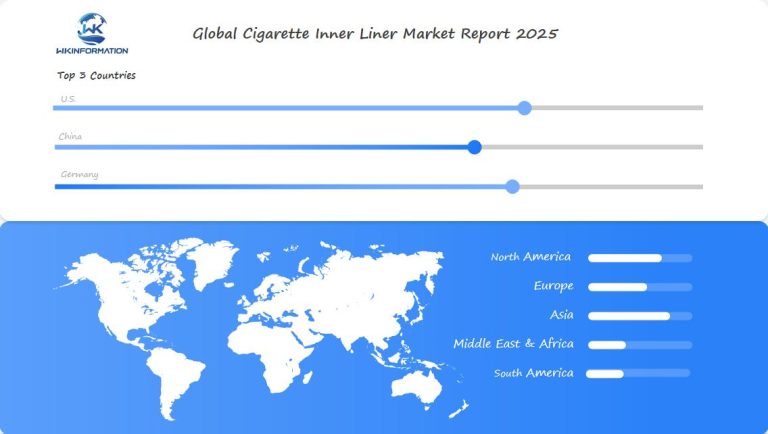

Global Market Insights: Regional Demand for Cigarette Inner Liner

The cigarette inner liner market is shaped by regional dynamics, with different countries exhibiting unique demand patterns.

The demand for cigarette inner liners varies significantly across regions, influenced by factors such as cigarette production levels, regulatory environments, and consumer preferences. In regions with high cigarette production, the demand for inner liners is typically higher.

Regional Analysis of Cigarette Inner Liner Demand

Different regions have distinct characteristics that affect the demand for cigarette inner liners. For instance, in regions with stringent regulations on tobacco packaging, there is a greater demand for inner liners that meet specific standards.

Regional demand is also influenced by the presence of major cigarette manufacturers, with countries having a significant tobacco industry typically having a higher demand for inner liners.

A closer examination of regional markets reveals that Asia, North America, and Europe are key regions driving the demand for cigarette inner liners. Each of these regions has its unique market dynamics, influenced by local factors such as consumer behavior and regulatory requirements.

The global market for cigarette inner liners is expected to be shaped by regional trends, with manufacturers needing to adapt to local demands and regulatory requirements to remain competitive.

U.S. Market Dynamics: Demand for Quality Cigarette Inner Liner in the Tobacco Industry

The demand for quality cigarette inner liners in the U.S. is largely driven by stringent packaging regulations and major tobacco companies. The U.S. tobacco industry is a significant player in the global market, with several large tobacco companies operating within the country.

Overview of the U.S. Tobacco Industry

The U.S. tobacco industry is dominated by a few large companies that control the market. These companies have a strong global presence and are known for their top-notch products. The industry is heavily regulated, especially when it comes to packaging, which includes the use of inner liners in cigarette packaging.

Regulatory compliance plays a crucial role in driving the demand for high-quality inner liners. The U.S. Food and Drug Administration (FDA) has strict guidelines for packaging tobacco products, including specific requirements for the materials used in inner liners.

The major tobacco companies in the U.S. are making significant investments in quality control measures to ensure that their products meet these regulatory requirements. This includes using high-quality inner liners that not only comply with regulations but also help maintain the freshness and quality of cigarettes.

Consumer preferences are also influencing the demand for quality inner liners. More and more consumers are seeking out products that not only meet regulatory standards but also provide a premium smoking experience. As a result, there has been a surge in demand for inner liners that are both functional and enhance the overall quality of cigarettes.

Key Factors Influencing Demand for Quality Inner Liners

- Stringent packaging regulations

- Investments in quality control measures by major tobacco companies

- Consumer preferences for premium products

China’s Growing Cigarette Industry and Impact on Inner Liner Demand

As the world’s largest cigarette producer, China’s industry trends have a substantial effect on the inner liner market. The country’s cigarette industry is a significant sector that influences not only the local economy but also the global tobacco and packaging industries.

The demand for inner liners in China is driven by the large-scale production of cigarettes. With numerous cigarette manufacturers operating in the country, the need for high-quality inner liners is paramount to ensure the freshness and flavor of cigarettes.

Overview of China’s Cigarette Market

China’s cigarette market is characterized by a high demand for cigarettes, driven by a large consumer base. The market is dominated by a few large state-owned enterprises, alongside some smaller private manufacturers.

Key Trends in China’s Cigarette Market:

- Increasing demand for premium cigarettes

- Regulatory pressures to improve product quality and packaging

- Growth of the filter-tipped cigarette segment

According to industry reports, the demand for inner liners in China is expected to grow in line with the cigarette production volumes. The table below highlights the projected growth in cigarette production and the corresponding inner liner demand.

China’s Cigarette Inner Liner Demand

As stated by a tobacco industry expert, “The growth in China’s cigarette industry will continue to drive the demand for high-quality inner liners, presenting opportunities for manufacturers to innovate and expand their product offerings.”

The growth of China’s cigarette industry and its impact on the inner liner demand underscores the importance of understanding market trends and regulatory environments to capitalize on emerging opportunities.

Germany’s Role in the Development of Cigarette Packaging Materials

Germany has become a key player in the evolution of cigarette packaging with its strong focus on innovation. The country’s expertise in engineering and manufacturing has driven significant advancements in the development of cigarette inner liners.

Innovations in Cigarette Packaging

Germany’s cigarette packaging industry is known for its dedication to quality and creativity. New materials and designs have been created to meet the changing needs of the worldwide tobacco industry. One significant improvement is the use of specialized liners that improve the freshness and taste of cigarettes.

The German market has seen the introduction of various packaging solutions that not only comply with regulatory requirements but also offer unique selling points. For example, liners made from non-toxic materials have gained popularity due to their safety and environmental advantages.

A comparison of traditional and innovative packaging materials used in Germany shows significant differences in terms of quality, safety, and environmental impact.

| Material Type | Quality | Safety Features | Environmental Impact |

| Traditional Liners | Standard | Basic | High |

| Innovative Liners | High | Advanced | Low |

Germany’s leadership in cigarette packaging innovations is expected to continue, driving growth in the global cigarette inner liner market.

Future Development: Innovations in Cigarette Inner Liner Materials

The Cigarette Inner Liner Market is about to undergo a significant change, driven by advancements in packaging innovations and inner liner materials. As manufacturers and consumers increasingly prioritize sustainability and quality, the demand for innovative inner liner solutions is expected to rise.

One of the key areas of innovation is in the development of sustainable materials. Companies are exploring alternatives to traditional materials, such as bioplastics and recycled papers, which not only reduce environmental impact but also offer unique packaging solutions.

Emerging Technologies in Inner Liner Production

Emerging technologies are playing a crucial role in enhancing the production of inner liners. Advanced manufacturing processes, such as nanotechnology and precision coating, are improving the barrier properties and overall quality of inner liners.

According to industry experts, “The integration of nanotechnology in inner liner production is expected to significantly enhance the barrier properties, freshness, and overall quality of cigarettes.”

The table below highlights some of the emerging technologies and their potential impacts on the Cigarette Inner Liner Market:

| Technology | Description | Potential Impact |

| Nanotechnology | Enhances barrier properties | Improved freshness and quality |

| Precision Coating | Uniform coating application | Consistent quality and reduced waste |

| Bioplastics | Sustainable, biodegradable materials | Reduced environmental impact |

As the market continues to evolve, it is essential for manufacturers to stay abreast of these emerging trends and technologies to remain competitive.

Competitive Landscape: Leading Companies in the Cigarette Inner Liner Market

The competitive landscape of the Cigarette Inner Liner Market is shaped by several key players. These companies are not only competing on the basis of product quality but also through innovative packaging solutions and strategic market expansions.

Market Share Analysis is crucial in understanding the dynamics of this competitive landscape. The major companies operating in this market have been analyzed based on their market share, production capacity, and strategic initiatives.

Key Players:

-

BMJ – UK

-

Delfort Group – Austria

-

Ispak Ambalaj – Turkey

-

CCL Industrial (Innovia Films) – UK

-

Eurofoil – UK

-

LLFlex – USA

-

Clondalkin Group – Ireland

-

OCTPAK – Switzerland

-

BrightPack – China

-

Symetal – Italy

Overall

| Report Metric | Details |

|---|---|

| Report Name | Cigarette Inner Liner Market |

| Base Year | 2024 |

| Segment by Type |

· Non-toxic · Standard |

| Segment by Application |

· Soft Cigarette Pack · Hard Cigarette Pack |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Key players in the market are focusing on quality control and regulatory compliance to maintain their competitive edge. As the demand for high-quality cigarette inner liners continues to rise, manufacturers must adapt to changing consumer preferences and regulatory requirements.

The Cigarette Inner Liner Market’s future outlook is closely tied to the overall tobacco industry’s performance. With the market expected to grow, companies that invest in research and development, and adopt sustainable practices, are likely to lead the way in this evolving landscape.

Global Cigarette Inner Liner Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cigarette Inner Liner Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Cigarette Inner LinerMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cigarette Inner LinerPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cigarette Inner Liner Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cigarette Inner Liner Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cigarette Inner Liner Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Cigarette Inner LinerMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Cigarette Inner Liner Market by 2025?

The Cigarette Inner Liner Market is projected to exceed $1.52 billion by 2025.

Which regions are driving the growth of the Cigarette Inner Liner Market?

The key markets driving the growth of the Cigarette Inner Liner Market include the U.S., China, and Germany.

What factors are influencing the demand for high-quality inner liners?

The demand for high-quality inner liners is on the rise due to increasing cigarette production and stringent packaging regulations.

What are the raw materials used in Cigarette Inner Liner Production?

The raw materials used in Cigarette Inner Liner Production include various types of paper and foil materials, with a focus on non-toxic and standard materials.

How do trade policies impact the Cigarette Inner Liner Market?

Trade policies and regulations significantly impact the production and trade of cigarette inner liners, affecting manufacturers and suppliers.

What is the difference between non-toxic and standard Cigarette Inner Liner materials?

Non-toxic materials are designed to be safer for consumers and the environment, while standard materials are more traditional and widely used in the industry.

What role do inner liners play in cigarette manufacturing?

Cigarette inner liners are essential for preserving the quality and freshness of cigarettes, impacting both the packaging and the overall experience for consumers.

How does the demand for Cigarette Inner Liner vary by region?

The demand for cigarette inner liners varies by region, influenced by factors such as cigarette production levels, regulatory environments, and consumer preferences.

What are the emerging trends in Cigarette Inner Liner materials?

Emerging trends in Cigarette Inner Liner materials include the development of sustainable and eco-friendly materials, as well as advanced manufacturing processes.

Who are the leading companies in the Cigarette Inner Liner Market?

The Cigarette Inner Liner Market is competitive, with several leading companies, including those specializing in packaging materials and tobacco industry suppliers.