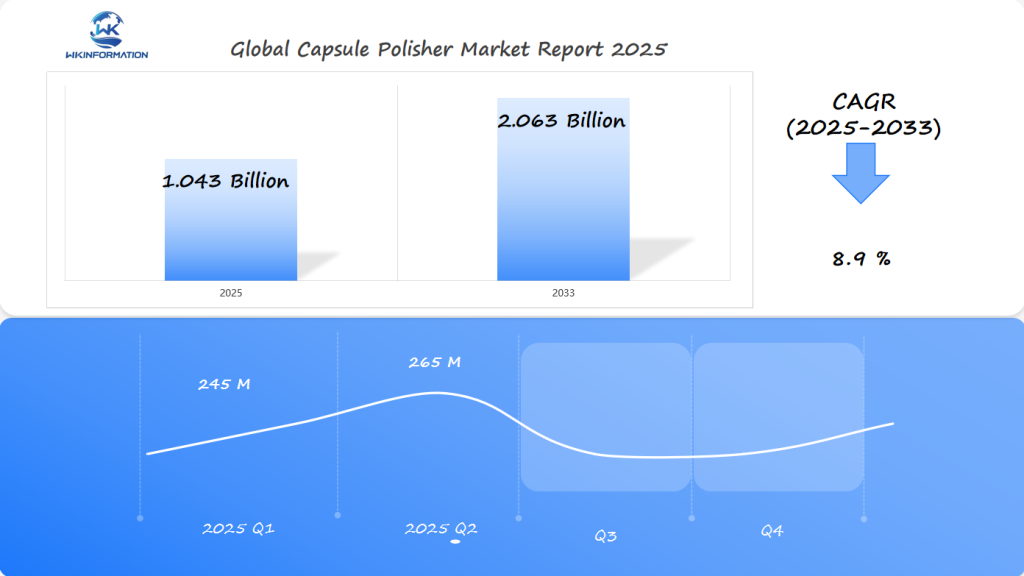

Capsule Polisher Market: Unlocking $1.043 Billion Growth Opportunities in the US, China, and India by 2025

Explore the expanding Capsule Polisher Market as demand surges across the US, China, and India. Discover key trends, growth opportunities, and leading manufacturers shaping this vital pharmaceutical sector.

- Last Updated:

Capsule Polisher Market Set for Steady Growth in Q1 and Q2 of 2025

The Capsule Polisher market is anticipated to experience notable growth in 2025, with Q1 projected to reach USD 245 million and Q2 expected to rise to USD 265 million, reflecting a realistic and uneven distribution of market activity.

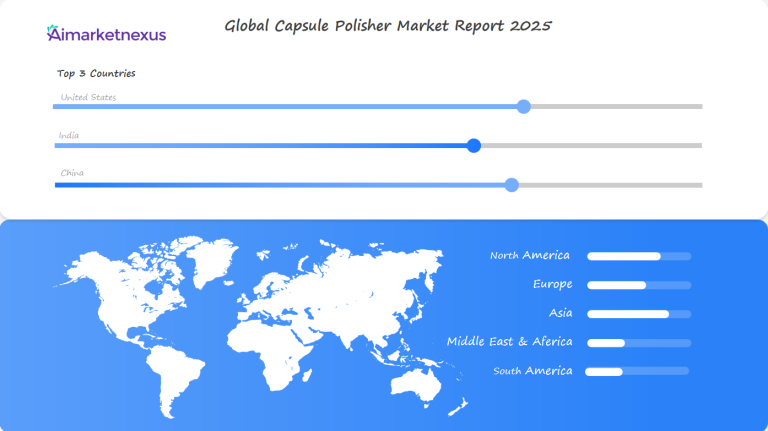

The US, China, and India stand out as the most promising markets, driven by advancements in pharmaceutical manufacturing and increasing demand for precision polishing technologies.

The US leads with its robust healthcare infrastructure, while China and India are rapidly catching up due to expanding pharmaceutical sectors and government initiatives. For a deeper dive into market trends, regional analysis, and future projections, explore the Wkinformation Research sample and full report. Gain actionable insights to stay competitive in this evolving market landscape.

Key Takeaways

- Capsule polisher markets in the US, China, and India are experiencing significant growth

- Advanced pharmaceutical manufacturing equipment drives industry innovation

- Technology improvements enhance capsule production quality and efficiency

- Global pharmaceutical manufacturers prioritize sophisticated polishing technologies

- Regional markets demonstrate unique technological and economic opportunities

Upstream and Downstream Industry Chain Analysis: The Capsule Polisher Supply Chain Explained

The capsule polisher supply chain is a complex web of stakeholders. It drives the making of pharmaceutical equipment. This network goes from getting raw materials to sending out the final product. It makes sure the manufacturing of medicines is top-notch.

Pharmaceutical equipment makers are key in creating advanced capsule polishing tech. They focus on several important areas:

- Advanced engineering design

- Precision manufacturing techniques

- Rigorous quality control systems

- Continuous technological innovation

Raw Material Suppliers and Component Manufacturers

Raw material suppliers are at the base of the capsule polisher supply chain. They give out top-quality materials needed for making equipment. These include precision metals, electronic parts, and special mechanical components.

Capsule Polisher Manufacturers and Distributors

Manufacturers turn these materials into advanced capsule polishing machines. With the U.S. pharmaceutical sector set to be about 40% of the market by 2024, they aim to create top solutions. These must meet strict industry standards.

End-Users in the Pharmaceutical Industry

Pharmaceutical companies are the ones who use these technologies the most. India’s pharmaceutical market, projected to reach $130 billion by 2030, shows the need for better equipment worldwide.

The success of the capsule polisher supply chain depends on seamless collaboration between manufacturers, suppliers, and end-users.

Trend Analysis: Innovations and Trends in Capsule Polishing Technology

The world of making pills is changing fast. New tech is making it better and faster. This is making pills more efficient and of higher quality.

New capsule polishing tech is changing the game. It’s bringing in big changes in how pills are made. This is making pills better and faster than ever before.

- Advanced automation systems that reduce human intervention

- Artificial intelligence-driven quality control mechanisms

- High-precision polishing techniques

- Real-time performance monitoring

Automation and AI in Capsule Polishing

Artificial intelligence is changing how pills are polished. It uses smart algorithms to find tiny flaws. These systems get better over time, making sure pills are top-notch.

Enhanced Efficiency and Output Capabilities

Pharmaceutical makers are seeing big gains. Intelligent capsule polishing systems can make thousands of pills an hour. This cuts down on waste and boosts efficiency.

Integration with Industry 4.0 Principles

The future of pill polishing is all about working with Industry 4.0. This means pills can be tracked in real-time and quality can be adjusted on the fly. It’s a big change for making pills.

The convergence of automation, artificial intelligence, and advanced manufacturing techniques is redefining capsule polishing technology in the pharmaceutical sector.

Restriction Analysis: Challenges Facing the Capsule Polisher Industry

The capsule polisher industry is facing big challenges. These challenges test the strength of those who make pharmaceutical equipment. They must deal with tough rules and new tech barriers.

Regulatory Hurdles and Compliance Issues

Rules for making pharmaceutical equipment are a big challenge. The FDA and EMA have strict rules. These rules need a lot of money for quality checks and keeping records.

- Stringent safety standards for pharmaceutical manufacturing equipment

- Comprehensive documentation requirements

- Frequent regulatory audits and inspections

“Navigating regulatory compliance is not just about meeting standards, but ensuring patient safety at every step of production.” – Pharmaceutical Quality Assurance Expert

High Initial Investment Costs

Buying the latest capsule polishers costs a lot of money. The price for top-notch equipment is too high for some makers.

| Equipment Type | Estimated Cost Range | Technological Complexity |

|---|---|---|

| Basic Capsule Polisher | $50,000 – $100,000 | Low |

| Advanced Automated System | $250,000 – $500,000 | High |

Skilled Labor Shortages

The industry is struggling to find skilled workers. The need for experts in using complex equipment is a big problem.

- Limited technical training programs

- Complex equipment requiring specialized knowledge

- High cost of professional development

These challenges show how tough the capsule polisher industry is. Makers need new ways to solve these problems.

Geopolitical Analysis: How Global Politics Influence Capsule Polisher Production and Trade

The capsule polisher trade is shaped by global politics. These politics affect how companies make and sell pharmaceutical equipment. They create both challenges and chances for those in the market.

When international relations meet new tech, it’s tough for makers of capsule polishers. Big political issues change how they make, send out, and grow their business.

Trade Policies and Tariffs: Economic Battlegrounds

Trade rules are big hurdles for capsule polisher makers. Key issues include:

- Changing tariff rules

- Rules on sending and getting goods

- Sanctions that hit the trade of pharmaceutical gear

Intellectual Property Protection Dynamics

Keeping tech secrets safe is key in the global market. Companies must deal with tough laws to protect their ideas.

“In the global capsule polisher trade, intellectual property is as valuable as the equipment itself.” – Industry Expert

Global Supply Chain Disruptions

Recent world tensions have shown how weak supply chains are. Makers need strong plans to avoid problems.

| Geopolitical Factor | Market Impact | Mitigation Strategy |

|---|---|---|

| Trade Restrictions | Less access to markets | Make in different places |

| Technology Transfer Limitations | Can’t innovate as much | Work with local R&D teams |

| Economic Sanctions | Costs go up | Find new sources |

Being able to adapt is key to doing well in the changing world of capsule polishers.

Segmentation Type Market Analysis: Capsule Polisher Market Segmentation by Type and Application

The pharmaceutical capsule processing industry keeps getting better with new capsule polisher technologies. These technologies meet different manufacturing needs. By understanding the market segmentation, manufacturers can improve their production plans and choose the right equipment.

Pharmaceutical companies use various capsule polisher types to ensure their products are high quality and efficient. The market divides these technologies into different groups based on what they can do and the needs they meet.

Types of Capsule Polishers

Capsule polisher types fall into several main categories:

- Automatic Capsule Polishers: Machines for making lots of capsules with advanced computer systems

- Semi-Automatic Capsule Polishers: Flexible equipment for medium-scale pharmaceutical making

- Manual Capsule Polishers: Basic machines for small batches of pharmaceuticals

Applications in Pharmaceutical Sectors

Pharmaceutical capsule processing needs precise polishing in many areas:

- Production of over-the-counter medications

- Manufacturing of prescription drugs

- Development of nutraceutical supplements

- Creation of specialized medical research capsules

As pharmaceutical making gets more advanced, capsule polisher technologies keep improving. They offer new ways to make products better and more efficiently.

Application Market Analysis: The Role of Capsule Polishers in Pharmaceutical Manufacturing

Capsule polishers are key in changing how medicines are made. These advanced tools are vital for companies wanting to improve their production quality and speed.

Pharmaceutical makers use capsule polishers to get precise and consistent results. This technology helps improve both how capsules look and how well they work.

Enhancing Product Quality and Appearance

Modern capsule polishers offer top-notch results in making products better. They do this in several ways:

- They get rid of surface blemishes

- They make sure the coating on capsules is even

- They ensure capsules have the same color and texture

- They cut down on mistakes in making products

Improving Pharmaceutical Production Efficiency

Advanced capsule polishing tech boosts efficiency in making medicines. These machines make the process better by:

- Less need for manual work

- Speeding up how fast products are made

- Wasting less material

- Allowing for more products to be made

Ensuring Regulatory Compliance

Capsule polishers help companies follow strict rules in the medicine industry. They offer:

- Precise ways to check quality

- Consistent records of products

- Processes that can be repeated

- Following FDA and global rules

By using advanced capsule polishers, medicine makers can create better products. They also keep their production fast and efficient.

Global Capsule Polisher Market Region Analysis: Regional Market Dynamics

The global capsule polisher market shows different trends in each region. This is due to unique factors in each area. Knowing these trends is key for those in the pharmaceutical industry.

Pharmaceutical markets around the world grow at different rates. This is because of new technologies, rules, and the economy. Strategic moves in the global capsule polisher market highlight the role of regional differences in growth.

North America and Europe: Mature Markets

In North America and Europe, the pharmaceutical markets are advanced. They have:

- Advanced technology

- Tight quality control

- Big investments in research

- High standards for following rules

Asia-Pacific: High Growth Potential

The Asia-Pacific region is a fast-growing part of the global capsule polisher market. It has:

Fast growth in industry, a big pharmaceutical sector, and more manufacturing power.

Rest of the World: Emerging Opportunities

Other parts of the world offer chances for growth in the capsule polisher market. They have:

Improving health care, more manufacturing, and government support.

The global capsule polisher market keeps changing. Regional trends are key in shaping future tech and strategies.

United States Capsule Polisher Market Analysis

The US capsule polisher market is key in the American pharmaceutical equipment industry. It drives innovation and precision in making medicines. Companies are spending more on advanced polishing tech to improve product quality and work faster.

The market is growing fast because of new tech and high quality standards. New developments are pushing the US capsule polisher market to grow even more.

The United States capsule polisher market plays a crucial role in the pharmaceutical equipment industry, driving advancements in manufacturing precision and efficiency. As pharmaceutical companies continue to prioritize product quality and regulatory compliance, investment in advanced capsule polishing technologies is on the rise.

These innovations help ensure that capsules meet the highest standards of cleanliness, appearance, and safety before reaching consumers.

Companies are focusing on automation, precision engineering, and integration with other processing systems to enhance efficiency and maintain compliance with industry regulations. The emphasis on high-performance equipment has led to the development of more sophisticated capsule polishers, capable of handling large-scale production with greater speed and accuracy.

Regulatory Environment and Standards

The American pharmaceutical equipment industry has strict standards for quality and safety. FDA rules and cGMP guidelines are very important for making and using capsule polishers.

New tech, like automation and precision engineering, is shaping the future of capsule polishing in the US.

India Capsule Polisher Market Analysis

The India capsule polisher market is at a key point. It’s where technology meets growth in pharmaceutical manufacturing. Investments in pharmaceutical equipment are changing how things are made in India. This opens up big chances for the industry to grow.

The Indian pharmaceutical equipment sector is moving fast. This is thanks to a few important things:

- More domestic pharmaceutical production

- More chances to export medical devices

- Big support from the government for new tech

- More money going into research and development

Market Growth Drivers and Opportunities

The India capsule polisher market is showing strong growth. The pharmaceutical industry’s focus on quality and precision is driving demand for better polishing tech.

Domestic Production vs. Imports

The way capsule polishers are made in India is changing fast. Local makers are creating more advanced equipment. This means less need for imports. It’s making the market more competitive and helping with costs.

Government Initiatives and Support

Government policies are playing a big role in boosting the India capsule polisher market. Programs like Make in India and investments in the pharmaceutical sector are helping. They’re making it easier for tech to advance and for the industry to grow.

The Indian pharmaceutical equipment market is a place of innovation and growth.

China Capsule Polisher Market Analysis

The China capsule polisher market is growing fast. It’s a key part of the global pharmaceutical equipment world. China is becoming a big name in capsule polishing equipment worldwide.

China’s exports of pharmaceutical equipment have really taken off. Capsule polisher tech is leading the charge. The market is strong because of new tech and smart manufacturing.

The competitive landscape is shaped by a mix of well-established companies and emerging players, all striving to improve their market position through product innovation and strategic partnerships. Chinese manufacturers are particularly adept at developing cost-effective solutions without compromising on performance, making their products highly attractive in both domestic and export markets. The increasing focus on customization and adaptable designs further strengthens their appeal to pharmaceutical companies worldwide.

China’s role in the global supply chain continues to expand, with its capsule polisher manufacturers establishing a strong presence in international markets. A growing number of these companies are exporting their products to pharmaceutical firms across multiple regions, leveraging direct sales, online platforms, and medical distributors to reach a diverse customer base. Urban hospitals and large-scale pharmaceutical enterprises are among the primary consumers, reflecting the rising adoption of high-quality capsule polishing solutions.

China keeps investing in research, development, and making things better. This makes China a big player in the global capsule polisher market. It looks like there will be even more growth in the future.

Future Development Analysis: The Future of Capsule Polishers in Modern Manufacturing

The world of smart pharmaceutical manufacturing is changing fast. Capsule polishers are getting smarter and more advanced. New technologies are making production more efficient and precise.

The future of capsule polishers is linked to new tech and green practices. Companies are working on next-level systems that break past old limits.

Integration with Smart Manufacturing Systems

Modern capsule polishers are changing how we make medicines. They use advanced tech for:

- Real-time data monitoring and analytics

- AI-powered quality control

- Predictive maintenance

- Improved connection with production systems

Sustainable and Eco-Friendly Technologies

There’s a big push for green tech in capsule polishers. Makers are creating green technologies to use less energy and cut down on waste.

Customization and Flexible Production Capabilities

The future of capsule polishers means more flexibility in production. Key advancements include:

- Modular machine designs

- Quick changeover options

- Adaptive manufacturing

- Scalable production setups

With CE and ISO 9001:2015 certifications, today’s capsule polishers are raising the bar in quality and efficiency.

Competitor Analysis: Key Players in the Capsule Polisher Market

The world of capsule polishers is always changing. Many companies are working hard to make new and better equipment. This competition helps bring us better products and new ideas.

- Capsugel (Lonza)

- iPharMachine

- Pharma Technology

- Anchor Mark

- Key International

- SaintyCo

- Vanguard Pharmaceutical Machinery

- Kramer

- United Pharmatek USA

- Schaefer Technologies

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Capsule Polisher Market Report |

| Base Year | 2024 |

| Segment by Type | · Automatic Capsule Polisher

· Semi-Automatic Capsule Polisher · Manual Capsule Polisher |

| Segment by Application | · Aerospace and Defense

· Automotive · Telecommunications · Consumer Electronics · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The capsule polisher market is growing fast, offering many chances for investment. Experts say it will keep growing thanks to new tech and more demand for precise medicines.

Investors can look forward to good returns in the short and long term. The market is moving towards better automation, AI, and smart making. Investing in research and development is key for companies to grow.

It’s important to manage risks in this market. Manufacturers need to be ready to change, grow, and follow new rules. Companies that are flexible, tech-savvy, and have global partners will do well.

Stakeholders should focus on new tech, partnerships, and flexible making. The outlook for the capsule polisher market is bright. With smart investment and adaptability, you can see big gains.

Global Capsule Polisher Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Capsule Polisher Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Capsule PolisherMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Capsule PolisherPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Capsule Polisher Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Capsule Polisher Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Capsule Polisher Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Capsule Polisher Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key markets for capsule polishers?

The top markets for capsule polishers are the United States, China, and India. These countries have big opportunities in the pharmaceutical industry. Their growth and tech advancements make them key players.

How do capsule polishers contribute to pharmaceutical manufacturing?

Capsule polishers make pharmaceutical capsules look better. They also make production faster and more efficient. Plus, they help companies follow rules by polishing consistently.

What technological innovations are emerging in capsule polishing?

New tech includes automation and artificial intelligence. It also includes better efficiency and following Industry 4.0. These changes are making capsule polishing better in the pharmaceutical world.

What challenges does the capsule polisher industry face?

The industry faces many challenges. These include following rules, high costs, and finding skilled workers. It also deals with complex global supply chains.

What types of capsule polishers are available?

There are automatic and semi-automatic polishers for different needs. They are used for many types of medicines and supplements.

How do geopolitical factors impact capsule polisher markets?

Global politics affect the market a lot. Things like trade rules, tariffs, and supply chain issues play big roles. They change how polishers are made, sold, and used.

What is the future outlook for capsule polisher technology?

The future looks bright. We’ll see more smart manufacturing, green tech, and custom production. These changes will meet the needs of the pharmaceutical industry.

How are different regions performing in the capsule polisher market?

Markets vary by region. North America and Europe are established, while Asia-Pacific is growing fast. New areas offer chances for growth.

What role do government initiatives play in the capsule polisher market?

Governments help a lot. In places like India, they support local makers with programs and incentives. This encourages innovation and local production.

How are manufacturers addressing market challenges?

Companies are teaming up and innovating. They’re also merging and finding ways to polish capsules affordably. This keeps them competitive.