$923.6 Million Carrier Tape Market Surges in 2025: China, South Korea, and Japan Lead Semiconductor Packaging Evolution

The global carrier tape market was valued at approximately $763 million in 2025 and is projected to reach around $1309.02 million by 2033, growing at a compound annual growth rate (CAGR) of 6.98% during this period. This growth is driven by increasing demand in the electronics and semiconductor industries, particularly due to the need for effective packaging solutions for smaller electronic components. The market is also supported by advancements in technology and rising applications across various sectors, including automotive and consumer electronics, which are expected to further enhance its expansion over the coming years.

- Last Updated:

Carrier Tape Market Q1 and Q2 2025 Forecast

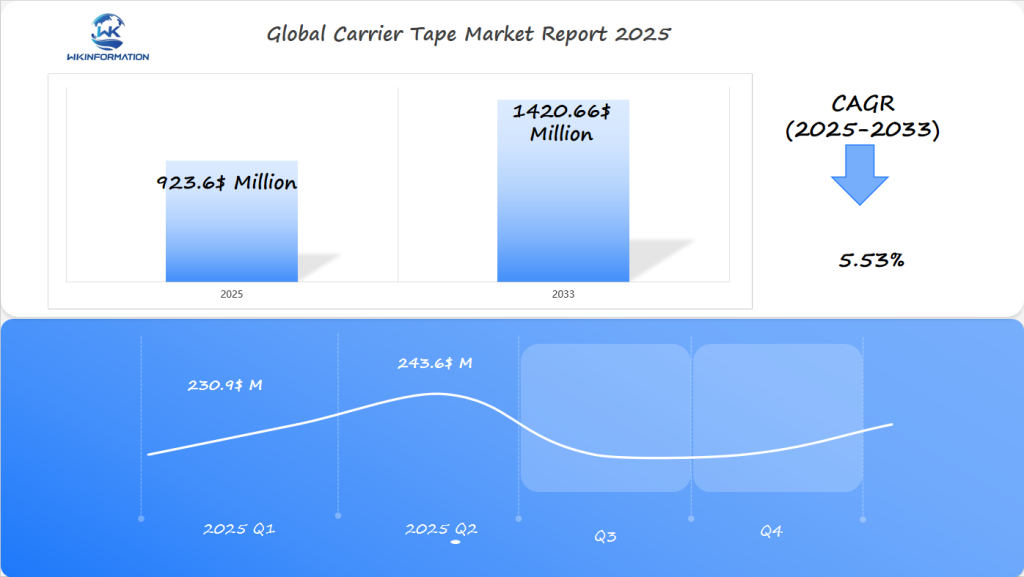

The Carrier Tape market is projected to reach $923.6 million in 2025, with a CAGR of 5.53% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $230.9 million, driven by growing demand in China, South Korea, and Japan, primarily in the electronics and semiconductor packaging industries, where carrier tapes play a critical role in the secure and efficient transport of components.

By Q2 2025, the market is forecast to reach $243.6 million, as the semiconductor industry in China and South Korea continues to scale up production, while Japan invests in automated assembly systems for electronics manufacturing. The increasing adoption of miniaturized components in consumer electronics will further drive the demand for high-quality carrier tapes.

Understanding the Upstream and Downstream Industry Chains for Carrier Tape

The carrier tape industry is crucial in electronic manufacturing. It connects raw material suppliers to end-users through a complex supply chain. This chain illustrates how manufacturers, component producers, and innovators collaborate.

Key Components of the Carrier Tape Industry Chain

The main parts of the carrier tape industry chain include:

- Raw material producers specialized in polymer and plastic technologies

- Semiconductor packaging equipment manufacturers

- Electronic component suppliers

- Advanced packaging research institutions

Industry chain analysis reveals how stakeholders cooperate to advance technology. The upstream part concentrates on material development, while the downstream focuses on precision packaging and component integration.

| Industry Chain Segment | Key Players | Primary Function |

| Upstream | Material Manufacturers | Develop specialized polymers |

| Midstream | Carrier Tape Manufacturers | Design and produce packaging solutions |

| Downstream | Electronics Manufacturers | Integrate components using carrier tapes |

Technological innovations and material science breakthroughs are transforming the carrier tape supply chain. They are making semiconductor packaging more efficient and effective.

Key Trends Driving the Carrier Tape Market: Growth in Semiconductor and Electronics Packaging

The digital world is changing fast, and so is the way we package semiconductors. The growth of the electronics industry is pushing for new packaging ideas. Carrier tapes are key in this technological leap.

Several trends are pushing the carrier tape market ahead:

- Rapid digitalization across multiple sectors

- Increasing demand for miniaturized electronic components

- Rising adoption of smart technologies

- Enhanced precision in semiconductor packaging

The trend towards smaller, better, and more reliable packaging is clear. Companies are spending a lot on research to make carrier tapes for the latest tech.

“Innovation in carrier tape technology is not just about protection, but about enabling the next generation of electronic capabilities.” – Industry Expert

Important factors driving the market include:

| Market Driver | Impact on Carrier Tape Market |

| 5G Technology Expansion | Increased demand for high-precision packaging |

| Internet of Things (IoT) | Need for smaller, more robust semiconductor components |

| Artificial Intelligence | Advanced packaging solutions for complex circuits |

The future of carrier tape technology lies in its ability to adapt to the evolving electronics industry, providing innovative solutions that meet the growing demands of digital transformation.

Challenges in Carrier Tape Manufacturing and Material Standardization

The carrier tape industry faces big challenges that need new ideas and smart plans. Making semiconductor packages needs better production methods because tech is always changing.

Carrier tape making problems come from many complex things that affect how well the tape works. Electronics makers must work on a few key areas to make the tape better and more reliable.

- Material durability and weather resistance

- Precision engineering for semiconductor packaging

- Maintaining consistent dimensional tolerances

- Reducing manufacturing variability

Overcoming Production Hurdles

Companies are coming up with new ways to solve material standardization problems. Studies show that strict quality checks can really help the tape perform better.

| Manufacturing Challenge | Proposed Solution | Expected Outcome |

| Material Inconsistency | Advanced Polymer Blending | Improved Dimensional Stability |

| Weather Resistance | Specialized Coating Technologies | Enhanced Durability |

| Production Variability | Precision Manufacturing Equipment | Consistent Product Quality |

Establishing Industry-Wide Standards

The semiconductor packaging industry requires clear material standards for reliable use. Industry leaders are collaborating to establish common guidelines for manufacturing packages.

New technologies and precise engineering will be crucial in addressing carrier tape production issues. By implementing innovative solutions, manufacturers can create stronger and more dependable packaging for advanced electronic components.

Geopolitical Influence on the Carrier Tape Market

The global carrier tape market has seen big changes because of complex geopolitical factors and shifting market dynamics. The COVID-19 pandemic showed how weak international semiconductor supply chains are. This made manufacturers change their strategies.

Key Geopolitical Challenges Affecting the Carrier Tape Market

Some of the main geopolitical issues affecting the carrier tape market are:

- Trade tensions between major semiconductor-producing nations

- Disrupted international logistics and transportation networks

- Regional manufacturing restrictions and export controls

- Semiconductor technology transfer limitations

During the pandemic, the semiconductor packaging industry faced huge challenges. Border closures and lockdowns made it hard to get raw materials and transport them. Manufacturers had to create strong supply chain strategies to handle unexpected global problems.

“The semiconductor industry’s adaptability during global crises determines its long-term sustainability.” – Industry Analyst

Companies responded to these challenges by diversifying their suppliers, investing in local manufacturing, and making production more flexible. Those who adapted quickly got ahead in the carrier tape market.

It’s important for stakeholders to understand these geopolitical factors to navigate the complex semiconductor packaging world. Being able to predict and react to global economic changes will be key to success in this fast-changing market.

Carrier Tape Market by Type: Embossed, Paper, and Plastic Variants

The semiconductor packaging industry uses different carrier tape technologies. These protect and move delicate electronic parts. Each type has special features for specific needs.

- Embossed carrier tape with precision-engineered surface features

- Paper carrier tape using sustainable materials

- Plastic carrier tape for better durability

Comparative Market Analysis

Each carrier tape type has its own benefits in semiconductor packaging. Embossed carrier tape offers top-notch protection with its special surface. Paper carrier tape is good for the environment. Plastic carrier tape is strong and durable.

Growth Projections

Market research shows that paper core carrier tape will lead in semiconductor packaging by 2028. This is due to the increasing demand for environmentally friendly and precise packaging solutions that can meet stringent standards.

Applications of Carrier Tape in Semiconductors, Passive Components, and LED Packaging

Carrier tapes play a crucial role in the semiconductor and electronics industry. They are used to protect and transport fragile components across various sectors.

1. Semiconductor Packaging

In the world of semiconductor packaging, carrier tapes are absolutely essential. They serve the important purpose of safeguarding delicate components throughout the entire process, including manufacturing, shipping, and assembly.

- Precision: Semiconductor packaging requires highly accurate carrier tapes to ensure that each component is securely held in place.

- Protection: These tapes are designed to provide electrostatic protection, preventing any damage caused by static electricity during handling.

- Stability: It is vital for the carrier tapes to maintain dimensional stability, ensuring that the dimensions of the packaged semiconductors remain consistent.

2. Passive Components

Passive components such as resistors, capacitors, and inductors also rely on specialized tape materials for their packaging needs.

- Moisture Resistance: Passive components are often sensitive to moisture, which can affect their performance. Therefore, it is important for the carrier tapes used in their packaging to have moisture-resistant properties.

- Dimensional Stability: Similar to semiconductors, passive components require stable dimensions to fit properly into electronic circuits. This can be achieved through the use of dimensionally stable carrier tapes.

3. LED Packaging

When it comes to LED (Light Emitting Diode) packaging, there are unique challenges that need to be addressed.

- Thermal Management: LEDs generate heat during operation, so it is crucial for the carrier tapes used in their packaging to have effective thermal management capabilities.

- Light Transmission: The choice of tape materials can also impact light transmission efficiency. Therefore, it is important to select carrier tapes that allow maximum light output from the packaged LEDs.

While carrier tapes are primarily associated with active components (such as integrated circuits), they also find applications in passive components and LED packaging. Here’s a breakdown of their market share:

As technology continues to advance, manufacturers are constantly working towards improving tape strength, ensuring static-free properties, and enhancing overall stability.

Global Insights into the Carrier Tape Market

The global carrier tape market is changing fast. It’s all about new ways to package semiconductors. People are really interested in how different areas of the world are doing.

The way we package semiconductors has changed a lot. The carrier tape market is growing in many places. Looking at each area helps us see what’s new and what’s coming next.

Emerging Markets Driving Innovation

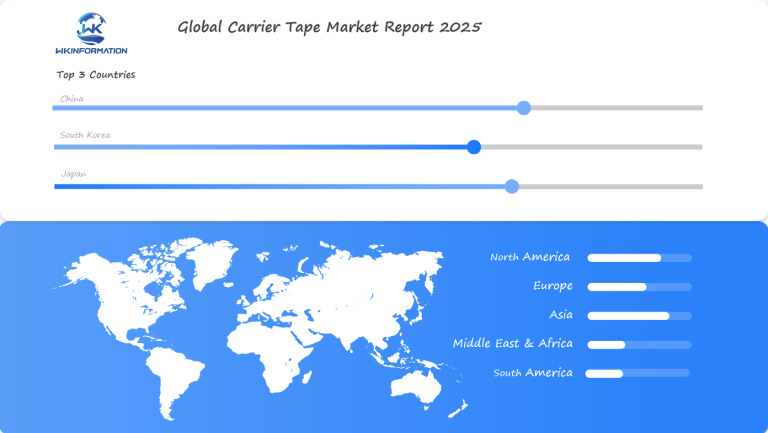

Some areas are really moving forward in the carrier tape market:

- Asia Pacific is leading with big tech investments

- China, South Korea, and Japan have top-notch factories

- There’s a big growth in electronics and semiconductors

Market Growth Opportunities

The carrier tape market has lots of chances to grow:

- More people want semiconductors

- New tech in packaging is coming

- More money is going into making electronics

New countries are helping the carrier tape market grow. They have great tech and strong factories.

The future of the global carrier tape market depends on new ideas and smart moves in different places.

China's Expanding Electronics Industry and Demand for High-Precision Packaging

The China electronics industry is a major force in global semiconductor packaging. It’s leading to fast growth in high-precision packaging technologies. Carrier tape market research shows China’s big role in changing how electronic components are made.

Several factors are making China a leader in the carrier tape market:

- Rapid economic growth

- Big investments in infrastructure

- Strong manufacturing skills

- High demand for consumer electronics

“China’s electronics ecosystem is the most dynamic packaging solution landscape globally,” said Dr. Wei Zhang, an industry analyst.

China’s focus on high-precision packaging puts it at the top in protecting semiconductor components. Places like Shenzhen, Shanghai, and Guangzhou are leading in carrier tape technology. They meet the needs of advanced electronic devices.

| Region | Market Contribution | Key Strengths |

| Shenzhen | 35% | Consumer Electronics |

| Shanghai | 25% | Advanced Manufacturing |

| Guangzhou | 20% | Technology Innovation |

Technological innovation and big investments keep pushing China’s electronics industry forward. This makes it even more competitive in semiconductor manufacturing.

South Korea's Technological Leadership in Semiconductor Manufacturing

The South Korea semiconductor industry leads the world in technology. Companies like Samsung and SK Hynix make the country a leader in advanced chip production. They create new solutions that change how we make electronics.

South Korea’s success comes from investing in research and development. The country has a strong system that supports new ideas in semiconductors. They use semiconductor wafer inspection equipment with great precision and advanced technology.

Key Achievements

South Korea has achieved significant milestones in the semiconductor industry, including:

- World-leading semiconductor memory chip production

- Advanced manufacturing technologies

- Significant global market share in semiconductor components

Factors Contributing to Success

Several factors contribute to South Korea’s success in the semiconductor industry:

- Big support from the government for tech research

- Strong teamwork between schools and companies

- Investing in the latest manufacturing tools

The nation’s chip makers always try to do better. They make more complex and efficient chips. Their drive for new ideas keeps them ahead in the fast-changing world of electronics.

Japan's Dominance in IC Packaging and Supply Chain Advancements

Japan is a leader in semiconductor technology. Its IC packaging skills drive innovation worldwide. The country’s semiconductor industry is known for creating advanced packaging solutions.

Shin-Etsu Chemical Co. Ltd. leads in the carrier tape market. Their approach to semiconductor materials makes them key in the global electronics world.

Key Factors Behind Japan’s Success

- Advanced precision in IC packaging techniques

- Cutting-edge material development for semiconductor components

- Robust supply chain management strategies

“Japanese manufacturers have transformed IC packaging from a technical process to an art form of engineering precision.” – Industry Expert

Japanese companies make high-performance carrier tapes. These meet complex semiconductor packaging needs. Their focus on technology gives them a market edge.

Japan’s semiconductor sector shows its ability to adapt and lead. Manufacturers invest in research and development. This keeps them ahead in IC packaging technologies.

The Future of Carrier Tape: Eco-Friendly and High-Precision Packaging Solutions

The semiconductor packaging industry is about to undergo a significant transformation. This transformation is driven by innovative eco-friendly packaging and high-precision carrier tape technologies. Companies are shifting away from traditional methods to contribute to environmental sustainability while maintaining superior quality.

Carrier tape technology is evolving in two key areas: being environmentally friendly and precise. Companies are investing heavily in developing materials that are more sustainable. Their goal is to ensure that the technology remains top-notch without causing harm to the planet.

Sustainable Materials Revolution

New eco-friendly packaging is changing the carrier tape world. Companies are looking into:

- Biodegradable polymer alternatives

- Recyclable composite materials

- Carbon-neutral production processes

- Bio-based packaging components

“The future of semiconductor packaging lies in balancing technological excellence with environmental responsibility.” – Industry Research Report

Precision Engineering Breakthroughs

High-precision carrier tape technologies are making big strides. New engineering methods allow for better accuracy and performance. This leads to more advanced packaging for sensitive semiconductor parts.

These advancements aim to:

- Cut down on waste

- Better protect components

- Support smaller parts

Combining eco-friendly materials with advanced engineering is a big step forward in packaging.

Competitive Landscape in the Carrier Tape Market

The carrier tape market is very competitive. Global manufacturers are always coming up with new ideas to get ahead. Carrier tape manufacturers use smart strategies to stay on top in this fast-changing world.

Leading companies in the market competition include:

- 1. 3M Company —— United States

- 2. Advantek Inc. —— United States

- 3. Shin-Etsu Chemical Co. Ltd. —— Japan

- 4. Sumitomo Bakelite Co. Ltd. —— Japan

- 5. C-pak Pte Ltd. —— Singapore

- 6. Laser Tek Taiwan Co. Ltd. —— Taiwan

- 7. Tek Pak Inc. —— United States

- 8. ITW ECPS —— United States

- 9. Nissho Corporation —— Japan

- 10. Ant Group (Carrier-Tech Precision) —— China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Carrier Tape Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The carrier tape market is booming, offering great chances for smart investments. It’s set to grow from USD 923.6 Million in 2025 to USD 1,552 Million by 2034. This growth rate of 5.53% is quite promising.

Key Growth Areas

Investors should look at China, South Korea, and Japan for semiconductor packaging. These areas have a lot of potential. The market is also moving towards eco-friendly materials and high-precision packaging.

Importance of Technology Investment

Investing in technology is key, especially in precision engineering and sustainable carrier tape. Companies that focus on new materials and processes will likely do well. The market is ripe for innovation in semiconductor and electronics packaging.

Targeting Electronics Infrastructure

Investors should aim for areas with strong electronics infrastructure. They should also invest in research for new carrier tape technologies. Sustainable packaging solutions are another area to explore. The carrier tape market is full of opportunities for those who are ready to take on the challenge.

Global Carrier Tape Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Carrier Tape Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Carrier TapeMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Carrier Tapeplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Carrier Tape Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Carrier Tape Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Carrier Tape Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCarrier TapeMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current market value of the carrier tape industry?

The carrier tape market is expected to hit $923.6 million by 2025. This growth is mainly due to Asian countries like China, South Korea, and Japan. They are key players in the semiconductor packaging sector.

Which industries primarily use carrier tapes?

Carrier tapes are mainly used in the electronics manufacturing industry. They are crucial in semiconductor packaging, handling passive components, and LED packaging.

What are the main types of carrier tapes available?

There are three main types of carrier tapes: embossed, paper, and plastic. Each type has its own properties and uses in electronics manufacturing.

How are geopolitical factors impacting the carrier tape market?

Events like trade tensions and the COVID-19 pandemic have severely affected supply chains. This has created challenges for manufacturers, forcing them to seek more dependable methods of production.

What challenges do carrier tape manufacturers currently face?

Manufacturers are working to make their products more durable and weather-resistant. They also aim to set industry-wide standards to improve quality and consistency across the market.

Which countries are leading the carrier tape market?

China, South Korea, and Japan are leading the market. Each country brings its own strengths to the table. They are key players in electronics manufacturing and semiconductor production.

What are the future trends in carrier tape production?

The industry is moving towards eco-friendly packaging and high-precision engineering. This is due to environmental concerns and the need for advanced semiconductor packaging technologies.

How is digitalization affecting the carrier tape market?

Digitalization is boosting demand for carrier tapes. This is especially true in smart technology and semiconductor packaging applications.

Key Companies in the Carrier Tape Market

Leading companies such as 3M Company, Advantek Inc., and Shin-Etsu Chemical Co. Ltd. are at the forefront of the carrier tape market. These companies are driving innovation and competition within the industry.

What role does China play in the carrier tape market?

China is a major player in the carrier tape market. Its booming electronics industry and expanding consumer electronics sector are driving growth. Its strong manufacturing capabilities also contribute to the demand for carrier tapes.