2025 Carbon Fiber Aerospace Market Breakthrough: Unlocking a $10.71 Billion Opportunity with Advanced Materials in U.S., Germany, and China

Discover the latest trends and key players shaping the carbon fiber aerospace market in 2025. Learn how the US, Germany, and China are driving innovation and growth through strategic partnerships, technological advancements, and market expansion in this comprehensive analysis of the aerospace industry’s future.

- Last Updated:

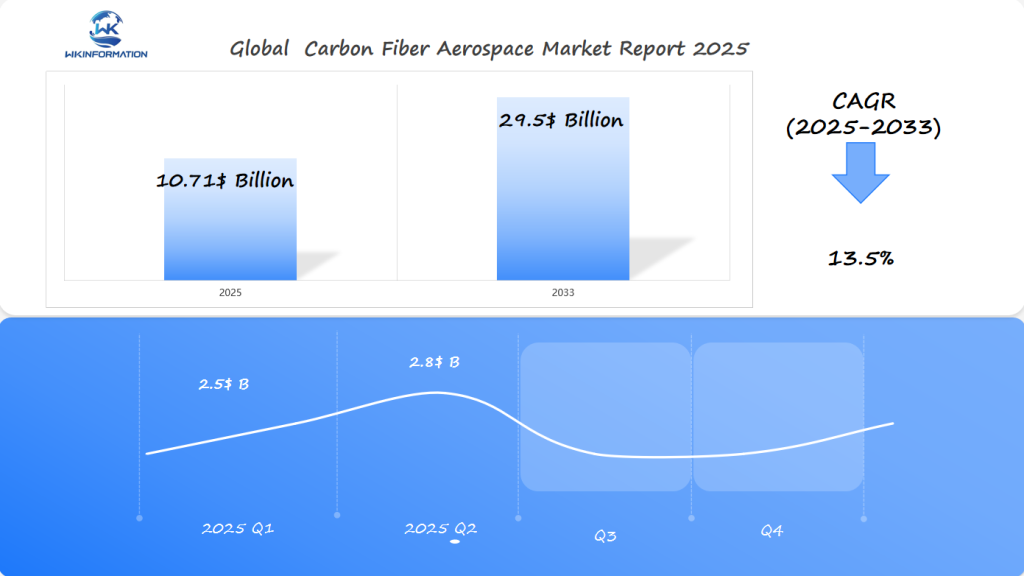

Carbon Fiber Aerospace Market: Q1 and Q2 2025 Predictions

The Carbon Fiber Aerospace market, valued at USD 10.71 billion in 2025, is expected to grow at a CAGR of 13.5% from 2025 to 2033, driven by the increasing demand for lightweight materials in aerospace applications.

In Q1 2025, the market is forecast to generate around USD 2.5 billion, with significant contributions from the U.S., Germany, and China. This early growth is attributed to ongoing advancements in aerospace technologies and a shift towards lighter materials to improve fuel efficiency. By Q2 2025, the market is expected to rise to approximately USD 2.8 billion, supported by increasing orders for commercial aircraft and military defense applications.

Key factors driving this growth include:

- Rising airplane deliveries, especially in North America with models like Boeing B787 and B777

- Advancements in composite material technology

- Sustainability initiatives focusing on eco-friendly production methods

Uncovering the Upstream and Downstream Industry Chains in the Carbon Fiber Aerospace Market

To fully understand the complexities and factors driving growth in the carbon fiber aerospace market, it’s essential to explore the industry chains at play. These chains consist of two main processes: upstream and downstream.

Upstream Processes: The Beginning of Production

The upstream processes encompass the initial stages of production, which involve activities such as raw material extraction and processing. This segment is crucial as it lays the foundation for the entire supply chain.

Key players in this segment include:

- Toray Industries

- Mitsubishi Chemical Corporation

These companies play a vital role by supplying essential precursor materials, particularly polyacrylonitrile (PAN) fibers, which are used in the production of carbon fiber.

Downstream Processes: Transforming Materials into Finished Products

On the other hand, the downstream processes focus on transforming these raw materials into finished products that are ready for use in aircraft manufacturing. This segment is equally important as it directly impacts the end-users of carbon fiber composites.

Notable contributors in this segment include:

- Hexcel Corporation

- Solvay Group

These companies have established themselves as key players by producing high-performance composite materials that are widely utilized by major aerospace manufacturers such as Boeing and Airbus.

The Impact of Industry Chains on Market Dynamics

The interplay between upstream and downstream processes has significant implications for market dynamics and competition within the carbon fiber aerospace sector.

- Influencing Costs: A robust upstream segment ensures a steady supply of raw materials, which helps stabilize costs throughout the production process.

- Driving Technological Advancements: Efficient downstream processes drive innovation in aircraft design through advanced composite applications, leading to improved performance and fuel efficiency.

- Determining Material Availability: The availability of specific materials used in carbon fiber production can impact both upstream suppliers and downstream manufacturers, affecting their respective operations.

Understanding these industry chains is crucial for stakeholders looking to navigate the complexities of the carbon fiber aerospace market. By grasping how these segments interact with one another, businesses can make informed decisions regarding pricing strategies, technological investments, and overall competitiveness within this evolving industry.

Key Trends Shaping the Carbon Fiber Aerospace Industry

The carbon fiber aerospace industry is experiencing significant changes that are reshaping aircraft design and performance. These changes emphasize the use of lightweight materials and sustainable aviation practices, opening up new opportunities for innovation.

1. Emergence of Nano-Enhanced Carbon Fibers

This cutting-edge technology is revolutionizing lightweight structures in aerospace. Nano-enhanced carbon fibers offer superior strength-to-weight ratios, making them ideal for constructing lighter, more efficient aircraft. The ability to incorporate nanomaterials means enhanced durability and performance, aligning with the industry’s push for advanced materials.

2. Automated Manufacturing Processes

Automation in production is increasingly being adopted to enhance efficiency and reduce costs. By integrating robotics and AI-driven systems into manufacturing, aerospace companies can achieve higher precision with less waste. This shift not only minimizes expenses but also accelerates production cycles, allowing manufacturers to meet growing demand swiftly.

3. Sustainability Initiatives

As environmental concerns gain prominence, sustainability initiatives are driving innovation in carbon fiber materials. Companies are investing in eco-friendly production methods and recycling technologies to minimize the carbon footprint of manufacturing processes. Sustainable aviation is becoming a central theme, with a focus on developing materials that support long-term environmental goals.

These trends highlight the ongoing changes within the carbon fiber aerospace sector, paving the way for further advancements and growth in the industry.

Overcoming Restrictions in Carbon Fiber Aerospace Material Production

The Carbon Fiber Aerospace Market faces challenges primarily due to high production costs, which can hinder widespread use in aerospace applications. The complex nature of manufacturing processes also presents significant challenges; these processes require specialized equipment and expertise that are not always accessible.

Here are some ways to overcome these challenges:

1. Process Optimization

Improving manufacturing operations can help lower costs. Methods like automated layup and resin infusion techniques are being explored to boost efficiency.

2. Material Substitution

Creating alternative materials that replicate the qualities of carbon fiber at a lower price is another possibility. Researchers are investigating hybrid composites that combine carbon fiber with less expensive materials without sacrificing performance.

3. Collaborative R&D Efforts

Partnerships between industry leaders, academic institutions, and government agencies can foster innovation. These collaborations can result in breakthroughs in affordable production methods and new material formulations.

By concentrating on these approaches, the market has the potential to lessen the economic obstacles linked to carbon fiber materials, opening doors for wider use in the aerospace industry.

The Geopolitical Impact on Carbon Fiber Aerospace Innovation and Adoption

Government policies and regulations significantly influence the development and commercialization of advanced materials for aircraft structures. Regulations concerning emissions, safety standards, and environmental impact play a crucial role in shaping how carbon fiber materials are integrated into aerospace applications. Supportive policies can accelerate innovation, while restrictive regulations may slow adoption rates.

The Role of Defense Budgets

Defense budgets are pivotal in promoting carbon fiber usage within military aviation projects. Countries with substantial defense spending often prioritize cutting-edge technologies to maintain strategic advantages. This prioritization leads to increased investment in the research and development of carbon fiber composites, contributing to their widespread adoption in military aircraft design.

International Collaborations and Competition

International collaborations and competition further shape the global landscape of carbon fiber aerospace technologies. Collaborative efforts between countries, such as joint ventures and research partnerships, drive technological advancements by pooling resources and expertise. At the same time, competitive pressures encourage nations to innovate rapidly to maintain or establish leadership positions in the aerospace sector.

These geopolitical factors create a dynamic environment where innovation and adoption rates of carbon fiber materials are continually influenced by global political dynamics, defense priorities, and international partnerships. Each element plays a part in determining how quickly these advanced materials become integrated into new aircraft designs across the globe.

Market Segmentation: Types of Carbon Fiber and Their Aerospace Applications

Understanding market segmentation within the carbon fiber aerospace industry involves recognizing the various types of carbon fibers utilized and their distinct applications. Two primary variants stand out: standard modulus and high modulus carbon fibers.

1. Standard Modulus Carbon Fiber

Characteristics: Exhibits a tensile modulus of approximately 33 to 35 million pounds per square inch (MSI). It is known for its balanced mechanical properties, offering both strength and flexibility.

Applications: Ideal for secondary components such as fairings and interior structures. Its versatility ensures it supports a wide array of non-load bearing applications, contributing to reduced weight without compromising integrity.

2. High Modulus Carbon Fiber

Characteristics: Features a tensile modulus exceeding 50 MSI, providing extremely high stiffness. This variant is less flexible but offers superior resistance to deformation.

Applications: Primarily used in primary load-bearing structures, like wing spars and fuselage sections. The enhanced stiffness makes it indispensable in critical areas where maintaining structural integrity is paramount.

These diverse applications highlight how different types of carbon fibers cater to varied demands within aerospace design, underscoring their critical role in modern aircraft manufacturing. As innovations progress, these materials continue to evolve, meeting the stringent performance requirements set by the aerospace industry.

Carbon Fiber in Aircraft Design, Fuel Efficiency, and Sustainability

Incorporating carbon fiber-reinforced composites into airframe designs offers remarkable benefits for modern aircraft. The reduced weight of these materials translates directly into significant weight savings, which enhances the overall aerodynamic performance of the aircraft. This weight reduction is crucial as it allows for increased payload capacity or extended range, both of which are valuable in commercial and military aviation sectors.

The contributions of carbon fiber materials to fuel-efficient aircraft operations are notable. By utilizing these advanced composites, manufacturers can achieve reduced drag, leading to improved fuel efficiency. This not only lowers operating costs over the lifecycle of the aircraft but also supports sustainability practices by decreasing greenhouse gas emissions. The emphasis on sustainability is increasingly driving innovation in the aerospace industry, with carbon fiber playing a pivotal role.

Key advantages of carbon fiber-reinforced composites include:

- Weight Savings: Lighter airframes result in enhanced fuel efficiency and performance.

- Aerodynamic Performance: Improved designs lead to reduced drag.

- Sustainability: Contributions to eco-friendly aviation practices through lower emissions and operational costs.

These attributes position carbon fiber as an essential material in achieving future goals for environmentally conscious and economically viable aviation advancements.

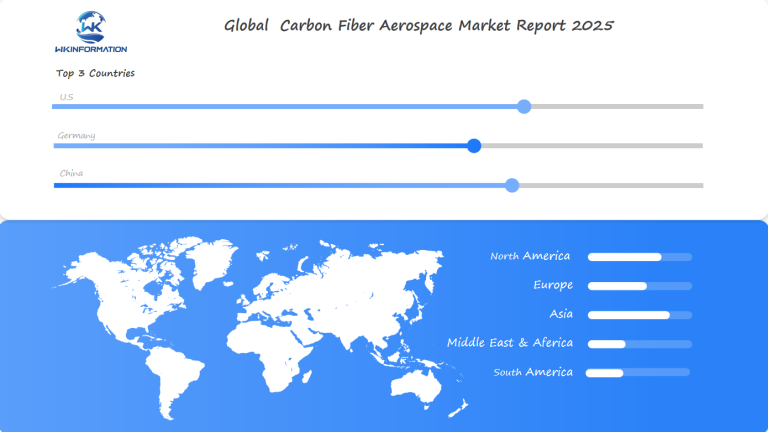

Regional Insights: Carbon Fiber Aerospace Market Growth Across Regions

The carbon fiber aerospace market is witnessing remarkable growth across key regions, with North America, Europe, and Asia-Pacific leading the demand for advanced materials.

USA’s Leadership in Carbon Fiber Aerospace Technologies

- The U.S. maintains a leading position due to its robust aircraft manufacturing sector and increasing aircraft deliveries.

- Innovations such as the Boeing B787 exemplify the integration of carbon fiber into airframe designs, significantly enhancing performance and efficiency.

Germany’s Role in Advancing Carbon Fiber Aerospace Materials

- Germany stands out for its focus on fuel efficiency through advanced composites.

- The country’s aerospace sector is dedicated to developing cutting-edge materials that align with sustainability goals while improving aircraft performance.

China’s Growing Market for Carbon Fiber in Aerospace Manufacturing

- China’s aviation industry is expanding rapidly, presenting substantial growth prospects for carbon fiber applications.

- Investments are pouring into this sector, driven by government initiatives to bolster domestic aerospace capabilities and compete globally.

USA’s Leadership in Carbon Fiber Aerospace Technologies

The United States is leading the way in carbon fiber aerospace technologies, thanks to its strong aviation industry and constant drive for innovation. Here are some key reasons why:

1. Rising Aircraft Deliveries

The demand for new aircraft models in the U.S., such as the Boeing B787 and B777, has significantly increased the use of carbon fiber materials. These aircraft are designed with more carbon fiber content to achieve better fuel efficiency and performance.

2. Technological Innovations

Advanced manufacturing techniques have allowed American companies to integrate carbon fiber into more components, making the overall structure stronger. For example, Boeing’s use of carbon composites in its Dreamliner series shows a commitment to using cutting-edge materials.

3. Strong Industrial Base

Major companies like Hexcel Corporation and Toray Industries have set up large research facilities and production capabilities in the U.S., creating an environment that encourages innovation in aerospace materials.

4. Defense Sector Influence

The U.S. defense budget plays a crucial role, promoting the use of lightweight yet strong materials like carbon fiber for military applications. This not only improves aircraft performance but also supports strategic defense efforts.

These developments position the United States as a leader in using carbon fiber technologies to advance both commercial and military aviation sectors. With ongoing investment in research and development, there is still great potential for further breakthroughs.

Germany’s Role in Advancing Carbon Fiber Aerospace Materials

Germany plays a crucial role in the development of carbon fiber aerospace materials, driven by a strong commitment to innovation and sustainability. The country’s aerospace industry focuses on improving fuel efficiency by using advanced composites, which greatly impacts the global carbon fiber market.

1. Innovative Composite Technologies

German companies are leading the way in developing cutting-edge composite technologies. These innovations aim to create lighter, stronger materials that reduce aircraft weight, resulting in better fuel efficiency and performance.

2. Sustainability Initiatives

Germany is well-known for its strong focus on environmentally friendly practices. The aerospace industry here actively includes sustainability initiatives, such as recycling and eco-conscious production methods, into the development of carbon fiber materials.

3. Collaboration with Major Players

Partnerships with key industry leaders like Airbus demonstrate Germany’s strategic approach to advancing carbon fiber technologies. This collaboration encourages the creation of next-generation aircraft components that meet strict environmental standards.

4. Government Support

The German government offers significant support through policies and funding aimed at research and development in aerospace materials. This assistance ensures ongoing innovation and competitiveness in global markets.

Germany’s commitment to advancing carbon fiber materials highlights its important role in shaping the future of sustainable aviation technologies. The country’s efforts align with worldwide trends towards lightweight, high-performance aircraft components that satisfy both economic and environmental needs.

China’s Growing Market for Carbon Fiber in Aerospace Manufacturing

China’s aerospace industry is experiencing rapid growth, driven by significant investments in carbon fiber technologies. The country’s dedication to improving its aviation sector is evident through its ambitious projects and increasing need for lightweight materials such as carbon fiber.

1. Investment Trends

Chinese manufacturers are heavily investing in carbon fiber production facilities and R&D centers. This strategic focus aims to reduce reliance on imports and enhance self-sufficiency in high-performance materials critical for aerospace applications.

2. Aviation Projects

Notable initiatives include the development of the C919 passenger jet, which incorporates carbon fiber composites to achieve weight reduction and improved fuel efficiency. This move aligns with China’s broader goal to compete on a global scale with established aerospace giants.

3. Government Support

Policies favoring innovation and technology advancement play a pivotal role. Government-backed funding provides the necessary impetus for research into new material technologies, fostering an environment conducive to growth in the carbon fiber sector.

China’s rapidly growing market offers lucrative opportunities for both domestic and international players. As the country continues to prioritize technological advancements and sustainability in aviation, the demand for advanced composite materials like carbon fiber is expected to surge, positioning China as a strong competitor in the global aerospace industry.

Future Trends and Innovations in Carbon Fiber Aerospace Solutions

The carbon fiber aerospace industry is on the verge of major advancements, driven by new technologies and creative processes.

3D Printing: A Game-Changer for Manufacturing

3D printing is making waves, promising to change the way carbon fiber components are made. This technology offers unprecedented design flexibility, enabling the production of complex structures that were previously unachievable with traditional methods.

Thermoplastic Composites: Faster and More Sustainable

Another groundbreaking development lies in thermoplastic composites. These materials offer significant advantages over conventional thermoset composites, including faster processing times and improved recyclability, aligning well with the industry’s sustainability goals. The ability to rapidly produce strong yet lightweight components is a game-changer for aerospace manufacturers seeking efficiency and cost-effectiveness.

Nano-Enhanced Carbon Fibers: Pushing the Limits

The introduction of nano-enhanced carbon fibers continues to push boundaries in material science. By incorporating nanoparticles into carbon fiber matrices, these advanced materials exhibit enhanced mechanical properties, such as increased strength and durability. This innovation not only improves the performance of aerospace components but also contributes to safer and more reliable aircraft operations.

As we explore these future trends, we see a potential disruption that could redefine aerospace manufacturing practices. As these technologies develop, they promise to reshape the landscape of carbon fiber applications within the industry, offering exciting opportunities for growth and innovation.

Key Competitors in the Carbon Fiber Aerospace Market

The carbon fiber aerospace market is influenced by several major companies whose strategic actions shape the competitive landscape.

-

SGL Carbon SE – Germany

-

TEIJIN LIMITED – Japan

-

Toray Industries, Inc. – Japan

-

Solvay S.A. – Belgium

-

DuPont de Nemours, Inc. – United States

-

Hexcel Corporation – United States

-

Mitsubishi Chemical Corporation – Japan

-

BGF Industries Inc. – United States

-

Taekwang Industrial Co. Ltd. – South Korea

-

Weihai Tuozhan Fibers Co. Ltd. – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Carbon Fiber Aerospace Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The carbon fiber aerospace market is about to undergo a major change, offering an exciting opportunity by 2025. With an estimated market size of around $10.71 billion, the demand for advanced materials is expected to drive innovation and sustainability in the aerospace industry.

Factors Driving Growth

The growth of this market can be attributed to several key factors:

- Integration of lightweight composites into aircraft designs

- Push towards sustainable aviation practices

As the industry evolves, it is crucial for stakeholders to leverage these trends in order to stay competitive.

Strategies for Success

Here are some strategies that can help businesses thrive in this evolving landscape:

- Harness Advanced Materials: Embracing cutting-edge technologies such as nano-enhanced carbon fibers and automated manufacturing processes can lead to substantial cost savings and efficiency improvements.

- Focus on Sustainability: Addressing environmental concerns through eco-friendly production methods and recycling initiatives will become increasingly important.

Importance of Collaboration

Investments in research and development, along with strategic partnerships, have the potential to unlock new opportunities within this rapidly growing market. Engaging with industry leaders and exploring innovative solutions will be vital for those seeking success in this dynamic environment.

Now is the time to take advantage of the opportunities presented by the carbon fiber aerospace market. By embracing advanced materials now, you can secure your position as a leader in aerospace innovation.

Global Carbon Fiber Aerospace Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Carbon Fiber Aerospace Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Carbon Fiber Aerospace Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Carbon Fiber Aerospace Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Carbon Fiber Aerospace Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Carbon Fiber Aerospace Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Carbon Fiber Aerospace Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Carbon Fiber Aerospace Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the carbon fiber aerospace market by 2025?

The carbon fiber aerospace market is projected to reach a significant opportunity of $10.71 billion by 2025, driven by advanced materials that enhance innovation and sustainability in aircraft design.

What are the upstream and downstream processes in the carbon fiber aerospace market?

In the context of the carbon fiber aerospace market, upstream processes involve raw material suppliers, while downstream processes include aircraft manufacturers. Each segment plays a crucial role in the supply chain, impacting market dynamics and competition.

What key trends are shaping the carbon fiber aerospace industry?

Key trends include the emergence of nano-enhanced carbon fibers for lightweight structures, integration of automated manufacturing processes to improve efficiency and reduce costs, and sustainability initiatives that drive innovation in carbon fiber aerospace materials.

What challenges exist in the production of carbon fiber aerospace materials?

High production costs and complex manufacturing processes hinder widespread adoption of carbon fiber materials in aerospace applications. Strategies to overcome these challenges include process optimization and material substitution.

How do geopolitical factors influence the carbon fiber aerospace market?

Geopolitical factors such as government policies and defense budgets play a significant role in promoting innovation and adoption rates of advanced materials for aircraft structures, shaping the global landscape of carbon fiber aerospace technologies.

What types of carbon fibers are used in aerospace applications?

The carbon fiber aerospace market features various types, including standard modulus and high modulus variants. Each type has distinct mechanical properties suited for specific applications, such as primary load-bearing structures or secondary components like fairings.